Izindawo Zokusebenza Ezihlukile Zesitampu Esibunjiwe

Izindawo Zokusebenza Ezihlukile Zesitampu Esibunjiwe

|

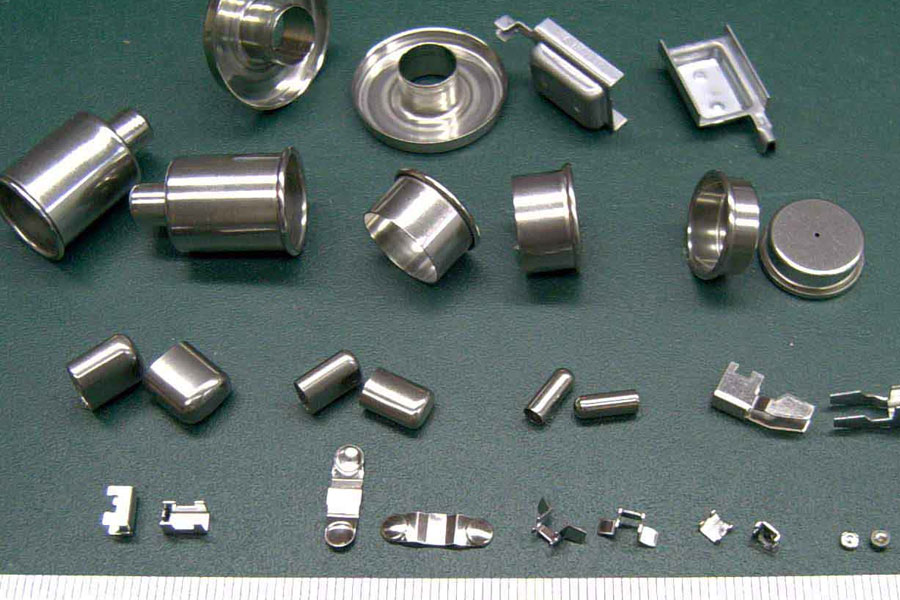

Izingxenyekazi zekhompiyutha zokunemba kwensimbi kungokwensimbi uyanyathela izingxenye, okuluhlobo lwezingxenye zomshini zentwasahlobo ezisebenza ngokuqina. Kungokwesigaba sezinto zokwakha ze-elektroniki. Ishubhu lokunemba kwehadiwe lenziwe ngensimbi engagqwali noma imanganizi ngemuva kokwelashwa kokushisa. Kungukuqina kweswishi ukwakha uhlangothi olulodwa, ngosizo lokuqhutshwa kwe- insimbi yensimbi. Ihardware precision shrapnel luhlobo lwezingxenye zomshini ezisebenza ngokuqina. Imvamisa yenziwe ngensimbi yensimbi yensimbi. Isetshenziselwa ukulawula izenzo zezingxenye zomshini, ukwenza buthaka ukushaywa noma ukudlidlizela, ukugcina amandla, ukukala amandla, njll. Kusetshenziswa kakhulu emishinini nasezinsizweni zomculo. Izinhlobo ze-hardware precap shrapnel ziyinkimbinkimbi futhi ziyahlukahluka. Ngokuya ngezitayela, kukhona imvalo yensimbi evunguza, iscrapnel yensimbi esongwayo, insimbi yensimbi eyisicaba, njll. |

Kuyini ukugxivizwa kwensimbi?

Ukunyathela insimbi kuyinqubo yokusebenzisa imishini yokushaya isitampu futhi ifa ukukhubaza noma ukuphula izinto ezingafani nensimbi, i-aluminium, nethusi ukufeza isitayela nosayizi othile. Ukunyathela insimbi ngezikhathi ezithile kubizwa ishidi lensimbi ukwakha, kepha kunomehluko omncane. Okubizwa ngokuthi ukwakhiwa kweshidi kubhekisa ekusetshenzisweni kwamashidi, amashubhu anezindonga ezincanyana, namaphrofayili amancane njengezinto zokusetshenziswa.

Kuyini ukucubungula isitampu se-elekthronikhi?

Inqubo yokwakha lapho kusetshenziswa khona amandla angaphandle kumacwecwe, amabhande, amashubhu namaphrofayli ngezibhakela bese ifa ukukhiqiza ukusikeka kwepulasitiki noma ukwahlukana, ngaleyo ndlela kutholwe ubuciko bokusebenza besitayela nobukhulu obudingekayo, nezinto zokwakha ezitholakalayo ziyizitembu.

Ukunyathela isitebhisi sehadiwe ukusetshenziswa kwemishini kanye nesikhunta ukufaka amandla wangaphandle kumacwecwe, emapheshana, amashubhu, kanye namaphrofayli ukukhiqiza ukusikeka kwepulasitiki noma ukwahlukana, ukuze kutholakale isitayela nosayizi odingekayo womsebenzi (wokushaya) owenza amakhono wokucubungula. Stamping futhi UKWAKHA kungokucutshungulwa kwepulasitiki (noma ukucindezelwa kwengcindezi), ngokuhlangene okubizwa ngokuthi UKWAKHA. Izikhala ezingenastamp ezibaluleke kakhulu zingamapuleti ensimbi asongwe ashisayo namakhaza.

Kuyini isitampu sokufa?

Ukushaya isitampu kuyimishini yenqubo ekhethekile yokucubungula izinto (insimbi noma okungeyona eyensimbi) zibe izingxenye (noma imikhiqizo eyingxenye) ekugxivweni okubandayo, okubizwa ngokuthi yi-cold stamping die. Ukunyathela uhlobo lwenqubo yokucubungula ingcindezi ekamelweni lokushisa. Isikhunta esifakwe emshinini sisetshenziselwa ukufaka ingcindezi kulokho okuhlukaniswayo noma ukukukhubaza ngoplastikhi ukuthola izingxenye ezidingekayo.

Izinzuzo zensimbi yokunyathela insimbi: nginyathela metal izingxenye zakhiwa ngobuchwepheshe bensimbi yokuqothula, isikhunta, imishini yokunyathela, nezinto zokwakha. Izinzuzo zokucubungula insimbi yensimbi ukukhiqiza okuphezulu, izindleko eziphansi zesikhunta, asikho isidingo sokusika amapuleti ensimbi, kanye nokufa okuqhubekayo kungonga izindleko ezingama-30%. Kodwa-ke, ukusetshenziswa kwayo kunqunyelwe ukujula kokudweba, ukuqondisa nokudlulisa izinto zebhande onqenqemeni, ezinendawo eqinile, futhi isetshenziselwa izingxenye ezilula ezinokujula komdwebo okungajulile. Isikhunta siyinkqubo ebalulekile yenqubo yokunyathela insimbi. Ikhwalithi ephezulu, usayizi omncane, ukukhiqiza kanye nezinzuzo zezomnotho zezingxenye zokugaya zinobudlelwano obuhle nokuhlelwa kwesikhunta kanye nohlelo lwaso olunengqondo. Ngokuya ngokuhlanganiswa kobuchwepheshe bensimbi yensimbi, kune-single-process molds elula, inqubo eningi yokwenza isikhunta esiqhubekayo kanye nesikhunta esihlanganisiwe. Lapho abakhiqizi bezingxenye ze-elekthronikhi besetha inqubo yokugxotshwa komsebenzi, ukukhishwa nokusebenza okuningana kwenqubo yokucubungula kuyinkinga eyinkimbinkimbi, encike kusayizi we-batch, ukwakheka nesitayela, izidingo zekhwalithi, nezici zenqubo. Mayelana nezingxenye zokunyathela izimoto ezivame ukukhiqizwa ngobuningi, kuyadingeka ukusebenzisa isitampu sokufa esiyinhlanganisela noma esiqhubekayo naphezu kohlelo olunamandla kakhulu lokwenza umkhiqizo nokukhiqiza umkhiqizo ophephile.

Ngokuya ngezidingo zomkhiqizo ezahlukahlukene zomkhakha, ipulatifomu yokusebenzisa i-hardware precap shrapnel nayo yehlukile. Isihleli esingezansi sizokwethula lezi zindawo zokuhlukanisa ezilandelayo:

- 1. Qongelela futhi ukhiphe amandla njengamandla, njengehardware shrapnel yamawashi kanye ne-hardware shrapnel yemishini.

- 2. Isenzo sokulawula umshini sifana ne- ngokunemba shrapnel of I-valve i-Hardware kunjini yomlilo yangaphakathi, kanye ne-shrapnel enembile yokulawulwa kwehadiwe ku-condenser.

- 3.Munca ukudlidliza namandla ashaqisayo, njenge-shrapnel enembile ye-hardware yebhafa ngaphansi kwenqola kanye negumbi lesitimela, ishubhu lensimbi elidonsa ukudlidliza ekuhlanganiseni, njll.

- 4. Isetshenziswa njengento yokulinganisa amandla, njengedivayisi yokulinganisa amandla, isigaxa sensimbi esikalini sesigaxa sensimbi, njll. Isilinganiso somthwalo kuye ekuguqulweni kwesishubhu sehadiwe kubizwa ukuqina kwesigaxa sehadiwe. Ubukhulu obukhulu, ubunzima be-hardware shrapnel. Yenziwe ngensimbi yasentwasahlobo futhi iyaqina emuva kokwelashwa kokushisa.

Ukukhiqizwa kwezingxenye ze-Hardware Stamping Stamping kuyikhono elengeziwe lokucubungula izinto (insimbi noma okungeyona eyensimbi) zibe izingxenye (noma imikhiqizo eyingxenye) ngokushaya okubandayo ngokufa kwabantu. Ukunyathela inqubo yokucubungula ingcindezi esebenzisa isikhunta esifakwe emaphephandabeni ukufaka ingcindezi ezintweni ezisezingeni lokushisa ekamelweni ukuze ziqhekeze noma zikhubaze oplastikhi, bese zithola izingxenye ezidingekayo.

Xhumanisa nale ndatshana: Izindawo Zokusebenza Ezihlukile Zesitampu Esibunjiwe

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa, ishidi lensimbi nokugxivizwa.Ukunikeza ama-prototypes, ama-run wokukhiqiza aphelele, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa, ishidi lensimbi nokugxivizwa.Ukunikeza ama-prototypes, ama-run wokukhiqiza aphelele, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi