Kahle Ngokuphelele Amakhono Ekubholeni Nokuzijwayeza Kwemishini Ye-Cnc!

01 Amathiphu okusebenzisa isipholile

Ukusetshenziswa okufanele kwesipholile kubalulekile ukuze uthole ukusebenza okuhle kokumba, kuzothinta ngokuqondile ukuphuma kwe-chip, impilo yamathuluzi kanye nekhwalithi yomgodi owenziwe ngomshini ngesikhathi somshini.

(1) Indlela yokusebenzisa i-coolant

1) Idizayini yokupholisa yangaphakathi

Idizayini yokupholisa yangaphakathi ihlale iyinketho yokuqala yokugwema ukuvinjwa kwe-chip, ikakhulukazi uma wenza izinto ze-chip ende futhi ubhoboza izimbobo ezijulile (ezinkulu kunezimbobo izikhathi ezi-3). Ukuze uthole i-drill bit evundlile, lapho isipholile siphuma endaweni yokubhoboza, akumele kube ne-undershoot yoketshezi olusikayo obude okungenani obungama-30 cm.

2) Umklamo wokupholisa wangaphandle

Ukusetshenziswa kwesipholisa sangaphandle kungasetshenziswa uma ukwakheka kwe-chip kukuhle futhi ukujula kwembobo kungashoni. Ukuze kuthuthukiswe ukukhishwa kwe-chip, kufanele okungenani kube khona umlomo wombhobho wokupholisa owodwa (noma imibhobho emibili uma kuwuhlelo olungaphenduki) eduze kwe-eksisi yethuluzi.

3) Izindlela zokumba ezomile ngaphandle kokusebenzisa isipholile

Ukubhoboza okomile ngokuvamile akunconywa.

- a) Ingasetshenziswa ezinhlelweni ezinezinto ezimfishane ze-chip kanye nokujula kwembobo kufika izikhathi ezi-3 ububanzi

- b) Ifanele amathuluzi omshini ovundlile

- c) Kunconywa ukunciphisa isivinini sokusika

- d) Impilo yamathuluzi izoncishiswa

Kunconywa ukuthi ungasebenzisi i-drilling eyomile:

- a) Insimbi engagqwali (ISO M kanye no-S)

- b) I-bit drill bit eshintshwayo

4) Ukupholisa kwengcindezi ephezulu (HPC) (~70 bar)

Izinzuzo zokusebenzisa i-high-pressure coolant yilezi:

- a) Ngenxa yomphumela wokupholisa othuthukisiwe, impilo yamathuluzi yinde

- b) Thuthukisa umthelela wokususwa kwe-chip ekwenziweni kwezinto ezisetshenziswa yi-chip ende njengensimbi engagqwali, futhi kungase kunwebe ukuphila kwamathuluzi

- c) Ukusebenza okungcono kokususwa kwe-chip, ukuphepha okuphezulu kakhulu

- d) Nikeza ukugeleza okwanele ngokuhambisana nengcindezi enikeziwe kanye nosayizi wembobo ukuze kugcinwe indawo yokupholisa

(2) Sebenzisa amakhono okupholisa

Qinisekisa ukuthi usebenzisa amafutha okusika ancibilikayo (emulsion) aqukethe izithasiselo ze-EP (ukucindezela okukhulu). Ukuze uqinisekise impilo engcono kakhulu yamathuluzi, okuqukethwe kukawoyela engxubeni kawoyela-amanzi kufanele kube phakathi kuka-5-12% (phakathi kuka-10-15% uma kwenziwa insimbi engagqwali kanye nezinto ze-superalloy). Lapho ukhulisa okuqukethwe kwamafutha oketshezi lokusika, qiniseka ukuthi ubheka isihlukanisi samafutha ukuze uqinisekise ukuthi okuqukethwe kwamafutha okunconyiwe akudluli.

Uma izimo zivuma, okokupholisa kwangaphakathi kuhlala kuwukukhetha kokuqala uma kuqhathaniswa nesipholisi sangaphandle.

Amafutha ahlanzekile angathuthukisa umphumela wokugcoba futhi alethe izinzuzo lapho kubholwa izinhlelo zensimbi engagqwali. Qiniseka ukuthi uyisebenzisa kanye nezithasiselo ze-EP. Kokubili izingcezu zokubhola eziqinile ze-carbide kanye nezingcezu zokubhoboza ezifakwayo ezinenkomba zingasebenzisa uwoyela ohlanzekile futhi zingafinyelela imiphumela emihle.

Umoya ocindezelwe, uketshezi lokusika inkungu noma i-MQL (ukugcoba okuncane) kungase kube ukukhetha okuphumelelayo ngaphansi kwezimo ezinzile, ikakhulukazi uma kwenziwa ama-ayina okusansimbi nama-alloys e-aluminium. Njengoba ukunyuka kwezinga lokushisa kungase kube nomthelela omubi empilweni yamathuluzi, kunconywa ukunciphisa isivinini sokusika.

02 Amakhono okulawula i-chip

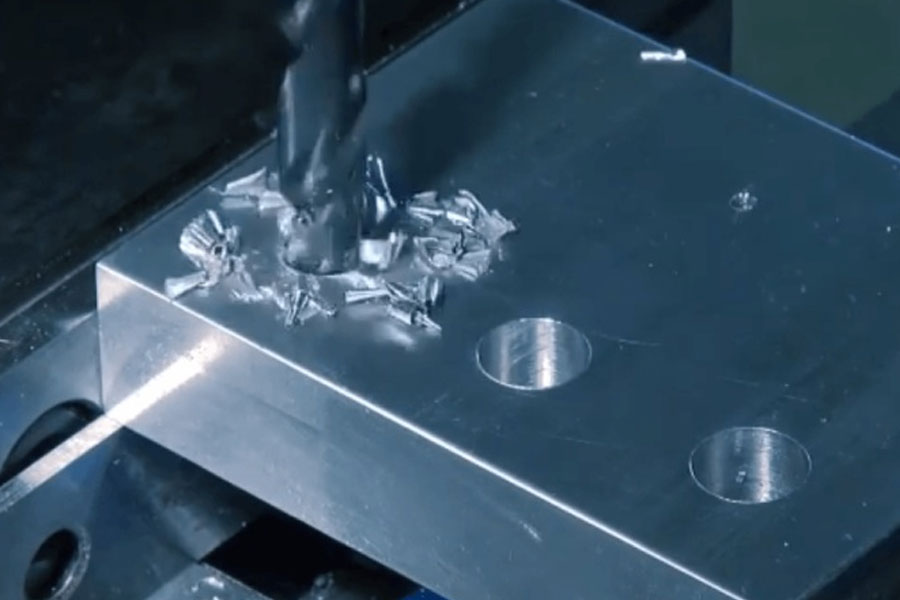

Ukwakhiwa kwe-chip kanye nokususwa kwe-chip yizinkinga ezibalulekile ekubholeni, kuye ngokuthi i-workpiece, ukukhetha kwe-drill/blade geometry, ingcindezi epholile/umthamo, kanye nemingcele yokusika.

Ukuvimba ama-chips kuzobangela ukuthi i-drill inyakaze ngamandla, okuzothinta ikhwalithi yembobo, impilo yokubhoboza nokuthembeka, noma kubangele ukuphuka kwe-drill/blade.

Lapho ama-chips engase akhishwe kahle ku-drill bit, ukubunjwa kwe-chip kuyamukeleka. Indlela engcono kakhulu yokuyibona iwukulalela ngesikhathi sokumba. Umsindo oqhubekayo ubonisa ukuphuma okuhle kwe-chip, futhi umsindo oqhubekayo ubonisa ukuvaleka kwe-chip. Hlola amandla okuphakelayo noma imonitha yamandla. Uma kukhona okungavamile, imbangela ingase ibe ama-chips avaliwe. Hlola ama-chips. Uma ama-chips ede futhi egobile, kodwa engagoqiwe, kusho ukuthi ama-chips avaliwe. Imbobo yokubuka. Ngemuva kokuvinjelwa, kuzobonakala indawo eqinile.

Amathiphu okugwema ukuqopha:

- 1) Qinisekisa ukuthi imingcele yokusika efanele kanye nejiyomethri yethiphu ye-drill/ithuluzi iyasetshenziswa

- 2) Hlola ukuma kwe-chip-lungisa izinga lokuphakelayo nesivinini

- 3) Hlola ukugeleza kwamanzi okusika nokucindezela

- 4) Hlola onqenqemeni lokusika. Uma yonke i-chipbreaker ingasebenzi, umonakalo onqenqemeni/i-chip ungase ubangele ama-chips amade

- 5) Hlola ukuthi umshini ushintshiwe ngenxa yeqoqo elisha lama-workpieces-lungisa imingcele yokusika

(1) Ama-chips asuka ku-indexable insert drill bits

Ama-chips acijile akhiwe i-central blade kulula ukuwabona. Ama-chips akhiwe yi-peripheral inserts afana nokuphenduka.

(2) Ama-chips asuka kuma-hard drill bits

I-chip ingakhiwa ukusuka maphakathi ne-cutting edge kuya ku-periphery. Kuyaqapheleka ukuthi ama-chips okuqala akhiqizwe lapho kubholwa i-workpiece ekuqaleni ahlala emide kakhulu, kepha lokhu akubangeli izinkinga.

(3) Ama-chips asuka kuma-bit drill ashintshashintshayo

03Ukulawulwa kokuphakelayo kanye nesivinini sokusika

(1) Umthelela wokusika isivinini Vc (m/min)

Ngaphezu kokuqina kwezinto ezibonakalayo, ijubane lokusika liphinde libe yisici esiyinhloko esithinta impilo yamathuluzi nokusetshenziswa kwamandla.

- 1) Ijubane lokusika liyisici esibaluleke kakhulu ekunqumeni impilo yamathuluzi

- 2) Isivinini sokusika sizothinta amandla e-Pc (kW) kanye ne-torque Mc (Nm)

- I-3) Isivinini sokusika esiphezulu sizokhiqiza izinga lokushisa eliphezulu futhi sikhulise ukugqoka kwe-flank, ikakhulukazi ithiphu lethuluzi le-peripheral

- 4) Lapho kwenziwa izinto ze-chip ezithambile ende (okungukuthi insimbi ephansi ye-carbon), isivinini sokusika esiphezulu sivumela ukwakheka kwe-chip.

Isivinini sokusika siphezulu kakhulu:

- a) I-flank igqoka ngokushesha kakhulu

- b) Ukuguqulwa kwepulasitiki

- c) Ikhwalithi yembobo engalungile kanye nobubanzi bembobo obumpofu

Isivinini sokusika siphansi kakhulu:

- a) Khiqiza isimila esakhekile

- b) Ukususwa kwe-chip okungekuhle

- c) Isikhathi eside sokusika

(2) Umthelela we-feed fn (mm/r)

- 1) Kuthinta ukwakheka kwe-chip, ikhwalithi yendawo kanye nekhwalithi yembobo

- 2) Amandla e-Influence Pc (kW) kanye ne-torque Mc (Nm)

- 3) Ukudla okuphezulu kuzothinta amandla okuphakelayo Ff (N), okufanele kucatshangelwe lapho isimo sokusebenza singazinzile

- I-4) Ukuthinta ukucindezeleka kwemishini nokucindezeleka okushisayo

Izinga lokuphakelayo eliphezulu:

- a) Ukuphulwa kwe-hard chip

- b) Isikhathi esifushane sokusika

- c) Ukugqokwa kwamathuluzi kuncane kodwa ingozi yokubhoboza unqenqema iyanda

- d) Izinga lembobo liyancipha

Izinga lokuphakelayo eliphansi:

- a) Amashiphu amade futhi azacile

- b) Ukuthuthukiswa kwekhwalithi

- c) Ukugqoka kwamathuluzi okusheshisiwe

- d) Isikhathi eside sokusika

-

e) Uma ubhoboza izingxenye ezincane eziqinile, izinga lokudla kufanele ligcinwe liphansi

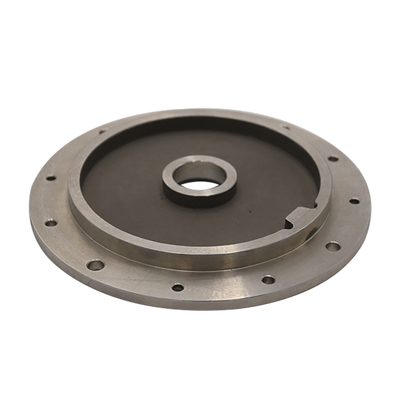

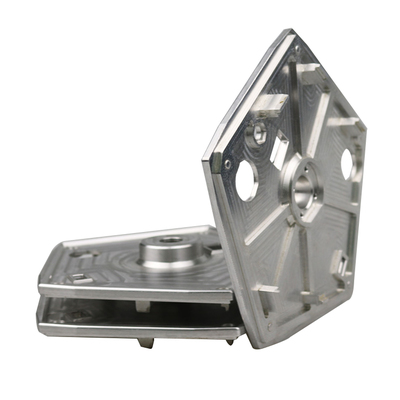

isithombe

04Amathiphu okuthola izimbobo zekhwalithi ephezulu

(1) Ukususwa kwe-chip

Qinisekisa ukuthi ukusebenza kokususwa kwe-chip kuhlangabezana nezidingo. Ukuvalwa kwe-chip kuthinta ikhwalithi yembobo, ukwethembeka nempilo yamathuluzi. I-drill/insert geometry kanye nemingcele yokusika ibalulekile.

(2) Ukuzinza, ukuqinisa ithuluzi

Sebenzisa i-drill bit emfushane kakhulu. Sebenzisa isibambi sethuluzi eliqinile elicolisisiwe ngokuphuma okuncane kakhulu. Qinisekisa ukuthi i-spindle yomshini isesimweni esihle futhi iqondaniswe kahle. Qinisekisa ukuthi izingxenye zilungisiwe futhi zizinzile. Faka isilinganiso sokuphakelayo esilungile ezindaweni ezingajwayelekile, izindawo ezithambekile nezimbobo eziphambanayo.

(3) Impilo yamathuluzi

Hlola ukuguga kwe-blade futhi usethe kusengaphambili uhlelo lokuphatha impilo yamathuluzi. Indlela ephumelela kakhulu ukusebenzisa i-feed force monitor ukuqapha ukumba.

(4) Isondlo

Shintsha isikulufu sokuminyanisa i-blade njalo. Hlanza isibambi sommese ngaphambi kokufaka i-blade, uqiniseke ukuthi usebenzisa isikrufu se-torque. Ungadluli inani eliphezulu lokuguga ngaphambi kokuphinda ugaye i-hard carbide drill bit.

05Amakhono okubhola wezinto ezahlukene

(1) Izindlela zokumba zensimbi ethambile

Ezinsimbi zekhabhoni eziphansi ezivame ukusetshenziselwa izingxenye zokushisela, ukwakheka kwe-chip kungaba yinkinga. Ukuncipha kokuqina, okuqukethwe kwekhabhoni, kanye nesibabule sensimbi, kulapho ama-chips akhiqizwa isikhathi eside.

- I-1) Uma inkinga ihlobene nokwakhiwa kwe-chip, khulisa isivinini sokusika i-vc futhi unciphise i-fn feed (sicela uqaphele ukuthi uma umshini wensimbi evamile, okuphakelayo kufanele kwandiswe).

- 2) Sebenzisa umfutho ophezulu kanye nokunikezwa kokupholisa kwangaphakathi.

(2) Amasu okumba we-austenitic kanye ne-duplex yensimbi engagqwali

I-Austenitic, i-duplex kanye ne-super duplex materials ingabangela izinkinga ezihlobene nokwakheka kwe-chip kanye nokukhishwa kwe-chip.

- 1) I-geometry efanele ibaluleke kakhulu, ngoba ingenza ama-chips akheke ngendlela efanele futhi ibasize ukuba bakhululwe. Ngokuvamile, kungcono ukusebenzisa umphetho obukhali wokusika. Uma inkinga ihlobene nokwakhiwa kwe-chip, ukukhulisa i-feed fn kuzokwenza ukuthi i-chip iphuke kakhulu.

- 2) Idizayini yokupholisa yangaphakathi, ingcindezi ephezulu.

(3) CGI (i-compact graphite cast iron) amakhono okumba

I-CGI ngokuvamile ayidingi ukunakwa okukhethekile. Ikhiqiza ama-chips amakhulu kune-grey cast iron, kodwa ama-chips kulula ukuphuka. Amandla okusika aphakeme ngakho-ke athinta impilo yamathuluzi. Kudingeka usebenzise izinto ezimelana kakhulu nokugqokwa. Kuzoba khona ukugqokwa kwethiphu yethuluzi elijwayelekile njengawo wonke ama-ayini acijile.

- I-1) Uma inkinga ihlobene nokwakhiwa kwe-chip, khulisa isivinini sokusika i-Vc futhi unciphise i-fn feed.

- 2) Idizayini yokupholisa yangaphakathi.

(4) Amakhono okumba i-aluminium alloy

Ukwakhiwa kwe-Burr kanye nokukhishwa kwe-chip kungaba inkinga. Kungase futhi kubangele ukuphila kwamathuluzi okufushane ngenxa yokunamathela.

- 1) Ukuqinisekisa ukwakheka kwe-chip okungcono kakhulu, sebenzisa ukondla okuphansi kanye nesivinini sokusika esikhulu.

- 2) Ukuze ugweme ukuphila kwamathuluzi okufushane, ukunamathela okuhlukile kungase kudingeke kuhlolwe ukuze kuncishiswe ukunamathela. Lezi zembatho zingabandakanya ukugqoka kwedayimane, noma ukungabikho nhlobo (kuye ngokuthi i-substrate).

- 3) Sebenzisa i-emulsion enengcindezi ephezulu noma isipholile senkungu.

(5) Amakhono okumba ama-alloys e-titanium nama-alloys ashisa kakhulu

Ukuqina komsebenzi we-hole surface kuthinta izinqubo ezilandelayo. Kunzima ukuthola ukusebenza okuhle kokususwa kwe-chip.

- 1) Lapho ukhetha i-geometry yokwenza ama-alloys e-titanium, kungcono ukuba nomkhawulo obukhali wokusika. Lapho wenza ama-alloys asekelwe ku-nickel, i-geometry eqinile ibalulekile. Uma kunenkinga yokuqina komsebenzi, zama ukukhuphula izinga lokudla.

- 2) I-coolant ephezulu efinyelela kubha engu-70 ithuthukisa ukusebenza.

(5) Amakhono okumba insimbi eqinile

Thola impilo yamathuluzi eyamukelekayo.

- I-1) Yehlisa ijubane lokusika ukuze unciphise ukushisa. Lungisa izinga lokuphakelayo ukuze uthole ama-chips amukelekayo futhi okulula ukuwakhipha.

- 2) I-emulsion exubekile ephezulu yokugxila.

Xhumanisa nale ndatshana: Kahle Ngokuphelele Amakhono Ekubholeni Nokuzijwayeza Kwemishini Ye-Cnc!

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi