Ukuhlaziywa kobunzima ku-Machining Gray Cast Iron

Ukuhlaziywa kobunzima ku-Machining Gray Cast Iron

|

Ukuze kuxazululwe izinkinga zemishini yokusakazwa kwe-iron empunga enkampanini, izingxenye kanye nezakhiwo zengulube ye-foundry kanye nokulingisa kwahlaziywa ngesibonakhulu esibonayo, isibonakhulu se-electron esithwebula, ubulukhuni be-Brinell, ubulukhuni be-Vickers obuncane kanye nokuhlaziywa kwe-spectrum. Imiphumela ibonisa ukuthi okuqukethwe kwe-S no-P kwe-26# yensimbi yengulube kwakungaphezu kohlangothi oluphakeme, okuqukethwe kwe-Si ye-iron engu-22# yengulube kuphansi, ngakho ukwakheka kwamakhemikhali akunelisi imibandela. Ikhabhoni elingana nokulingwa ngu-4.36%, okuyingxenye yokulingisa okulingana nekhabhoni ephezulu. Isilinganiso sika-Si no-C singu-0.46, esisohlangothini oluphansi. Okuqukethwe kuka-Si no-Mn ekulingiseni kuphansi, ngaphezu kokuqukethwe kwe-Cr kuphezulu, okwanele ukukhiqiza into epholile, kukhona isici esingu-V ekulingiseni okwengeziwe. I-microstructure ye-casting i-ferrite, i-pearlite, i-graphite ne-carbide. Enye ingxenye ye-carbide iqukethe i-Cr, V nezinye izakhi ze-micro-alloying, kanti ubulukhuni obuncane bungaphezu kwe-1 100 HV, okuyimbangela enkulu yomshini onzima. Ngakho-ke, ukuze kuthuthukiswe i-machining c apacity, okokuqala, okuqukethwe kwe-V ne-Cr akufanele kudlule izinga. Okwesibili, okuqukethwe kwe-Si kufanele kwandiswe futhi kufanele kuqala kukhethe ukungeza ku-inoculation. Ngokusakazwa okudingayo, i-carbide ingaboliswa nge-graphitizing annealing. |

Amakhona amhlophe ensimbi empunga enezindonga ezincane ayiziphambeko ezivamile ekubunjweni [1-4]. Ngokuvamile, ama-casting amancane anezindonga ezincane futhi afakwe esihlabathini esiluhlaza. Nakuba ukwakheka kwamakhemikhali ensimbi encibilikisiwe kuyafaneleka, ngenxa yethonya lokujiya kodonga olubunjiwe kanye nokuhanjiswa okushisayo kokuphonswa kwensimbi, izingxenye eziwugqinsi nezincane zokubunjwa okufanayo. Kokubili ingaphakathi nangaphandle kungathola inhlangano ehlukile. Ikakhulukazi amakhona ama-castings athambekele emilonyeni emhlophe, okubangela ubunzima ekwenzeni imishini, okuholela kulokho okubizwa ngokuthi "izinto ezinzima". Iningi lezingxenye ze-grey cast iron "material hard" zenzeka engxenyeni yengxenye enzima. Okufana nalokhu: imiphetho namakhona, imisele, indawo eyi-convex, indawo engaphezulu, njll. Ukuqina kwempahla kuhlobene kakhulu nokuthambekela komlomo omhlophe. Ihlose izinkinga ezinzima zemishini ekukhiqizeni kwangempela kokusakazwa kwenkampani ethile, leli phepha lenza ucwaningo oluhlelekile, lihlaziya izimbangela "zezinto eziqinile", futhi liphakamisa izixazululo ezihambisanayo.

1 Izinto zokuhlola nezindlela

I-casting pig iron 22#, 26# kanye nenombolo yomshini wokulingisa 0# kwathathwa amasampula esizeni. Ukusampula ngocingo kwenziwa ngokulandelana, futhi ukubhekwa kwezicubu ze-optical kanye nezicubu zokuskena kwenziwa. Ikhemikhali ku-cast iron and castings

Ukuhlolwa kokuqamba ukuze kukhiphe umthelela wama-elementi okulandelela ekusebenzeni kokucubungula kokulingisa. Ukulingisa kwenziwe isampula ukuze kubonwe i-metallographic kumakroskopu we-ZEISS optical and scanning, i-HBS-3000 digital Brinell tester yobulukhuni kanye ne-HTM-1000TM micro hardness tester zasetshenziselwa ukuhlola ubulukhuni. Ukwakheka kwamakhemikhali ensimbi yengulube nokubunjwa kukhonjiswe kuThebula 1.

| C | Si | Mn | P | S | W | Te | Bi | Cr | V | Ce | B | Mo | |||

| 0 3.73 # | 1.75 | 0.17 | 0.15 | 0.12 | ≤0.01 | 5 | 5 | 0.11 | 0.027 | 0.01 | 0.004 | 4 | ≤0.01 | ||

| 22 4.08 # | 1.86 | 0.055 | 0.07 | 0.02 | ≤0.01 | 5 | 5 | ≤0.010 | ≤0.010 | 0.01 | 0.002 | 2 | ≤0.01 | ||

| 26 3.38 # | 2.51 | 0.17 | 0.45 | 0.095 | ≤0.01 | 5 | 5 | 0.023 | 0.044 | 0.01 | 0.008 | 9 | ≤0.01 |

2.1 Ukuhlaziywa kokwakheka kwamakhemikhali

Lapho i-carbon cast iron iron ikhona ngendlela yama-carbides, yandisa ukuthambekela kokwenza mhlophe, okwenza umshini ube nzima futhi ubangele inkinga ebizwa ngokuthi "izinto ezinzima". Ngakho-ke, insimbi empunga kufanele inciphise ukuthambekela kokuba mhlophe, ukuze ikhabhoni ibe sesimweni segraphite. Izakhi ezihlukahlukene zinemiphumela ehlukene enqubweni ye-graphitization, namanye amatshe asheshayoI-inking, enye inciphisa i-graphitization. Ngokuvamile, izakhi eziningi ezingenza buthaka amandla okubopha phakathi kwama-athomu ensimbi nekhabhoni futhi zandise ikhono lokuzisakaza lama-athomu ensimbi zingakhuthaza ukwenziwa kwe-graphitization ye-cast iron; ngaphandle kwalokho, kuzovimbela i-graphitization yensimbi eyinsimbi, okungukuthi, ukwandisa ukuthambekela komlomo omhlophe. . Okokuhlola insimbi ekhonjiwe

Izinga lensimbi yengulube kanye nokuqedwa komthelela wezakhi zokulandelela ekuba mhlophe kwama-castings. Izakhi ezinhlanu nezinto ezivamile zokumhlophe zezinto ezingavuthiwe nokulingwa zihloliwe. Isampula ngayinye ihlolelwe izici eziyi-13. Ingqikithi yamaqoqo angama-39 ensimbi yengulube kanye nokubuswa kwahlolwa. Ukwakheka kwamakhemikhali kuboniswa kuThebula 1.

Izinga le-iron yensimbi yensimbi yaseChina (GB/T 718-2005) [5], ngokwezinga, okuqukethwe kwe-Si kwe-iron engu-22# kungu-2.00% ~ 2.40%, kanti okuqukethwe kwe-Si kwe-26# ye-pig iron kungu-2.40% ~ 2.80%. Ngokusho kweThebula 2, ukuhlolwa kwe-pig iron 22# kanye ne-26# yenkampani kubonise ukuthi okuqukethwe kwe-Si kwe-22# yensimbi yengulube kwakuyi-1.86, engazange ihlangabezane nomkhawulo ophansi wezinga.

Ihlangabezana nezinga, futhi okuqukethwe kwe-Mn nakho kuphansi. 26# i-pig iron P ne-S okuqukethwe kuphezulu kakhulu, okuqukethwe kwe-P kufinyelela ileveli 5, okuqukethwe kwe-S kweqa izinga, futhi kuqukethe inani elithile le-Cr. Ukwakheka kokuhlola kokusakaza okungu-0# kubonisa ukuthi okuqukethwe kwe-Cr kuphela kwezinto ezimhlophe okufinyelele ukuthambekela kokumhlophe, futhi okuqukethwe kwezinye izici zokulandelela akukafinyeleli kokuqukethwe okuncane okubangela ukuba mhlophe, ngakho umthelela awunaki. Uma kuqhathaniswa nokukhethwa kwezakhi ezinhlanu ku-"Casting Handbook" [6], kungabonakala ukuthi okuqukethwe kwekhabhoni ekulingiseni kulolu cwaningo kuphezulu kakhulu, okuqukethwe kwe-Si kuphansi kakhulu, kanti okuqukethwe kwe-Mn kuphansi kakhulu. .

2.2 Ukuhlolwa kokuqina

Ku-HBS-3000 digital display tester Brinell hardness tester, ukuhlolwa kungu-1875 N, ububanzi be-indenter bungu-2.5 mm, futhi ukuqina kwezivivinyo ezi-5 kuboniswe kuThebula 2. Kumhloli we-microhardness wedijithali, indawo emhlophe esithombeni esibonakalayo. imakwe nge-microhardness. Imiphumela ikhonjiswe kuThebula 3. Ngakho-ke, nakuba ubulukhuni obujwayelekile be-matrix buphansi kakhulu, ukuqina kweBrinell kuphela okungaba ngu-145 HB, ukuqina kwendawo yangakini kuphezulu kakhulu, kufinyelela ukuqina kwe-Vickers okungaba ngu-1 000 HV. . Umgodi omncane, ukuqina kokuqina. Ngokusho kwezincwadi, ubulukhuni be-phosphorus eutectic yi-500 ~ 700 HV, i-ledeburite ≤ 800 HV, ne-carbide> 900 HV.

Ngakho-ke, imiphumela yokuhlaziywa kokuqina ibonisa ukuthi indawo emhlophe iqinile futhi i-brittle cementite carbide, okuyinto ngokuyisisekelo engabandakanyi i-phosphorus eutectic, okuyisizathu esiyinhloko sezinto eziqinile. Ukuze unqume ngokunembile ukwakheka kwale carbide, ukuhlaziywa kwe-energy spectrum kuyadingeka.

2.3 Ukuhlaziywa kwe-spectrum yamandla

Ukwandiswa okuyingxenye kwendawo emhlophe ye-optical kuboniswe ku-Fig. 2 no-Fig. 3. Kubonakala ngokusatshalaliswa kwezimbobo ezihlehliwe ku-matrix kanye nesici se-eutectic. Ngakho-ke, ukuhlaziywa kwamandla kule ndawo kubonisa ukuthi izakhi eziqukethwe engxenyeni ehlehlisiwe yendawo ziyi-Fe, P kanye ne-C element, ngakho-ke kubhekwa njenge-Fe3 (C, P), i-P element igcinwa.

Ukuhlukaniswa. I-elementi engu-P engxenyeni ehoxisiwe iphakeme, hhayi umkhiqizo we-eutectic, kodwa imbobo eyakhiwe ukuqiniswa kokugcina nokuncipha. Umfanekiso 4 Imiphumela yokuhlaziywa kwe-spectrum yamandla ibonisa ukuthi ngaphezu kwezakhi ze-Fe, P no-C, indawo emhlophe iqukethe i-Cr ne-V, eyenza i-alloy carbides, eqinile futhi eqinile.

Thatha ukusika.

2.4 Ukuhlaziywa kwenhlangano

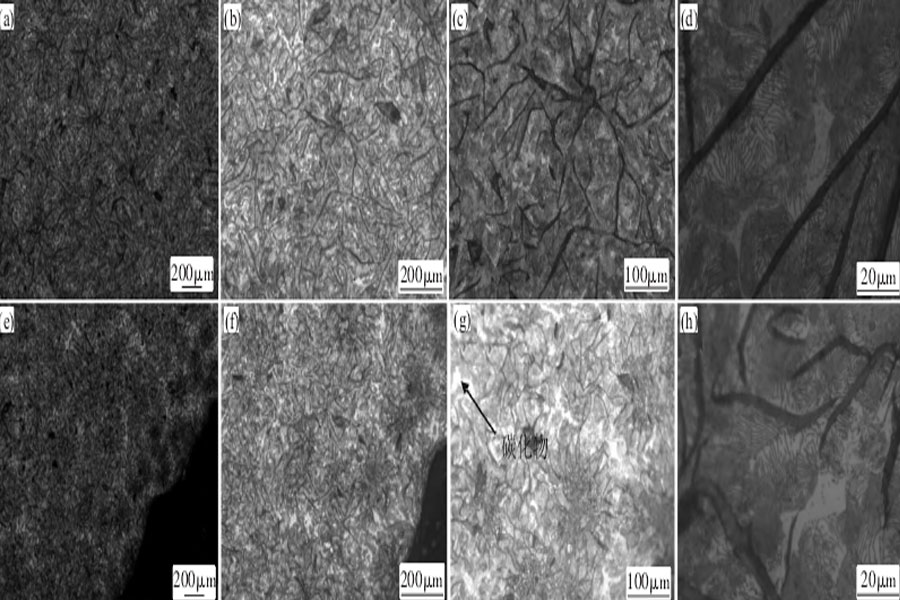

Isithombe se-optical sibonisa isakhiwo se-metallographic sokubunjwa okwenziwe ngokunamathisela ngo-4% we-nitric acid alcohol, njengoba kukhonjisiwe kuMfanekiso 5. Phakathi kwazo, u-a, b, c, no-d kukhona uhlaka oluyinhloko lokulingisa, kanye no-e, f, g, kanye no-h yisakhiwo sonqenqema sokubunjwa. a, b, c, d kanye no-e, f, g, h bahambisana nezithombe zethishu izikhathi ezingu-50, 100, 200, kanye nezikhathi eziyi-1,000. Isithombe sethishu esiskeniwe sikhonjiswe kuMfanekiso 6, futhi umcibisholo ukhomba endaweni emhlophe esithombeni esihambisanayo sethishu yamehlo, okuyi-carbide. Izindawo ezimhlophe ziyi-carbides, ama-flakes ayi-graphite, kanti izindawo ezimpunga ziyi-pearlite. Kungabonakala ukuthi isakhiwo se-metallographic yi-ferrite + pearlite + graphite + carbide, isakhiwo se-pitted. Ubumhlophe bamaphethelo kusobala ukuthi bubucayi ukwedlula obenhliziyo. Uma kuqhathaniswa ne-GB/T7216-2009, kungabonakala ukuthi [7], izicubu zenhliziyo ziyisiqalo.

Uhlobo lwegraphite F olumise okwenkanyezi eluhlaza lunobude obungaba ngu-150 μm nobubanzi obungaba ngu-5 μm. Lokhu kwakhiwa insimbi encibilikisiwe enekhabhoni ephezulu ngaphansi kwezimo ezinkulu zokupholisa kancane. Isakhiwo sesendlalelo sonqenqema siyi-graphite egobile ecolekile eqoqwe ekusabalaliseni okufana nechrysanthemum kohlobo B lwegraphite. Ubude bungaba ngu-100 μm futhi ububanzi bungu-3 μm. Nquma inani lama-carbides

Inani le-carbide esicutshini senhliziyo cishe li-5%, lifinyelela izinga lesi-3. Inani lama-carbides emaphethelweni ezicubu cishe li-10%, lifinyelela izinga lesi-4. Uma ikhabhoni isesimweni segraphite, igraphite ingasetshenziswa ukugcoba ngesikhathi somshini, futhi ukusika kulula. Uma i-carbon ikhona ngesimo se-carbide (Fe3C), ngoba i-Fe3C cementite iqinile futhi i-brittle, umshini womshini unzima, ikakhulukazi uma uqukethe ezinye izakhi ze-alloying (ezifana ne-Cr), i-alloy cementite ((Fe, M) 3C) Le nhlanganisela kunzima futhi kunzima ukusika, futhi inkinga ebizwa ngokuthi "impahla eqinile" ivela ngesikhathi somshini [8]. Ngakho-ke, ekubunjweni kwezingxenye zensimbi ezimpunga, kuyadingeka ukunciphisa inani lekhabhoni ukuze ugweme ukubukeka kwe-carbides, futhi uthathe izinyathelo ezithile zokukhuthaza i-carbon graphitization uma kunesidingo.

3 Ukuhlaziya nengxoxo

Izinto eziyinhloko ezithinta ukusebenza komshini wokulingisa ukwakheka kwamakhemikhali ensimbi esakazwayo kanye nezinga lokupholisa eliqinile. Okuqukethwe kwekhabhoni kanye nokuqukethwe kwe-silicon ekwakhekeni kwamakhemikhali ensimbi eyinsimbi yizici ezimbili ezibaluleke kakhulu zokulawula. Izinga lokupholisa le-casting lincike kakhulu ekugqineni kodonga lokubunjwa. Uma okuqukethwe kwekhabhoni ne-silicon ensimbini ekhonjiwe kungashintshi, udonga oluncibilikayo luba mncane, kuyanda ukuthambekela kwensimbi ewuketshezi ekubeni mhlophe. Uma ukushuba kodonga lokubunjwa kungashintshi, lapho inani eliphelele lekhabhoni ne-silicon ensimbi ecijile liba likhulu, kulapho izinga le-graphitization yensimbi ephonswe licophelela khona.

Ikhabhoni elingana nokulingwa kulolu cwaningo ingu-4.36%, okuwukulinganisa okulingana nekhabhoni ephezulu; isilinganiso se-Si/C singu-0.46, esiphansi. Ukwandisa okulingana nekhabhoni kwenza ama-graphite flakes abe mkhulu, inani liyanda, futhi amandla nobulukhuni kuncipha. Ukwandisa i-Si/C kunganciphisa ukuthambekela komlomo omhlophe.

Ekukhiqizeni i-grey cast iron, ithonya lokushisa ngokweqile kanye nomphumela wokukhulelwa nakho kufanele kucatshangelwe. Ukwenyusa izinga lokushisa lensimbi encibilikisiwe phakathi kobubanzi obuthile kungenza ukucwengwa kwegraphite, ukwakheka kwe-matrix kube ngcono, amandla aqinile anda, nokuqina kwehle. Kuyadingeka ukuthi kubhekwe kabanzi ukwakheka kweshaja, okokusebenza okuncibilikisa, kanye nezici zamandla zokwakheka kwamakhemikhali. Ukwelashwa kwe-inoculation ukufaka isitofu ensimbi encibilikisiwe ukushintsha isimo se-metallurgical yensimbi encibilikisiwe ngaphambi kokuba insimbi encibilikisiwe ingene emgodini wokuphonsa, futhi ukwandisa i-nucleus engavamile ukucwengwa kwe-graphite. Ngaleyo ndlela kuthuthukisa i-microstructure nokusebenza kwe-cast iron. Izitofu ezivamile zihlanganisa i-ferrosilicon, i-calcium silicon ne-graphite. Ukuhlanganisa imikhiqizo yethu nezindleko zokukhiqiza, kunconywa ukusebenzisa i-ferrosilicon (i-silicon engu-75%, inani elingeziwe lingaba ngu-0.4% wesisindo sensimbi encibilikisiwe). Okwesibili, i-barium ferrosilicon ne-strontium ferrosilicon. I-Ferrosilicon ijova umphumela wokusebenza ngokushesha, ifinyelele isiqongo phakathi kwemizuzu engu-1.5, futhi yehle esimweni esingakhulelwe ngemva kwemizuzu engu-8~10, enganciphisa izinga lokupholisa okukhulu nokuthambekela komlomo omhlophe, ikhulise inani lamaqoqo e-eutectic, yakha uhlobo lwe-A. graphite, ngcono ukufana kwesigaba, futhi andise ukumelana. Amandla okuqina yi-10-20MPa. Ukungalungi: ukumelana kabi nokubola. Uma inqubo yokujova sekwephuzile ingasetshenziswa, ayilungele ukuhluka okukhulu kodonga kanye nesikhathi eside sokuthulula.

I-Barium ferrosilicon inamandla anamandla okwandisa inani lamaqoqo e-eutectic futhi ithuthukise ukufana kwesigaba kune-ferrosilicon. Ikhono lokumelana nokwehla linamandla, futhi umphumela wokujova ungagcinwa imizuzu engu-20. Ifanele amamaki ahlukahlukene ezingxenye zensimbi ezimpunga, ikakhulukazi ezilungele izingxenye ezinkulu ezinodonga oluqinile nezimo zokukhiqiza ezinesikhathi eside sokuthulula.

I-Strontium ferrosilicon inekhono lokunciphisa ubumhlophe obuphakeme obungu-30% ukuya ku-50% kune-ferrosilicon, futhi inokufana okungcono kwesigaba nekhono lokungaboli kune-ferrosilicon. Ngesikhathi esifanayo, ayikhulisi inani lamaqoqo e-eutectic, kulula ukuhlakazeka, futhi ine-slag encane. Izingxenye ezinezindonga ezincane, ikakhulukazi izingxenye ezidinga ukushwabana nokuvuza ezinamaqoqo aphezulu e-eutectic azifunwa.

Okuqukethwe kwe-Mn kwabalingiswa kulolu cwaningo kuphansi. I-Manganese ngokwayo iyisici esivimbela ukwenziwa kwe-graphitization, kodwa i-manganese ingasusa umthelela oqinile wokuba mhlophe wesulfure. Ngakho-ke, ngaphakathi komkhawulo wokunciphisa umphumela wesulfure, i-manganese empeleni idlala indima ekukhuthazeni i-graphitization. Ukuzijwayeza kufakazele ukuthi ukwanda kokuqukethwe kwe-manganese akukwazi nje ukwandisa futhi kucwengisise i-pearlite, kodwa akulimazi ukuphumuza ngokufanelekile ukulawula kwesibabule. Ngakho-ke, kunconywa ukwandisa ngokufanelekile okuqukethwe kwe-Mn.

Isiphetho se-4

Isizathu esiyinhloko sobunzima bemishini yokukhipha kulolu cwaningo ukubukeka kwe-cementite carbides, ikakhulukazi i-cementite carbides yama-alloys aqukethe i-Cr, V nezinye izakhi ziyisizathu esiyinhloko sobunzima bomshini. Ukuthuthukisa le nkinga, umqondo wokuqala ukunciphisa noma ukuqeda ama-carbides enhlanganweni. Ukushintsha ukwakheka kokulingisa kanye nokulungisa inqubo yokukhiqiza kuyizindlela ezisebenzayo. Kuhlanganiswe nesimo esithile sokukhiqiza sokulingisa kulolu cwaningo, kubekwe iziphakamiso ezilandelayo zokukhiqiza:

- (1) Ukwandisa okuqukethwe kwe-silicon, ukukhetha kokuqala ukufaka i-inoculant ngaphambi kokuthulula. Ku-ferrosilicon (75% silicon), i-barium ferrosilicon ne-strontium ferrosilicon nayo ingasetshenziswa ngokuya ngesikhathi sokuthulula kanye nemiphumela yasendaweni. Kunconywa ukusebenzisa izitofu ezihlanganisiwe (i-Si-Ba ne-RE-Si).

- (2) Khulisa okuqukethwe kwe-manganese ekubunjweni ukuze unciphise umphumela womlomo omhlophe oqinile wesibabule.

- (3) Thuthukisa izinga lensimbi yezingulube. 26#Okuqukethwe kwe-pig iron P no-S kuphezulu kakhulu.

- (4) Yehlisa okuqukethwe kwe-Cr ekulingiseni. Okuqukethwe okuphezulu kwe-Cr (>0.1) ekulingiseni kungase kukhiqize umthelela wokuba mhlophe. I-Cr ingakhuphula kakhulu ubulukhuni futhi ilimaze ukusebenza kwemishini.

Xhumanisa nale ndatshana: Ukuhlaziywa kobunzima ku-Machining Gray Cast Iron

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi