5 Amakhono Obuchwepheshe Abalulekile Wezikhungo Zomshini ze-CNC Okufanele Uzazi Kahle

2023-09-15

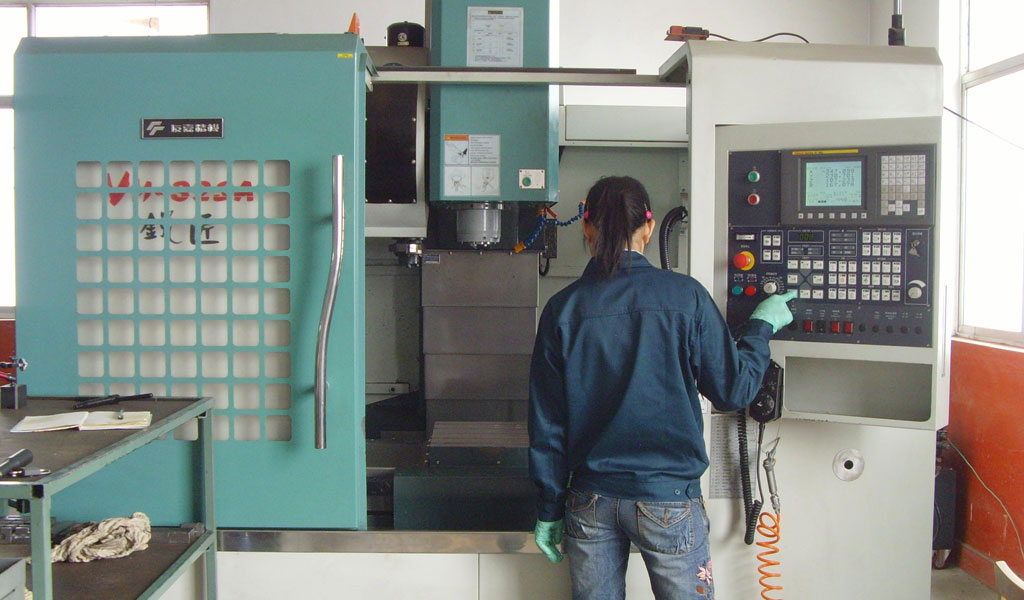

Emhlabeni wokukhiqiza wesimanje, izikhungo zemishini ye-CNC (Computer Numerical Control) ziguqule indlela esidala ngayo izingxenye ezinembayo nezingxenye. Le mishini eyinkimbinkimbi ithembele ekuhlanganiseni kwezingxenyekazi zekhompiyutha kanye nobuchwepheshe besoftware ukwenza imisebenzi yokusika enembile, ukubhoboza, nokubumba ngokunemba okungenakuqhathaniswa nokusebenza kahle. Njengomashini we-CNC noma umshisekeli, kubalulekile ukuhambisana nentuthuko yakamuva kwezobuchwepheshe ukuze uhlale uqhudelana kulo mkhakha onamandla. Lesi sihloko esibanzi sizohlola amakhono amahlanu abalulekile ezobuchwepheshe wonke Ukufakwa kwe-CNC opharetha wesikhungo kanye nomqambi kufanele bazi. Noma ngabe ungumuntu osaqalayo ofuna ukungena emhlabeni wemishini ye-CNC noma uchwepheshe onolwazi ofuna ukuthuthukisa amakhono akho, lo mhlahlandlela uzokunikeza imininingwane ebalulekile emikhakheni ebalulekile yolwazi nobungcweti okufanele ukuhlakulele.

Emhlabeni wokukhiqiza wesimanje, izikhungo zemishini ye-CNC (Computer Numerical Control) ziguqule indlela esidala ngayo izingxenye ezinembayo nezingxenye. Le mishini eyinkimbinkimbi ithembele ekuhlanganiseni kwezingxenyekazi zekhompiyutha kanye nobuchwepheshe besoftware ukwenza imisebenzi yokusika enembile, ukubhoboza, nokubumba ngokunemba okungenakuqhathaniswa nokusebenza kahle. Njengomashini we-CNC noma umshisekeli, kubalulekile ukuhambisana nentuthuko yakamuva kwezobuchwepheshe ukuze uhlale uqhudelana kulo mkhakha onamandla. Lesi sihloko esibanzi sizohlola amakhono amahlanu abalulekile ezobuchwepheshe wonke Ukufakwa kwe-CNC opharetha wesikhungo kanye nomqambi kufanele bazi. Noma ngabe ungumuntu osaqalayo ofuna ukungena emhlabeni wemishini ye-CNC noma uchwepheshe onolwazi ofuna ukuthuthukisa amakhono akho, lo mhlahlandlela uzokunikeza imininingwane ebalulekile emikhakheni ebalulekile yolwazi nobungcweti okufanele ukuhlakulele.

Ubungcweti bokuHlela be-CNC

Uhlelo lwe-CNC luyisisekelo sokusebenzisa isikhungo semishini ngempumelelo. Kubandakanya ukudala isethi yemiyalelo eqondisa umshini we-CNC ekukhiqizeni ingxenye oyifunayo. Ukuze ube nekhono ezinhlelweni ze-CNC, udinga ukuqonda okulandelayo:- a. Okuyisisekelo kwekhodi ye-G kanye nekhodi ye-M: Funda izisekelo zamakhodi e-G (amakhodi ejiyomethri) kanye namakhodi we-M (amakhodi okusebenza ahlukahlukene) asetshenziselwa ukulawula imishini ye-CNC. Qonda ukuthi ubhalwa kanjani, uhlele, uphinde uxazulule kanjani lawa makhodi ukuze uzuze imisebenzi yomshini enembayo.

- b. Ukusetshenziswa kwesofthiwe ye-CAD/CAM: Zijwayeze nesofthiwe ye-Computer-Aided Design (CAD) yokudala amamodeli e-3D nesofthiwe ye-Computer-Aided Manufacturing (CAM) ukuze ukhiqize izindlela zamathuluzi kanye nekhodi ye-G kusuka kulawa mamodeli. Hlola izinketho zesofthiwe ezidumile njenge-AutoCAD, i-SolidWorks, ne-Mastercam.

- c. Ukwenziwa kwendlela yamathuluzi: Ingcweti kwezobuciko bokudala izindlela zamathuluzi ezisebenza kahle nezilungiselelwe ezinciphisa izikhathi zomjikelezo, zinciphise ukuguga kwamathuluzi, futhi zikhiqize izingxenye zekhwalithi ephezulu. Hlola amasu ahlukene omshini we-2D ne-3D, okuhlanganisa ukukhonta, ukufaka ephaketheni, nezindlela zamathuluzi eziguquguqukayo.

- d. Ukulingisa nokuqinisekisa: Qonda ukubaluleka kokulingisa nokuqinisekisa izinhlelo zakho ze-CNC usebenzisa amathuluzi esofthiwe. Funda ukuthi ungathola kanjani futhi ulungise amaphutha ngaphambi kokuthi abangele amaphutha abizayo emshinini.

Ukusethwa Komshini Nokugcinwa

Ukusethwa okufanele nokugcinwa komshini kubalulekile ukuze kuqinisekiswe ukuphila isikhathi eside kwezikhungo zemishini ze-CNC kanye nokuzuza imiphumela engaguquki, nenembile. Izihloko ezibalulekile ongazihlola kule ndawo zihlanganisa:- a. Ukulinganiswa komshini: Funda indlela yokulinganisa izimbazo zomshini namathuluzi ukuze ugcine ukunemba kulo lonke inkontileka cnc machining inqubo.

- b. Ukukhetha nokuphathwa kwamathuluzi: Qonda ukuthi ungawakhetha kanjani amathuluzi okusika afanele wezinto ezithize nezinhlelo zokusebenza. Hlola izinqubo zokushintsha amathuluzi kanye nokuphathwa kwempilo yamathuluzi.

- c. Amasu okusebenza: Thola izindlela zokubamba ezahlukahlukene, njengama-clamp, ama-vises, kanye zalapho, nokuthi ungayikhetha kanjani inketho efaneleke kakhulu yomsebenzi wakho.

- d. Amasistimu okugcoba nokupholisa: Zijwayeze ngokubaluleka kokuthambisa okufanele nokupholisa ukuze uvimbele ukushisisa ngokweqile nokuguga kwamathuluzi. Funda ukuthi ungawagcina kanjani lawa masistimu ukuze asebenze kahle.

- e. Imisebenzi yokulungisa okujwayelekile: Yakha ishejuli yokulungisa yokuhlanza, ukuhlola, nokugcinwa kokuvikela isikhungo sakho semishini ye-CNC. Funda ukuhlonza kanye nokuxazulula izinkinga ezivamile ngokushesha.

I-CNC Machine Control

Ukuze usebenzise isikhungo semishini ye-CNC ngempumelelo, kufanele ube nokuqonda okujulile kohlelo lwayo lokulawula. Izihloko ezibalulekile ongazihlola kulesi sigaba zihlanganisa:- a. Ukusebenzelana komshini: Funda indlela yokuzulazula nokusebenzisa iphaneli yokulawula yomshini, okuhlanganisa ikhibhodi, ukuqapha, nezilawuli ezenziwa ngesandla.

- b. Ukulawula i-eksisi: Qonda ukuthi uhambisa futhi umise kanjani izimbazo zomshini ngokunembile usebenzisa zombili izindlela ezenziwa ngesandla nezizenzakalelayo.

- c. Ukulayishwa nokusebenza kohlelo: Yingcweti inqubo yokulayisha izinhlelo ze-CNC, ukubeka ama-offsets omsebenzi, nokwenza imisebenzi yomshini ngokuphepha.

- d. Izinqubo zezimo eziphuthumayo: Zijwayeze nezinqubo zokumisa izimo eziphuthumayo kanye nezimiso zokuphepha ukuze uvikele kokubili umshini kanye nabaqhubi bawo.

CNC Machining Strategies

Amasu okwenza imishini abalulekile abalulekile ekuthuthukiseni umkhiqizo kanye nokuzuza izingxenye zekhwalithi ephezulu. Hlola izihloko ezilandelayo ezihlobene namasu omshini we-CNC:- a. Isivinini sokusika nokuphakelayo: Funda indlela yokubala nokulungisa isivinini sokusika kanye nokuphakelayo kwezinto ezihlukene, izinhlobo zamathuluzi, nezimo zokusika.

- b. Ukuthuthukiswa kwendlela yamathuluzi: Qonda ukuthi ungayilungiselela kanjani izindlela zamathuluzi zokukhishwa okuthuthukisiwe kwe-chip, ukunciphisa ukuguga kwamathuluzi, kanye nezikhathi zomjikelezo ezincishisiwe.

- c. I-High-speed machining (HSM): Hlola amasu athuthukile njenge-HSM, enika amandla ukukhanda kwesivinini esikhulu ngokunemba okuphezulu nokuqedwa kwendawo.

- d. I-Multi-axis machining: Zijwayeze ngamakhono namasu wokwenza ama-axis amaningi, okuhlanganisa i-4-eksisi kanye 5-eksisi machining, ukwandisa amakhono akho okwenza imishini.

I-Automation kanye Nezimboni 4.0 Ukuhlanganisa

Ikusasa lezikhungo zemishini ye-CNC lilele ekuzishintsheni nasekuhlanganisweni nobuchwepheshe be-Industrial 4.0. Hlala ngaphambi kwejika ngokufunda mayelana:- a. I-CNC automation: Hlola ukusetshenziswa kobuchwepheshe bokuzenzakalela njengokulayisha/ukukhipha ngerobhothi, izishintshi zephalethi, namasistimu okuthutha ukuze kuthuthukiswe ukukhiqiza nokunciphisa izindleko zabasebenzi.

- b. I-inthanethi Yezinto (IoT) nokuhlaziywa kwedatha: Qonda ukuthi izinzwa ze-IoT nokuhlaziywa kwedatha kunganikeza kanjani ukuqapha kwesikhathi sangempela sokusebenza komshini kanye nemininingwane yokubikezela yokulungisa.

- c. Inethiwekhi ye-CNC: Funda mayelana nenethiwekhi yemishini ye-CNC ukuze unike amandla ukushintshaniswa kwedatha, ukuqapha okukude, nokulawula okuphakathi.

- d. I-Cybersecurity: Hlala unolwazi mayelana nezinqubo ezihamba phambili ze-cybersecurity ukuze uvikele imishini ye-CNC kanye nedatha ezinsongweni ezingaba khona.

Isiphetho

Ezweni lanamuhla lokukhiqiza elithuthukayo, ukwazi amakhono ezobuchwepheshe ahlotshaniswa nezikhungo zomshini ze-CNC kubalulekile ekukhuleni kwemisebenzi nokuhlala unokuncintisana. Ngokuthuthukisa ubuhlakani ezinhlelweni ze-CNC, ukusethwa komshini nokugcinwa kahle, ukulawula umshini we-CNC, amasu okwenza imishini, kanye ne-automation, ungavula amandla aphelele ale mishini enamandla futhi ufake isandla ekusaseni ukukhiqiza okunembayo. Noma ngabe ungumfundi osanda kufunda we-CNC noma umakhi wemishini onolwazi, ukufunda okuqhubekayo nokuzijwayeza nobuchwepheshe obusafufusa kuzoqinisekisa ukuthi uhlala uphambili ekuthuthukisweni kwemishini ye-CNC. Yamukela amathuba ethulwe yi-Industry 4.0 kanye nezinqubo ezintsha eziqhubekayo kubuchwepheshe be-CNC ukuze kuthuthukiswe umsebenzi wakho futhi kube neqhaza entuthukweni ethokozisayo yokukhiqiza yesimanje.

Imisebenzi Yethu

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

Case Studies

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

Uhlu lwezinto

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi

Izingxenye zegalari