Indlela Elungile Yokukhetha Yamapharamitha Wokugaya Machining

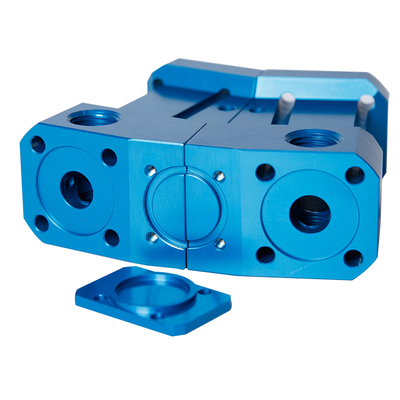

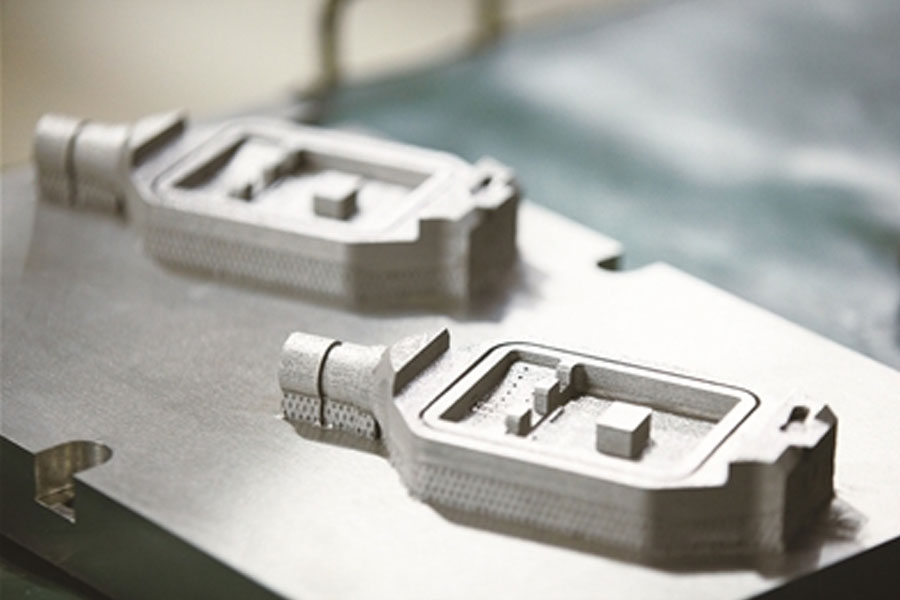

Imishini yokugaya ye-CNC iyimishini eyimishini esetshenziswa ukwenza isikhunta, ukuhlolwa zalapho, isikhunta, indawo egobile eyinkimbinkimbi enezindonga ezincane, izitho zokwenziwa, izindwani, njll., kanye nezinzuzo nezindima ezibalulekile zemishini yokugaya ye-CNC kufanele kusetshenziswe ngokugcwele lapho kukhethwa ukugaya i-CNC.

Ngesikhathi sohlelo lwe-NC, umenzi wohlelo kufanele anqume imingcele yokusika yenqubo ngayinye, okuhlanganisa isivinini sokuphotha kanye nesivinini sokuphakela. Imingcele yokusika ehlukene idinga ukukhethelwa izindlela ezahlukahlukene. Okulandelayo kwethula kafushane uhlelo lokukhetha ipharamitha lwenqubo yokugaya:

Ukuzimisela kwejubane lokuphotha

Ijubane lokuphotha kufanele likhethwe ngokuya ngesivinini esivumelekile sokusika kanye nobubanzi bomsebenzi wokusebenza. Ekugcineni, isivinini sokuphotha esibaliwe kufanele sikhethwe ngokuya ngemanuwali yethuluzi lomshini.

Ukunqunywa kwezinga lokuphakelayo

Ijubane lokuphakelayo liyipharamitha ebalulekile kumapharamitha wokusika wamathuluzi omshini we-CNC, akhethwa ngokuyinhloko ngokuya ngokunemba kanye nezidingo zokuqina kwendawo yezingxenye kanye nezakhiwo ezibonakalayo ze-workpiece. Izinga lokuphakelayo likhawulelwe ukuqina kwethuluzi lomshini nokusebenza kwesistimu yokuphakelayo. Uma i-contour iseduze nekhona, izinga lokuphakelayo kufanele lehliswe ngokufanelekile ukuze kunqotshwe into ebizwa ngokuthi "i-overtravel" noma "i-undertravel" ekhoneni lekhonta ngenxa yokungabi nasici noma ukuwohloka kwesistimu yenqubo.

Umgomo wokunquma izinga lokuphakelayo

- (1) Lapho ikhwalithi ye-workpiece ingaqinisekiswa, ukuze kuthuthukiswe ukusebenza kahle, izinga eliphezulu lokuphakela lingakhethwa.

- (2) Lapho usika, imbobo ejulile noma insimbi enesivinini esikhulu, kufanele kukhethwe izinga eliphansi lokuphakelayo.

- (3) Uma ukunemba nobulukhuni bendawo kudingeka ukuthi kube phezulu, isivinini sokuphakela kufanele sibe sincane.

- (4) Uma ungenzi lutho, ikakhulukazi "ngokubuyiselwa kweqanda" okude, okuphakelayo okunikezwe uhlelo lwe-CNC lwethuluzi lomshini kungakhethwa.

Yidla emuva. Inani liyanqunywa

Inani lokuphakela emuva linqunywa ngokuvumelana nokuqina kwethuluzi lomshini, ucezu lomsebenzi kanye nethuluzi. Ukuze kuqinisekiswe ikhwalithi ephezulu, umkhawulo omuhle womsebenzi ungashiywa. Uma ukuqina kuvuma, inani le-back-feeding kufanele lilingane ne-margin ye-workpiece ngangokunokwenzeka, ukuze inani lokuhamba lincishiswe futhi ukusebenza kahle kungathuthukiswa.

Ukugaya intambo. Izinhlobo eziyinhloko

(1) Ukugaya intambo eyicylindrical.

Ukugaya intambo eyicylindrical. Umumo ufana kakhulu nenhlanganisela ye-cylindrical end milling kanye nentambo kampompi, kodwa umkhawulo wayo wokusika intambo uhlukile kumpompi. I-spiral lift ekuphakameni okungeyona i-helical ibonakala ngokuhamba kwethuluzi lomshini. Ngenxa yalesi sakhiwo esikhethekile, ithuluzi lingasetshenziselwa kokubili izintambo ezingakwesokudla kanye nesobunxele, kodwa alifaneleki emicu ye-pitch emikhulu.

(2) Umshini wokugaya intambo yokuqinisa kanye nocezu

Ukugaya intambo yomshini wokugawula. Ifanele imicu emikhulu yobubanzi. Isici sayo ukuthi i-chip kulula ukuyikhiqiza, futhi eminye imicu ingasikwa nhlangothi zombili, kodwa ukumelana komthelela kubi kakhulu kunokokugaywa kwentambo ebalulekile. Ngakho-ke, leli thuluzi livame ukunconywa ngezinto ze-aluminium alloy.

(3) Kuhlanganiswe intambo ekhethekile yeziteshi eziningi eyisicefe nokugaya

I-multi-station special thread boring ne-milling ehlanganisiwe ibonakala nge-multi-edge, iziteshi eziningi zingaqedwa ngesikhathi esisodwa, ezingonga isikhathi esiyisizayo njengokushintsha futhi sithuthukise kakhulu ukusebenza kahle.

Ithrekhi yokugaya intambo

Ithrekhi yokunyakaza yokugaya intambo ingumugqa ovunguzayo, ongabonakala ngokuxhumanisa ama-eksisi amathathu wethuluzi lomshini we-CNC. Njengokugaya kwe-CNC yamakhontolo ajwayelekile, ukusika kwe-arc eyindilinga noma ukusika komugqa nakho kungasetshenziswa lapho ukugaya intambo kuqala. Lapho ugaya, kufanele uzame ukukhetha ucezu lokugaya ububanzi balo bukhulu kunobude bentambo ezokwenziwa ngomshini. Ukugaya kudinga kuphela ukuzungezisa ukuze kuqedelwe uchungechunge.

Lokhu okungenhla kuwuhlelo lokwakhiwa kwemingcele yenqubo yokugaya ukuze kuqinisekiswe ukunemba kanye nobulukhuni bobuso bezingxenye, ukunikeza ukudlala okugcwele ekusebenzeni kokusika, ukuqinisekisa ukuqina okunengqondo futhi kunikeze ukudlala okugcwele ekusebenzeni kwethuluzi lomshini.

Xhumanisa nale ndatshana:Indlela Elungile Yokukhetha Yamapharamitha Wokugaya Machining

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi