Zisebenza Kanjani Izingxenye Ezinembe Kakhulu

2023-09-22

Ukwenza ngokunemba kuyinqubo ebalulekile embonini yokukhiqiza, okuvumela ukudalwa kwezingxenye ezinemba okuphezulu eziyizingxenye ezibalulekile zemishini ehlukahlukene, amadivayisi, namasistimu. Lezi zingxenye zitholakala ezimbonini kusukela ku-aerospace kanye nezimoto kuya kwezokwelapha kanye ne-electronics. Ukuzuza izinga elidingekayo lokunemba ekwenzeni imishini kuwumsebenzi onzima futhi onzima odinga ukuqonda okujulile kwezinto, ubuchwepheshe obusezingeni eliphezulu, nekhono eliyingqayizivele. Kulesi sihloko esibanzi, sizongena emhlabeni we ukulungisa okucacile, ukuhlola amasu, amathuluzi, kanye nezindlela ezisetshenziswayo ukuze kwakhiwe izingxenye ezinembayo eziphezulu.

Ukwenza ngokunemba kuyinqubo ebalulekile embonini yokukhiqiza, okuvumela ukudalwa kwezingxenye ezinemba okuphezulu eziyizingxenye ezibalulekile zemishini ehlukahlukene, amadivayisi, namasistimu. Lezi zingxenye zitholakala ezimbonini kusukela ku-aerospace kanye nezimoto kuya kwezokwelapha kanye ne-electronics. Ukuzuza izinga elidingekayo lokunemba ekwenzeni imishini kuwumsebenzi onzima futhi onzima odinga ukuqonda okujulile kwezinto, ubuchwepheshe obusezingeni eliphezulu, nekhono eliyingqayizivele. Kulesi sihloko esibanzi, sizongena emhlabeni we ukulungisa okucacile, ukuhlola amasu, amathuluzi, kanye nezindlela ezisetshenziswayo ukuze kwakhiwe izingxenye ezinembayo eziphezulu.

Ukuqonda Precision Machining

I-Precision machining iyisisekelo sokukhiqiza kwesimanje, okubophezelekile ukukhiqiza izingxenye eziyinkimbinkimbi nezinembile ezisetshenziswa ezinhlobonhlobo zezimboni. Ukuze sibambe ukubaluleka kwakho ngokugcwele, ake sihlole imiqondo ewumongo yemishini enembayo, indima yayo ebalulekile emikhakheni ehlukahlukene, kanye nohambo lomlando oluholele esimweni sayo samanje sobuhle.A. Iyini i-Precision Machining?

Precision machining isho iqoqo lezinqubo zokukhiqiza ezisusa okokusebenza kucezu lokusebenza ngezinga eliphezulu lokunemba nokulawula, okuholela ezingxenyeni eziklanywe kahle ezinokubekezelelana okuqinile. Le nqubo iguqula izinto zokusetshenziswa, njengezinsimbi, amapulasitiki, noma izitsha zobumba, zibe izingxenye ezinembile ezihlangabezana nezimfuneko eziqinile. Izici eziyinhloko zomshini wokunemba zihlanganisa:- Ukunemba: Ukwenza imishini enembile kuqinisekisa ukuthi umkhiqizo wokugcina uhambisana ngokunembile nomklamo ohlosiwe, ngokuchezuka okuncane.

- Ukubekezelelana Okuqinile: Ivumela ukukhiqizwa kwezingxenye ezinokubekezelelana okuqinile kakhulu, okusho ukuthi izingxenye eziqediwe zihambisana eduze nezilinganiso ezishiwo.

- I-Superior Surface Qeda: Ukwenza imishini enembile kunikeza ukuqedwa okukhethekile kwendawo, ngokuvamile kuqeda isidingo sezinqubo zokuqedela ezengeziwe.

- Amajiyometri ayinkimbinkimbi: Ingakha ubujamo obuyinkimbinkimbi, amakhonsathi, nezici, iyenze ibaluleke kakhulu ekukhiqizeni izingxenye ezinemiklamo eyinkimbinkimbi.

- Ukuphindaphinda: Ukunemba inqubo machiningama-es aphindaphindeka kakhulu, aqinisekisa ikhwalithi engaguquki ezingxenyeni eziningi.

- yizinhlobonhlobo: Ingasetshenziswa ezinhlobonhlobo zezinto zokwakha, okwenza ifanele izimboni ezihlukahlukene.

B. Ukubaluleka Komshini Wokunemba

Ukunemba kwemishini kunokubaluleka okukhulu ezimbonini ezimbalwa ezibalulekile, okunomthelela ezicini ezihlukahlukene zokuphila kwethu kwansuku zonke. Nazi izizathu ezibalulekile zokubaluleka kwayo:- Umkhakha Wezindiza: Emkhakheni we-aerospace, ukunemba kwemishini ibalulekile ekwenzeni izingxenye ezimelana nezimo ezibucayi. Izinjini zezindiza, ukuhlala igiya, kanye nezakhi zesakhiwo zincike ezingxenyeni ezinomshini onembile ngokuphepha nokusebenza.

- Amadivaysi Ezokwelapha: Imishini yezokwelapha njengamathuluzi okuhlinza, ama-prosthetics, namadivayisi afakelwayo adinga ukunemba komshini wokuhambisana kwezinto eziphilayo, ukunemba, nokuphepha kwesiguli.

- Umkhakha Wezimoto: Izingxenye ezinomshini onembile zibalulekile embonini yezimoto ukuze kuqinisekiswe ukwethembeka nokusebenza kahle kwezimoto. Izingxenye ezifana nezingxenye zenjini, amasistimu okudlulisa, nezindlela zokubhuleka zincike emshinini onembayo.

- Ama-Electronics namaSemiconductors: Ukwenza ukunemba kwemishini kubaluleke kakhulu ekukhiqizweni kwezingxenye ze-microelectronic namadivayisi we-semiconductor, lapho ukubekezelelana okuncane kubalulekile ekusebenzeni.

- Umkhakha Wezamandla: Imboni yamandla ithembele ekwenziweni kwemishini enembile ukuze kukhiqizwe izingxenye ezibalulekile ezisetshenziswa ekuphehlisweni kukagesi, okuhlanganisa izinjini zomoya, amajeneretha, nezingxenye zokudlulisela.

- Ukwenza Ithuluzi Nokufa: Ukwenza ukunemba kubalulekile ekukhiqizeni amathuluzi futhi kuyafa, okuthi, kamuva, kusetshenziselwe ukwakha inqwaba yeminye imikhiqizo.

- Consumer Electronics: Ukukhiqizwa kwama-smartphones, amakhompuyutha aphathekayo, nokunye kuzuzisa izinto zikagesi zabathengi kusukela kumishini enembile ukuze kuqinisekiswe imiklamo eshelelezayo nokusebenza okuphelele.

- Ucwaningo nentuthuko: Abacwaningi nososayensi bancike ezingxenyeni zomshini onembile ukuze kuhlolwe, ama-prototypes, namathuluzi aselabhorethri.

C. Umbono Womlando

Uhambo lomshini wokunemba lubuyela emuva empucukweni yasendulo, lapho izingcweti ezinekhono zazisebenzisa amathuluzi angajwayelekile ukubumba izinto. Nokho, ukunemba okwafinyelelwa ngalezo zikhathi kwakulinganiselwe uma kuqhathaniswa nezindinganiso zangaleso sikhathi.- I-Early Precision Machining: Uguquko lwezimboni lwekhulu le-18 nele-19 luphawule isikhathi esibalulekile ekuthuthukisweni komshini wokunemba. Ukusungulwa kwamathuluzi omshini, njengemishini yokugaya kanye nemishini yokugaya, kuguqule ukukhiqizwa ngokunika amandla ukunemba okukhulu nokuvumelana.

- IMpi Yezwe II: Ukwenza ukunemba kwadlala indima ebalulekile eMpini Yezwe II, njengoba bekubalulekile ekukhiqizeni amathuluzi ezempi ngokunemba okudingekayo nokufana. Lesi sikhathi sabona intuthuko kumasu okwenza imishini kanye nokuvela kwezinto ezintsha.

- Intuthuko Yangemva Kwempi: Isikhathi sangemva kwempi sabona ukwanda kokuqanjwa kabusha kwezobuchwepheshe, okuhlanganisa ukusetshenziswa kwemishini yokulawula izinombolo zekhompyutha (CNC). Ukufakwa kwe-CNC kuvunyelwe ukusebenza okuzenzakalelayo nokunembe kakhulu, okuletha inkathi entsha yokukhiqiza.

- I-Digital Age: Ukuhlanganiswa kwamakhompuyutha kanye nesofthiwe kuzinqubo zomshini kuye kwaphakamisa futhi ukwenziwa kwemishini enembile. Imishini yesimanje ye-CNC ingakwazi ukwenza imisebenzi eyinkimbinkimbi ngokunemba okungenakuqhathaniswa, okuyenza ibaluleke kakhulu endaweni yokukhiqiza yanamuhla.

Impahla Nokubaluleka Kwazo

Izinto zokwakha ziyisisekelo sokunemba kwemishini, futhi ukukhethwa kwezinto ezifanele kudlala indima ebalulekile ekukhiqizweni kwezingxenye ezinemba okuphezulu. Kulesi sigaba, sizocubungula ukubaluleka kokukhetha izinto ezifanele, siqonde ukubaluleka kwezakhiwo zezinto ezibonakalayo, futhi sihlole izici ezahlukahlukene ezithinta ukusebenza kahle.A. Ukukhethwa Kwezinto Ezisetshenziswayo

Ukukhethwa kwezinto zokwakha kumshini wokunemba kuyisinqumo esibalulekile esithinta ngokuqondile ukusebenza, ukuqina, nokusebenza komkhiqizo wokugcina. Abakhiqizi kufanele bacabangele izici ezimbalwa lapho bekhetha izinto zokwakha:- Ukufaneleka Kwezinto ezibonakalayo: Impahla kumele ifanele isicelo esihlosiwe. Izimboni ezahlukene kanye nezicelo zinezidingo ezihlukene, ezifana nokumelana nezinga lokushisa, ukumelana nokugqwala, kanye nokuhamba kukagesi.

- Izakhiwo mechanical: Izici zemishini njengamandla aqinile, ubulukhuni, kanye ne-ductility zibalulekile. Isibonelo, endaweni ye-aerospace, izinto ezinamandla amakhulu okudonsa zikhethwa ezingxenyeni zesakhiwo.

- Izakhiwo ezishisayo: Ezinye izinhlelo zokusebenza zidinga izinto ezinokusebenza okuhle kakhulu kwe-thermal noma ukumelana nokushisa okuphezulu. Lokhu kubaluleke kakhulu ezimbonini ezifana nokukhiqiza amandla kanye ne-electronics.

- Ukuphikiswa Kwe-Corrosion: Ezimweni lapho ukugqwala kuyinto ekhathazayo, izinto zokwakha ezimelana kakhulu nokugqwala, njengensimbi engagqwali noma i-titanium, ziyakhethwa.

- Ukucatshangelwa Kwesisindo: Izimboni ezifana nezezimoto kanye ne-aerospace ngokuvamile zibeka phambili izinto ezingasindi njenge-aluminium noma izinhlanganisela ze-carbon fiber ukuze kuncishiswe ukusetshenziswa kukaphethiloli nokuthuthukisa ukusebenza.

- Izithibelo Zezindleko: Izindleko ziyisici esibalulekile ekukhetheni izinto ezibonakalayo. Izinto ezisebenza kahle kakhulu zingabiza, ngakho-ke abakhiqizi kufanele balinganise phakathi kokusebenza nokusebenza kahle kwezindleko.

- Ukuthobela Ukulawula: Ezimbonini ezifana nokunakekelwa kwezempilo, izinto ezisetshenziswayo kufanele zihlangabezane nezindinganiso eziqinile zokulawula ukuhambisana kwe-biocompatibility nokuphepha.

- Ukutholakala: Ukutholakala kwezinto kanye nemithombo yazo nakho kuthinta ukukhetha. Amanye ama-alloys akhethekile noma izinhlanganisela angase abe nokutholakala okulinganiselwe.

B. Izinto ezibonakalayo

Ukuqonda izici zezinto zokwakha kubalulekile ekwenzeni ukunemba kwemishini. Nazi ezinye zezinto ezibalulekile kanye nokubaluleka kwazo:- Amandla Amandla: Amandla aqinile akala ikhono lempahla lokumelana namandla okudonsa ngaphandle kokuphuka. Kubalulekile ezingxenyeni zesakhiwo kanye nezingxenye ezingaphansi kokucindezeleka kwemishini.

- ubulukhuni: Ukuqina kukhombisa ukumelana kwempahla ekugugekeni nasekuguge. Izinto eziqinile zifanele amathuluzi okusika, kuyilapho izinto ezithambile zingakhethwa kwezinye izinhlelo zokusebenza, njengezimpawu.

- Ductility: I-Ductility isho ikhono lempahla lokonakala ngaphandle kokuphuka lapho lingaphansi kwengcindezi eqinile. Izinto eziwuketshezi zibumbeka kalula kodwa zingase zingalungeli izinhlelo zokusebenza ezidinga ukuqina.

- Ukuqhuba Ukushisa: Izinto ezinokusebenza okuphezulu kwe-thermal zihlakaza kahle ukushisa. Lesi sakhiwo sibalulekile lapho ukulawulwa kwezinga lokushisa kubalulekile.

- Ukusebenza kukagesi: I-conductivity kagesi ibalulekile kuma-elekthronikhi nasezintweni zikagesi, lapho izinto kufanele zenze kube lula ukuhamba kukagesi.

- Izakhiwo Zezibuthe: Izakhiwo zikazibuthe zibalulekile ezimbonini ezifana ne-electromagnetics ne-electronics, lapho izinto ezingase kudingeke zibe yi-ferromagnetic noma okungezona uzibuthe.

- Ukumelana Kwamakhemikhali: Izinto ezisetshenziswayo kumele zimelane nokugqwala kwamakhemikhali ezindaweni lapho zichayeka khona kuma-asidi, izisekelo, noma ezinye izinto ezigqwalisayo.

C. Izici Zokusebenza

I-Machinability ibhekisela ekukhululekeni kokwenziwa komshini, ukusikwa, noma ukulolongwa okuthile. Kuthonywa yizici ezihlukahlukene, okuhlanganisa:- Ukuqina Kwezinto Ezibalulekile: Izinto ezithambile ngokuvamile kulula ukuzisebenzisa, kuyilapho izinto eziqinile zingadinga amathuluzi namasu akhethekile.

- Ukwakhiwa kweChip: Ukwakheka nokukhishwa kwama-chips ngesikhathi somshini kuthinta ukusebenza kahle kwenqubo nokuqedwa kwendawo.

- I-Tool Wear: Izinto ezisetshenziswayo ezihlukene zingabangela amazinga ahlukene okugqoka kwamathuluzi, kube nomthelela wesivinini somshini kanye nezindleko.

- Ukupholisa kanye Nokugcoba: Ukupholisa okufanele nokugcobisa kubalulekile ukuze kuncishiswe ukungqubuzana, ukushisa, nokuguga kwamathuluzi ngesikhathi somshini.

- Isivinini sokusika: Ijubane lapho ithuluzi lokusika lihamba ngayo ezintweni lithinta kokubili ukukhiqiza kanye nekhwalithi yendawo esebenza ngomshini.

- Ithuluzi Material: Ukukhethwa kwezinto zamathuluzi okusika, njenge-carbide noma insimbi enesivinini esikhulu, kuncike kulokho okwenziwa ngomshini.

- Ukusika Amapharamitha: Ukulungisa amapharamitha okusika afana nesilinganiso sokuphakelayo nokujula kokusika kungathuthukisa inqubo yokwenza imishini yezinto ezithile.

Amathuluzi Omshini Wokulungisa Ukunemba

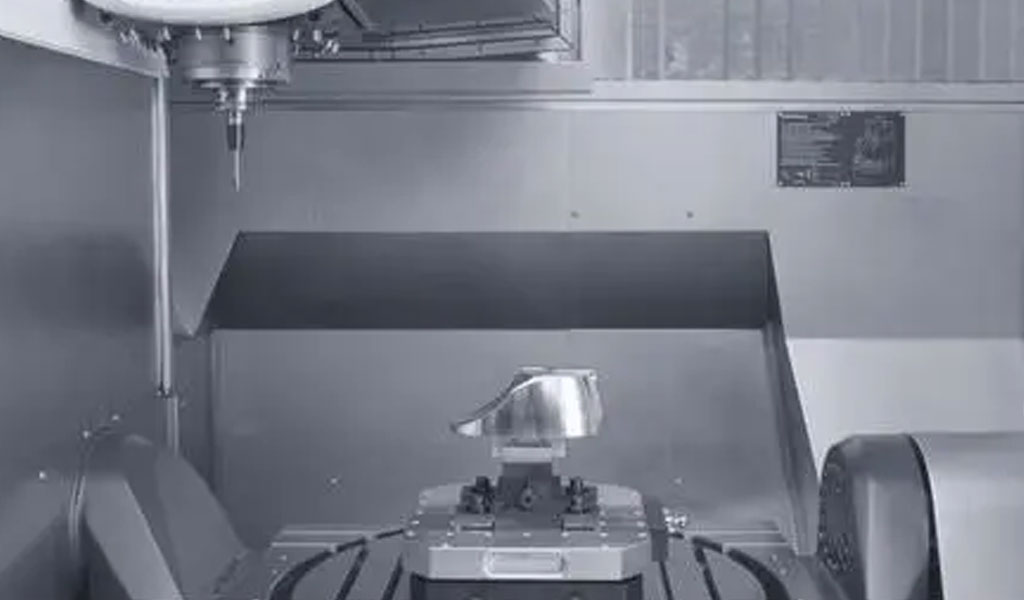

Amathuluzi omshini ayinhliziyo yomshini wokunemba, ovumela ukuguqulwa kwezinto ezingavuthiwe zibe izingxenye ezinemba okuphezulu. Kulesi sigaba, sizohlola izinhlobo ezine ezibalulekile zamathuluzi omshini asetshenziswa emishinini enembayo: Izikhungo Zomshini ze-CNC, Imishini Yokuguqula, Imishini Yokugaya, kanye ne-EDM (I-Electrical Discharge Machining). Ngamunye wale mishini udlala indima eyingqayizivele ekukhiqizeni izingxenye eziqondile.A. CNC Machining Centers

Izikhungo zemishini ye-CNC (Computer Numerical Control) ziguquguquka futhi zisetshenziswa kabanzi ekwenzeni ukunemba. Ziyizinhlelo ezizenzakalelayo ezilawula ukunyakaza kwamathuluzi okusika nezinto zokusebenza ngokunemba okukhethekile. Nakhu okufingqiwe kwezikhungo zemishini ye-CNC nokubaluleka kwazo:- yizinhlobonhlobo: Izikhungo zemishini ye-CNC zingenza imisebenzi ehlukahlukene yokwenza imishini, okuhlanganisa ukugaya, ukubhola, nokuthinta. Lokhu kuguquguquka kuvumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi ezinezici eziningi.

- Ukuqonda Okuphezulu: Ukulawulwa ngekhompuyutha kwemishini ye-CNC kuqinisekisa ukuma kwamathuluzi okunembayo kanye nemiphumela engaguquki, okuyenza ibe ilungele izingxenye ezinokubekezelelana okuqinile.

- Ukuzenzekelayo: Izikhungo zemishini ye-CNC zingasebenza ngokuqhubekayo, ngokungenelela okuncane komuntu. Lokhu okuzenzakalelayo kwandisa ukusebenza kahle futhi kunciphisa ubungozi bamaphutha.

- Amajiyometri ayinkimbinkimbi: Zisebenza kahle kakhulu ekwenzeni izimo eziyinkimbinkimbi namakhonsathi, okuzenza zifanelekele izimboni ezifana ne-aerospace, lapho izingxenye eziyinkimbinkimbi zivamile khona.

- Imiphumela Ephindaphindwayo: Imishini ye-CNC inikeza ukuphindaphinda okuhle kakhulu, iqinisekisa ukuthi ingxenye ngayinye ekhiqizwayo ihambisana nokucaciswa okuqondile komklamo.

- Izikhathi Zokusetha Ezincishisiwe: Izikhungo zemishini ye-CNC zingahlelwa ukuthi zishintshe phakathi kwemisebenzi ehlukene ngokushesha, ukunciphisa izikhathi zokusetha nokwandisa ukusebenza kahle kokukhiqiza.

B. Imishini Yokujika

Imishini yokuguqula isetshenziselwa ukudala izingxenye ze-cylindrical ngokuzungezisa isiqeshana somsebenzi ngenkathi ithuluzi lokusika lisusa izinto endaweni yalo yangaphandle. Zibalulekile ekukhiqizeni umphinis, izikhonkwane, nezinye izingxenye ezinokulinganisa okujikelezayo. Amaphuzu abalulekile mayelana nemishini yokuguqula afaka:- Izingxenye ze-Cylindrical: Imishini yokujika igxile ekukhiqizeni izingxenye ze-cylindrical noma ze-tubular, kuhlanganise nalezo ezinezintambo noma izisele eziyinkimbinkimbi.

- Isivinini Esiphezulu: Asebenza ngesivinini esiphezulu, okwenza afaneleke izingxenye ezidinga isiphetho esibushelelezi nesinembile.

- Ukusebenza kwe-Single-eksisi: Imishini eminingi yokuguqula i-axis eyodwa, igxile ekubumbeni indawo yangaphandle ye-workpiece.

- Isebenza kahle ekukhiqizeni okuningi: Ukuphenduka kuphumelela kakhulu ezingxenyeni ezikhiqiza ngobuningi ezinodoti omncane wezinto ezibonakalayo.

- Imishini yokugeza: Imishini ye-lathe elawulwa yi-Manual kanye ne-CNC ivame ukusetshenziswa imishini yokujika, ehlinzeka ngamakhono ahlukahlukene.

C. Imishini Yokugaya

Imishini yokugaya iklanyelwe ukunemba kokuqedwa kwendawo kanye nokulolongwa kwezinto eziqinile noma ezihuquzelayo. Zibalulekile ekufinyeleleni ukubekezelelana okuqine kakhulu kanye nokuqedwa okuphezulu kwe-surface. Nakhu ukuthi kungani imishini yokugaya ibalulekile:- Ukunemba Kwezinga Le-Micron: Imishini yokugaya ingafinyelela ukunemba kwezinga le-micron, iyenze ibaluleke ezinhlelweni ezidinga izinga eliphezulu lokunemba.

- Ukususwa Kwezinto Ezibalulekile: Asusa okokusebenza ngokuhuzuka, okuvumela ukulungiswa kokungapheleli kwendawo kanye nokuzuza ukushelela okukhethekile.

- Ithuluzi kanye Cutter Ukugaya: Ngaphezu kokugaya okungaphezulu, kunemishini yokugaya ekhethekile yokulola amathuluzi okusika kanye nokukhiqiza amaphrofayili anembile.

- Izinhlobonhlobo Zezindlela Zokugaya: Izinhlobo ezahlukene zemishini yokugaya, kuhlanganise nezigayi ezingaphezulu, izigayi ze-cylindrical, kanye nezigayi ezingenayo indawo, zihlinzekela izidingo ezihlukahlukene zomshini.

- Izinto Eziqinile: Ukugaya kufaneleka ikakhulukazi ezintweni eziqinile njengensimbi yamathuluzi nezitsha zobumba, lapho izindlela zokugaya zendabuko zingase zingasebenzi.

D. EDM (Umshini Wokukhipha Ugesi)

I-EDM, noma i-Electrical Discharge Machining, iwuhlelo lwemishini okungeyona yendabuko esebenzisa ukukhishwa kukagesi ukubumba izinto. Ilungele ukudala izingxenye eziyinkimbinkimbi nezintekenteke lapho amathuluzi okusika endabuko angase adale khona umonakalo. Izici ezibalulekile ze-EDM zifaka:- Akekho Othintana Naye Ngongokoqobo: I-EDM ayibandakanyi ukuthintana okuqondile ngokomzimba phakathi kwethuluzi nomsebenzi, ukunciphisa ingozi yokugqoka kwamathuluzi kanye nokulimala kwezinto ezibuthakathaka.

- Ukuqonda Okuphezulu: Ingafinyelela ukunemba okuphezulu kanye nekhwalithi yokuqeda ngaphezulu, ngisho nangezinto eziqinile ezihlukile.

- I-EDM yocingo kanye ne-Sinker EDM: Kunezinhlobo ezimbili eziyinhloko zemishini ye-EDM: ukusika ucingo I-EDM, esebenzisa i-electrode yocingo, ne-sinker EDM, esebenzisa i-electrode emise okwezimo.

- Izimo Eziyinkimbinkimbi: I-EDM ingakhiqiza izimo eziyinkimbinkimbi, ezifana ne-dies and molds, enemininingwane eyinkimbinkimbi nezici ezinhle.

- Indawo Ethinteke Ukushisa: Njengoba i-EDM ingakhiqizi ukushisa endaweni yokusebenza, ifanele izinto ezizwela ukushisa njengama-alloys e-aerospace.

- Inqubo Enensayo: I-EDM ihamba kancane uma iqhathaniswa nezinye izindlela zokuwenza, okuyenza ifanelekele kakhulu inani eliphansi, imisebenzi enokunemba okuphezulu.

Amathuluzi Ukusika kanye Tooling

Amathuluzi okusika ahamba phambili ekwenzeni imishini enembayo, esebenza njengezisetshenziswa ezilolonga futhi eziguqula izinto zokusetshenziswa zibe izingxenye ezinemba okuphezulu. Kulesi sigaba, sizohlola izinhlobo ezahlukene zamathuluzi okusika, ukubaluleka kwezingubo zamathuluzi, nezici ezithinta impilo yamathuluzi nokuguga.A. Izinhlobo Zamathuluzi Okusika

Ukunemba kwemishini kuncike ezinhlobonhlobo zamathuluzi okusika, ngalinye lakhelwe imisebenzi ethile nezinto zokwakha. Ukukhethwa kwethuluzi lokusika kuthonya kakhulu ukusebenza kahle nokunemba kwenqubo yomshini. Nazi ezinye izinhlobo ezivamile zamathuluzi okusika:- Qeda Izigayo: Izigayo zingamathuluzi ahlukahlukene asetshenziselwa imisebenzi yokugaya. Zinemiphetho eminingi yokusika futhi zingasusa okokusebenza kucezu lokusebenza ngezindlela ezihlukahlukene, okuhlanganisa ukubheka, ukukhonta, nokuslotha.

- Iziqu: Ama-drill aklanyelwe ukudala izimbobo kuma-workpieces. Ziza ngezinhlobo ezahlukene, okuhlanganisa ama-twist drill, ama-cent drill, nama-indexable drill.

- Ukuguqula Ukufaka: Lezi zisetshenziswa emshinini wokujika ukuze ulolonge izingxenye ezingamacylindrical. Ama-turning inserts ayatholakala ngezinhlobonhlobo zomumo nezinto zokwakha ukuze ahambisane nezinhlelo zokusebenza ezahlukene.

- Ama-Milling Cutters: Abasiki be-Milling bafika ngezindlela ezihlukene, njengezigayo zobuso, izigayo zebhola, nabasiki be-slotting, futhi basetshenziswa emishinini yokugaya ukuze benze izici ezihlukahlukene ku-workpiece.

- AmaReamers: Ama-Reamers asetshenziselwa ukuqedela nokulinganisa izimbobo ezibhojwe ngaphambilini ukuze zibe nobukhulu obunembile. Baqinisekisa izindawo zembobo ezibushelelezi nezinembile.

- Ompompi Nokufa: Lawa mathuluzi okusika asetshenziselwa ukuthunga imisebenzi. Ompompi badala uchungechunge lwangaphakathi, kuyilapho ifa idala uchungechunge lwangaphandle.

- Amasondo Okugaya: Amasondo okugaya angamathuluzi abrasive asetshenziselwa ukunemba kokugaya indawo. Atholakala ngezinto ezihlukahlukene zokulunywa kanye nosayizi wegrit.

- Ama-broaches: Ama-broaches angamathuluzi akhethekile asetshenziselwa ukusika izimo namaphrofayili angaphakathi nangaphandle, afana nokhiye kanye nama-splines.

- Ama-Counterbores kanye nama-Countersinks: Lawa mathuluzi asetshenziselwa ukudala ama-recesses noma ama-chamfer azungeze izimbobo fasteners.

- Amabha ayisicefe: Imigoqo eyisicefe isetshenziswa emisebenzini eyisicefe ukuze kwandiswe izimbobo ezikhona ngokunemba.

B. Izingubo Zamathuluzi

Izingubo zamathuluzi ziyizingqimba ezincane zezinto ezisetshenziswa kumathuluzi okusika ukuze kuthuthukiswe ukusebenza kwawo nokuqina. Lezi zembozo zinikeza izinzuzo eziningana:- I-Friction Encishisiwe: Izembatho ezifana ne-titanium nitride (TiN) ne-titanium carbonitride (TiCN) zinciphisa ukungqubuzana phakathi kwethuluzi nomsebenzi, okuholela ekusikeni okushelelayo nokuphila kwamathuluzi okude.

- Ukuqina Okuthuthukisiwe: Izembatho zandisa ubulukhuni bendawo yethuluzi, yenze ukuthi imelane nokuguga nokwelula impilo yamathuluzi.

- Ukumelana Nokushisa Okuthuthukisiwe: Izembatho zingamelana namazinga okushisa aphezulu akhiqizwa ngesikhathi somshini, ukunciphisa ukugqoka kwamathuluzi ahlobene nokushisa nokwandisa isivinini sokusika.

- Anti-Buildup Properties: Ezinye izinto zokumboza zinezakhiwo zokulwa nokunamathela, ezivimbela ukunqwabelana kwezinto emaphethelweni okusika amathuluzi.

- I-Lubricity eyengeziwe: Amathuluzi amboziwe athuthukise ukuthambisa, ehlisa isidingo sokupholisa ngokweqile nokuthuthukisa ukuphuma kwe-chip.

C. Impilo Yethuluzi Nokugqoka

Ukuqonda impilo yamathuluzi nokuguga kubalulekile ukuze kuthuthukiswe izinqubo zokwenza imishini kanye nokunciphisa izindleko zokukhiqiza. Impilo yamathuluzi isho ubude besikhathi ithuluzi lokusika elihlala lisebenza ngaphambi kokuba lidinge ukushintshwa noma ukulungiswa kabusha. Kunezici ezimbalwa ezithonya impilo yamathuluzi nokuguga:- Isivinini sokusika: Isivinini sokusika esiphezulu singaholela ekwenyukeni kokugqoka kwamathuluzi ngenxa yamazinga okushisa aphezulu akhiqizwa ngesikhathi somshini. Ukukhetha kahle isivinini sokusika kubalulekile ukulinganisa impilo yamathuluzi kanye nokukhiqiza.

- Isilinganiso Sokudla: Izinga ithuluzi lokusika elithuthukela ngalo kucezu lokusebenza lithinta ukuguga kwamathuluzi. Amazinga aphezulu okuphakelayo angase asheshise ukuguga, kuyilapho amanani okuphakelayo aphansi anganweba impilo yamathuluzi.

- Ukujula kweSika: Ukujula kokusikwa kuthonya inani lezinto ezisusiwe ngokudlula ngakunye. Ukusikeka okujulile kungakhuphula ukuguga kwamathuluzi, ngakho ukukhulisa ukujula kubalulekile.

- Ukuqina Kwezinto Ezibalulekile: Ukusika izinto eziqinile kungasheshisa ukugqoka kwamathuluzi. Amathuluzi akhethekile kanye nama-coatings asetshenziselwa ukukhanda izinto eziqinile ngokuphumelelayo.

- Ukupholisa kanye Nokugcoba: Ukupholisa okufanele nokugcobisa kusiza ukuqeda ukushisa futhi kunciphise ukungqubuzana, kunwebe ukuphila kwamathuluzi.

- Ithuluzi Material: Izinto ezenziwe ngazo ithuluzi lokusika zithinta ukumelana nokugqoka kwayo. Izinto ezifana ne-carbide ne-ceramic zinikeza ukumelana okuhle kakhulu kokugqoka.

- Ithuluzi Jiyomethri: Ijiyomethri yethuluzi lokusika, okuhlanganisa i-rake angle, i-engeli yokukhulula, nedizayini ye-chipbreaker, idlala indima ebalulekile kumaphethini okugqoka.

- I-Workpiece Material: Uhlobo lwempahla eyenziwa ngomshini luthinta ukuguga kwamathuluzi. Izinto ezilimazayo zingaholela ekugugeni kwamathuluzi ngokushesha.

Precision Machining Izinqubo

Izinqubo zemishini enembile ziyizindlela lapho izinto zokusetshenziswa ziguqulwa zibe izingxenye ezinemba okuphezulu ezinokubekezelelana okuqinile kanye nokuqedwa okukhethekile kwendawo. Kulesi sigaba, sizohlola izinqubo ezinhlanu ezisemqoka zokunemba kwemishini: Ukujika, Ukugaya, Ukubhoboza, Ukugaya, kanye Nemishini Yokukhipha Ugesi (EDM). Ngayinye yalezi zinqubo inenhloso ehlukile futhi isetshenziswa ngokusekelwe ezidingweni ezithile zocezu lokusebenza.A. Ukuphenduka

Ukuphenduka kuyinqubo yomshini esetshenziselwa ngokuyinhloko ukubumba izingxenye ze-cylindrical. Kubandakanya ukuzungezisa ucezu lokusebenza ngenkathi ithuluzi lokusika elinephuzu elilodwa lisusa izinto endaweni yangaphandle. Nazi izici ezibalulekile zokuguqula:- Izingxenye ze-Cylindrical: Ukuphenduka kulungele ukukhiqiza izingxenye ze-cylindrical ezifana namashafti, izikhonkwane, nemikhono.

- I-Rotational Symmetry: Ifaneleka kahle ezingxenyeni ezidinga ukulinganisa okujikelezayo, njengoba ucezu lokusebenza luzungeza i-lathe ngenkathi ithuluzi lokusika liyilolonga.

- Imisebenzi Ehlukahlukene: Ukuphenduka kungenza imisebenzi ehlukahlukene, okuhlanganisa ukubheka, ukuphenduka (ukunciphisa ububanzi), ukuguqula i-taper, nokuhlanganisa.

- Ukusika Iphuzu Elilodwa: Ithuluzi elilodwa lokusika lisusa izinto ngokunyakaza okuqhubekayo, okuholela ekukhishweni kwezinto ezisebenzayo.

- Imishini yokugeza: Yomibili imishini ye-lathe elawulwa yi-CNC ijwayele ukusetshenziselwa ukuguqula imisebenzi.

B. Milling

I-Milling iyinqubo yokwenza imishini enembayo enembayo esebenzisa amathuluzi okusika amaphuzu amaningi ukuze isuse into ethile kucezu lokusebenza. Ifaneleka kahle ekudaleni izinhlobonhlobo zezimo nezici. Izici ezibalulekile zokugaya zihlanganisa:- yizinhlobonhlobo: Ukugaya kungakhiqiza izindawo eziyisicaba, izikhala, amapokhethi, namakhonsathi ayinkimbinkimbi. Isetshenziselwa kokubili 2D kanye 3D machining.

- I-Multi-Point Cutting: Imiphetho eminingi yokusika ethuluzini isebenzisana ne-workpiece ngesikhathi esisodwa, okuvumela ukususwa kwezinto ezisebenzayo.

- Izinhlobo Zokugaya: Ukugaywa kungenziwa kusetshenziswa izinhlobo ezahlukene zabasiki, okuhlanganisa izigayo zokugcina, izigayo zobuso, nezigayo zebhola.

- CNC Machining Centers: Imishini yokugaya elawulwa yi-CNC inikeza ukulawula okunembile kokunyakaza kwamathuluzi futhi isetshenziswa kabanzi ekwenzeni imishini yesimanje.

- Isivinini Esiphezulu: Ukugaya kungenziwa ngesivinini esikhulu, okuvumela ukukhiqiza okuphumelelayo.

C. Ukubhoboza

Ukubhoboza kuyinqubo yomshini enembayo esetshenziselwa ukudala izimbobo kuma-workpieces. Kuwumsebenzi oyisisekelo ezimbonini ezahlukahlukene. Izici ezibalulekile zokumba zihlanganisa:- Ukudalwa Kwemigodi: Imishini yokumba isebenzisa amathuluzi akhethekile abizwa ngokuthi ama-drill ukuze asuse izinto futhi adale izimbobo zamadayamitha athile.

- Izinhlobo Zokubhoboza: Izinhlobo ezihlukene zokuzibhoboza ziyatholakala, okuhlanganisa ama-twist drill, ama-center drill, nama-drill anenkomba, ngayinye yakhelwe izinhlelo zokusebenza ezithile.

- Ukunemba: Ukuma okunembe nokuqondanisa kubalulekile ekubholeni ukuze kuqinisekiswe ukuthi izimbobo zidalwe ngokunemba.

- Isivinini kanye Nesilinganiso Sokuphakelayo: Amapharamitha okubhoboza afana nesivinini sokujikeleza kanye nezinga lokuphakelayo kubalulekile ukuze kuzuzwe ubukhulu bembobo obufunekayo.

- Ukupholisa kanye Nokugcoba: Isipholile esifanele kanye nokugcobisa kusetshenziswa ukuqeda ukushisa nokunciphisa ukungqubuzana ngesikhathi sokumba.

D. Ukugaya

Ukugaya kuyinqubo yokwenza imishini enembayo esebenzisa amasondo abrasive ukususa impahla futhi kuzuze ukubekezelelana okuqinile nokuqedwa kwendawo. Izici eziyinhloko zokugaya zihlanganisa:- Ukunemba Okukhethekile: Ukugaya kungafinyelela ukunemba kwezinga le-micron, kuyenze ilungele izinhlelo zokusebenza ezidinga ukunemba okuphezulu.

- surface Qeda: Ikhiqiza ukuqedwa okuphezulu okuphezulu, ngokuvamile kuqeda isidingo sezinqubo zokuqeda ezengeziwe.

- Materials: Ukugaya kulungele izinto eziqinile neziqhumayo, okuhlanganisa insimbi eqinile, izitsha zobumba, nama-carbides.

- Izinhlobonhlobo Zezindlela Zokugaya: Izinhlobo ezahlukene zemishini yokugaya, njengezigayi ezingaphezulu, izigayi ze-cylindrical, nama-grinders angenasikhungo, zihlinzekela izidingo ezihlukahlukene zomshini.

- Okupholisayo: Isipholile esifanele sibalulekile ekugayeni ukuvimbela ukushisa ngokweqile nokugcina ubuqotho besondo.

I-E. Electrical Discharge Machining (EDM)

I-EDM, noma i-Electrical Discharge Machining, iyinqubo yokunemba okungeyona yendabuko esebenzisa ukukhishwa kukagesi ukuze kukhishwe izinto. Ifaneleka ngokukhethekile ukukhanda izimo eziyinkimbinkimbi neziyinkimbinkimbi, kanye nezinto eziqinile nezimelana nokushisa. Izici ezibalulekile ze-EDM zifaka:- Umshini Ongathintana Naye: I-EDM ayibandakanyi ukuthintana okuqondile phakathi kwethuluzi nomsebenzi, ukunciphisa ingozi yokugqoka ithuluzi nokulimala.

- Ukuqonda Okuphezulu: I-EDM ingafinyelela ukunemba okuphezulu, iyenze ifaneleke izinhlelo zokusebenza lapho ukubekezelelana okuqinile kubalulekile.

- Izimo Eziyinkimbinkimbi: Ihamba phambili ekukhiqizeni izimo eziyinkimbinkimbi, iyafa, isikhunta, nezingxenye ezinemininingwane emihle.

- I-EDM yocingo kanye ne-Sinker EDM: Kunezinhlobo ezimbili eziyinhloko zemishini ye-EDM: i-EDM yocingo, esebenzisa i-electrode yocingo, ne-sinker EDM, esebenzisa i-electrode emise okwezimo.

- Inqubo Enensayo: I-EDM ihamba kancane uma iqhathaniswa nezinye izindlela zokuwenza, okuyenza ifanelekele kakhulu inani eliphansi, imisebenzi enokunemba okuphezulu.

Ukubekezelela kanye Nokulawulwa Kwekhwalithi

Ukucofa imishini kudinga ukunakwa okucophelelayo emininingwaneni kanye nokuzinikela ngokuqinile ekulawuleni ikhwalithi ukuze kuqinisekiswe ukuthi izingxenye zihlangabezana namazinga ashiwo. Kulesi sigaba, sizohlola izici ezintathu ezibalulekile zokulawula ikhwalithi ekwenzeni imishini enembayo: I-Geometric Dimensioning and Tolerance (GD&T), Ukulawulwa Kwenqubo Yezibalo (SPC), kanye Nokuqinisekiswa Kwekhwalithi.A. I-Geometric Dimensioning and Tolerancing (GD&T)

I-Geometric Dimensioning and Tolerancing, evame ukufushaniswa njenge-GD&T, iwuhlelo olusetshenziselwa ukuchaza nokuxhumana ngokuhlukahluka okuvumelekile ngosayizi, isimo, umumo, kanye nendawo yezici engxenyeni ethile. I-GD&T ibalulekile ekwenzeni ukunemba ngezizathu ezilandelayo:- Ukuxhumana Okuqondile: I-GD&T ihlinzeka ngolimi olusezingeni lonjiniyela, abaklami, nochwepheshe bemishini ukuze baxhumane nenhloso yedizayini kanye nezidingo zobukhulu ngokunembile.

- Ukubekezelela Ukucaciswa: Isiza ukuchaza ukuhluka okwamukelekayo kubukhulu obubucayi, iqinisekisa ukuthi bonke ababambiqhaza bayakuqonda ukuchezuka okuvumelekile.

- Ikhwalithi Ethuthukisiwe: I-GD&T iphromotha ikhwalithi ethuthukisiwe ngokunciphisa ukungaqondakali kokucaciswa kwedizayini, ukunciphisa ubungozi bamaphutha ngesikhathi somshini.

- Ukusebenza Kwezindleko: Ukucaciswa okucacile kwe-GD&T kungaholela ezindlekweni zokukhiqiza ezincishisiwe, njengoba izingxenye mancane amathuba okuthi zilahlwe noma zidinga ukusetshenzwa kabusha ngenxa yokungaqondi kahle noma ukuhunyushwa kabi.

- IJomethri Eyinkimbinkimbi: Iwusizo ikakhulukazi ezingxenyeni ezinejometri eyinkimbinkimbi, iqinisekisa ukuthi zonke izici zenziwa ngendlela ebekiwe efiselekayo.

B. Ukulawulwa Kwenqubo Yezibalo (SPC)

Ukulawulwa Kwenqubo Yezibalo (SPC) kuyindlela yokulawula ikhwalithi esebenzisa amasu ezibalo ukuqapha nokulawula inqubo yokwenza imishini. I-SPC ibalulekile ekwenzeni ukunemba ngezizathu ezilandelayo:- Ukuqapha Inqubo: I-SPC isiza ukuqapha izinqubo zokwenza imishini ngesikhathi sangempela, ikhomba ukuhluka noma ukuchezuka kumapharamitha afunekayo.

- Ukutholwa Kwangaphambi Kwezinkinga: Ngokuqhubeka nokuqapha inqubo, i-SPC ivumela ukutholwa kusenesikhathi kwezinkinga ezingaholela ezingxenyeni ezingaphandle kwe-spec, ukunciphisa imfucuza nokusebenza kabusha.

- Ukwenziwa Kwezinqumo Okuqhutshwa Yidatha: I-SPC ithembele kudatha nokuhlaziywa kwezibalo ukuze yenze izinqumo ezinolwazi mayelana nokulungiswa kwenqubo, iqinisekisa ukuthi inqubo yokwenza imishini ihlala ngaphakathi kwemikhawulo eyamukelekayo.

- Ukuvumelana Okuthuthukisiwe: I-SPC ikhuthaza ukuhambisana kwenqubo futhi yehlisa amathuba okukhiqiza izingxenye ezingavumelani.

- I-Scrap Encishisiwe Nokusebenza Kabusha: Ngokuhlonza kanye nokubhekana nokuhlukahluka kwenqubo ngokushesha, i-SPC inciphisa ukukhiqizwa kwezingxenye ezingasebenzi kahle, inciphisa izindleko ezilahliwe nezokusebenza kabusha.

C. Ukuqinisekiswa Kwekhwalithi Kumachining Precision

Ukuqinisekisa ikhwalithi ekwenzeni imishini enembile kuhlanganisa indlela ebanzi yokuqinisekisa ukuthi izingxenye ezikhiqiziwe ziyahlangabezana noma zeqe izindinganiso zekhwalithi ezishiwo. Kubandakanya izici ezahlukahlukene, kufaka phakathi:- Inqubo Amadokhumenti: Imibhalo enemininingwane yezinqubo zemishini, okuhlanganisa izinqubo ezijwayelekile zokusebenza (ama-SOP) nemiyalelo yomsebenzi, iqinisekisa ukuthi isinyathelo ngasinye senziwa ngokungaguquki.

- Ukuhlola kanye Nesilinganiso: Ukuhlola okuqinile nokulinganisa kusetshenziswa amathuluzi anembayo namasu e-metrology kuqinisekisa ukuthi izingxenye zihambisana nokubekezelelana okucacisiwe namazinga ekhwalithi.

- Ukulinganisa: Ukulinganiswa okuvamile kwemishini yokwenza imishini namathuluzi okulinganisa kubalulekile ukuze kugcinwe ukunemba nokulandeleka.

- Ukuqinisekisa Okubalulekile: Ukuqinisekiswa kwezinto ezibonakalayo, ukwakheka, kanye nekhwalithi kubalulekile ukuze kuqinisekiswe ukuthi okokusebenza okusetshenzisiwe kuhlangabezana nezidingo zedizayini.

- Ukuqeqeshwa Kwabasebenzi: Izinhlelo zokuqeqesha nokuthuthukisa amakhono ochwepheshe bemishini kanye nezisebenzi zokulawula ikhwalithi ziqinisekisa ukuthi banolwazi endimeni yabo nasezimbotsheni zabo.

- Ukuhlaziywa Kwembangela Yomsuka: Uma izingxenye ezingavumelani zikhonjwa, kuhlaziywa umsuka wembangela ukuze kutholwe umthombo wenkinga futhi kusetshenziswe izinyathelo zokulungisa.

- Ngcono okuqhubekayo: Isiko lokuthuthuka okuqhubekayo likhuthaza ukuqamba okusha futhi liqhuba izithuthukisi eziqhubekayo ezinqubweni zomshini kanye nezinqubo zokulawula ikhwalithi.

- Impendulo Customer: Ukuqoqa nokuhlaziya impendulo yekhasimende kusiza ukuhlonza izindawo okufanele zithuthukiswe futhi kuqondise izinqubo zomshini nokulindelwe yikhasimende.

Isiphetho

A. Ubuciko Nesayensi Yemishini Enembile

Ukunemba kwemishini kuma empambanweni yobuciko nesayensi, lapho ubuciko, ikhono, nokusungula kuhlangana khona ukuze kukhiqizwe izingxenye ezinembayo eziphezulu ezishayela izimboni futhi zilolonge umhlaba wesimanjemanje. Kokubili kuyindlela yobuciko, edinga ubuciko nobungcweti bochwepheshe bemishini abaguqula izinto zokusetshenziswa zibe imisebenzi yobunjiniyela obusezingeni eliphezulu, kanye nesayensi ethembele kubuchwepheshe obuphambili, isayensi yezinto zokwakha, nezinqubo ezithuthukile ukuze bathole ukunemba okungenakuqhathaniswa. Uhambo lwemishini enembile lusiyisa ekuqondeni izinto zokwakha kanye nezakhiwo zazo, ukuba nekhono kwamathuluzi okusika nemishini, nokulawulwa ngokucophelela kwezinqubo nokubekezelela. Ihlanganisa ulimi lokulinganisa nokubekezelela kwejiyomethri, ukuqapha kokulawulwa kwenqubo yezibalo, nokuzibophezela ekuqinisekiseni ikhwalithi. Ukwenza ukunemba kwemishini kudlala indima ebaluleke kakhulu ezimbonini ezahlukahlukene, kusukela ku-aerospace nezimoto kuya kumishini yezokwelapha nezinto zikagesi, kubumba yonke into kusukela ezinjinini zezindiza kuya kumajoyinti okwenziwa nama-microchip. Ivumela ukudalwa kwezingxenye ezisebenza ngokunemba okungenakuqhathaniswa nokwethembeka, ngokuvamile icindezela imingcele yalokho okungenzeka.B. Imicabango Yokugcina

Njengoba siphetha lokhu kuhlola ukunemba kwemishini, kuyacaca ukuthi lo mkhakha awukona nje kuphela ngokudalwa kwezingxenye; imayelana nokudalwa kwamathuba. Ukufuna ukunemba kushayela ukuqamba okusha, ukweqa imingcele yalokho okungazuzwa. Kungakhathaliseki ukuthi ubuciko obuthambile obudingekayo ukuze kwakhiwe amagiya ewashi ayinkimbinkimbi noma ubuchwepheshe obuthuthukisiwe obudingekayo ukuze kwenziwe izingxenye ze-aerospace eziyinkimbinkimbi, ukunemba komshini kuyingqikithi yakho konke. Ikusasa lemishini enembile ligcwele isithembiso. Ukuthuthuka kwesayensi yezinto zokwakha, i-automation, kanye nobuchwepheshe bedijithali kuyaqhubeka nokubumba kabusha isimo sezwe. I-Miniaturization, ukuphrinta kwe-3D, kanye nezinqubo zokukhiqiza ezizinzile ziya ngokuya zigqama, zingenisa ama-horizons amasha embonini. Ezweni lapho ukunemba kubaluleke kakhulu kunangaphambili, ukunemba kwemishini kuhlala kuyinsika ebalulekile yobunjiniyela besimanje. Kuwubufakazi bobuhlakani bomuntu kanye nokuphishekela kwethu ngokungagodli ukwenza kahle kuzo zonke izici zokukhiqiza. Njengoba isidingo sokunemba okuphezulu kanye nezingxenye eziyinkimbinkimbi kakhulu sikhula, ukunemba kwemishini kuzoqhubeka nokuvela, kuhlangabezana nezinselele zakusasa ngokuzinikezela okufanayo nokunemba osekukuchaze amakhulu eminyaka.

Imisebenzi Yethu

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

Case Studies

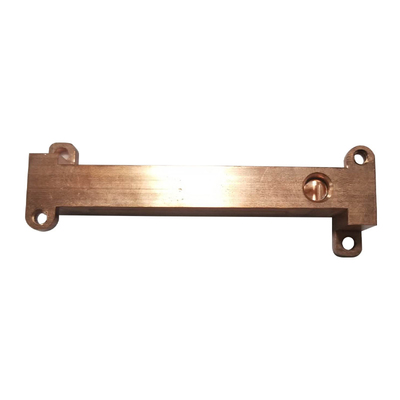

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

Uhlu lwezinto

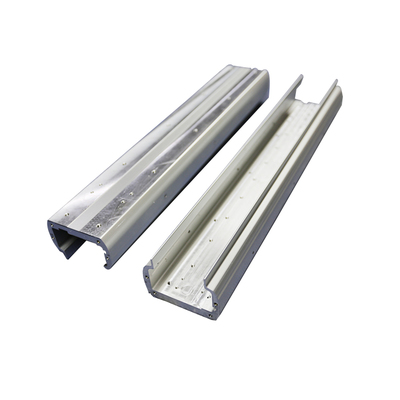

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi

Izingxenye zegalari