Insimbi ye-Tungsten faka ukukhiqizwa kwenaliti ngokunemba insimbi ye-tungsten faka ukucubungula inaliti

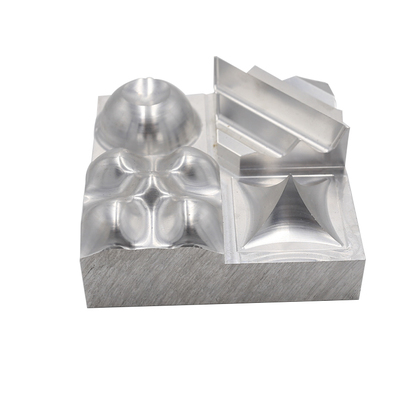

Ukufakwa kwensimbi ye-Tungsten kukhiqiza ukucutshungulwa kokufakwa kwensimbi okunembayo, i-PTJ tungsten steel processing ihlinzeka ngokunemba okufakiwe kwensimbi ye-tungsten okwenziwe ngokwezifiso, okusetshenziselwa ngokomsebenzi izingxenye zemishini zokubumba.

Ukusetshenziswa kwezinto ezisetshenziswayo kuyisidingo sokukhiqizwa kwezimboni ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza kanye namazinga. Njengokufakwa okuhambisanayo kokubumba okunembayo, okufakiwe kwensimbi ye-tungsten okucutshungulwa ngensimbi ye-tungsten kunokusebenza okuhle. Njengokufakwa kwe-carbide enosimende esetshenziswa ekubunjweni okunembayo, ukuhambisana komkhiqizo kuyisici esibalulekile, esizothinta ngokuqondile impilo yesevisi yesikhunta kanye nokunemba kobukhulu bomkhiqizo. Ukufakwa kwensimbi ye-Tungsten kukhiqiza ukucutshungulwa kokufakwa kwensimbi okunembayo kwe-tungsten, futhi izidingo zokunemba kobukhulu bokufakwa ngakunye kwe-carbide enosimende kudingeka ukuthi zihambisane ngokuvumelana nemidwebo ukuze kuhlangatshezwane nezidingo zokunemba zokukhiqiza nokusetshenziswa kwemishini yokubumba. Uma isisebenzi sifuna ukwenza kahle, kufanele siqale silole amathuluzi aso. Izinto ezinhle ze-alloy zicutshungulwa ngokunemba kanye nensimbi ye-tungsten ecophelelayo ukuze kuqedelwe ukufakwa kwesikhunta. Umkhiqizo oqediwe udlula idatha yokuhlola enobukhulu futhi uhlangabezana nezimfuneko zokubekezelela imidwebo. Yonke inqubo idinga ukuqina futhi isebenze ukuze kuqinisekiswe ukuthi usayizi ngamunye ongu-A uhlangabezana nezidingo zomdwebo. Ukufakwa kwensimbi ye-Tungsten kukhiqiza ukufakwa kwensimbi okunembayo kwe-tungsten okufanelekile futhi kushiye imboni. Umbiko wedatha yokuhlola uhlinzekwa ukusiza ukuhlola nokuqinisekiswa kwangempela kwamakhasimende. Lokhu akudingi nje ubukhulu bokufakwa kwensimbi ye-tungsten ukuhlangabezana nokubekezelelana, kodwa futhi kudinga ukuthi ukufakwa ngakunye okwenziwe ngensimbi ye-tungsten ngokusho kosayizi womdwebo kuhlangabezane nokufana.

Isikhunta siyisidingo esidingekayo ekusebenzeni kwenqwaba ekukhiqizweni kwezimboni, ikakhulukazi i-value-added, ukunemba okuphezulu kuyisidingo sokuqala sokuthuthukisa ukusebenza kahle kokukhiqiza. Izingxenye ezinembayo ezidingekayo ukuze kwenziwe isikhunta esinembayo esisezingeni eliphezulu ziyingxenye ebalulekile yokusebenza kwayo okuvamile, ikakhulukazi izinsimbi ze-tungsten ezidingekayo ukuze kwenziwe imisebenzi ethile enembile. Ukufakwa kwensimbi ye-Tungsten kukhiqiza ukucutshungulwa kwensimbi ye-tungsten enembile. Ngokwezidingo zokuklama nokusetshenziswa kwemishini yokubumba, hlinzeka ngokufaka isikhunta sensimbi ye-tungsten ngaphambili, ukufaka isikhunta sensimbi ye-tungsten ngemuva, ukufaka isikhunta sensimbi ye-tungsten enyakazayo, ukufakwa kwesikhunta esingaguquki sensimbi ye-tungsten, ukufakwa kwesilayidi sensimbi ye-tungsten, ukufakwa kwesikhunta sensimbi ye-tungsten nokunye ukunemba kwesikhunta. ifaka.

Njengomkhiqizi wensimbi ye-tungsten e-China, sizibophezele ekuhlinzekeni ngokunemba imikhiqizo ecutshungulwe yensimbi ye-tungsten yemishini nemishini. Insimbi ye-Tungsten steel ikhiqiza ukucutshungulwa kokufakwa kwensimbi okunembayo kwe-tungsten, okufakwe ngokunemba kwe-PTJ carbide kwenziwa ngendlela oyifisayo, futhi usayizi we-micro-diameter ungahlangabezana nezidingo zokufakwa kwesikhunta emuva okungu-Φ0.013, Φ0.02 okufakwa isikhunta esingashintshi, kanye Φ0.04 Uchungechunge lwe-tungsten ukufakwa kwensimbi ngokubekezelela okunembayo okufana nokufaka okufa okuhambayo, Φ0.128 okufakwayo okwenza, Φ0.67 ukufakwa okuphindwe kabili, njll., ukubekezelelana kokunemba kuhlangabezana no-± 0.002, futhi izidingo ezikhethekile zokubekezelela zingahlangabezana ne-±0.0005. Yiqiniso, uma ziphakeme izidingo zokubekezelela ngokunemba zokucubungula insimbi ye-tungsten, izindleko ezihambisanayo zokucubungula zizoba phezulu kakhulu.

Xhumanisa nale ndatshana: Insimbi ye-Tungsten faka ukukhiqizwa kwenaliti ngokunemba insimbi ye-tungsten faka ukucubungula inaliti

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

I-PTJ® ingumkhiqizi wangokwezifiso ohlinzeka ukulungisa okucacile nokuqondisa umphiniukufaka isicelo samanzi ahlanzekile namanzi olwandle olwandle. Bonke bakhona inkambiso yensimbi yangokwezifiso futhi fastener. Amakhono okukhiqiza ahlanganisa 5 Axis Precision Machining Izingxenye Zethusi, igiya ukusika, CNC Milling, I-CNC Lathing, ukuphefumula, CNC yokumba, ukuzilibazisa, ukucija, nokwakheka kwangaphakathi nangaphandle. Ezinye izinkonzo zihlanganisa ukuqeda, ukulola, ukugaya, ukufaka imicu, amaphethelo acijile, ukuchama, ukuqondisa nokusaha. Ukhiye werediyasi usikwa ngokuya ngokucaciswa. I umphini uhlelo lucutshungulwa lube yi-SAE J755 ejwayelekile.

I-PTJ® ingumkhiqizi wangokwezifiso ohlinzeka ukulungisa okucacile nokuqondisa umphiniukufaka isicelo samanzi ahlanzekile namanzi olwandle olwandle. Bonke bakhona inkambiso yensimbi yangokwezifiso futhi fastener. Amakhono okukhiqiza ahlanganisa 5 Axis Precision Machining Izingxenye Zethusi, igiya ukusika, CNC Milling, I-CNC Lathing, ukuphefumula, CNC yokumba, ukuzilibazisa, ukucija, nokwakheka kwangaphakathi nangaphandle. Ezinye izinkonzo zihlanganisa ukuqeda, ukulola, ukugaya, ukufaka imicu, amaphethelo acijile, ukuchama, ukuqondisa nokusaha. Ukhiye werediyasi usikwa ngokuya ngokucaciswa. I umphini uhlelo lucutshungulwa lube yi-SAE J755 ejwayelekile.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi