Isimo samanje nokuthuthuka kobuchwepheshe bokwelashwa kokushisa kwesikhunta

Ukwelashwa kokushisa kwesikhunta kuyinqubo ebalulekile yokuqinisekisa ukusebenza kwesikhunta, futhi kunomthelela oqondile ekunembeni kokukhiqiza isikhunta, amandla esikhunta, impilo yokusebenza kwesikhunta, izindleko zokukhiqiza isikhunta, njll. Kusukela ngawo-1980, ukuthuthukiswa okusheshayo kobuchwepheshe bokwelapha ukushisa kwesikhunta ngamazwe kuye kwaba ubuchwepheshe bokwelashwa kokushisa kwe-vacuum, ubuchwepheshe bokuqinisa isikhunta kanye nobuchwepheshe bokubumba ngaphambi kokuqina.

Ubuchwepheshe bokwelapha ukushisa kwesikhunta

Ubuchwepheshe bokwelashwa kwe-vacuum wuhlobo olusha lobuchwepheshe bokwelapha ukushisa olwakhiwe eminyakeni yamuva nje. Inezici ezidingeka ngokushesha ekukhiqizweni kwesikhunta, njengokuvimbela ukushisisa kanye ne-oxidation kanye ne-non-decarburization, i-vacuum degassing noma i-degassing, kanye nokuqeda i-Hydrogen embrittlement kuthuthukisa ipulasitiki, ukuqina namandla okukhathala kwezinto (izingxenye). Ukushisisa kwe-vacuum okuhamba kancane kanye nomehluko omncane wezinga lokushisa phakathi kwengaphakathi nangaphandle kwezingxenye kunquma ukuwohloka okuncane kwezingxenye okubangelwa inqubo yokwelapha ukushisa kwe-vacuum.

Izicelo eziyinhloko ekwelashweni kokushisa kwe-vacuum kwesikhunta ukucisha uwoyela we-vacuum, ukucisha i-vacuum kanye ne-vacuum tempering. Ukuze kugcinwe izici ezinhle kakhulu zokushisa kwe-vacuum ye-workpiece (njengesikhunta), ukukhethwa nokwakhiwa kwesipholisa kanye nenqubo yokupholisa kubaluleke kakhulu. Inqubo yokucisha isikhunta ikakhulukazi isebenzisa ukupholisa uwoyela nokupholisa umoya. Ezindaweni zokusebenza zesikhunta ezingasakhiwa ngomshini ngemva kokwelashwa kokushisa, i-vacuum tempering kufanele isetshenziswe ngangokunokwenzeka ngemva kokucisha, ikakhulukazi ama-workpieces acinywe nge-vacuum (isikhunta), engathuthukisa izakhiwo zemishini ezihlobene nekhwalithi ephezulu, njengokusebenza kokukhathala, ukukhanya kwendawo, ukumelana nokugqwala, njll.

Ukuthuthukiswa okuphumelelayo kanye nokusetshenziswa kobuchwepheshe bokulingisa ikhompyutha yenqubo yokwelapha ukushisa kwenza ukwelashwa okuhlakaniphile kokushisa kwesikhunta kwenzeke. Ngenxa yeqoqo elincane (ngisho nocezu olulodwa), izici eziningi ezihlukahlukene zokukhiqiza isikhunta, kanye nezidingo eziphakeme zokusebenza kokwelashwa kokushisa kanye nezici zokungavumeli imikhiqizo yemfucuza, ukwelashwa kokushisa okuhlakaniphile kwesikhunta kuba yisidingo. Amazwe athuthukile ezimbonini zangaphandle, njenge-United States, Japan, njll., nawo athuthuke ngokushesha mayelana ne-vacuum kanye nokucisha igesi enomfutho ophezulu, ikakhulukazi eqondise isikhunta.

Isibungu ukwelashwa surface ubuchwepheshe

Ngaphezu kokuxhumana okunengqondo kwe-matrix enamandla aphakeme ngokwanele kanye nokuqina, izakhiwo ezingaphezulu zesikhunta zibaluleke kakhulu ekusebenzeni kokusebenza kanye nempilo yesevisi yesikhunta. Ubuchwepheshe bokwelapha obungaphezulu besikhunta ubunjiniyela obuhlelekile bokushintsha i-morphology, ukwakheka kwamakhemikhali, ukwakheka kanye nesimo sokucindezeleka kwendawo yesikhunta ngokusebenzisa ukumbozwa kwendawo, ukuguqulwa kwendawo noma ubuchwepheshe bokwelapha obuhlanganisiwe ukuze kutholwe izakhiwo ezidingekayo. Njengamanje, i-nitriding, carburizing kanye nokufakwa kwefilimu eqinile kusetshenziswa kakhulu ekukhiqizeni isikhunta.

Ngenxa yokuthi ubuchwepheshe be-nitriding bungakha ubuso obusebenza kahle kakhulu, futhi inqubo ye-nitriding kanye nenqubo yokucisha yensimbi yokufa inokuxhumana okuhle, ngesikhathi esifanayo, izinga lokushisa le-nitriding liphansi, futhi asikho isidingo sokupholisa okukhulu ngemva kwe-nitriding, futhi ukwakheka kwesikhunta kuncane kakhulu. Ukuqinisa ubuso ubuchwepheshe be-nitriding bangaphambili, futhi yibo obusetshenziswa kakhulu.

I-Mold carburizing ukuthuthukisa amandla kanye nokuqina kwesikhunta, okungukuthi, indawo yokusebenza yesikhunta inamandla aphezulu nokumelana nokugqoka. Ubuchwepheshe bokufakwa kwefilimu eqinile njengamanje i-CVD evuthiwe, i-PVD. Isikhunta simbozwe ngobuchwepheshe befilimu obuqinile kusukela ngawo-1980. Ngaphansi kwezimo zamanje zobuchwepheshe, izindleko zobuchwepheshe bokufakwa kwefilimu eqinile (ikakhulukazi okokusebenza) ziphezulu uma kuqhathaniswa, futhi zisasetshenziswa kuphela ekubunjweni okuthile okunembayo nokuphila isikhathi eside. Uma isikhungo sokwelapha ukushisa sisungulwa, izindleko zokumboza ifilimu eqinile zizoncishiswa kakhulu. , Uma isikhunta esiningi samukela lobu buchwepheshe, izinga eliphelele lokukhiqiza isikhunta ezweni lethu lingathuthukiswa.

Ubuchwepheshe bangaphambi kokuqina kwezinto zokubumba

Kusukela ngeminyaka yawo-1970s, umqondo wokwenza ukuqina kwangaphambilini usuphakanyiswe emhlabeni jikelele. Kodwa-ke, ngenxa yemingcele yokuqina kwethuluzi lomshini wokucubungula kanye nethuluzi lokusika, ubulukhuni be-pre-harding abukwazi ukufinyelela ubulukhuni besikhunta, ngakho-ke ukutshalwa kwezimali kwe-R & D kubuchwepheshe bangaphambi kokuqina akukukhulu. Ngokuthuthukiswa kokusebenza kwamathuluzi omshini wokucubungula kanye namathuluzi okusika, ukuthuthukiswa kobuchwepheshe bokuqina kwangaphambi kokuqina kwezinto zokubumba kuye kwashesha. Ngeminyaka yawo-1980, ingxenye yamazwe athuthukile ezimbonini zamazwe ngamazwe asebenzisa amamojula aqiniswe ngaphambili ezintweni zokubunjwa kwepulasitiki yase ifinyelele ku-30% (okwamanje Ngaphezu kwama-60%).

Ubuchwepheshe bangaphambi kokuqina bezinto zokubumba ezweni lami bunesiqalo sekwephuzile kanye nesilinganiso esincane, futhi okwamanje abukwazi ukuhlangabezana nezidingo zokukhiqiza isikhunta sasekhaya. Ukusetshenziswa kwezinto zokubumba eziqiniswe ngaphambili kungenza inqubo yokukhiqiza isikhunta ibe lula, kufinyeze umjikelezo wokukhiqiza isikhunta, futhi kuthuthukise ukunemba kokukhiqiza kwesikhunta. Kuyaqapheleka ukuthi ngokuthuthuka kobuchwepheshe bokucubungula, izinto zokubumba eziqiniswe ngaphambili zizosetshenziswa ezinhlotsheni eziningi zokukhunta.

Xhumanisa nale ndatshana: Isimo samanje nokuthuthuka kobuchwepheshe bokwelashwa kokushisa kwesikhunta

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

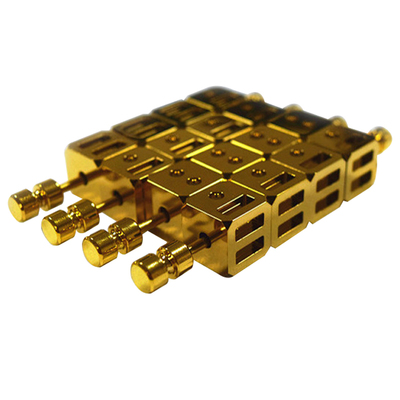

I-PTJ® ingumkhiqizi owenziwe ngezifiso ohlinzeka ngohlu olugcwele lwemigoqo yethusi, izingxenye zethusi futhi izingxenye zethusi. Izinqubo zokukhiqiza ezijwayelekile zifaka ukuvala, ukufaka imbossing, ukwenza i-coppersmithing, wire edm amasevisi, ukuhuba, ukubumba nokugoba, ukucasula, kushisa UKWAKHA nokucindezela, ukubhoboza nokubhoboza, ukugingqa intambo nokuguqa, ukugunda, imishini eminingi yokuphotha, i-extrusion kanye ukubumba insimbi futhi uyanyathela. Izicelo zifaka amabha amabhasi, amakhondakta kagesi, izintambo ezinamagagasi, amagagasi, izingxenye ze-transistor, amashubhu e-microwave, amashubhu esikhunta angenalutho, kanye i-powder metallurgy amathangi e-extrusion.

I-PTJ® ingumkhiqizi owenziwe ngezifiso ohlinzeka ngohlu olugcwele lwemigoqo yethusi, izingxenye zethusi futhi izingxenye zethusi. Izinqubo zokukhiqiza ezijwayelekile zifaka ukuvala, ukufaka imbossing, ukwenza i-coppersmithing, wire edm amasevisi, ukuhuba, ukubumba nokugoba, ukucasula, kushisa UKWAKHA nokucindezela, ukubhoboza nokubhoboza, ukugingqa intambo nokuguqa, ukugunda, imishini eminingi yokuphotha, i-extrusion kanye ukubumba insimbi futhi uyanyathela. Izicelo zifaka amabha amabhasi, amakhondakta kagesi, izintambo ezinamagagasi, amagagasi, izingxenye ze-transistor, amashubhu e-microwave, amashubhu esikhunta angenalutho, kanye i-powder metallurgy amathangi e-extrusion.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi