I-Research On Ni-Si Alloy Slender Shaft Turning Technology

I-Research On Ni-Si Alloy Slender Shaft Turning Technology

|

I-nickel-silicon alloy iyingxube evamile yokushisa okuphezulu. Kuyinto okunzima ukuyicubungula futhi isetshenziswa kakhulu emkhathini, ezondiza kanye neminye imikhakha. Ukusika kwayo kuyiphuzu elinzima kubuchwepheshe besimanje bemishini. Ukuhlanganisa izici ze-nickel-silicon alloy materials, ukuthatha othintana nabo benkampani ye-nickel-silicon alloy njengesibonelo, ubuchwepheshe bokucubungula i-turning buye bacwaningwa, futhi ubuchwepheshe obuthile obusezingeni eliphezulu lokucubungula impahla ye-alloy bugcinelwe indawo yokusebenzela, enomsebenzi othile. inani lohlelo lokusebenza. |

1. Isingeniso

Ama-alloys asezingeni eliphezulu abizwa nangokuthi ama-alloys angangeni ukushisa noma ama-alloys anamandla okushisa. Kuyingxubevange enezingxenye eziningi esekelwe kunsimbi, i-nickel, i-cobalt, i-titanium, njll., futhi ingasebenza ngaphansi kwemvelo yokushisa okuphezulu kwe-oxidation nezimo zokugqwala kwegesi engu-600 ~ 1000 ℃. Ngaphezu kwalokho, ingasebenza isikhathi eside ngaphansi kokucindezeleka okuthile, futhi inamandla amahle kakhulu okushisa, ukuzinza kokushisa nokusebenza kokukhathala okushisayo.

Kodwa-ke, ama-alloy asezingeni eliphezulu ayizinto ezijwayelekile zokusika okunzima ukuzisika, ezinobunzima obungaphezu kuka-250HBS, amandla σb>0.98GPa, ubude δ>30%, inani lomthelela ak>9.8×105J/m2, ukuguquguquka kwe-thermal k<41.9W/ (m2℃), ukumelana nokushisa okuphezulu kwandisa ngqo ubunzima bokucubungula. Ngaphansi kwesenzo esihlangene samandla amakhulu okusika kanye nokushisa okuphezulu ngesikhathi sokucubungula, ithuluzi likhiqiza izingcezu noma ukuguqulwa, bese liphuka; ngaphezu kwalokho, lolu hlobo lwe-alloy luzokhiqiza ngokushesha into yokuqinisa umsebenzi, futhi i-workpiece izokhiqizwa ngesikhathi sokucubungula. Ubuso obunzima bethuluzi buzokwenza ukuthi umkhawulo wokusika wethuluzi ukhiqize izikhala ekujuleni kokusika, futhi ubangele ukucindezeleka okungafuneki ku-workpiece, futhi ubhubhise ukunemba kwejometri yezingxenye zomshini.

2. Ukuhlaziya isimo samanje

Izazi zakwamanye amazwe zenze ucwaningo oluningi ngokusikwa kwama-superalloy. Ngo-1939, iBritish Mond Nickel Company (International Nickel Company) yaqala yathuthukisa ingxubevange esekwe ku-nickel i-Nimonic 75, kwase kuthi i-Nimonic 80 yasetshenziswa ngempumelelo kuma-blade material yezinjini ze-turbojet, yakha uchungechunge lwe-alloy olusekelwe ku-nimonic. Ekuqaleni kuka-1940, i-United States yakha i-alloy esekwe i-Hastelloy B nickel ukuze isetshenziswe enjini yejethi ye-GE's Belp-59. Ngo-1950, i-American PW Company, i-GE Company kanye ne-Special Metal Company yakha i-Waspalloy, M-252 kanye ne-Udmit 500 alloys ngokulandelana, futhi yakha amamaki e-Inconel, Mar-M kanye ne-Udmit ngalesi sisekelo, asetshenziswa kakhulu kuma-turbine blades. . Kusukela ngo-1940 kuya phakathi kuka-1950, ukwakheka kwe-alloy kwalungiswa. I-1950: Ukuvela kobuchwepheshe bokuncibilika kwe-vacuum kuvumela ukuthuthukiswa kwenani elikhulu lama-superalloys aphezulu asebenza kahle njenge-Mar-M200 kanye ne-In 100. Ngemva kwe-1960, ukuthuthukiswa kwezinqubo ezintsha ezifana nokuqina kokuqondisa, ama-crystal alloys eyodwa, i-powder metallurgy, ingxubevange yemishini, kanye ne-ceramic filtration isothermal UKWAKHA baye baba amandla amakhulu okushayela ukuthuthukiswa kwama-superalloys. Ngokufanayo, osolwazi basekhaya nabo benze ucwaningo oluningi. Kusukela ngo-1956 kuya ku-1957, i-GH3030, GH4033, GH34 kanye ne-K412 alloys akhiqizwa ngempumelelo izinjini ze-WP-5; ngo-1960, GH4037, GH3039, GH3044, GH4049, GH3128, K417 namanye ama-alloys akhiqizwa ngokulandelana. Ithuthukiswe ngempumelelo; futhi ngokulandelana kwathuthukisa iqoqo lama-superalloy ezinjini ezihlukahlukene zamarokhethi; ngesikhathi esifanayo, ama-superalloys aqala ukuthandwa futhi asetshenziswa emikhakheni yezimboni zomphakathi, njengama-turbocharger edizili, ama-turbine egesi aphansi, njll., kanye nenqwaba yama-alloys aphikisana nokushisa okuphezulu athuthukiswa ngokulandelana. Imihuzuko kanye nama-superalloy amelana nokugqwala; ngo-1970, ukukhiqizwa kwesilingo kanye nocwaningo lwama-superalloys seluqalile ukumila. Ngokulingisa, ukugaya kanye nokuthuthukiswa kwama-superalloys aseSoviet njenge-alloy eyinhloko nekhwalithi yayo yenqubo, ifinyelele noma yeqe izinga leSoviet kanye nezinga langempela. Zonke izinto ezidingekayo enjinini zitholakala eChina.

Okwamanje, inkampani izixhumanisi futhi ama-relay awanawo amagobolondo engxubevange okushisa aphezulu. I-Suzhou Huatan ihlinzeka nge-Halliburton futhi ivame ukucubungula ama-alloys asezingeni eliphezulu. I-Guiyang Product Division inesibopho sokusika amapharamitha, izinto zamathuluzi nama-engeli, ukupholisa nokugcoba, kanye nezinto ngesikhathi sokucutshungulwa kwama-alloys asezingeni eliphezulu. Ucwaningo oluhlelekile ngokusebenza alwanele, futhi ucwaningo oluhlelekile mayelana nokucubungula ingxubevange yezinga lokushisa eliphezulu ludingeka ngokushesha ukuze kwakhiwe isisekelo sokukhiqizwa ngobuningi bokusebenza okuphezulu. izixhumanisi esikhathini esizayo. Ngakho-ke, kunesidingo esiphuthumayo sokwenza ucwaningo mayelana nobuchwepheshe bokucubungula i-alloy high-temperature ukuze kuhlangatshezwane nezidingo zangempela zokukhiqiza ze-workshop.

3. Ukuhlaziywa kwesakhiwo sengxenye

Izitho zomzimba yenaliti ezacile umphini zidinga amandla aphezulu emishini kanye nokumelana nokukhuphuka okuqinile ekushiseni okuphezulu. Ubude obuphelele bomzimba yenaliti bungu-32mm, kanti amadayamitha ngokulandelana kwawo φ1.2mm, φ1.5mm, kanye no-φ1.58mm, okungeyeslender umphini izingxenye. , Kulula ukuguqula ngesikhathi sokucubungula, futhi ukuguqulwa kudinga ukulawulwa ukuze kuhlangabezane nezidingo zokukhiqiza.

4. Ukukhetha ithuluzi

Njengoba ukucutshungulwa kwe-nickel-silicon alloy kudinga ubulukhuni obuphezulu, ukuthungwa okuqinile, umphumela omuhle wokudlulisa ukushisa, nomsebenzi oqinile wokushisa okuphezulu, ikakhulukazi ku-600 ℃, izokwakha isixazululo esiqinile esinomoya-mpilo ne-nitrogen. Lapho ucubungula i-nickel-silicon alloy, ubulukhuni bobuso buzokhula kakhulu. Inomphumela onamandla wokuhuzuka. Ngenxa yokumelana nokugqoka nokumelana nokushisa okuphezulu kwamathuluzi ahlanganisiwe, amathuluzi okugcoba kufanele asetshenziswe ngangokunokwenzeka lapho kucutshungulwa izingxenye ezinjalo ze-alloy high-temperature.

Amathuluzi e-carbide enziwe ngosimende acishe afanele ukusika izinto ezihlukahlukene ezinzima emshinini, kodwa ukusebenza kwe-coating (ukugqoka okukodwa kanye nokuhlanganisa okuhlanganisiwe) kuhluke kakhulu. Ngakho-ke, i-coatings efanelekile kufanele ikhethwe ngokusho kwezinto ezihlukahlukene zokucubungula Ithuluzi lempahla. I-carbide enosimende ehlanganiswe ngedayimane kanye ne-DLC (I-Diamond Njenge-Carbon) ehlanganiswe ne-carbide enosimende iqhubekisela phambili ukwandisa ububanzi bokusetshenziswa kwamathuluzi amboziwe, futhi ngokungaboni lutho ikhethe izindwani zempahla ezintsha ezidingweni zangempela zokucubungula, ezingase futhi zandise izindleko zokucubungula nokusebenzisa izinto ezintsha Lapho ufaka i-blade. , uma isivinini sokusika kanye nesilinganiso sokuphakelayo singalungile, sizophinde sithinte ikhwalithi ye-workpiece kanye nempilo yesevisi yethuluzi. Ngakho-ke, lapho ukhetha ukufakwa kokusika kwezinto ezilukhuni emshinini, kuyadingeka ukuhlola kahle umnotho wokucubungula futhi ucabangele ngokuphelele yonke inqubo yokucubungula.

Ngokusekelwe ekuhlaziyweni kokukhethwa kwamathuluzi, lesi sihloko sikhetha ukufakwa kwe-nickel alloy alloy okukhethekile kwe-Kyocera kanye nokufakwa okukhethekile kwe-nickel alloy ye-Sandvik ukuze kusetshenziswe izivivinyo. Ukusebenza kwamathuluzi okusika kukhonjiswe kuThebula 1.

|

Igama |

Imodeli yokucaciswa |

I-engeli yethiphu |

Ithiphu R |

Material |

esinemthombo |

|

I-Kyocera Cylindrical Knife |

I-VBGT110301R-F PR930 |

35 ° |

0.1 |

I-PR930: Isisekelo sezinhlayiyana ze-Ultrafine |

I-TICN(PVD) |

|

I-Sandvik Cylindrical Knife |

I-VCGT110301-UM 1125 |

35 ° |

0.1 |

I-GC1125: Into esetshenziselwa izidingo zokuqina okuphezulu |

I-TICN(PVD) |

5. Ukuhlaziywa koketshezi lokusika

I-fluid yokusika ingaba uketshezi lokusika olusekelwe emanzini, olunokudluliselwa kokushisa okusheshayo kanye ne-fluidity enhle. Akunakwenzeka ukusebenzisa uketshezi lokusika oluqukethe i-chlorine. Ngeke ihlanganiswe ne-aluminium, i-zinc nama-alloys ayo, ithusi nethini ngesikhathi sokucubungula. Uma uketshezi olusikiwe luqukethe i-Chlorine izobola futhi ikhulule i-hydrogen emazingeni okushisa aphezulu phakathi nenqubo yokusika, okuzokwenza ukuthi i-epidermal embrittlement ngemva kokumuncwa i-nickel, futhi ingase ibangele ukugqwala kwe-high-temperature corrosion corrosion of nickel alloys.

I-workshop cutting fluid ikakhulukazi isebenzisa uhlobo lwe-Flowserve, imodeli i-ECOCOOL EM5 iwuketshezi olunqamula amanzi olumhlophe olumhlophe oluyi-milky, futhi ukwakheka kwayo kwamakhemikhali kuboniswa kuThebula 2. Kungabonakala kuThebula lesi-2 ukuthi lolu ketshezi lokusika lusekelwe emanzini, ingxenye eyinhloko ngamafutha amaminerali, ayinayo i-chlorine, futhi ihlangabezana nezidingo zomshini we-nickel alloys. Lolu ketshezi lokusika lungahlangabezana nezidingo ze-nickel ingxubevange machining.

6.Gibbscam uhlelo lwesofthiwe

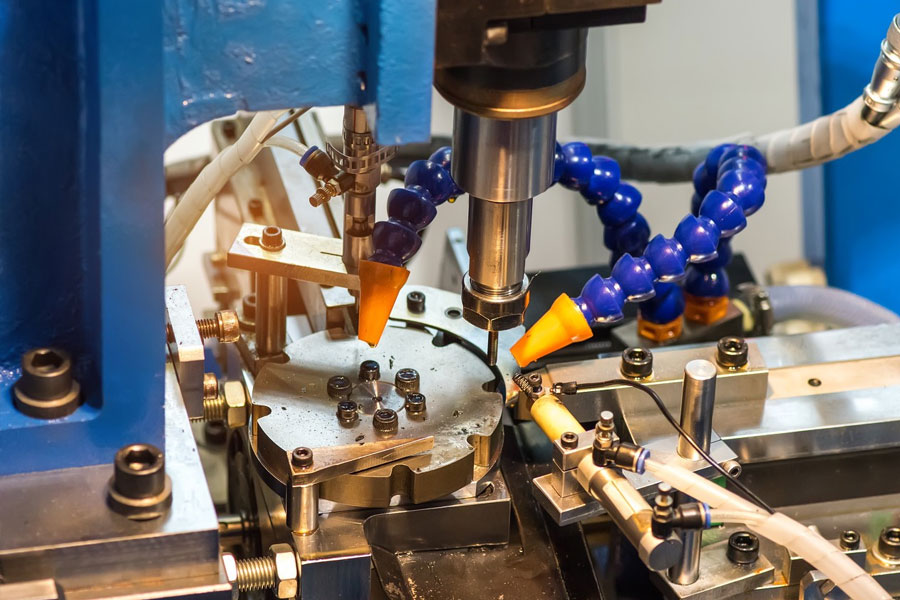

I-GibbsCAM iyisofthiwe ye-CAM yezingxenye ze-cnc machining, ikakhulukazi izixazululo zokucubungula i-CAM emkhakheni wokujika nokugaya. Ngaphezu kokuphenduka nokugaya, iphinde isekele i-axis engu-2 ukuya ku-5-axis milling, ukuguqula, ukugaya okuhlanganisiwe kwemisebenzi eminingi kanye nokusika izintambo. Isici sayo esikhulu kunazo zonke isixhumi esibonakalayo esifushane, kulula ukusifunda nokusebenzisa, futhi imodi yokusebenza ihambisana kakhulu nemikhuba yethu yezandla. Ingene emakethe yaseShayina ngoJuni 2008. Inkampani yethu yathenga isofthiwe ngoJulayi 2009. Isetshenziswa kakhulu ekuguquleni idijithali kwenkampani, ukugaya ngedijithali, okuyinhlanganisela yokugaya kanye nezikhungo zemishini ze-axis ezinhlanu. Lolu hlobo lwemishini lunokuphenduka, ukugaya, nokubhoboza. , Boring, broaching (slots) kanye neminye imisebenzi, nge X, Y, Z, C, E kanye A izimbazo. Isoftware ye-CAM ingasetshenziselwa noma yikuphi ukuxhumana kwe-multi-eksisi ukuze kubonwe ukucutshungulwa kwezingxenye eziyinkimbinkimbi. Ngokuhlukahluka nobunkimbinkimbi bezingxenye ezintsha, kubalulekile ukusebenzisa isofthiwe yokuhlela yohlelo lwe-NC. Indlela yamathuluzi yengxenye ye-shaft encane iboniswa kuMfanekiso 4.

7. Ukushintsha ukuhlaziywa kokuqinisekiswa kokucubungula

Njengoba ukuguqulwa okuzenzakalelayo kwe-slitting kungokwakho ukusika okukodwa endaweni, amandla okusika makhulu, okwenza izingxenye zikhubazeke kalula futhi izinga eliphezulu libi. Kuyadingeka ukuhlola ingxenye ngayinye, ukuguqula ukuhluka ngesikhathi, futhi ushintshe imingcele yohlelo kanye nesinxephezelo samathuluzi. Ngesikhathi esifanayo, ngoba imishini yokucubungula iyimoto ezenzakalelayo yokusika i-longitudinal, imishini ayihlukanisi umshini onzima futhi omuhle, futhi konke ukunemba kwe-dimensional kusetshenzwa ngephasi eyodwa, ngakho izidingo eziphakeme zibekwe ekusebenzeni kwamathuluzi.

Lapho usika i-nickel-chromium-nickel-silicon alloy, izinga lokushisa lokusika liphezulu, ukuqina kwethuluzi kuphansi, futhi isivinini sokusika sinethonya elikhulu ekushiseni okusikayo. Ngokuvamile, ithuluzi le-carbide elihlanganisiwe ligcinwa ku-650 ℃ ~ 750 ℃. Ngokusebenzisa izivivinyo ezimbalwa zokuguqula, imingcele elandelayo yokusika iyatholakala:

1) Ukusika isivinini vc

Isivinini sokusika sinomthelela omkhulu ekuqineni kwethuluzi. Kungcono ukusetha isivinini sokusika ngaphansi kwesimo sokugqoka okuncane kwethuluzi. Ingasethwa ngokusho kokuqina nokujula kokusika kwezinto ezihlukene zokusika. Zama ukukhetha isivinini esiphansi sokusika ukucubungula ama-alloys e-nickel. Ngokuvamile, ukugaya ama-rough 20-50m/min, kanti ukugaya kahle kungu-40-70m/min;

2) Inani lokuphakelayo f

Izinga lokuphakelayo linomthelela omncane ekuqineni kwethuluzi. Endabeni yokuqinisekisa ubulukhuni bobuso bomshini, izinga lokuphakelayo elikhudlwana lingakhethwa. Ngokuvamile, 0.003~0.006mm/r angakhethwa, futhi izinga lokuphakelayo alikwazi ukuba likhulu kakhulu. Okuningi kuzokwenza ukuthi ithuluzi liguge ngokushesha, kwandise amandla okusika, futhi kubangele ukuguqulwa kwezingxenye. Ngakho-ke, ngokuvamile akufanele kube ngaphezu kuka-0.006 mm/r;

3) Ukujula kokusika kwe-ap

Ukujula kokusika kunomphumela omncane ekuqineni kwethuluzi. Ngokuvamile, ukujula okukhulu kokusika kungasetshenziswa kuqala, okungavimbela ithiphu yethuluzi ekugawulweni kwesendlalelo esiqinile, futhi kungandisa ubude bokusebenza konqenqema lwamathuluzi, okuzuzisa ukuchithwa kokushisa. Ukubekezelela i-Dimensional, ukujula kokusikwa kulingana nokususa okungenalutho kosayizi wengxenye, futhi akukwazi ukulungiswa mathupha.

Ngokusebenzisa izindwani ezikhethekile ze-nickel alloy processing blades ze-Kyocera kanye nezindwani ezikhethekile ze-nickel alloy ze-Sandvik zokuqinisekisa ukucubungula, ingxenye ye-cnc machining imiphumela iboniswa ku-Figure 5 no-6. Umphumela ongaphezulu wezingxenye muhle, futhi ithuluzi alinakho ukuguga okusobala; ubulukhuni bezingxenye ezicutshungulwa ama-Sandvik blades bukhulu, obungakwazi ukuhlangabezana nezidingo zemidwebo. Ngakho-ke, ama-Kyocera blades asetshenziselwa izindwani eziyindilinga zangaphandle. Uma umkhiqizo udinga ukulungiswa, ama-Kyocera blades ayakhethwa.

I-8. Isifingqo

Ihlose inkinga yokuthi othintana nabo be-nickel-chromium-nickel-silicon alloy abanalo ikhono lokucubungula, lesi sihloko siqala ezintweni zamathuluzi nemingcele yokucubungula, yenza izivivinyo eziningi zenqubo, ithola ithuluzi elifanele i-nickel-chromium- i-nickel-silicon alloy processing, ithuthukisa imingcele yokucubungula, futhi ixazulule inkinga. Ukuze kuxazululwe inkinga yokucutshungulwa kwe-nickel-chromium-nickel-silicon alloy, i-workshop ikwazile ukucubungula impahla kusukela ekungakwazi ukuyicubungula. Ngokokuqala ngqa, inamandla okucubungula izinto ze-nickel-chromium-nickel-silicon alloy, ezithuthukisa kakhulu izinga lokucubungula nokusebenza kahle kwezingxenye ze-cnc. Ukukhiqizwa kweqoqo lokuxhumana kwe-alloy kwabeka isisekelo.

Xhumanisa nale ndatshana: I-Research On Ni-Si Alloy Slender Shaft Turning Technology

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi