Ubuchwepheshe bokwelapha ukushisa kwe-aviation aluminium alloy

Ngokuthuthukiswa kobuchwepheshe bezokuthutha, i-aluminium alloy isetshenziswe kabanzi ezintweni zezindiza ngenxa yesisindo sayo esilula, amandla aphezulu, nokucubungula okulula. Ukusetshenziswa okuphumelelayo kwe-aluminium alloy kunciphisa isisindo sesakhiwo sendiza, kuthuthukisa ukusebenza kwendiza futhi kwandisa izinzuzo zezomnotho. Ngakho-ke, ubuchwepheshe be-aviation aluminium alloy nabo buye bathola ukunakwa okwengeziwe.

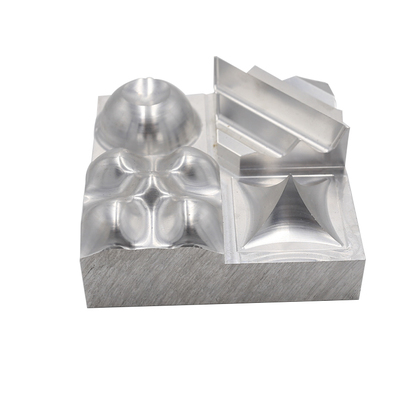

Ukwelashwa kokushisa kwe-aluminium alloy ngesithando somlilo sikagesi sokujikeleza komoya esikhundleni sesithando somlilo se-nitrate

Ukwelashwa kokushisa kwendabuko kusebenzisa isithando somlilo se-nitrate sokushisa, esinobubi bokungcoliswa kwemvelo okukhulu, ukusetshenziswa kwamandla kanye nemfucuza, kuyilapho isithando somlilo sikagesi sokujikeleza komoya sinezinzuzo zokuqalisa ngokushesha kanye nomphumela omuhle wokonga amandla, kanye nesikhathi sokudlulisa esicishayo. iyashesha futhi iyalungiseka, engahlangabezana nezidingo zezingxenye ezahlukene ze-aluminium alloy. Dinga. Ngemuva kokuthi isithando somlilo sikagesi sokujikeleza komoya sishisiwe, ukucisha isixazululo akungcolisi indawo yokupholisa, okuzuzisa ukwazisa ukusetshenziswa kwe-organic quenching medium, ukunciphisa ukuhlanekezela kokwelashwa kokushisa, nokuthuthukisa ukusebenza kahle kokukhiqiza.

Ubuchwepheshe obubalulekile besithando somlilo sokujikeleza komoya yindlela yokuqinisekisa ukufana kwezinga lokushisa kwesithando (±3~±5℃), ikakhulukazi kwizithando zomlilo ezinosayizi omkhulu, kanye nendlela yokuhlangabezana nezidingo zokushisa okuphansi (100~150℃) ukufana kwezinga lokushisa. Ubuchwepheshe besibili obuyisihluthulelo buyindlela yokuqinisekisa isikhathi sokudlulisa esicisha ngokushesha, futhi singalungiswa futhi silawulwe ngokuvumelana nezidingo ezahlukene zezingxenye.

I-Organic quenching medium

I-aluminium alloy quenching medium ivame ukusetshenziswa amanzi noma amanzi ashisayo, kodwa ukuguqulwa kokwelashwa kokushisa kukhulu noma ukuguqulwa kuqinile, amanzi ashisayo awakwazi ukuhlangabezana nezidingo, futhi isisombululo se-organic quenching medium aqueous kumele sikhethwe. Ukusetshenziswa kwe-organic quenching medium aqueous solution esikhundleni samanzi esithandweni somoya sokujikeleza kunciphisa ukuguqulwa kokwelashwa kokushisa kwe-aluminium alloy kanye nesikhathi sokulungisa ishidi lensimbi izingxenye ezingaphezu kuka-50%.

Ukutholwa kokwenziwa

Njengoba izinto ze-aluminium alloy zisetshenziswa ekwenzeni izindiza, ukuhlolwa kwe-tensile noma ukuhlolwa kokuqina kusetshenziswe ukuthola ikhwalithi yokwelashwa kokushisa kwe-aluminium alloy. Ngemva kokuba ingxubevange ye-aluminium iphathwa ngokushisa, ngaphansi kwenani lamandla elilodwa (ubunzima), kungase kube nezifunda ezimbili ezihlukene, futhi ngokuphambene nalokho, ngaphansi kwesimo esisodwa, kungase kube namanani amabili ahlukene (ubulukhuni). Ngakho-ke, ukusebenzisa kuphela ubulukhuni noma amandla ukuze ulawule ikhwalithi ye-aluminium alloy ngemva kokwelashwa kokushisa kuyindlela yokubona eyisidala futhi ayikwazi ukuqinisekisa ngokuphelele ikhwalithi.

Ukutholwa kwe-conductivity kunezinzuzo ezihlukile zokunethezeka nokushesha, ukusebenza kahle okuphezulu, futhi ngokuyisisekelo akukhawulelwe umumo nesisindo sengxenye ehloliwe, futhi kunenzuzo eyingqayizivele yokungabibikho komonakalo engxenyeni. Kusukela ngawo-1980s, ukutholwa kokusebenza kuye kwasetshenziswa kancane kancane ekuhloleni isimo sokwelashwa kokushisa kwezinto/izingxenye ze-aluminium alloy e-China. Esilinganisweni se-GB/T12966-1991 "Aluminium Alloy Electrical Conductivity Eddy Current Test Method", indlela yokuhlola inikezwa, GJB2894-l997 "Aluminium Alloy Electrical Conductivity and Hardness Requirements", ecacisa ukuqhutshwa kukagesi kanye nezidingo zenani lokuqina.

Xhumanisa nale ndatshana: Ubuchwepheshe bokwelapha ukushisa kwe-aviation aluminium alloy

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

I-PTJ® ingumkhiqizi owenziwe ngezifiso ohlinzeka ngohlu olugcwele lwemigoqo yethusi, izingxenye zethusi futhi izingxenye zethusi. Izinqubo zokukhiqiza ezijwayelekile zifaka ukuvala, ukufaka imbossing, ukwenza i-coppersmithing, wire edm amasevisi, ukuhuba, ukubumba nokugoba, ukucasula, kushisa UKWAKHA nokucindezela, ukubhoboza nokubhoboza, ukugingqa intambo nokuguqa, ukugunda, imishini eminingi yokuphotha, i-extrusion kanye ukubumba insimbi futhi uyanyathela. Izicelo zifaka amabha amabhasi, amakhondakta kagesi, izintambo ezinamagagasi, amagagasi, izingxenye ze-transistor, amashubhu e-microwave, amashubhu esikhunta angenalutho, kanye i-powder metallurgy amathangi e-extrusion.

I-PTJ® ingumkhiqizi owenziwe ngezifiso ohlinzeka ngohlu olugcwele lwemigoqo yethusi, izingxenye zethusi futhi izingxenye zethusi. Izinqubo zokukhiqiza ezijwayelekile zifaka ukuvala, ukufaka imbossing, ukwenza i-coppersmithing, wire edm amasevisi, ukuhuba, ukubumba nokugoba, ukucasula, kushisa UKWAKHA nokucindezela, ukubhoboza nokubhoboza, ukugingqa intambo nokuguqa, ukugunda, imishini eminingi yokuphotha, i-extrusion kanye ukubumba insimbi futhi uyanyathela. Izicelo zifaka amabha amabhasi, amakhondakta kagesi, izintambo ezinamagagasi, amagagasi, izingxenye ze-transistor, amashubhu e-microwave, amashubhu esikhunta angenalutho, kanye i-powder metallurgy amathangi e-extrusion.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

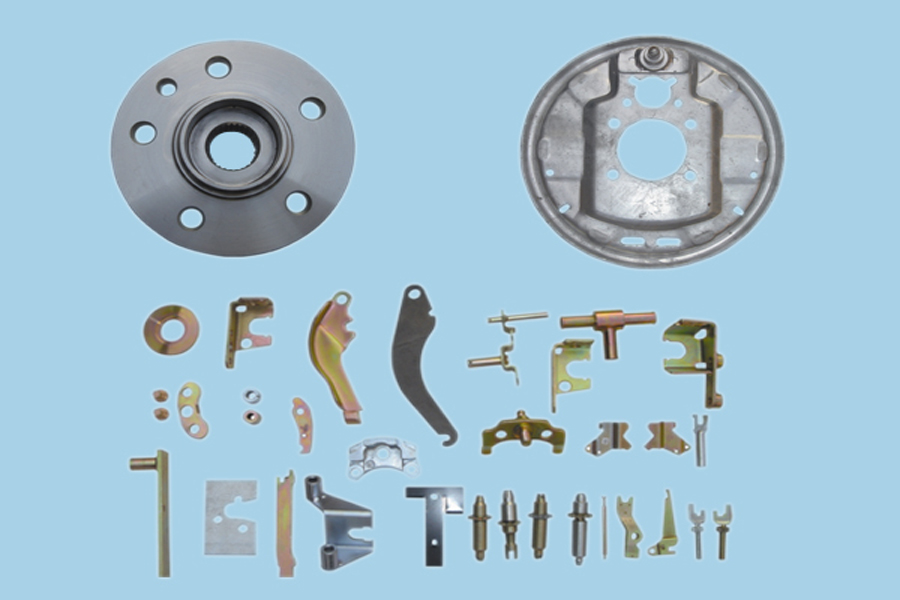

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi