-

Isakhiwo Esikhethwayo Sendiza Ye-Aluminium Alloy 7A09

Phakathi kwezinto ze-aluminium zezimoto ze-aerospace e-China, i-7A09 alloy ingenye yama-alloy akhethwayo aphezulu ezingxenyeni eziyinhloko zesakhiwo esigcizelelwe. Imikhiqizo eseqediwe kancane etholakalayo ihlanganisa amapuleti, imicu, imigoqo, amaphrofayili, amashubhu anezindonga eziwugqinsi, ama-forging, njll. Ukwakheka kwamakhemikhali kunengqondo kakhulu kunaleyo ye-7A04 alloy, ngakho inokusebenza okubanzi okuphakeme futhi iba enye yezinto eziyinhloko zomklami. . Ukwakheka kwayo kwamakhemikhali (ubuningi): 0.5Si, 0.5Fe, (1.2—2.0) Cu, 0.15 Mn, (2.0-3.0) Mg, (0.16-0.30) Cr, (5.1-6.1) Zn, 0.10Ti, okunye ukungcola ngawodwana angu-0.05, ahlanganisa u-0.10, kanti amanye angu-Al.

2021-10-16

-

I-7A04 Alloy - Amandla Okukhiqiza Aseduze Namandla Aqinile

I-7A04 alloy iyingxubevange ye-Al-Zn-Mg-Cu ekwazi ukumelana nokushisa ekwazi ukumelana nokushisa kwe-aerospace super-hard aluminium alloy, engaphathwa ngokushisa futhi iqiniswe. Ukwakheka kwayo kufakwe kuhlu ku-GB/T3190-2008, futhi ihambisana ne-B95 alloy yeSoviet Union neRussia kanye ne-AlZnMgCu1 yaseJalimane. .5.3.4365 ingxubevange iyalingana, ngoba ngo-1944 ifektri yeSoviet Union yesi-95 yavivinya ngempumelelo lo mkhiqizo owenziwe ingxubevange oqediwe, yingakho kuthiwa i-B95 alloy. Ngo-1957, i-China Northeast Light Alloy Co., Ltd. (eyayikhona ngaleso sikhathi i-Harbin Aluminium Processing Plant) yakhiqiza le ngxube ngosizo lochwepheshe baseSoviet. Amapuleti e-alloy nezinto ezikhishiwe.

2021-10-09

-

Isizathu Sokuthi Izingxenye Zensimbi Yeshidi Zibuyiselwa Kancane Kancane Ngama-Plastics E-Thermoplastic

Ishidi lensimbi ubuchwepheshe bokucubungula izinsimbi obenza uchungechunge lokucubungula njengokugunda, ukusika, ukubhoboza, nokusonga amashidi wensimbi. Iningi lezinto ezisetshenzisiwe zingamapuleti ensimbi, futhi imikhiqizo esetshenzisiwe isetshenziswa kabanzi, ikakhulukazi embonini yezimoto.

2021-09-18

-

I-Surface Treatment Technology Ye-Aluminium Alloy

I-Aluminium inezinzuzo eziningi njengokuqina okuphansi, amandla aphezulu aqondile, ukumelana okuhle nokugqwala, ukuqhutshwa okuphezulu kagesi nokushisa, ukuqina, ubucwebe obuhle, ukucubungula okulula nokwakha, nezakhiwo ezinhle kakhulu zokuhlobisa. Ingxubevange ye-Aluminium yenziwa nge-aluminium emsulwa ngokungeza ezinye izakhi zokuxuba

2021-08-14

-

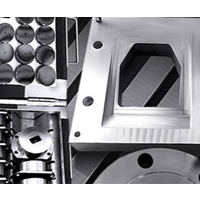

Amazinga Wemishini Ye-CNC Esetshenziswa Ngokuvamile Wokudweba Isikhunta

Ukwelula i-die machining kuyinqubo ebaluleke kakhulu yenqubo yokunyathela ukukhiqizwa, futhi ingumkhiqizo osebenzisa ubuchwepheshe. Ubunzima besakhiwo semishini ngokungenakugwenywa buzoholela ekuxakekeni kokuma kwezingxenye zesikhunta. Okulandelayo kuchaza ulwazi mayelana nezindinganiso ze-CNC ezisetshenziswa kakhulu zokudweba imishini yokubumba.

2021-08-14

-

Umehluko Phakathi Kwensimbi Ephakeme Nensimbi yeTungsten

Insimbi esheshayo (HSS) iyinsimbi yensimbi enobulukhuni obuphakeme, ukumelana nokugqoka okuphezulu kanye nokumelana nokushisa okuphezulu, okwaziwa nangokuthi yinsimbi yomoya noma insimbi engaphambili, okusho ukuthi ingaqiniswa noma ipholile emoyeni ngesikhathi sokucima, futhi icijile impela. Ibizwa nangokuthi insimbi emhlophe.

2021-08-14

-

Ulwazi Oluyisisekelo Lokubumba Kokhonkolo Kanye Nokumodelwa Kobumba

I-Gypsum imvamisa amhlophe amhlophe we-powdery, kanye namakristalu aphuzi abomvu ngokubomvu. Kungokwesimiso se-crystal monolithic. Ngokuya ngokwakhiwa, ihlukaniswe yaba yi-dihydrate gypsum ne-anhydrous gypsum. Uhlelo lokusebenza lokukhiqizwa kwesikhunta semboni ye-ceramic ngokuvamile luyi-dihydrate gypsum.

2021-08-28

-

Yini i-GR2 Titanium

I-titanium engu-GR2 iyinsimbi emhlophe esiliva enobuningi buka-4.5g / cm3 (20 ℃) nendawo encibilika ka-1668 XNUMX. Izinto ze-Titanium ne-titanium alloy zinezici zokumelana nokugqwala okuhle, ukuminyana okuphansi namandla aphezulu athile.

2020-06-13

-

Yini iHastelloy C-276

IHastelloy C-276 ingxubevange ye-nickel-molybdenum-chromium-tungsten enokumelana okuhle nokugqwala nezakhiwo ezinhle zokwakha.

2020-05-15

-

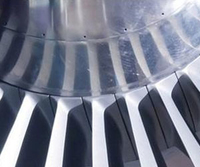

Amakhono Wokugaya we-Titanium Alloy

Imishini ye-TC4 titanium alloy inzima kakhulu. Inqubo ebanzi ye-titanium ne-titanium alloy yehluke kakhulu kunensimbi, i-aluminium alloy nezinsimbi eziningi ezisindayo ngokwesakhiwo se-crystal, izakhiwo zomzimba nezakhiwo zamakhemikhali. Ingxubevange iyinsimbi okungelula ukuyicubungula.

2020-05-16

-

Yini i-Inconel 690

I-Inconel 690 (UNS N06690) i-alloy-based alloy inokuqukethwe kwe-chromium okungu-27.0-31.0% kanye ne-alloy-based alloy ene-nickel engaba ngu-59%.

2020-05-23

-

Yini i-Inconel 718

I-Inconel 718 iyi-alloy-based alloy engaqiniswa yimvula. Isakhombisa amandla wokukhiqiza okuphezulu, amandla we-tensile namandla okuqhekeka okushisa emazingeni aphezulu okushisa aze afike ku-704 ° C.

2020-05-15

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi