Izici Of CNC Turning Technology

Yiziphi izici ze-CNC ukuvula ubuchwepheshe?

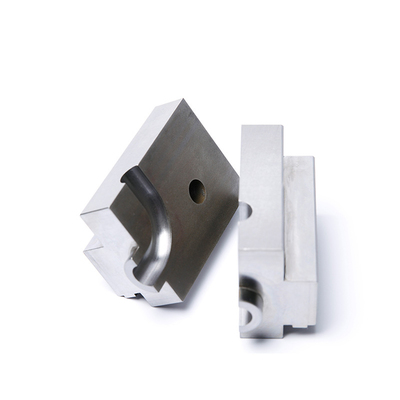

| Ukuguqula kuyindlela yokusika okokusebenza ku-lathe usebenzisa i-workpiece ehlobene nokujikeleza kwethuluzi. Ukuguqula kuyindlela elula kakhulu futhi ejwayelekile yokusika. Umsebenzi omningi onendawo ejikelezayo ungenziwa ngomshini ngokuphenduka, okufana nendawo yangaphakathi neyangaphandle eyindilinga, indawo eyindilinga yangaphakathi nangaphandle, ubuso bokugcina, imisele, imicu kanye nendawo yokwakha ejikelezayo. Izinsika ezijwayelekile zingahlukaniswa zibe izendlalelo ezivundlile, izihlalo ezisezingeni eliphansi, izihlalo eziqonde mpo, izihlakala ze-turret, nezindawo zokuphrinta, iningi lazo okuyizintambo eziqondile. |

Ngenxa yokuthuthuka kwesayensi nobuchwepheshe besimanje, kusetshenziswa izinto ezahlukahlukene zobunjiniyela obuphezulu nobulukhuni. Ubuchwepheshe bokujika bendabuko bunzima noma abunakwenzeka ukubona ukucutshungulwa kwezinto ezithile ezinamandla aphezulu nobulukhuni. Ubuchwepheshe bokujika kanzima benza lokhu kwenzeke futhi buletha izinzuzo ezinkulu ekukhiqizeni.

Isingeniso sezimpawu zokuphenduka

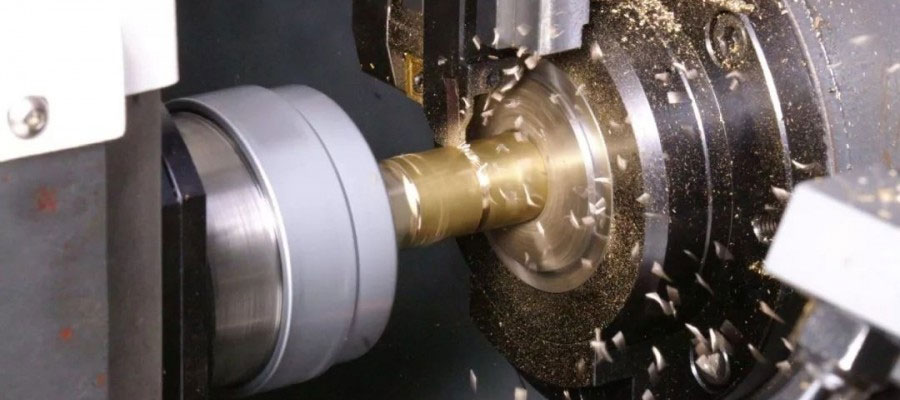

(1) Ukuphenduka okuphezulu

Ukuguqula kunekhono eliphakeme kunokugaya. Ukuguqula kuvame ukusebenzisa ijubane elikhulu lokusika nesivinini sokusebenza. Izinga lokususwa kwensimbi livame ukuphindwa kaningana lelo lokugaya. Ukuqinisa isikhathi esisodwa kungaqedela ukwenziwa kwemishini ehlukahlukene ngesikhathi sokujika, ngenkathi ukugaya kudinga ukufakwa okuningi, ngakho-ke isikhathi sokusiza sifushane futhi ukunemba kwesimo phakathi kwezindawo ezenziwe ngomshini kuphezulu.

(2) Izindleko zokufaka eziphansi

Lapho umkhiqizo ufana, utshalomali lwe-lathe ngokusobala lungcono kunomshini wokugaya, futhi izindleko zohlelo olusizayo nalo luphansi. Ukukhiqizwa okuncane kwe-batch, ukuphenduka akudingi imishini ekhethekile, kanti ukwenziwa kwevolumu ephezulu yezingxenye ezinemba kahle kudinga imishini ye-CNC ngokuqina okuhle, ukubeka ngokunemba nokuphindaphinda okuphezulu.(3) Ifanele amaqoqo amancane

Ukukhiqizwa okuguquguqukayo kudinga ukuthi i-lathe uqobo luyindlela yokucubungula eguquguqukayo enebanga lokucubungula elibanzi. I lathe kulula ukusebenza futhi ukuvula kanye clamping kuyashesha. Uma kuqhathaniswa nokugaya, ukujika kanzima kungahlangabezana kangcono nezidingo zokukhiqizwa okuguquguqukayo.(4) Ukujika kanzima kungafinyelela ukunemba okuhle kwemishini jikelele yezingxenye

Iningi lokushisa okukhiqizwa ekuphendukeni kanzima kususwa ngamafutha okusika. Akukhiqizi ukusha komhlaba nemifantu njengokugaya. Inekhwalithi ephezulu kakhulu yobuso nokuzungeza okuqondile. Ingaqinisekisa izinga eliphakeme phakathi kwezindawo ezenziwe ngomshini. Ukunemba kwesimo.

Izinto zokuvula amathuluzi nokukhethwa kwazo

(1) Camera carbide ithuluzi

Amathuluzi we-carbide ahlanganisiwe aboshwe ngendwangu eyodwa noma ngaphezulu yokuqina kokugqoka okuhle kumathuluzi anzima we-carbide. Ukumboza kuvame ukudlala izindima ezimbili ezilandelayo: ngakolunye uhlangothi, kunethuluzi elithile I-coefficient yokudlulisa ukushisa ephansi kakhulu ye-substrate nezinto zokusebenza zomsebenzi kunciphisa isenzo sokushisa kwesisekelo sethuluzi; ngakolunye uhlangothi, ingathuthukisa ngempumelelo ukungqubuzana nokunamathela kwenqubo yokusika futhi inciphise ukukhiqizwa kokushisa okusika. Uma kuqhathaniswa namathuluzi we-carbide ahlanganisiwe, amathuluzi e-carbide ahlanganisiwe anikela ngokuthuthuka okuphawulekayo emandleni, ubulukhuni nokuqina kokugqoka.

(2) Ceramic impahla umsiki

Imimese ye-Ceramic inezici zobulukhuni obuphakeme, amandla aphakeme, ukumelana okuhle kokugqoka, ukuqina kwamakhemikhali okuhle, ukusebenza okuhle kokulwa nokuvinjelwa, inani eliphansi lokungqubuzana nentengo ephansi. Uma isetshenziswa ngokujwayelekile, ihlala isikhathi eside ngokwedlulele futhi ingashesha izikhathi eziningana kune-carbide enosimende. Kuyinto efanelekayo ikakhulukazi ubulukhuni impahla ukucutshungulwa, kokuqeda futhi ngesivinini machining.

(3) Umsiki we-Cubic boron nitride

Ubulukhuni nokugqokwa kokuqina kwe-cubic boron nitride kungokwesibili kudayimane kuphela, futhi kunobulukhuni obuhle kakhulu bokushisa okuphezulu. Uma kuqhathaniswa namathuluzi e-ceramic, ukumelana nokushisa kwawo kanye nokuqina kwamakhemikhali kuncane kakhulu, kepha amandla okuthelela nokulwa nokuchoboza kungcono. Isetshenziswa kabanzi ekusetshenzisweni kwensimbi eqinile, i-pearlitic grey iron iron, i-chilled cast iron kanye nama-alloys okushisa okuphezulu, futhi ijubane layo lokusika lingakhuphuka nge-oda lobukhulu uma liqhathaniswa namathuluzi we-carbide aqinisiwe.

Ukukhethwa kukawoyela wokusika

- (1) Abasiki bensimbi yamathuluzi banokumelana nokushisa okuncane futhi balahlekelwe ukuqina emazingeni okushisa aphezulu. Ngakho-ke, kuyadingeka ukusebenzisa uwoyela wokusika ngokusebenza okuhle kokupholisa kanye ne-viscosity ephansi.

- (2) Uma kusetshenziswa amathuluzi okusika insimbi enejubane elikhulu ukusika okwejubane, inani lokusika likhulu futhi kwenziwa inani elikhulu lokushisa okusika, futhi kufanele kusetshenziswe uwoyela wokupholisa onezindawo zokupholisa ezinhle. Uma kusetshenziswa amathuluzi wensimbi yejubane elikhulu ukuqedela okuphakathi nokwejubane, uwoyela wokusika we-viscosity ovame ukusetshenziselwa ukunciphisa isibopho sokuxabana phakathi kwethuluzi nendawo yokusebenza, cindezela ukwakheka kwesigaxa sokusika, futhi uthuthukise ukunemba kwemishini.

- (3) Amathuluzi e-carbide ahlanganisiwe anendawo yokuncibilika nobulukhuni, ukuzinza okungcono kwamakhemikhali nokushisa, nokusika nokugqoka okungcono kunamathuluzi wensimbi asheshayo. Amafutha okusika isulfure asebenzayo angasetshenziswa ekucubunguleni jikelele. Uma kungukusika okusindayo, izinga lokushisa lokusika liphakeme kakhulu, futhi kulula ukugqoka ithuluzi ngokushesha okukhulu. Ngalesi sikhathi, kufanele kukhethwe u-oyela wokusika ongasebenzi ongasebenzi futhi izinga lokugeleza kukawoyela wokusika kufanele lenyuswe ukuqinisekisa ukupholisa okwanele nokuthambisa.

- (4) Amathuluzi we-Ceramic, amathuluzi wedayimane namathuluzi we-cubic boron nitride anokuqina okuphezulu nokuqina kokugqoka. I-low-viscosity uwoyela wokusika ongasetshenziswanga uvame ukusetshenziselwa ukusika ukuqinisekisa ukuphela kwento yomsebenzi.

Xhumanisa nale ndatshana: Izici Of CNC Turning Technology

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi