Chaza kafushane isimo samanje nesiqondiso sokuthuthukiswa kobuchwepheshe bokwelapha ukushisa embonini yokuthela

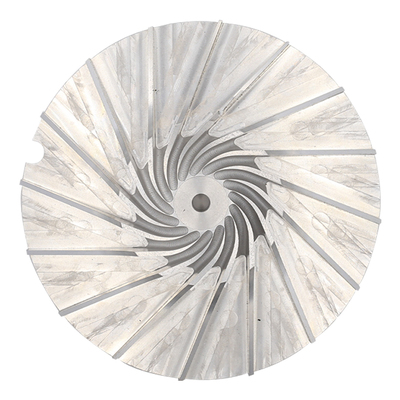

Lapho eziveza impahla kunqunywa, ubuchwepheshe yokwelapha ukushisa iyona ubuchwepheshe ukhiye ukunquma impilo yesevisi eziveza. Ezweni lami eziveza imboni, ukunemba kokukhiqiza kwe ezivezas isifinyelele ezingeni langaphandle, kodwa ukunemba kokusetshenziswa kusalele emuva kakhulu emazweni angaphandle; impilo ye ezivezas ayikwazi ukuqhathaniswa namazwe angaphandle. Imakethe yama-bearings asezingeni eliphezulu ngokuyisisekelo ihlala izimboni ezithwala izimpahla zangaphandle. Ikhwalithi yokwelashwa kokushisa kwezingxenye ezithwalayo ithinta ngokuqondile ukunemba nokuphila kokuthwala. Ukwelashwa kokushisa kwama-bearings ezweni lami kwaqala sekwephuzile, kodwa ukwelashwa okuvamile kokushisa kwama-bearings kuye kwakhula ngokushesha eminyakeni eyishumi edlule, futhi ukwelashwa kokushisa kwama-bearings ngokunemba okuvamile nokuphila okujwayelekile kungaqaphela ngokugcwele ukukhiqizwa kwenqwaba.

Isikhathi eside, ukwelashwa kokushisa kwama-carbon chromium bearings kusebenzisa i-martensite quenching + ukushisa okuphansi kwezinga lokushisa, futhi inqubo yokucisha kanye nenqubo yokushisa isetshenziswa kuphela emikhakheni yezimoto zabagibeli zikaloliwe kanye namanye ama-mill bearings. Amabheringi e-chromium ekhabhoni ephezulu angaphandle awasakhawulelwe ekucimeni sekukonke, futhi ukuguqulwa kwendawo kukumabheringi e-carbon chromium ephezulu ukuze kuzuzwe ukukhiqizwa okukhulu. Ukuguqulwa kobuso ikakhulukazi kuhlanganisa ukungena kwe-ion yezinga lokushisa eliphansi, i-carbonitriding, i-ion nitriding, ukunamathela kwendawo, ukufakwa kwe-ion, nokwelashwa kokushisa kwe-laser high-energy beam. I-seape yezinga lokushisa eliphansi ingathuthukisa ukuzigcobisa kwe-bearing futhi kunciphise i-coefficient yokungqubuzana kokuthwala; i-carbonitriding, i-ion nitriding, njll. ingakhuphula ubulukhuni bobuso futhi ikhulise ukumelana nokuguga.

Inqubekelaphambili yobuchwepheshe yenqubo yokuthwala i-annealing ibonakala kakhulu ekongeni amandla kanye nokufana kwezinga lokushisa. Ukusetshenziswa kokushisa kukadoti, izithando zomlilo ezinemigqa emibili ezonga amandla zamukelwe ngamaqoqo embonini yokuthela. Ikhwalithi ye-anneal ngokusobala ithuthukisiwe, futhi i-annealing ifana. Ngesikhathi esifanayo, ukonga amandla okungenani ku-25% uma kuqhathaniswa nangaphambili, futhi ubuncane bungafinyelela ku-110 degrees/t. Ukusetshenziswa kwamandla okunciphisa ngokuyisisekelo kulingana namazwe angaphandle. Kodwa-ke, kusekhona igebe elithile phakathi kwezinga lokucwengisiswa kwesakhiwo ngemva kokuhliswa kanye namazwe angaphandle. Ukucwengwa kanye nokufana kwama-carbides kunomthelela empilweni yesevisi ye-bearing. Ngemva kokuzala UKWAKHA, inqubo eyodwa yokucwenga kanye nenqubo yokucwenga kabili nayo iye yasetshenziswa phesheya. Alukho uhlelo lwe-batch yezimboni e-China. Sezikhona izinkampani ezenza lo msebenzi. Kulinganiselwa ukuthi intuthuko yezobuchwepheshe izotholakala maduze. Ngokusho kwemibiko, inqubo yokucwenga kabili Ukuguqulwa kungandisa impilo yokuthwala izikhathi ezingaphezu kwe-1. Kodwa-ke, inqubo yokucwenga kabili iyingozi, futhi ubuchwepheshe obuyinhloko benqubo buphuliwe. Ukwenziwa kwezimboni kuyathuthuka, futhi inqubo yokuhluzwa kabili izophinde ithuthukiswe kuma-bearings asezingeni eliphezulu esikhathini esizayo esiseduze. Inqubo yokucwenga kabili ayikwazi nje ukwandisa impilo ye-bearing, kodwa futhi ithuthukise ukuzinza kwe-dimensional yokusebenza kokuthwala. Ngesikhathi esifanayo, inganikeza ukudlala okugcwele ezindaweni ezibonakalayo futhi igcine izinsiza ezibonakalayo.

I-Bainite quenching ikhiqiza ukwakheka okuphansi kwe-bainite enokuqina komthelela okungcono. Uma kuqhathaniswa ne-martensite, i-bainite inokuqina komthelela okungcono, ukuqina kokuphuka kanye nokuzinza kwe-dimensional, kodwa ukuqina kwayo kuphansi kune-martensite. I-high-carbon chromium enensimbi yokucisha i-bainite isetshenziswe ngempumelelo kumzila wesitimela nakwezinye izimboni, futhi izuze izinzuzo ezinhle.

Izinqubo ze-carburizing kanye ne-carbonitriding zensimbi enekhabhoni ephezulu ye-chromium sezivuthiwe phesheya, futhi abanye abakhiqizi basekhaya bangene kukho. I-Carburizing kanye ne-carbonitriding high-carbon chromium bearings isetshenziswa kakhulu ezimotweni ezisezingeni eliphezulu, izithuthuthu ezisezingeni eliphezulu kanye namathuluzi omshini wokunemba. Lezi zimakethe manje sezigcwele amazwe angaphandle, futhi le makethe inekusasa eliqhakazile. Izinqubo ze-carburizing kanye ne-carbonitriding zensimbi enekhabhoni ephezulu ye-chromium zingandisa impilo yesevisi yokuthwala.

Ubuchwepheshe bokufakelwa kwe-ion sebuneminyaka ecishe ibe ngu-20 ishintshwa endaweni ene-bearing surface. Iyakwazi ukuthuthukisa ukungqubuzana kwe-substrate. Ukugqokwa, ukugqwala nezinye izakhiwo zamakhemikhali kuwubuchwepheshe obusha obunenjongo kakhulu bokulungiswa kwendawo yezinto. Kube khona izinqubo zezimboni phesheya, kanti owasekhaya usesezingeni laselabhorethri.

Lobu buchwepheshe bokuguqulwa kwendawo bungakhuphula kakhulu impilo yesevisi yamabheringi futhi bufanele ukukhushulwa ekwelashweni kokushisa okuzalayo kwasekhaya. Ngesikhathi esifanayo, ubuchwepheshe bokuguqula indawo yensimbi enekhabhoni chromium ephezulu bubaluleke kakhulu ekongeni amandla nasekunciphiseni ukusetshenziswa. Ukusebenzisa amandla ezinto ezisetshenziswayo kuze kube umkhawulo kukonga amandla okukhulu kakhulu kanye nokunciphisa ukusetshenziswa; kuyindlela engcono kakhulu yokonga izinsiza. Ubuchwepheshe bokwelapha ukushisa kuyindlela engcono kakhulu yokwandisa amandla ezinto ezibonakalayo.

Ubuchwepheshe obunembayo bokwelashwa kokushisa kwamabhereli nabo buthuthuka ngendlela enhle. Izinga lokushisa eliqondile lesithando somlilo kanye nendawo yokupholisa elawulekayo iqinisekisa ukuthi ukuhlakazwa kosayizi wokuthwala ngemva kokucisha kuncishisiwe, kodwa izindleko ziphezulu, okunzima ukuthi amabhizinisi ajwayelekile afinyelele. Olunye uhlobo lwenqubo yokucisha elinganiselwe luthuthukiswe ngempumelelo embonini yokuthwala, futhi umphumela wokulawula ukuguquguquka ungcono. Ukucisha uhlobo lokuvala kuhlukile ekucimeni ukufa ngemva kokungcwatshwa kwe-carburizing. Insimbi ene-high-carbon chromium enensimbi ayifanele ukucisha i-die-quenching, futhi i-die-quenching ijwayele izindawo ezithambile nezakhiwo ezingafanelekile; ukucisha uhlobo olulinganiselwe kusebenzisa ukucisha kwamahhala emafutheni angaphezu kuka-300℃, 300℃ Izibunjwa ezilandelayo zikhawulelwe ekupholiseni.

Ngamafuphi, isiqondiso sokuthuthukiswa kobuchwepheshe bokwelapha ukushisa ukusebenzisa imikhawulo yezinto ezibonakalayo, ukonga izinsiza ezibonakalayo, nokunciphisa ukukhishwa kokungcola.

Xhumanisa nale ndatshana:

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

I-PTJ® ingumkhiqizi owenziwe ngezifiso ohlinzeka ngohlu olugcwele lwemigoqo yethusi, izingxenye zethusi futhi izingxenye zethusi. Izinqubo zokukhiqiza ezijwayelekile zifaka ukuvala, ukufaka imbossing, ukwenza i-coppersmithing, wire edm amasevisi, ukubhoboza, ukubumba nokugoba, ukucasula, ukukhanga nokucindezela okushisayo, ukubhoboza nokubhoboza, ukugingqa intambo nokuguqa, ukugunda, imishini eminingi yokuphotha, i-extrusion kanye ukubumba insimbi futhi uyanyathela. Izicelo zifaka amabha amabhasi, amakhondakta kagesi, izintambo ezinamagagasi, amagagasi, izingxenye ze-transistor, amashubhu e-microwave, amashubhu esikhunta angenalutho, kanye i-powder metallurgy amathangi e-extrusion.

I-PTJ® ingumkhiqizi owenziwe ngezifiso ohlinzeka ngohlu olugcwele lwemigoqo yethusi, izingxenye zethusi futhi izingxenye zethusi. Izinqubo zokukhiqiza ezijwayelekile zifaka ukuvala, ukufaka imbossing, ukwenza i-coppersmithing, wire edm amasevisi, ukubhoboza, ukubumba nokugoba, ukucasula, ukukhanga nokucindezela okushisayo, ukubhoboza nokubhoboza, ukugingqa intambo nokuguqa, ukugunda, imishini eminingi yokuphotha, i-extrusion kanye ukubumba insimbi futhi uyanyathela. Izicelo zifaka amabha amabhasi, amakhondakta kagesi, izintambo ezinamagagasi, amagagasi, izingxenye ze-transistor, amashubhu e-microwave, amashubhu esikhunta angenalutho, kanye i-powder metallurgy amathangi e-extrusion.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi