Ukuhlaziywa Kwesici Sokusebenza Kwemishini Engamakhompiyutha Amancane

Ukuhlaziywa Kwezici ze-Machining Surface Micro-profiles

|

Ukuthatha isampuli ejwayelekile yokufaka into, into efundwayo ehlukahlukaniswa nobuso bezindawo ezahlukahlukene zemishini, kuyahlaziywa izici zobuso bendawo ezitholwe yimishini eyahlukahlukene, futhi nobuso bendawo enobulukhuni obuhlukile obutholwe ngendlela efanayo yemishini buyabonwa . . Imiphumela ikhombisa ukuthi: i-surface morphology kanye namagugu okuganga amasampuli ajwayelekile atholakala ngezindlela ezahlukahlukene zemishini ahlukile kumazinga ahlukahlukene; Ubuningi besakhiwo esihle nokuphakama kwephrofayili ye-machining surface morphologies ehlukile, ehlukile kunalokho. Indlela yokucubungula ihlobene; isakhiwo se-morphology sobukhulu obuhlukile obutholwe uhlobo olufanayo lwemishini sinokuzifanisa, futhi sinezici ezijwayelekile ze-morphology nezakhiwo, ezingasetshenziswa ukuhlukanisa izindlela ezahlukahlukene zokuchofoza. |

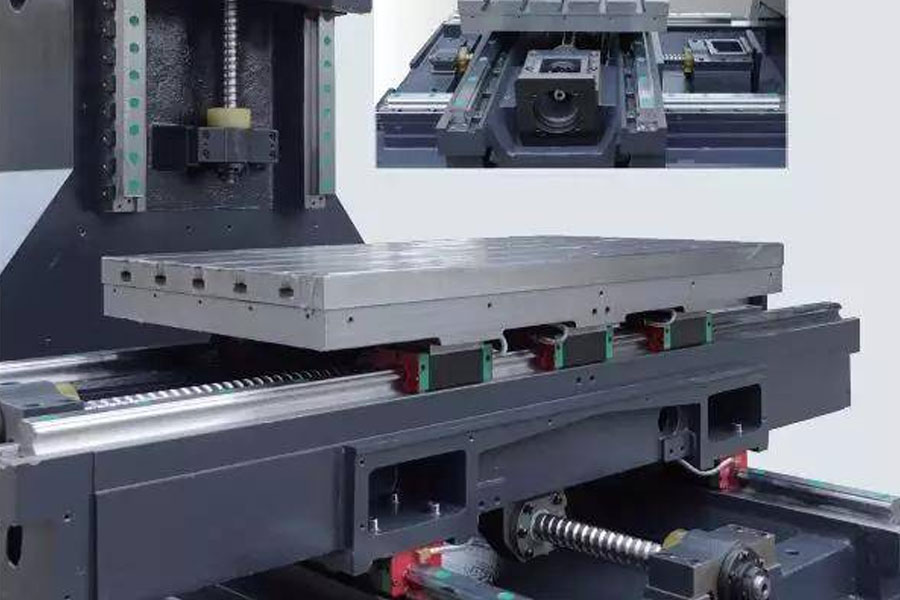

Ngokuthuthuka okusheshayo kwesayensi nobuchwepheshe, izidingo zekhwalithi yemikhiqizo ehlukahlukene yemishini ziya ngokuya zikhula. I-surface morphology nokwakheka akuthinti nje kuphela izakhiwo zemishini yohlelo lwemishini njengokuxubana nokugqoka, ukuqina kokuxhumana, amandla okukhathala, izakhiwo zokukhwelana, ukunemba kokudlulisa, ukusebenza ngokufaka uphawu, nokunemba kokubona, kepha kuthinta ngqo ukusebenza, impilo nokubukeka komshini.

Kumishini emincane, i-surface micro-morphology nayo ihlobene kakhulu nokushayisana kwayo, ukugqoka, ukuthambisa nezinye izinto zokungqubuzana.

Ubuso be-morphology (i-geometry nokuthungwa, njll.) Kobuso obenziwe ngomshini buxhomeke ebudlelwaneni bokuvumelana bobabili phakathi kwethuluzi nomsebenzi wokusebenza ngesikhathi sokusika. Akuhlobene kuphela nendlela ethile yokusika nezimo zokusika, kepha futhi namandla okuma kwesakhiwo sethuluzi lomshini Izici, amathuluzi okusika kanye nezinto ezibonakalayo nezomshini wozosebenza zihlobene [4]. Ukufundwa kwezimpawu nemithetho yangaphakathi ye-micro-morphology yezindawo ezahlukahlukene zemishini kubaluleke kakhulu kunenani lesethenjwa lokuqonda ngokujulile izindlela zemishini yezindlela ezahlukahlukene zemishini nokwehluka kwazo, futhi kunikeza nesisekelo sobuchwepheshe semishini.

Umbhali waleli phepha uthatha ukwenziwa kwemishini (ukujika, ukuhlela, ukuphela kokugaya, ukugaya okuyisicaba, okuyisidina, ukugaya okuyisicaba) amabhlogo esampula ajwayelekile njengento, efunda umehluko ebukhali bendawo etholakala ngezindlela ezahlukahlukene zemishini, futhi ahlaziye izindlela ezahlukahlukene zemishini Izici i-surface morphology nokwakheka kwatholakala, futhi umthetho we-morphology wobuso obukhali obuhlukile obutholwe ngendlela efanayo yemishini wabonwa. Ngakho-ke, qonda izici zezindlela ezahlukahlukene zemishini nokwehluka kwazo.

1 Umehluko kubukhulu besimo semikhakha ehlukene eyenziwe ngomshini

Ithuluzi lokwakheka komhlaba lingalinganisa izinhlobo ezingama-28 zamapharamitha wobuso bendawo. Khetha ubude besampula bube ngu-5mm nesikhathi sokulinganisa kube ngu-1.25 μm ukukala amapharamitha wendlela yokwakheka komhlaba webhulashi lesampuli elijwayelekile. Ukuphakama kwenani eliphakathi nendawo elisetshenziswa kakhulu le-Ra kukhethwa njengepharamitha yokuhlola ubukhali ukuhlaziya umehluko kubukhulu bezindawo ezahlukene zomshini. Izindlela ezahlukahlukene zemishini zithola inani le-Ra lamasampuli ajwayelekile wokuqina (thatha isilinganiso sezilinganiso ezi-3), nomehluko phakathi kwenani lokulinganisa elilinganisiwe nobukhali besibhulokhi sesampula.

- (1) Kunamaphutha ahlukene kumanani wokuqina alinganisiwe wesimo sendawo sobukhulu besampuli esezingeni elilinganayo etholwe izindlela ezahlukahlukene zokuchofoza. Isibonelo, ngezindlela ezahlukahlukene zokucubungula, amanani alinganisiwe alukhuni nokwehluka kobuso besampula ejwayelekile yesampula enobunzima beRa 0.8 μm kwehlukile. Encane kuya kwenkulu), inani lokulinganisa elilinganisiwe lincane kunenani lesampula lesilinganiso sokuqina ukuze kube yisicefe, ukuphela kokugaya, nokugaya okuyisicaba (kusuka kokuncane kuye kokukhulu).

- (2) Iphutha eliphakathi kwenani elilinganisiwe lobukhulu bendawo ngobukhulu obuhlukile obutholwe yindlela efanayo yemishini kanye nenani lesikhukhula sesampula esejwayelekile nalo lihlukile. Isibonelo, ngokuguqula ukucubungula, ubukhulu besimo sezinhlobo ezijwayelekile ezitholakele nguRa 0.8 μm, 1.6 μm, 3.2 μm, 6.3 μm, kanye nomkhuba wokushintsha kwephutha phakathi kobukhulu bawo obulinganisiwe uhlukile, futhi inani lobukhulu yiRa0. Amanani wokulinganisa alinganisiwe we-8μm, 1.6μm kanye no-6.3μm makhulu kunobunzima besampula ejwayelekile yesampula; lapho inani le-roughness lingu-Ra3.2 μm, inani elilinganisiwe lobukhulu lincane kunenani lobukhulu bebhulokhi yesampuli ejwayelekile. Kodwa-ke, amaphutha alinganisiwe wezinhlobo ezine zokuba lukhuni ezicutshungulwe ngokugaya ukuphela konke akubi, okungukuthi, amanani alinganisiwe alinganiselwe onke angaphansi kwamanani obulukhuni wezinhlobo ezijwayelekile.

Izici ze-micro-morphology zezindawo ezahlukahlukene ezakhiwe ngomshini zitholwa ngokusebenzisa izindlela ezahlukahlukene zokuchofoza (ukujika, ukubhoreka, ukuphela kokugaya, ukugibela, ukugaya okuyisicaba, ukugaya okuyisicaba) kwamasampuli ajwayelekile ngobunzima obufanayo (i-Ra0.8 μm) Kunomehluko omkhulu ku-surface morphology

-

(1) Ubuningi besakhiwo se-microstructure ehlukile eyenziwe ngomshini buhlukile, ukusuka kokuphansi kuye phezulu, kungukugaya okuyisicaba, ukugibela amapuleti, ukuphela kokugaya, ukugaya okuyisicaba, okuyisidina nokujika.

-

(2) Ubuso be-morphology nokwakheka kwezindawo ezahlukahlukene zemishini kunokufana okuthile. Isibonelo, ukujika nokubhoreka kuyizakhiwo ezifana nentwasahlobo; ukuhlela nokugaya okuyizicaba kuyizinto ezinjengegagasi; ukuphela kokugaya nokugaya okuyizicaba kuyizakhiwo ezinamakhemikhali.

- (3) Ukuphakama kokushintshwa kobubanzi bephrofayili yendawo kugaya flat, ukujika, ukugibela, ukuphela kokugaya, okuyisidina, nokugaya okuyisisekelo ngokuhlehla, okuhlobene nenqubo yokucubungula yezindlela ezahlukahlukene zokuchofoza.

Inani lendawo yokugaya yenqubo yokugaya liphakeme kakhulu, futhi izici ezinomthelela omkhulu yilezi:

-

Cutting Umkhawulo wokusika (okusanhlamvu olwalazayo) wesondo lokugaya akuyona umugqa oqondile oqondile, ozoshiya indawo ethile eyinsalela ku-workpiece ngemuva kokugaya

-

Ngenqubo yokugaya, ukusikeka kwepulasitiki kwensimbi ebusweni bento yokusebenza kubangela ukuthi izinga lokushisa lokusika likhuphuke ngokuqhubekayo, okusheshisa ukugqokwa kwesondo lokugaya futhi kubangele ukukhishwa okungathi sína;

- SelectionUkukhethwa kwamapharamitha afana nenani lokugaya, ukugaya uketshezi kanye nesabelo sokugaya kunethonya elithile ebusweni bendawo yokusebenza.

Izici zobuso be-Surface zendlela efanayo yokucubungula ngobukhali obuhlukile

Ijika lephrofayili engaphezulu yebhulokhi yesampuli ejwayelekile ngobukhulu obuhlukile (i-Ra0.8μm, i-1.6μm, i-3.2μm) itholwa ngumshini wokugaya oyisicaba. Ubude besampula ngu-3.75mm, isikhathi sokusampula singu-1.25μm, futhi inani lamaphoyinti okusampula angamaphuzu ayi-3,000. .

-

(1) Iphrofayili yendawo enobudlova beRa 0.8 μm, 1.6 μm, 3.2 μm etholwe ngumshini wokugaya oyisicaba inesakhiwo esifanayo se-wavy, esibonisa ukuthi isakhiwo sendawo yokwakheka komhlaba ngobulukhuni obuhlukile obutholwe ngendlela efanayo yemishini sinokufana, futhi inezici ezijwayelekile zokuhleleka nokwakheka, okungasetshenziswa ukuhlukanisa izindlela ezahlukahlukene zokukhanda.

-

(2) Inani eliphakeme lephrofayili yendawo yokugaya eyisicaba iyakhuphuka ngokukhuphuka kwenani le-roughness, elihambisana nepharamitha ye-Ra yenani lobude obuphakathi bephrofayili yendawo.

- (3) Ubuningi besakhiwo se-micro-topography ebusweni buyancipha ngokwanda kobukhulu, futhi nebanga eliphakathi kwezintaba liyakhula.

Isiphetho se-4

-

(1) Kunamaphutha wamazinga ahlukahlukene kumanani wokuma kobuso bendawo yokuma kobukhulu besampuli ezijwayelekile zokutholakala kwemishini ehlukile.

-

(2) Uma usebenzisa indlela efanayo yokwenza imishini ukuthola izindawo ezinama-roughness ahlukene, iphutha eliphakathi kwenani lokukala elilinganisiwe nenani lesilinganiso sesampula elijwayelekile nalo lihlukile.

-

(3) Imidwebo ehlukahlukene eyenziwe ngomshini, ukuminyana kwesakhiwo esihle nokuphakama kwephrofayili konke kuhlukile, okuhlobene nendlela yokusebenza.

-

(4) I-surface morphology nesakhiwo esitholwe ngezindlela ezahlukahlukene zemishini zinezinga elithile lokufana. Isibonelo, ukujika nokubhoreka kuyizakhiwo ezifana nentwasahlobo; ukuhlela nokugaya okuyizicaba kuyizinto ezinjengegagasi; ukuphela kokugaya nokugaya okuyizicaba kuyizakhiwo ezinamakhemikhali.

- (5) Ubuso be-morphology kanye nokwakheka kobukhulu obuhlukile obutholwe ngendlela efanayo yemishini kuyafana, futhi kunezici ezijwayelekile ze-morphology nezakhiwo, ezingasetshenziswa ukuhlukanisa izindlela ezahlukahlukene zokuchofoza

Xhumanisa nale ndatshana: Ukuhlaziywa Kwesici Sokusebenza Kwemishini Engamakhompiyutha Amancane

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi