Isakhiwo Esikhethwayo Sendiza Ye-Aluminium Alloy 7A09

I-T73 Artificial Aging Specification for Plates, Extrusions and Forgings

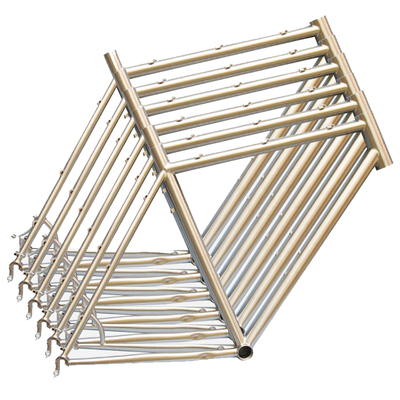

Phakathi kwezinto ze-aluminium zezimoto ze-aerospace e-China, i-7A09 alloy ingenye yama-alloy akhethwayo aphezulu ezingxenyeni eziyinhloko zesakhiwo esigcizelelwe. Imikhiqizo eseqediwe kancane etholakalayo ihlanganisa amapuleti, imicu, imigoqo, amaphrofayili, amashubhu anezindonga eziwugqinsi, UKWAKHAs, njll. Ukwakheka kwamakhemikhali kunengqondo kakhulu kunaleyo ye-7A04 alloy, ngakho-ke inokusebenza okubanzi okuphakeme futhi iba enye yezinto eziyinhloko zomklami. Ukwakheka kwayo kwamakhemikhali (ubuningi): 0.5Si, 0.5Fe, (1.2—2.0) Cu, 0.15 Mn, (2.0-3.0) Mg, (0.16-0.30) Cr, (5.1-6.1) Zn, 0.10Ti, okunye ukungcola ngawodwana angu-0.05, ahlanganisa u-0.10, kanti amanye angu-Al.

I-7A09 ingxubevange inezinto ezinhle zokwakha ezifundeni ezishubile nezixazululo. Ngemuva kokuguga okufakelwayo, izakhiwo zokwakha ziphansi, futhi ukuqina kwe-fracture kuyanelisa esimweni se-T6; nakuba amandla ngaphansi kwe-T73 yesimo sokuguga ephansi kunaleyo ye-T6 state, Inokumelana okuhle nokucindezeleka kokuqhekeka kokugqwala futhi inokuqina okuphezulu. Impahla ye-T76 inokumelana okuphezulu nokuqhekeka nokugqwala. I-T74 inamandla aphezulu kanye nokumelana nokuqhekeka kokugqwala kwengcindezi ngasikhathi sinye.

Amandla aqinile we-Rm we-7A09 alloy aphakeme kunalawo e-aluminium alloys angu-2A12 no-2A14, futhi ukumelana nokuqhekeka kwe-stress corrosion cracking nakho kuphakeme kunokwabo. Ngakho-ke, ukusetshenziswa kwayo ekwenzeni izingxenye zendiza akugcini nje ngokuba nomphumela omkhulu wokunciphisa isisindo, kodwa futhi kunokuphepha okuphezulu. Ngakho-ke, amandla ayo okukhathala awazange akhuliswe ngokufanele. Ngakho-ke, kubalulekile ukucabangela ngokungathí sina lolu daba lapho uklama izingxenye ezibhekene nomthwalo wokukhathala. Lapho izinga lokushisa likhuphuka, amandla we-7A09 alloy ayancipha ngokushesha, ngakho-ke izinga lokushisa elisebenzayo akufanele lidlule i-125 ° C.

Ukucaciswa kwe-annealing okungaphelele kwe-7A09 alloy: 290℃——320℃, 2h——4h, ukupholisa komoya; ukucaciswa okuphelele kokuthungatha: (390℃——430℃)/(0.5h——1.5h), no-≤30℃/h Izinga lokupholisa lingaphansi noma lilingana no-200℃, bese lipholiswa umoya esithandweni.

Izinga lokushisa lokwelapha isixazululo lale alloy lingu-460℃—475℃, kodwa izinga lokushisa lokwelashwa kweshidi eligqoke i-aluminium kufanele libe ngaphansi kunomkhawulo ophansi, hhayi izikhathi ezingaphezu kwezingu-2, ukuze kuvinjwe izakhi zengxubevange ukuthi zingangeni ku-aluminium- i-clad layer futhi inciphise ukumelana nokugqwala kwezinto. Indawo yokupholisa izinga lokushisa kwegumbi, amanzi afudumele noma enye indawo efanelekile, ukudluliswa akufanele kube ngaphezu kwama-15s. Izinga lokushisa lokucubungula lepuleti le-T6 lithi (135℃±5℃)/(8h—16h), kanti kwezinye izinto, lingu-(140℃±5℃)/16h. Bheka ithebula ukuze uthole izicaciso zokuguga zokwenziwa zamapuleti e-T73, izinto ezikhishiwe kanye nezinto zokubumba.

Imishini yokuncibilikisa ye-7A09 alloy iyafana neyamanye ama-alloys e-aluminium ekhandiwe. Izinga lokushisa elincibilikayo lingu-710 ℃-750 ℃, futhi izinga lokushisa lokuphonsa lingu-710 ℃-735 ℃. Usayizi we-ingot mncane futhi izinga lokushisa eliphansi lokusakaza liyakhethwa. Izinga lokushisa elincibilikayo le-alloy lingu-477 ℃. ——638°C.

I-7A09 alloy iyingxubevange ebalulekile ye-aluminium yesakhiwo sokucindezeleka. Isetshenziswe kabanzi ekwenzeni ama-fighters, amabhomu aphakathi nendawo, izindiza zokuthutha kanye nabaqeqeshi. Isetshenziselwa ukukhiqiza ukuhlalisa ikhala igiya izingxenye, imishayo yangaphambili yamaphiko, imishayo, kanye ne-fuselage docking. Izingalo nezinsika zokusekela uhlaka, ama-partitions, izimbambo, amalunga e-boam main, umsila oyisicaba odongeni olungaphezulu nangaphansi, izingxenye zesistimu ye-hydraulic, izinti ze-hydraulic tank piston rods, amasilinda angaphakathi nangaphandle nezinye izingxenye ezibalulekile.

Ukuqina kokuphuka (Kc, N/mm2,) kwe-7A09-T73 ingxubevange kungaphezulu kwalokho kwempahla ye-T6, futhi izinga lakho lokukhula lokuqhekeka liphansi kunelo lezinto ze-T6. Amandla ayo okukhathala nawo angcono kunalawo ezinto ze-T6, futhi ukuguquguquka kwayo okushisayo nakho kuphakeme kunaleyo yezinto ze-T6. Umthamo wokushisa othize we-7A09-T6 ingxubevange ku-50°C ngu-888J/(kg.°C), futhi izinga lokushisa legumbi ngu-18.5MS/m. Ngaphandle kokusebenza kokuqhekeka kwe-stress corrosion, ukumelana nokugqwala okuvamile kwe-7A09 alloy kulingana nalokho kwe-2A12 alloy. I-7A09 alloy iyazwela ekuqhekekeni kokugqwala kwengcindezi ekuqondeni kwe-ST, futhi umkhawulo wokugqwala kwengcindezi kuzikhombisi-ndlela ze-LT ne-L mkhulu kuno-300N/mm2, ngakho ukumelana nokuqhekeka kokugqwala kwengcindezi kulezi zindlela ezimbili kwanele ukuhlangabezana nezidingo zokusetshenziswa. Uma imfuneko iphakeme, kungasetshenziswa impahla ye-T73. Amandla aqinile we-Rm wento ekhona kulesi simo cishe angaphansi ngo-10% kunaleyo yento ye-T6, kodwa inani le-stress corrosion cracking threshold value in the LT direction likhulu kakhulu kunalelo lika-300N/mm2.

Ezingxenyeni ezidinga kokubili amandla nokusebenza kokugqwala kwengcindezi, izinto ze-T74 state kufanele zisetshenziswe. I-stress corrosion cracking threshold ye-7A09-T74 alloy die forgings ingu-210N/mm2. Izinyathelo zokunqanda ukugqwala ze-7A09 alloy zifaka i-anodic oxidation, ukwelashwa ngamakhemikhali okulwa nokugqwala kanye nopende.

Isakhiwo se-7A09 alloy siqukethe isixazululo esiqinile se-α-Al kanye nezinhlayiya zesigaba sesibili. Isigaba sesibili sinezinhlobo ezintathu: uhlobo lokuqala yizinhlanganisela ze-intermetallic ezakhiwe ngesikhathi sokuqiniswa kwe-alloy, njenge-Al7FeCR, i-Al3Fe, ne-Mg2Si. Usayizi mkhulu. Igaywa ibe yizigaxa bese isakazwa ngamaqoqo. Usayizi 0.5μm-10μm. Ayincibiliki kusixazululo esiqinile uma ishisisiwe futhi inciphisa ukuqina kwento. Uhlobo lwesibili izinhlayiya ezine-chromium ezifana ne-Al2CrMg2, okuyizingosi ezenziwe nge-homogenized futhi Idonswa kusukela kusixazululo esiqinile ngesikhathi sokushisisa ngaphambi kokucubungula, futhi usayizi wayo ngu-0.05μm-0.5μm, onesithiyo esikhulu inqubo recrystallization kanye nokukhula okusanhlamvu impahla; uhlobo lwesithathu yisigaba sokuqinisa ukuguga, okuwukwelashwa kwesisombululo esiqinile. Ukufaka esixazululweni esiqinile nokuguga ukuphuma esixazululweni esiqinile yizici ezibalulekile ezithinta izakhiwo zezinto ezibonakalayo. Izinhlayiya eziqinisayo zezinto zombuso we-T6 ikakhulukazi indawo ye-GP ≤4nm, izinhlayiya eziyinhloko eziqinisayo zezinto ze-T74 ziyisigaba soshintsho η'of 5nm-6nm, isigaba sokuqinisa se-T73 yisigaba soshintsho η'of 8nm-12nm futhi 20nm-80nm Η izinhlayiya zesigaba.

Ukwakheka kwento engu-7A09-O kulingana nalokho kwe-alloy engu-2A12-O, futhi inokwakheka okuhle kokungu-180°C-370°C; ukwakheka kwento entsha ecinyiwe icishe ifane naleyo yengxubevange ye-2A12. Ipuleti licinywa ekamelweni lokushisa 4h Kusenokwakheka okuhle ngaphakathi, kanye nesikhathi sokuqhwa ukuze kugcinwe ukwakheka: 24h ku-0℃, 3d ku -7℃, 7d ku -18℃.

Izinga lokushisa lokubumba lika-7A09 ingxubevange lingu-320°C-440°C, futhi izinga lokushisa lokuvula lokuvula kufanele libe ngu-≤400°C. Ukuphakama kakhulu kuzodala i-brittleness eshisayo, ikakhulukazi ngesikhathi sokufoja mahhala. Ingxubevange ye-7A09 akulula ukuyishisela, ngisho ne-resistance welding ayilungile njenge-2A12 alloy. Ama-Forgings angacinywa emanzini ashisayo ≤80 ℃. Ingxubevange engu-7A09 ngemva kokucisha kanye nokwelashwa okuphumelelayo inokusebenziseka okuhle.

Xhumanisa nale ndatshana: Isakhiwo Esikhethwayo Sendiza Ye-Aluminium Alloy 7A09

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi