Indlela Yokunciphisa Ingxoxo Ku-CNC Milling - Amathiphu Okunciphisa Ukudlidliza Kwemishini

2023-10-30

I-CNC Milling inamandla futhi iguquguquka inqubo machining okuvumela ukukhiqizwa kwengxenye enembile neyinkimbinkimbi. Kodwa-ke, udaba olulodwa olujwayelekile ochwepheshe bemishini abahlangabezana nalo ngesikhathi sokugaya i-CNC yingxoxo. Ingxoxo, kumongo wokwenza imishini, ukudlidliza okungafuneki noma i-oscillation eyenzeka ngesikhathi sokusika. Kungaholela ekuqedweni okungalungile kwendawo, ukunciphisa impilo yamathuluzi, ngisho nokulimala emshinini. Kulo mhlahlandlela ophelele, sizohlola izimbangela zengxoxo ku-CNC Milling futhi sinikeze anhlobonhlobo amathiphu namasu okunciphisa noma ukuqeda ngempumelelo.

Ukuqonda Chatter in CNC Milling

Iyini i-Chatter ku-CNC Milling?

I-Chatter, kumongo wokugaya i-CNC, iyisimo esiphazamisayo nesilimazayo esenzeka phakathi nenqubo yokwenza imishini. Kuvela njengokudlidliza okungafuneki noma ukunyakazisa ethuluzini lomshini, ucezu lokusebenza, noma ithuluzi lokusika. Lo mkhuba uvamise ukubonakala ngomsindo ohlukile, ongajabulisi futhi ungaba nemithelela engathi sína ekusebenzeni komshini. Ukuze siqonde ingxoxo ngokugcwele, ake sihlukanise izingxenye zayo ezibalulekile namandla.Izingxenye Ezibalulekile Zengxoxo:

- Ithuluzi lomshini: Ithuluzi lomshini we-CNC, okuhlanganisa izingxenye zalo zesakhiwo, i-spindle, kanye ezivezas, kungaba umthombo wengxoxo uma bengenakho ukuqina noma zinganakekelwa kahle.

- I-workpiece: Impahla eyenziwa ngomshini kanye nezakhiwo zayo, njengokuqina nokulungisa, kungaba nomthelela engxoxweni.

- Ithuluzi: Ukukhethwa kwamathuluzi okusika, ijiyomethri yawo, isimo, nezinto ezibonakalayo, kungadlala indima ebalulekile ekwenzekeni kwengxoxo.

- Ukusika Amapharamitha: Ukukhethwa kwemingcele yokusika, okuhlanganisa izinga lokuphakelayo, isivinini sokusika, nokujula kokusika, kungathinta ukuzinza kwenqubo yomshini.

I-Dynamics of Chatter:

Ukuxoxa kwenzeka lapho kunokungalingani phakathi kwamandla asebenza ethuluzini lokusika kanye nokumelana okunikezwa yi-workpiece material. Lokhu kungalingani kuholela ekudlidlizeni, okungaholela emiphumeleni eminingi engemihle, okuhlanganisa:- I-Surface Emibi: Ukudlidliza okubangelwa ingxoxo kungashiya ngemuva kokuqedwa okungajwayelekile nokumaholoholo engxenyeni eyenziwe ngomshini, kwehlise ikhwalithi nokunemba kwayo.

- Impilo Yethuluzi Encishisiwe: I-oscillation engaguquki, esheshayo ethuluzini ingaholela ekugugekeni kwamathuluzi ngokweqile futhi kufinyeze kakhulu ukuphila kwayo.

- Ukulimala Komshini: Ukuchayeka isikhathi eside engxoxweni kungafaka engozini ubuqotho bomshini we-CNC ngokwawo. Ngokuhamba kwesikhathi, ukucindezeleka kwemishini okunqwabelene kungaholela ekulungiseni okubizayo kanye nesikhathi sokuphumula.

- Ukulahleka Komkhiqizo: Ingxoxo ngokuvamile idinga ukuncishiswa kwesivinini sokusika noma okuphakelayo ukuze kuncishiswe inkinga, okungase kubangele izikhathi ezinde zomshini kanye nokunciphisa ukukhiqiza kukonke.

Kungani Ingxoxo Ibalulekile

Ukuqonda ukuthi kungani izindaba zengxoxo zibalulekile kunoma yikuphi ukugaya kwe-CNC. Nakuba kungase kubonakale njengokucasulayo noma ukuphazamiseka, umthelela wako udlulela ngalé kwalokho. Nakhu ukuthi kungani ukuxoxa kuyindaba ekhathaza kakhulu:- Ikhwalithi Yengxenye Eqediwe: Ukuxoxa kungonakalisa kakhulu ikhwalithi nokunemba kwengxenye eyenziwe ngomshini. Uma umgomo wakho uwukukhiqiza izingxenye ezinemba okuphezulu, ukuxoxa kungaba yisithiyo esikhulu.

- Impilo Yethuluzi: Ukudlidliza okubangelwa ingxoxo kungaholela ekugugeni kwamathuluzi ngokushesha kanye nokuphuka. Lokhu kusho ukwenyuka kwezindleko zokushintshwa kwamathuluzi kanye nokuphazamiseka okuvamisile kunqubo yokwenza imishini.

- Ubuqotho bomshini: Ukuchayeka isikhathi eside engxoxweni kungabangela umonakalo emshinini we-CNC ngokwawo. Lokhu kuhlanganisa ukuguga kwezingxenye zomshini, ukulimala kokuphotha, nezinye izinkinga zesakhiwo.

- Ukukhiqiza: Ingxoxo iphoqa ochwepheshe bemishini ukuthi behlise isivinini sokusika nokuphakelayo ukuze bagweme ezinye izinkinga. Lesi sivinini esinensayo kunciphisa ukukhiqiza okuphelele futhi kungaholela ekubambezelekeni kokuphothula imisebenzi yomshini.

- Ukuphepha Ukukhathazeka: Ukuxoxa kungadala ngisho nezingozi zokuphepha endaweni yokusebenzela. Ukudlidliza nokungazinzi okukudalayo kungaholela ezingozini, ekukhishweni kwamathuluzi, noma ekulimaleni kwengcezu yokusebenza.

Iyini i-Machining Vibration?

Ukudlidliza komshini, okuvame ukubizwa ngokuthi "ukudlidliza" kumongo wezinqubo zomshini, ukunyakaza okungafuneki futhi okuguquguqukayo noma ukuzulazula okwenzeka ngesikhathi sokusikwa noma ukwenziwa kwemishini. Lesi senzakalo sibonakala njengokunyakaza okuya emuva naphambili okusheshayo, ngokuvamile ngendlela yokudlidliza, ukunyakazisa, noma ukunyakazisa, ethuluzini lomshini, ucezu lomsebenzi, ithuluzi lokusika, noma inhlanganisela yalezi zingxenye. Ukudlidliza komshini kuyinkinga evamile ezinqubweni ezihlukahlukene zokusebenzisa imishini, okuhlanganisa ukuphenduka, ukugaya, ukubhola, nokugaya. Izici ezibalulekile zokudlidliza komshini zifaka:- Ukunyakaza okungafunwa: Ukudlidliza kumelela ukunyakaza okungafuneki kusistimu yokwenza imishini. Kungaholela ekungazinzini, okuthinta ukunemba kanye nekhwalithi yezingxenye zomshini.

- I-Oscillation ephindaphindayo: Ukudlidliza ngokuvamile kwenzeka ngefrikhwensi ethile noma amaza, okuholela ekunyakazeni okuphindaphindayo emuva naphambili. Lawa ma-oscillations angabonakala ekuhambeni kwe-workpiece, ithuluzi lokusika, noma umshini wonke.

- Umsindo: Ukudlidliza kuvame ukukhiqiza umsindo wesici, ongaba umphumela wezingxenye ezihambayo noma ezidlidlizayo ngokumelene nezinye. Lo msindo ungasebenza njengenkomba ezwakalayo yokudlidliza.

- I-Surface Finish Encishisiwe: Ukudlidliza kungaholela ekuqedeni okungalingani noma okungajwayelekile ezingxenyeni zomshini, okuthinta ikhwalithi nokunemba kwazo.

- Impilo Yethuluzi Elifushanisiwe: Ukunyakaza okushesha nokungajwayelekile okuhambisana nokudlidliza kungaholela ekugugekeni okudlulele kanye nokulimala kwamathuluzi, okuholela esidingweni sokushintsha njalo kwamathuluzi.

- Ukugqoka Nokulimala Komshini: Ukuchayeka isikhathi eside ekudlidlizeni kungasheshisa ukuguga nokulimala ezingxenyeni zomshini, okuhlanganisa ama-spindle, ama-bearing, nama-elementi esakhiwo.

- Ukunemba nokuhlukahluka kobukhulu: Ukudlidliza kungabangela ucezu lokusebenza noma ukuchezuka kwethuluzi, okuholela ekungalungisweni nokuhluka kobukhulu kumkhiqizo wokugcina.

Izimbangela Zengxoxo

Ingxoxo ekugayweni kwe-CNC yinto eyinkimbinkimbi ethonywa inhlanganisela yezinto. Ukuqonda lezi zimbangela kubalulekile ekuxazululeni ngempumelelo nasekunciphiseni izingxoxo. Lezi zici zingahlukaniswa kabanzi ngezindawo ezine ezibalulekile:1. Izinto Zethuluzi Lomshini

Izici nesimo somshini we-CNC ngokwawo zinegalelo elikhulu engxoxweni. Izinto ezimbalwa ezihlobene nomshini zingathonya ukwenzeka kwengxoxo:a. Ukuqina:

Ukuqina isho ikhono lomshini lokumelana nokuguquguquka noma ukuguquguquka phakathi nenqubo yomshini. Umshini oqinile awujwayele ukuxoxa. Izingxenye zomshini, njengombhede womshini, amakholomu, nokuphotha, kufanele zakhelwe futhi zakhiwe ngokuqina okuphezulu engqondweni. Ukuqina komshini kuqinisekisa izimo zokusika ezizinzile, kunciphisa amathuba okuxoxa.b. Isivinini se-Spindle:

The isivinini sokuphotha kuyisici esibalulekile ekulawuleni ingxoxo. Ijubane lokuphotha kufanele lihambisane ngokufanele nezinto zokusebenza kanye nethuluzi lokusika elisetshenziswayo. Ukusebenza ngesivinini esilungile sokuphotha kusiza ukuvimbela ingxoxo ngokugcina inqubo yokusika ezinzile futhi elinganiselayo.c. Ukunciphisa:

Eminye imishini ye-CNC iza ifakwe ezakhelwe ngaphakathi amasistimu wokudambisa yakhelwe ukumunca ukudlidliza ngesikhathi somshini. Lezi zinhlelo zokudambisa zisiza ukunciphisa ukuxoxa, ikakhulukazi ngesikhathi sokusebenza komshini onesivinini esikhulu. Ukutshala imali emshinini onezici ezithuthukisiwe zokudambisa kungaba yisixazululo esisebenzayo sokunciphisa ingxoxo.d. Ukunemba Nokunemba:

Imishini enamazinga aphezulu we ngokunemba futhi Ukunemba mancane amathuba okuba uzwe ukuxoxa. Ukunemba komshini kuqinisekisa ukuthi ugcina izimo zokusika ezingaguquki, ukunciphisa ingozi yokudlidliza nokungazinzi ngesikhathi somshini.2. Izinto Zokusebenza

I-workpiece, okuhlanganisa izakhiwo zayo ezibonakalayo, usayizi, kanye ne-fixturing, ingathinta kakhulu ingxoxo. Izici ezihlobene nomsebenzi zihlanganisa:a. Izinto ezibonakalayo:

The izakhiwo ezibonakalayo we-workpiece material yizinto ezicatshangelwayo ezibalulekile. Ukuqina, ukuminyana, kanye nokusebenza okushisayo kwezinto kuthonya amandla ayo okumunca nokukhipha ukushisa okukhiqizwa ngesikhathi somshini. Lezi zakhiwo zingathuthukisa izimo zokusika ezizinzile noma ziholele engxoxweni.b. Ukulungiswa kwe-Workpiece:

Ukulungisa isho indlela ucezu lokusebenza oluboshwe ngayo ngokuvikelekile noma olugcinwe endaweni ngesikhathi somshini. Ukulungiswa okufanele kubalulekile ukuze uvimbele ukuxoxa, njengoba noma yikuphi ukunyakaza noma ukudlidliza endaweni yokusebenza kungaphazamisa inqubo yokusika. Ukubopha ngokuphephile ucezu lokusebenza kuqinisekisa ukuzinza futhi kunciphisa ubungozi bokuxoxa.c. I-Overhang:

The ngaphezulu yibanga phakathi kwendawo yokusebenza nesibambi samathuluzi. Ama-overhang amade angakhulisa ingxoxo ngenxa yokuphambuka okwandisiwe kwamathuluzi. Ukunciphisa i-overhang noma ukusebenzisa amathuluzi amafushane kungasiza ukunciphisa lo mphumela.3. Izinto Zokusebenza

Ukukhethwa kwamathuluzi okusika, isimo sawo, ijometri, nezinto ezibonakalayo, kungaba nomthelela omkhulu engxoxweni. Izinto eziphathelene namathuluzi okufanele zicatshangelwe zifaka:a. Ithuluzi:

Ukukhetha ifayili le- impahla yethuluzi okusekelwe ku-workpiece impahla kubalulekile. Izinto ezihlukene zinikeza amazinga ahlukene okumelana nokugqoka nokumelana nokushisa. Ukukhetha okubalulekile kwethuluzi kunganciphisa ukuguga kwamathuluzi kanye nethuba lokuxoxa.b. Ithuluzi leJiyomethri:

The ithuluzi lejometri, okuhlanganisa nenani lemitshingo, i-rake angle, ne-helix angle, kungathonya amandla okusika futhi, ngenxa yalokho, ukuxoxa. Amajiyometri wamathuluzi anikezela ngokulawula kwe-chip okungcono futhi anciphise amandla okusika anconyelwa ezintweni ezivame ukuxoxa.c. Isimo Sethuluzi:

The isimo samathuluzi okusika idlala indima ebalulekile ekwenzekeni kwengxoxo. Amathuluzi agugile noma alimele maningi amathuba okuba abangele ingxoxo. Ukuhlolwa nokugcinwa kwamathuluzi okuvamile kubalulekile ukuze kuqinisekiswe ukuthi amathuluzi asesimweni esifanele.4. Ukusika Amapharamitha

Ukukhethwa kwamapharamitha wokusika, njengezinga lokuphakelayo, isivinini sokusika, nokujula kokusika, kuthinta ngokuqondile ukwenzeka kwengxoxo. Ukusika izici ezihlobene nepharamitha zifaka:a. Izinga lokuphakelayo:

An isilinganiso sokuphakelayo esingalungile lokho kuphezulu kakhulu kungabangela amandla okusika ngokweqile futhi, kamuva, ukuxoxa. Ukulinganisa izinga lokuphakelayo namanye amapharamitha wokusika kubalulekile ukuze uvimbele ukuxoxa.b. Isivinini sokusika:

The isivinini sokusika kufanele kukhethwe ngendlela efanele ngokusekelwe ezintweni ezisetshenziswayo namathuluzi asetshenziswayo. Isivinini esingafanele sokusika, kungakhathaliseki ukuthi siphezulu kakhulu noma siphansi kakhulu, singabangela ingxoxo. Isivinini esilungile sokusika sincike ezintweni ezifana nohlobo lwezinto ezibonakalayo, impahla yamathuluzi, nejiyomethri yamathuluzi.c. Ukujula Kokusika:

The ukusika ukusika kuthinta umthwalo we-chip namandla asebenza ethuluzini. Ukusika okujulile kungalayisha kakhulu ithuluzi, okuholela ekudlidlizeni nasekuxoxeni. Ukunciphisa ukujula kokusika kungasiza ekuvimbeleni ukuxoxa, ikakhulukazi uma kwenziwa izinto eziyinselele. Ukuqonda ukusebenzisana kwalezi zici kanye nomthelela wazo othize engxoxweni kubalulekile ukuze kuthuthukiswe amasu asebenzayo okunciphisa noma ukuqeda lesi simo esiyingozi ngesikhathi sokugaya i-CNC. Ezigabeni ezilandelayo, sizocubungula amasu ahlukahlukene kanye nezindlela ezingcono kakhulu zokunciphisa ukuxoxa ngokubhekana nalezi zimbangela.Amasu Okunciphisa Ingxoxo

Ingxoxo ekugayweni kwe-CNC ingaba inselele eqhubekayo, kodwa kunamasu amaningi asebenzayo namasu okukunciphisa noma ukukuqeda. Lawa maqhinga ahlanganisa ukuthuthukiswa kwamathuluzi omshini, ukulungiswa okufanele kwengcezu yokusebenza, ukukhethwa nokugcinwa kwamathuluzi, ukwenziwa kahle kwemingcele yokusika, ukuhlela indlela yamathuluzi, amasu okudambisa, kanye nokusetshenziswa kwezinhlelo zokuqapha nokulawula. Ake sihlole ngalinye lalawa maqhinga ngokuningiliziwe:1. Ukuthuthukiswa Kwethuluzi Lomshini

Ukuthuthukisa umshini we-CNC ngokwawo kuyindlela ephumelelayo yokunciphisa ingxoxo. Nazi ezinye izindlela ongazicabangela:a. Ukuthuthukela Emshinini Oqine Kakhudlwana:

Uma umshini wakho wamanje untula ukuqina nokuzinza, cabanga ukuthuthukela koqine kakhulu. Umshini oqinile unciphisa ukuchezuka futhi ungadambisa ngempumelelo ukudlidliza phakathi nenqubo yomshini, wehlise ithuba lokuxoxa.b. Amasistimu wokudambisa:

Eminye imishini iza ifakwe eyakhelwe ngaphakathi amasistimu wokudambisa yakhelwe ukumunca ukudlidliza. Lezi zinhlelo ziwusizo ikakhulukazi ekwehliseni ingxoxo ngesikhathi somshini onesivinini esikhulu. Ukuthuthukela emshinini onezici ezithuthukisiwe zokuthambisa kunganciphisa kakhulu ingxoxo.c. Ukulungiswa Komshini Okuvamile:

Ukunakekela njalo kubalulekile. Hlola njalo futhi ulungise izingxenye zomshini ezibalulekile ukuze uqinisekise ukuthi umshini usebenza kahle. Lokhu kubandakanya ukuhlola nokuqinisa amabhawodi, ukulinganisa i-spindle, nokugcina isimo somshini sisonke.2. Ukulungiswa Kwezingcezu Zokusebenza

Ukulungiswa kahle kweziqeshana zokusebenza kubalulekile ukuze uvimbele ukuxoxa. Cabangela lezi zinyathelo ezilandelayo:a. Ukulungiswa Okuvikelekile:

Qinisekisa ukuthi i-workpiece ilungile iboshwe ngokuvikelekile noma ilungiswe ukuvimbela noma yikuphi ukunyakaza okungahlosiwe noma ukudlidliza. Ukulungiswa okufanele kubalulekile ukuze kugcinwe ukuzinza ngesikhathi somshini.b. Ukukhetha Okubalulekile:

Khetha impahla efanele ngocezu lwakho lomsebenzi olususelwe kuzidingo ezithile zomshini. Izakhiwo zezinto ezibonakalayo, njengokuqina kanye ne-thermal conductivity, zingathinta ingxoxo. Ukukhetha impahla efanele kungakhuthaza izimo zokusika ezinzile.c. Nciphisa i-Overhang:

Ama-overhang amade phakathi kwe-workpiece nethuluzi kungakhulisa ingxoxo ngenxa yokwanda kokuchezuka kwamathuluzi. Ukunciphisa i-overhang noma ukusebenzisa amathuluzi amafushane kungasiza ukunciphisa lo mphumela.3. Ukukhetha Ithuluzi Nokugcinwa

Ukukhethwa kwamathuluzi okusika nesimo sawo kuthinta kakhulu ingxoxo. Izinto eziphathelene namathuluzi okufanele zicatshangelwe zifaka:a. Ithuluzi:

Khetha elilungile ithuluzi impahla ngokusekelwe ku-workpiece material. Izinto ezihlukene zinikeza amazinga ahlukene okumelana nokugqoka nokumelana nokushisa. Ukukhetha okubalulekile kwethuluzi kunganciphisa ukuguga kwamathuluzi kanye nethuba lokuxoxa.b. Ithuluzi leJiyomethri:

Cabanga ngalokhu ithuluzi lejometri, okuhlanganisa inombolo yemitshingo, i-rake angle, ne-helix angle. Amajiyometri amathuluzi afanele anikeza ukulawula okuhle kwe-chip nokunciphisa amandla okusika anconyelwa ezintweni ezivame ukuxoxa.c. Ukulungiswa Kwethuluzi Okujwayelekile:

Qinisekisa ukuthi amathuluzi okusika akhona isimo esihle ngokuhlola nokunakekela njalo. Amathuluzi agugile noma alimele maningi amathuba okuba abangele ingxoxo. Ukunakekelwa okufanele kwamathuluzi kuhlanganisa ukucija, ukulungisa kabusha, kanye noshintsho lwamathuluzi njengoba kudingeka.4. Amapharamitha wokusika alungile

Ukukhetha imingcele efanele yokusika kubalulekile ukuze uvimbele ukuxoxa. Ukusika izici ezihlobene nepharamitha zifaka:a. Izinga lokuphakelayo:

Khetha i isilinganiso esifanele sokudla lokho kulinganisa namanye amapharamitha wokusika. Izinga lokudla okuphezulu ngokweqile lingaholela ekwandeni kwamandla okusika nokuxoxa. Lungisa izinga lokuphakelayo ukuze ulondoloze imishini ezinzile.b. Isivinini sokusika:

The isivinini sokusika kufanele kukhethwe ngendlela efanele ngokusekelwe ezintweni ezisetshenziswayo namathuluzi asetshenziswayo. Ijubane lokusika elingafanele lingabangela ingxoxo. Isivinini esilungile sokusika sincike ezintweni ezifana nohlobo lwezinto ezibonakalayo, impahla yamathuluzi, nejiyomethri yamathuluzi.c. Ukujula Kokusika:

The ukusika ukusika ithinta umthwalo we-chip namandla wamathuluzi. Ukusika okujulile kungalayisha kakhulu ithuluzi, okuholela ekudlidlizeni nasekuxoxeni. Ukunciphisa ukujula kokusika kungasiza ekuvimbeleni ukuxoxa, ikakhulukazi uma usebenza ngezinto eziyinselele.5. Ukuthuthukisa Indlela Yamathuluzi

Ukuthuthukisa indlela yamathuluzi kunganciphisa ukuxoxa ngokugwema izinguquko ezingazelelwe kumandla okusika. Cabangela lezi zindlela ezilandelayo:a. I-Trochoidal Milling:

Ukugaya i-Trochoidal kuyindlela ehilela amaphethini wendlela yamathuluzi alawulwayo, aqhubekayo lokho kunganciphisa ukuxoxa. Kubandakanya ithuluzi elilandela indlela eyindilinga noma egobile kunokwenza ukusikeka okuqondile.b. Ukukhuphuka vs. Ukugaya Okuvamile:

Ukukhetha phakathi khuphuka ukugaya (lapho umsiki ezungeza khona lapho okuphakelayo) kanye ukugaya okuvamile (lapho umsiki ezungeza khona lapho okuphakelayo) kungaba nomthelela engxoxweni. Ukugaya i-Climb ngokuvamile kudala ingxoxo encane, njengoba kunciphisa umthelela wamandla okusika.6. Amasu okudambisa

Ukuze kuxazululwe ingxoxo ngesikhathi somshini, amasu ahlukahlukene okudambisa angasetshenziswa:a. Ithuluzi Dampers:

Ama-dampers amathuluzi yizinanyathiselwa ezingangezwa kumphathi wamathuluzi ukunciphisa ukudlidliza nokuxoxa. Lawa ma-dampers amunca ukudlidliza futhi athuthukise ukuzinza kwenqubo yomshini.b. Izimeli Ezimelana Nengxoxo:

Cabangela ukusebenzisa iziphathi-mathuluzi eziklanyelwe ngokukhethekile ukunciphisa ukuxoxa. Laba baphathi bamathuluzi bahlanganisa ubuchwepheshe bokudambisa okuthuthukisiwe ukuze kuthuthukiswe ukuzinza kwemishini.c. Ukufaka Okungangeni Kwengxoxo Emashini:

Okufaka ukumelana nengxoxo kungafakwa ethuluzini lokusika. Lokhu kufaka kuklanyelwe ukudambisa ukudlidliza nokuthuthukisa ukuqina kwamathuluzi.7. Amasistimu Wokuqapha Nokulawula

Ukuze ulawule ingxoxo ngempumelelo, cabangela ukusetshenziswa kwezinhlelo zokuqapha nokulawula:a. Izinhlelo Zokuqapha Ukudlidliza:

ukufaka amasistimu wokuqapha ukudlidliza emshinini we-CNC ukuthola ingxoxo ngesikhathi sangempela. Lawa masistimu angalungisa ngokuzenzakalelayo amapharamitha okusika noma indlela yamathuluzi ukuze kuncishiswe ukuxoxa uma kwenzeka.b. I-Adaptive Control Systems:

Amasistimu okulawula okuguquguqukayo asebenzisa idatha yesikhathi sangempela ukuze alungise imingcele yokusika kanye nendlela yamathuluzi ngendlela eguquguqukayo ukuze kuvinjelwe ukuxoxa. Lezi zinhlelo zingasebenza kahle kakhulu ekwehliseni izingxoxo.c. Ukusika Amandla Ukukala:

Ukulinganisa nokuqapha ukusika amandla ngesikhathi somshini singanikeza idatha ebalulekile ukusiza ukuvimbela ingxoxo. Ngokuqonda amandla adlalwayo, ukulungiswa kungenziwa ukuze kuncishiswe ukudlidliza. Ukusebenzisa lawa maqhinga namasu kunganciphisa kakhulu noma kuqede ingxoxo emshinini wokugaya we-CNC, okuholela ekuthuthukisweni kwekhwalithi yengxenye, impilo yamathuluzi ende, ukwethembeka komshini, kanye nokwanda kokukhiqiza. Ukwengeza, lezi zindlela zingashintshwa ukuze zihambisane nezidingo zakho ezithile Ukufakwa kwe-CNC ukusebenza, ukwenza ukunciphisa izingxoxo kube umgomo osebenzayo nofinyelelekayo.Ekuphetheni

Ingxoxo ekugayweni kwe-CNC yinkinga ebucayi engaba nomthelela omkhulu kwikhwalithi, ukusebenza kahle, kanye nokuphumelela kwezindleko zokusebenza komshini. Ukuqonda izimbangela zengxoxo, okuhlanganisa izici zamathuluzi omshini, izinkinga ezihlobene nengxenye yokusebenza, izici zamathuluzi, nokucatshangelwa kwepharamitha yokusika, kubalulekile ekubhekaneni nale nselele ngempumelelo. Ukunciphisa noma ukuqeda ingxoxo, ochwepheshe bemishini bangasebenzisa amasu namasu anhlobonhlobo:- Ukuthuthukiswa Kwethuluzi Lomshini: Ukuthuthukela emishinini eqinile, ukusebenzisa amasistimu okumanzisa, nokuqinisekisa ukunakekelwa okuvamile kungathuthukisa ukuzinza komshini futhi kunciphise ukuxoxa.

- Ukulungiswa Kwezingcezu Zokusebenza: Ukulungiswa okufanele, ukukhethwa kwezinto ezibonakalayo, nokunciphisa i-overhang kunomthelela ekuzinzeni kocezu lomsebenzi kanye nengxoxo encishisiwe.

- Ukukhetha Ithuluzi Nokugcinwa: Ukukhetha amathuluzi afanele namajiyometri, kanye nokugcina amathuluzi esesimweni esihle, kunganciphisa ukuxoxa.

- Elilungile Cutting Amapharamitha: Ukulungisa amazinga okuphakelayo, isivinini sokusika, nokujula kokusika ukuze kugcinwe amandla okusika alinganiselayo kubalulekile ekwehliseni izingxoxo.

- Ukuthuthukisa Indlela Yamathuluzi: Ukusebenzisa i-trochoidal milling nokukhetha indlela yokugaya efanele (ukugibela noma okuvamile) kungasiza ukuvimbela ingxoxo.

- Amasu okudambisa: Ukusebenzisa ama-dampers amathuluzi, izibambi zamathuluzi ezikwazi ukumelana nengxoxo, nezinto ezifakwa ngomshini eziklanyelwe ukudambisa ukudlidliza kunganciphisa ingxoxo.

- Amasistimu Wokuqapha Nokulawula: Ukusebenzisa amasistimu okuqapha ukudlidliza, amasistimu okulawula okuguquguqukayo, kanye nokulinganisa amandla okusika kungathola futhi kukhulume ingxoxo ngesikhathi sangempela.

Imisebenzi Yethu

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

Case Studies

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

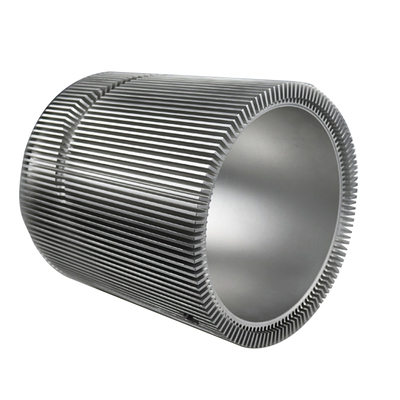

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

Uhlu lwezinto

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi

Izingxenye zegalari