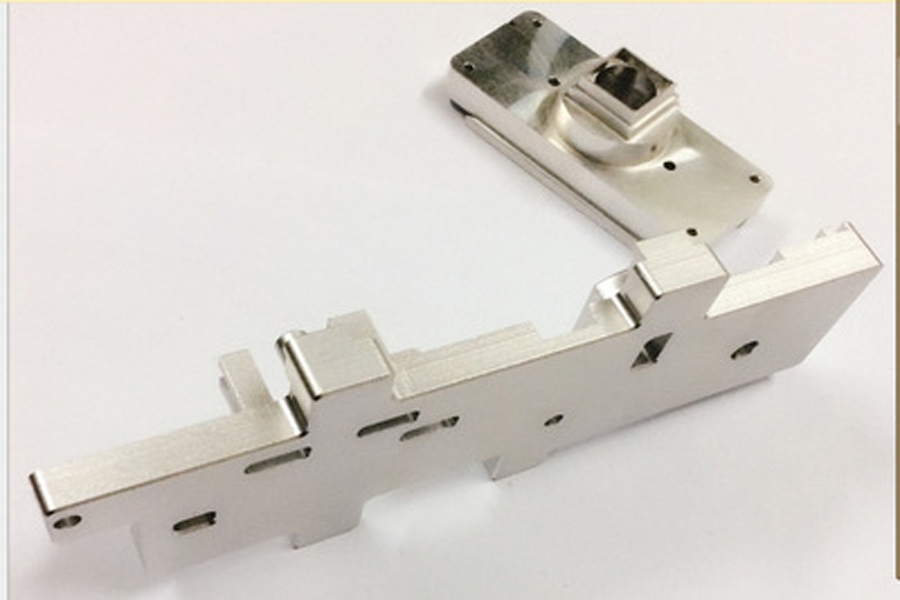

Ukucutshungulwa okwenziwe ngokwezifiso kwezimbobo ezincane ze-tungsten zensimbi yomshini wokushisela webhola le-solder

I-tungsten steel nozzle yomshini wokushisela ibhola le-solder yenziwe ngokwezifiso ngezimbobo ezincane ezinembayo. I-PTJ tungsten steel processing inikeza ukukhiqizwa okunembayo kwe-tungsten steel nozzle yomshini wokushisela ibhola le-solder. Isetshenziswa ngokomsebenzi ukusoda nge-laser nokufutha nge-laser.

I-tungsten steel nozzle esetshenziswa emshinini wokushisela ibhola le-solder isekelwe ekusebenzeni kwempilo ye-laser solder ibhola le-welding kanye nezidingo zosayizi wokunemba. Ukuthuthukiswa kokusebenza kwempahla yamathuluzi kanye nemininingwane yenqubo kuyindlela ephumelelayo yokuthuthukisa ukusebenza kahle kokukhiqiza kanye nesivuno. Imishini yebhola ye-laser solder ikakhulukazi ihlanganisa inqubo ye-laser soldering kanye nenqubo yokufafaza nge-laser. I-laser spray soldering isetshenziswa embonini ye-elekthronikhi enezidingo zokunemba okuphezulu, njengemboni ye-microelectronics, imojuli yekhamera enencazelo ephezulu, ikhamera yedijithali yekhamera ethambile yokuxhuma iphuzu lokuxhuma, idivayisi yokulawula izwi ngokunemba, umugqa wedatha welding point welding, inzwa yokushisela, I-aerospace high precision Welding of electronic products, njll. I-laser spray tin welding system yemishini yokushisela ye-laser entsha isebenzisa ubuchwepheshe bokuhlanganiswa kwebhola le-laser spray solder inezinzuzo zokungathintani, akukho mshini, ukushisa okuphansi, i-solder enembile futhi elawulekayo, njll. I-tungsten steel nozzle isetshenziswa njengesesekeli esiyinhloko somsebenzi wesikole wokuqeda imishini ye-laser soldering.

Ukusebenza kwe-laser solder ball welding kanye nokusebenza kwe-laser solder ball jetting kudinga i-tungsten steel processing solder ball nozzles. Imibhobho yensimbi ye-tungsten imelana nokushisa okuphezulu futhi inempilo ende. Imibhobho ye-carbide enosimende, imibhobho yensimbi ye-tungsten, i-substrate iyinsimbi eqinile ye-tungsten elungiselelwe i-powder metallurgy ubuchwepheshe, obunobuhle bamandla aphezulu, ubulukhuni obuphezulu, ukumelana nokugqoka, ukumelana nokugqwala, ukumelana nezinga lokushisa eliphezulu, kanye ne-coefficient encane yomugqa wokwandisa. Isetshenziswa kabanzi ekukhiqizeni izimboni kanye nokusebenza kokucubungula. Izinto zensimbi ze-Tungsten zinokuzinza okuhle ngokomzimba, ikakhulukazi lapho kudingeka ukusebenza isikhathi eside ekushiseni okuphezulu nokumelana nokugqwala. Umkhiqizo oqediwe we-tungsten steel nozzle womshini wokushisela ibhola le-solder ngemuva kokukhiqizwa okunembayo nokucubungula unokuphila okuhle kwenkonzo. Ukukhiqizwa kwensimbi ye-Tungsten kanye nokucubungula i-laser tin Ukusebenza kahle kwe-nozzle yebhola akuqhathaniswa nezinye izinto zamathuluzi.

Imibhobho yensimbi ye-Tungsten yomshini wokushisela amabhola kathini enziwa ngokwezifiso ngezimbobo ezincane ezinembayo, futhi ukunemba kwensimbi ye-PTJ tungsten kukhiqiza imibhobho yebhola likathayela. Ngokwezidingo zemidwebo yemishini yomshini wokushisela we-laser, izimbobo ezincane ze-tungsten steel nozzles zenziwe ngokwezifiso futhi zicutshungulwe. Ubukhulu kanye nomthamo we-micro-hole ye-tungsten steel nozzle kunqunywa ngokuvumelana nezidingo ezahlukene zebhola le-tin 150um ~ 350um ~ 760um. Imilomo yensimbi ye-tungsten enembile idinga izindonga zangaphakathi ezibushelelezi. Imibhobho yensimbi ye-tungsten ye-laser soldering cemented carbide nozzles ikakhulukazi idinga ukuqedwa okuhle ukuze kuqinisekiswe impilo yokusebenza ehlala isikhathi eside. Zama ukugwema ukunamathela kukathini emsebenzini isikhathi eside. Umbhobho wenziwa ngensimbi ye-tungsten yekhwalithi ephezulu, enokuqina okuhle nokuqedwa kwendawo. Uma ufutha amabhola e-solder, ngenxa yokuqeda okuphezulu kwe-nozzle, amabhola e-solder angadutshulwa kahle ngaphandle kwe-nozzle futhi akulula ukuvimba ukuvulwa kwe-nozzle.

Xhumanisa nale ndatshana: Ukucutshungulwa okwenziwe ngokwezifiso kwezimbobo ezincane ze-tungsten zensimbi yomshini wokushisela webhola le-solder

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

I-PTJ® ingumkhiqizi wangokwezifiso ohlinzeka ukulungisa okucacile nokuqondisa umphiniukufaka isicelo samanzi ahlanzekile namanzi olwandle olwandle. Bonke bakhona inkambiso yensimbi yangokwezifiso futhi fastener. Amakhono okukhiqiza ahlanganisa 5 Axis Precision Machining Izingxenye Zethusi, igiya ukusika, CNC Milling, I-CNC Lathing, ukuphefumula, CNC yokumba, ukuzilibazisa, ukucija, nokwakheka kwangaphakathi nangaphandle. Ezinye izinkonzo zihlanganisa ukuqeda, ukulola, ukugaya, ukufaka imicu, amaphethelo acijile, ukuchama, ukuqondisa nokusaha. Ukhiye werediyasi usikwa ngokuya ngokucaciswa. I umphini uhlelo lucutshungulwa lube yi-SAE J755 ejwayelekile.

I-PTJ® ingumkhiqizi wangokwezifiso ohlinzeka ukulungisa okucacile nokuqondisa umphiniukufaka isicelo samanzi ahlanzekile namanzi olwandle olwandle. Bonke bakhona inkambiso yensimbi yangokwezifiso futhi fastener. Amakhono okukhiqiza ahlanganisa 5 Axis Precision Machining Izingxenye Zethusi, igiya ukusika, CNC Milling, I-CNC Lathing, ukuphefumula, CNC yokumba, ukuzilibazisa, ukucija, nokwakheka kwangaphakathi nangaphandle. Ezinye izinkonzo zihlanganisa ukuqeda, ukulola, ukugaya, ukufaka imicu, amaphethelo acijile, ukuchama, ukuqondisa nokusaha. Ukhiye werediyasi usikwa ngokuya ngokucaciswa. I umphini uhlelo lucutshungulwa lube yi-SAE J755 ejwayelekile.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi