Yiziphi izidingo zobuchwepheshe okufanele zilandelwe uma kwenziwa imishini

Ngokwamakhono okucubungula imishini, kuphela ngokuhambisana nalezi zidingo zamakhono lapho imikhiqizo ecutshunguliwe ingaba sezingeni futhi inengqondo. Izidingo zamakhono ezinemininingwane zimi kanje

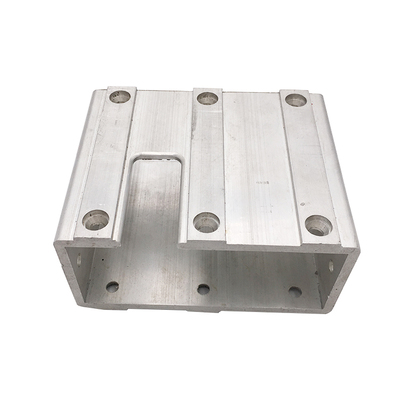

(1) Ukubukeka okucutshunguliwe kwezingxenye akumele kube namaphutha njengokuklwebheka nokuklwebheka okulimaza ukubukeka kwezingxenye.

(2) Khipha isikali se-oxide ezingxenyeni.

(3) Izisebenzi zikahulumeni efomini elingajovwe zizohlangabezana nezimfuneko ze-GB1184-80, futhi iphutha okuvunyelwene ngalo lesikali sobude obungajovwe ngu-±0.5mm.

(4) Ibhande elisemthethweni lokusakaza liyalingana nezinto ezisetshenziswayo ezijwayelekile zokulingisa okungenalutho.

(5) Faka ukugoqa ezivezas, futhi kuvunyelwene ukuthi kusetshenziswe amafutha ukufudumeza, futhi izinga lokushisa likawoyela akufanele lidlule ku-100°C.

(6) Lapho ufaka uhlelo lwe-hydraulic, kuvunyelwene ukuthi kusetshenziswe izithasiselo zokuvala ama-sealants, kodwa kufanele zivinjelwe ukungena ohlelweni.

(7) Izingxenye kanye nezingxenye ezifaka ukufakwa zidinga ukuhlola isitifiketi sokuvumelana sengxenye.

(8) Izingxenye kufanele zihlanzwe ngaphambi kokufakwa, futhi akufanele kube nama-burrs, ukukhanya, izikhumba ze-oxide, ukugqwala, ama-chips, amabala kawoyela, ama-colorants, uthuli, njll.

(9) Ngaphambi kokufaka, buyekeza isikali sokubambisana esiyinhloko sezingxenye nezingxenye, ikakhulukazi isikali sokubambisana esidlulele nokunemba okuhlobene.

(10) Phakathi nenqubo yokufaka, izingxenye akufanele zingqubuzane, zingqubuzane, zilimale, noma zigqwale.

(11) Uma kuqiniswa izikulufu, amabhawodi namantongomane, akuvumelekile ukuthinta noma ukusebenzisa izinto ezisetshenziswayo eziphendukayo ezingafanele kanye nama-wrenches. Ngemva kokuqiniswa, ungalimazi izikulufo, amantongomane nezikulufu, namakhanda ebhawodi.

(12) I-torque yokuqinisa edingekayo ngokomthetho idinga ukuba kukhethwe isikrufu se-torque, futhi i-torque yokuqinisa kufanele iqiniswe ngokomthetho.

(13) Ngemva kokubopha, khipha ingcina esele egeleza iphume.

(14) Izimbobo eziyisiyingi zeringi yangaphandle yeringi kanye nesihlalo esivulekile nesivalo akumele kuvinjwe. Iringi yangaphandle ye-bearing kanye nembobo eyisiyingi yesihlalo esivulekile sokuthwala kanye nesembozo sokuthwala kunokuthintana okuhle. Uma ihlolwa ngombala, ilingana nomugqa omaphakathi wesihlalo esiphethe. 120°, ukuthintana okufanayo nekhava ethwele ngaphakathi kwebanga elingu-90° elilinganayo emugqeni omaphakathi. Uma uhlola nge-feeller gauge phakathi kobubanzi obungenhla, i-feeller gauge engu-0.03mm akufanele ifakwe ku-1/3 yobubanzi bendandatho yangaphandle.

(15) Ngemva kokufaka indandatho yangaphandle ye-bearing, kufanele ihlangane ngokufanayo nobuso bokuphela kwesigqoko sokuthwala sokuphela kokuma.

(16) Ngemva kokufakwa kwe-rolling bear, ingagoqwa ngendlela eguquguqukayo futhi iqine ngesandla.

(17) Izindawo ezihlangene zezihlahla ezithwalayo ezingaphezulu nangaphansi zisondelene futhi azikwazi ukubonakala ngegeji yokuzizwa engu-0.05mm.

(18) Lapho ulungisa isihlahla esithwalayo ngephini lokubeka, qiniseka ukuthi ubuso obuvulayo kanye nokuvala kanye nezinkwa zokuvala zesokhethi nobuso bokuphela kwembobo yokubhoboza efanele ziyalingana. Ihinge nokuthengisa ngeke kukhululwe ngemva kokukhansela.

(19) Izingqimba ezinengxubevange azivunyelwe ukusetshenziswa uma ziphuzi ngokubukeka. Umthetho uwukuthi i-nucleation phenomenon ayivunyelwe ngaphakathi kwe-engeli yokuthinta, futhi indawo ye-nucleation ngaphandle kwe-engeli yokuthinta akufanele idlule u-10% wendawo yonke yendawo engathinteki.

(20) Ubuso bokuphela kwenkomba be igiya (umsunu igiya)** ihambisana nehlombe (noma ubuso bokugcina bomkhono obeka endaweni), futhi ayikwazi ukubonakala ngegeji yokuzizwa engu-0.05mm. Qinisekisa izimfuneko ze-perpendicularity zobuso besiphetho sesithenjwa se- igiya kanye ne-eksisi.

(21) Hlola ngokuqinile amakhona abukhali, ama-burrs nezinto zangaphandle ezisele ngesikhathi sokucutshungulwa kwezingxenye ngaphambi kokuhlanganisa futhi uzisuse. Qinisekisa ukuthi uphawu ngeke lonakale lapho uphawu lufakiwe.

(22) Ukubonakala kwe-castings akuvumelani neziphambeko zokuhlukanisa okubandayo, ukuqhekeka, izimbobo ezinciphayo, amaphutha angena ngaphakathi kanye nomonakalo omkhulu.

(23) Ukufakwa kwe-casting kufanele kuhlanzwe, kungabi nama-burrs kanye nokubaneka. Ukuphuma okukhonjiswe ngokungacutshungulwa kufanele kube bushelelezi ngokubukeka kwama-castings.

(24) Ukulingisa nokumaka kokubukeka okungacutshunguliwe kokulingisa kufanele kukhonjwe ngokucacile, futhi indawo nefonti kufanele kuhlangabezane nezimfuneko zephethini.

25

(26) Isihlabathi esibumbayo, isihlabathi esiwumgogodla kanye nethambo eliwumgogodla ekubunjweni kufanele kususwe.

(27) Ama-castings anezingxenye ezigobile, futhi amabhande awo asemthethweni kufanele ahlonyiswe ngokulinganayo eduze kwendiza etshekile.

(28) Lungisa uhlobo olulungile nolungalungile, ukuchezuka kokuqondisa komphathi, njll., ukuze kuzuzwe inguquko ebushelelezi nokuqinisekisa ikhwalithi yokubukeka.

(29) Ubuso bokubunjwa kufanele bushelelezi, futhi isango, i-burr, isihlabathi, njll. kufanele kukhishwe.

(30) Ukusakaza akuthembisi ukukhubazeka kokuphonsa njengezithiyo ezibandayo, ukuqhekeka, izimbobo, njll. okuzolimaza ukusetshenziswa.

(31) Ngaphambi kokufafaza, ukubonakala kwayo yonke imikhiqizo yensimbi edinga ukufafazwa idinga ukususwa ekugqwaleni, esikalini se-oxide, kugrisi, uthuli, inhlabathi, usawoti, nokungcola.

(32) Ukubukeka okungacutshungulwanga kokulingisa komkhiqizo oyimishini kudinga ukuchama okudutshulwa noma ukwelashwa ngamarola ukuze kuhlangatshezwane nezimfuneko zeleveli ye-Sa21/2 yokuhlanzeka.

Xhumanisa nale ndatshana: Yiziphi izidingo zobuchwepheshe okufanele zilandelwe uma kwenziwa imishini

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

I-PTJ® ingumkhiqizi wangokwezifiso ohlinzeka ukulungisa okucacile nokuqondisa umphiniukufaka isicelo samanzi ahlanzekile namanzi olwandle olwandle. Bonke bakhona inkambiso yensimbi yangokwezifiso futhi fastener. Amakhono okukhiqiza ahlanganisa 5 Axis Precision Machining Izingxenye Zethusi, igiya ukusika, CNC Milling, I-CNC Lathing, ukuphefumula, CNC yokumba, ukuzilibazisa, ukucija, nokwakheka kwangaphakathi nangaphandle. Ezinye izinkonzo zihlanganisa ukuqeda, ukulola, ukugaya, ukufaka imicu, amaphethelo acijile, ukuchama, ukuqondisa nokusaha. Ukhiye werediyasi usikwa ngokuya ngokucaciswa. I umphini uhlelo lucutshungulwa lube yi-SAE J755 ejwayelekile.

I-PTJ® ingumkhiqizi wangokwezifiso ohlinzeka ukulungisa okucacile nokuqondisa umphiniukufaka isicelo samanzi ahlanzekile namanzi olwandle olwandle. Bonke bakhona inkambiso yensimbi yangokwezifiso futhi fastener. Amakhono okukhiqiza ahlanganisa 5 Axis Precision Machining Izingxenye Zethusi, igiya ukusika, CNC Milling, I-CNC Lathing, ukuphefumula, CNC yokumba, ukuzilibazisa, ukucija, nokwakheka kwangaphakathi nangaphandle. Ezinye izinkonzo zihlanganisa ukuqeda, ukulola, ukugaya, ukufaka imicu, amaphethelo acijile, ukuchama, ukuqondisa nokusaha. Ukhiye werediyasi usikwa ngokuya ngokucaciswa. I umphini uhlelo lucutshungulwa lube yi-SAE J755 ejwayelekile.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi