I-Femtosecond Laser Cutting: Impahla Yayo Nokusebenza

Ama-laser asheshayo afaka ama-laser e-picosecond kanye ne-femtosecond. Amalaser e-Picosecond awukuthuthukiswa kobuchwepheshe kwama-nanosecond lasers, futhi ama-lasecond lasers asebenzisa ubuchwepheshe bokukhiya imodi, kuyilapho ama-nanosecond lasers esebenzisa ubuchwepheshe obushintshwayo be-Q. Ubuchwepheshe be-Femtosecond busebenzisa umzila wezobuchwepheshe ohluke ngokuphelele. Ukukhanya okukhishwa umthombo wembewu kunwetshwa i-pulse stretcher, kukhuliswe isikhulisi samandla se-CPA, futhi ekugcineni kucindezelwe yi-pulse compressor ukuze kukhishwe ukukhanya. Ubuchwepheshe bunzima kakhulu.

Uma kuziwa ku-laser ye-femtosecond, into yokuqala efika engqondweni ingase ibe ukusetshenziswa okuvamile okufana nokulungiswa kwe-femtosecond myopia kanye nokususwa kwe-femtosecond freckle esetshenziswa ku-cosmetology yezokwelapha. Ama-laser we-Femtosecond nawo ahlukaniswe ngamaza ahlukene afana ne-infrared, ukukhanya okuluhlaza, kanye ne-ultraviolet. Phakathi kwazo, ukukhanya okungabonakali Njengamanje, ingasetshenziswa emikhakheni eminingi njengokunemba kwezinto ukusika kwe-laser, ukuhlinzwa, umthengi, ukuxhumana nge-elekthronikhi, i-spectroscopy, i-aerospace, izinhlelo zokusebenza zokuvikela kanye nesayensi eyisisekelo. Ngakho-ke kulokhu sizokwethula izinhlelo zokusebenza ezimbalwa ezijwayelekile ze-Be-Cu infrared femtosecond lasers embonini.

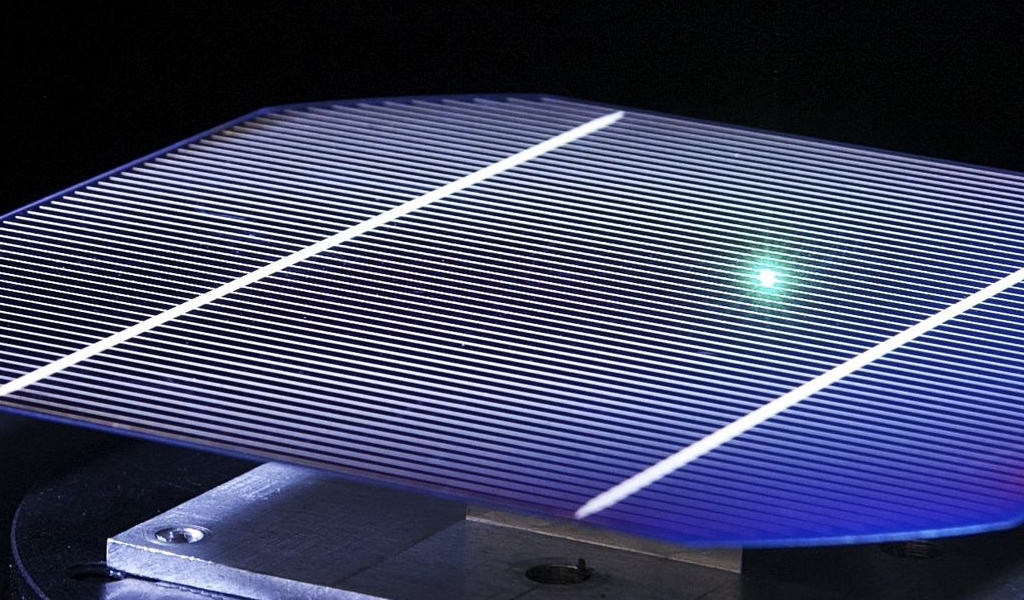

I-Laser Cutting Ultra-Thin Glass (UTG)

Njengamanje, izinto zengilazi ezacile kakhulu zisetshenziswe kakhulu ekubonisweni kwe-electronics yabathengi kanye nezimboni ze-semiconductor. Isibonelo, ingilazi ye-substrate ezikrinini zethu ze-OLED ezivame ukusetshenziswa yingilazi e-ultra-thin (UTG).

Ngokusungulwa okuqhubekayo kobuchwepheshe beselula, izikrini zamaselula ziba zintsha futhi zihluke kakhulu, futhi ubuchwepheshe besikrini sokugoqa buvele njengoba izikhathi zidinga. Kodwa-ke, omakhalekhukhwini besikrini sokugoqa banezidingo eziphakeme kakhulu zengilazi. Uma ingilazi ibe mncane, kuba ngcono ukusebenza kokudlulisa ukukhanya, ukuguquguquka okungcono, nesisindo siba lula. Kodwa-ke, lolu hlobo lwengilazi ye-electronic Laser Cutting ludinga ukunemba okuphezulu, ukusebenza kahle okuphezulu, akukho mifantu emincane, akukho mifantu emnyama, njll Izidingo zokuchopha onqenqemeni kanye nemifantu emincane ziyanda, i-femtosecond laser isibe yisinqumo esingcono kakhulu.

I-Femtosecond laser cutting ine-ultra-high energy density futhi ingadlula kalula umkhawulo wokulimala kwengilazi; ngesikhathi esifanayo, ingilazi encane kakhulu izwela ukushisa, futhi i-femtosecond pulse iyimodi "ebandayo ye-Laser Cutting", engenza unqenqema lwendawo yokukhanya luphelele, amabala okukhanya awaphambanisi, futhi afinyelele. I-ultra-low fracture Effect: Ngesikhathi senqubo ye-Laser Cutting, udonga oluseceleni lungenziwa bushelelezi, ukuqhekeka okungavamile mancane amathuba okuba kwenzeke, futhi imifantu engavamile ebangelwa ukushisa ngokweqile mancane amathuba okuba yenzeke. Ayinawo umthelela kurediyasi yokugoba ye-UTG futhi ingakhulisa impilo yokugoba.

I-Laser Cutting Gold-Plated Copper Foil

I-copper foil ingenye yezingxenye ezivame ukusetshenziswa embonini ye-electronics. I-electrolyte iyi-electrolyte engeyinhle efakwa ungqimba ku-substrate yebhodi lesifunda futhi isebenza njengomqhubi kagesi webhodi lesifunda. I-copper foil ingumkhiqizo wethusi omncane kakhulu. I-Copper iyafana nephepha futhi ukujiya kwayo kungama-microns. Ngokuvamile 5um-135um, ezacile futhi banzi kuba nzima ukwenza. Kalula nje, i-foil yethusi icindezelwa emashidini amancane kakhulu.

I-foil yethusi isetshenziswa kabanzi kuzo zonke izici, njengezimoto zikagesi, i-electronics yabathengi, i-aerospace, imishini yokuxhumana neminye imikhakha. Indlela yendabuko yokusika i-Laser ngokuyinhloko i-die-cut, kodwa kukhona ukushiyeka ekusebenzeni kahle, isivinini sokusika i-Laser, ukulahlekelwa kanye nokunemba kokusika. Uma usebenzisa i-laser cutting evamile, umphumela oshisayo mkhulu. Umthelela oshisayo emaphethelweni wenza i-foil yethusi ibe lula ukusonteka nokonakala, futhi imiphetho ifakwe i-carbonized, okuholela ekuwohlokeni kwempahla.

I-laser ye-femtosecond inezinzuzo ezisobala kakhulu ku-Laser Cutting ucwecwe lwethusi ngenxa yemodi yayo "ebandayo ye-Laser Cutting". I-laser ye-Femtosecond inobubanzi obuncane be-pulse, obungakwazi ukucubungula impahla ngomphumela omncane kakhulu wokushisa, igweme ukulimala kwezinto ezibangelwa ukunqwabelana kokushisa, futhi ivikele kahle ungqimba olufakwe ngegolide ekuweni;

Phakathi nenqubo yokusika ngokuqondile, ngeke kube khona ukuguquguquka, akukho ukuncibilika, akukho ukungcoliswa kwezinto ezibonakalayo, njll; futhi i-laser ye-femtosecond inomphumela omuhle kakhulu wekhwalithi ye-beam. Ngemuva kokugxila, kungaqinisekisa ukuhambisana komphumela onqenqemeni wezinto ezicutshungulwayo kanye nendlela yokusika. , ukucaba kwezinhlangothi zombili zobuso bokuphela kwenza ukusika okunembe ngempela; iphinde isekele imisebenzi eminingi yokuhlela i-burst and pulse, ithuthukise ngokwengeziwe ukusebenza kahle kwe-Laser Cutting kanye nomthelela.

I-Laser Cutting Zirconia Ceramics

Mayelana ne-ceramics, i-zirconia (YSZ) i-ceramic substrates inokumelana nokushisa okuphezulu kakhulu futhi ingasetshenziswa njengamashubhu okushisa okungenisa, izinto eziphikisayo, nezinto zokufudumeza. Futhi inemingcele yokusebenza kagesi ebucayi, ukuqina okuphezulu, amandla aphezulu aguquguqukayo nokumelana nokugqoka okuphezulu, izakhiwo ezinhle kakhulu zokufakwa kwe-thermal, i-coefficient yokwandisa okushisayo nezinye izinzuzo eziseduze nensimbi. Isetshenziswa kakhulu emimese ye-ceramic, izinzwa ze-oxygen, ama-thermal substrates amaseli kaphethiloli, amaseli kaphethiloli we-Solid oxide nezinto zokushisa ezishisa kakhulu, njll.

Uma kuqhathaniswa nezinsimbi, i-zirconia ceramics inezinzuzo zokungagugi kangcono, indawo ebushelelezi, ukuthungwa okuhle, futhi akukho oxidation. Imikhiqizo eminingi eyaziwayo yezinga eliphezulu iphinde yethule amawashi e-ceramic aphezulu, athatha indawo emkhakheni wokugqoka ohlakaniphile; izinsimbi ze-ceramic nemikhono nazo zisetshenziswa kabanzi emkhakheni we-fiber optical izixhumanisi; ngasikhathi sinye, i-zirconia ceramics ayinakho ukuvikela isignali, i-anti-drop, ayifaki ukugqokwa, futhi Inezinzuzo zokugoqa, ukubukeka okufudumele nokubushelelezi, nokuzwakala kahle kwesandla, futhi isetshenziswa kabanzi emikhakheni ye-elektroniki ye-3C njengeselula. amafoni. Kodwa-ke, ngesikhathi sokusika kwe-Laser ye-ceramics ye-zirconia yendabuko, kukhona nakanjani uchungechunge lwezinkinga ezifana nekhwalithi embi ye-Laser Cutting kanye nokusebenza kahle kwe-Laser Cutting. Lokhu kudinga ukusetshenziswa kwe femtosecond Laser Cutting, engaxazulula le nkinga ngokunembe nangempumelelo.

Ngenxa yokuphakama kwamandla aphezulu we-femtosecond pulses, imodi ebandayo ye-Laser Cutting ingabonakala, engahlangabezana kangcono nezidingo eziqinile zemikhiqizo. Ngesikhathi somkhiqizo we-Laser Cutting, i-laser ye-femtosecond idla amandla amancane futhi ibangela ukulimala okuncane ezintweni, ngakho-ke ukunemba kwe-Laser Cutting kuphezulu; Ukuthintwa kweMechanical okungezona ezendabuko Ukusika kwe-Laser akunangcindezi futhi kusakazwa ngokulinganayo emaphethelweni esampula. I-Ceramic chipping mancane amathuba okuthi yenzeke esimweni esincibilikile futhi nekhwalithi ingcono. I-laser ye-femtosecond inokuminyana kwamandla aphezulu kakhulu phakathi nenqubo ye-Laser Cutting futhi ingafinyelela amakhono okusika asebenza kahle wezinto zobumba ze-zirconia. , ekwazi ukusika ngokushesha izakhiwo zempahla zibe yisimo.

Izinhlelo zokusebenza eziningi zokuhlola zibonisa izinzuzo ezinkulu zobuchwepheshe be-femtosecond Laser Cutting (nge-stent kanye i-hypotube laser cutting) emkhakheni wezimboni. I-Be-Cu nayo ihlale iyihlakulela, ikhulisa imisebenzi yokuhlola yohlelo lokusebenza ukuze inikeze ukudlala okugcwele kuzinzuzo ezengeziwe ze-femtosecond futhi iqhubeke nokuhlinzeka Ukuguqulwa nokuthuthukiswa kwezimboni zokukhiqiza ezithuthukile kwakha isisekelo esiqinile futhi kukhuthaze intuthuko.

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

3, 4 no-5-eksisi ngokunemba Ukufakwa kwe-CNC nezinsizakalo ze i-aluminium machining, i-beryllium, i-carbon steel, i-magnesium, umshini we-titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite kanye nokhuni. Iyakwazi izingxenye zemishini kuze kufike ku-98 in. Turning dia. kanye +/- 0.001 ku. ukubekezelelana okuqondile. Izinqubo zifaka ukugaya, ukujika, ukubhola, ukubhoreka, ukuchusha, ukuthepha, ukwakha, ukujija, ukuphikisa, ukucabanga kabusha, ukuphinda usebenzise futhi ukusika kwe-laser. Izinsizakalo zesibili ezifana nokuhlangana, ukugaya okungenasikhungo, ukwelashwa ukushisa, ukugoqa nokushisela. I-prototype nokukhiqizwa kwevolumu ephansi kuya phezulu enikezwa ngamayunithi aphezulu we-50,000. Ifanele amandla oketshezi, i-pneumatics, ama-hydraulic kanye I-valve izinhlelo zokusebenza. Ihlinzeka ngezimboni zezindiza, izindiza, ezempi, ezokwelapha nezokuvikela.I-TPTJ izokwenza amasu nawe ukuze inikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi