Ukuhlaziywa Okuningiliziwe Kwe-Hard Chrome Plating vs. I-Decorative Chrome Plating

I-Chrome plating iyindlela esetshenziswa kakhulu yokuqeda indawo ethuthukisa ukubukeka nokuqina kwezinto ezahlukahlukene. Izinhlobo ezimbili ezijwayelekile zokufakwa kwe-chrome i-chrome plating ne-chrome plating yokuhlobisa. Nakuba behlanganyela inqubo efanayo eyisisekelo, izinhlelo zabo zokusebenza, izici, nezinjongo zihluka kakhulu. Kulesi sihloko, sizocubungula imininingwane ye-hard chrome plating kanye nokuhlobisa i-chrome plating, sigqamisa ukuhluka kwabo kanye nezinhlelo zokusebenza.

I-Hard Chrome Plating:

-

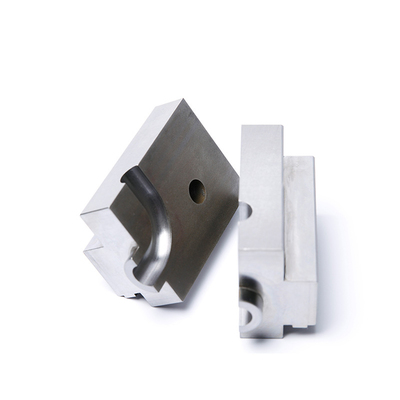

Inhloso: I-hard chrome plating, eyaziwa nangokuthi i-industrial chrome plating, isetshenziselwa ngokuyinhloko ukuthuthukisa ukumelana nokuguga, ukumelana nokugqwala, kanye nobulukhuni bendawo. Isetshenziswa kakhulu ezinhlelweni zezimboni lapho ukuqina nokusebenza kubaluleke kakhulu.

-

Ubukhulu: Ukufakwa kwe-chrome eqinile ngokuvamile kubangela ukunamathela okukhulu uma kuqhathaniswa nokuhlobisa kwe-chrome. Ugqinsi lungasukela ku-0.002 kuye ku-0.02 amayintshi, lunikeze isendlalelo esiqinile nesihlala isikhathi eside.

-

Ama-substrates: I-Hard chrome plating ifanele ama-substrates ahlukahlukene, okuhlanganisa insimbi, i-aluminium, nezinye izinsimbi. Ivamise ukukhethelwa izakhi ezingaphansi kokuguga nokukhala okukhulu, njengezinduku ze-hydraulic, ama-piston, nemishini yezimboni.

-

Ukubukeka: Ukubukeka kwe-chrome plating eqinile ngokuvamile akubukeki kangako uma kuqhathaniswa ne-chrome yokuhlobisa. Ijwayele ukuba nesiphetho se-matte noma se-satin, igxile kakhulu ekusebenzeni kunokukhanga okubonakalayo.

-

Inqubo: Inqubo ye-chrome plating eqinile ihlanganisa ukusebenzisa ungqimba lwe-chromium ku-substrate ngenqubo ye-electroplating. Lokhu kubangela indawo eqinile futhi eqinile engamelana nezimo ezinzima.

I-Decorative Chrome Plating:

-

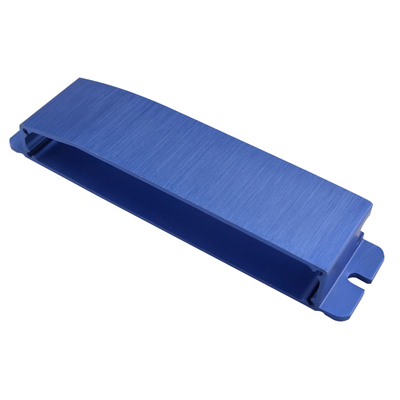

Inhloso: Ukuhlobisa nge-chrome plating kusetshenziselwa ngokuyinhloko ukuthuthukisa ukukhanga kobuhle bendawo. Ivame ukutholakala ezingxenyeni zezimoto, zasendlini zalapho, kanye nezimpahla ezihlukahlukene zabathengi lapho kufunwa isiphetho esicwebezelayo nesikhangayo.

-

Ubukhulu: Ukuhlobisa kwe-chrome plating kubangela ukunamathela okuncane uma kuqhathaniswa ne-chrome plating. Ugqinsi luvamise ukuhluka ukusuka ku-0.0002 kuye ku-0.002 amayintshi, kunikeza isendlalelo esicwebezelayo nesikhangayo ngokubukeka.

-

Ama-substrates: Ukuhlobisa nge-chrome plating kuvame ukusetshenziswa ezintweni ezifana nethusi, i-zinc, nepulasitiki, ngaphezu kwezinsimbi ezifana nensimbi ne-aluminium. Lokhu kuguquguquka kuyenza ifanele uhla olubanzi lwemikhiqizo yabathengi.

-

Ukubukeka: Isici esivelele sokuhlobisa i-chrome plating ukubukeka kwayo okucwebezelayo nokucwebezela. Isiphetho sivame ukufana nesibuko, okunomthelela ekuthandeni okuphelele kwento eboshiwe.

-

Inqubo: Inqubo yokuhlobisa i-chrome plating ifana ne-hard chrome plating, ehlanganisa inqubo ye-electroplating. Kodwa-ke, kugcizelelwa ukuzuza indawo ebushelelezi futhi ecwebezelayo kunezici zokusebenza.

Isiphetho: Kafushane, nakuba kokubili ucwecwe oluqinile lwe-chrome nokuhlobisa i-chrome plating kuhlanganisa ukufakwa ngogesi kwe-chromium kuma-substrates, izinjongo zakho nezici zihluka kakhulu. I-hard chrome plating igiyaihlotshiswe ekuqineni nasekusebenzeni, enoqweqwe olushubile kanye nesiphetho se-matte, kuyilapho ukuhlobisa nge-chrome plating kugxile kubuhle, kuhlinzeka ngokuqedwa okuzacile, okucwebezelayo. Ukuqonda lo mehluko kubalulekile ekukhetheni indlela efanele ye-chrome plating ngokusekelwe kuhlelo oluhlosiwe kanye nomphumela ofisayo.

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi