Izibonelo eziningiliziwe ze-Shaft Machining Technology

Izibonelo eziningiliziwe ze-Shaft Machining Technology

| Ukwakhiwa kokucaciswa kwenqubo kufayela le- umphini izingxenye zihlobene ngqo nekhwalithi yomsebenzi, ukukhiqizwa kwabasebenzi kanye nezinzuzo zezomnotho. |

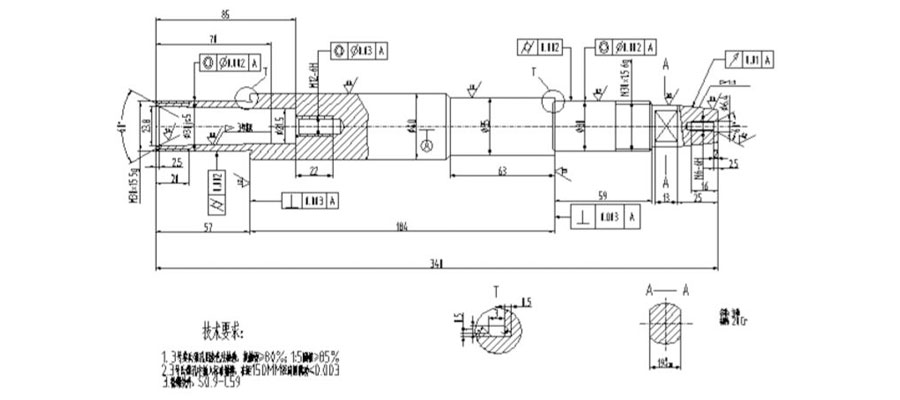

Ukuphendula izidingo ezingenhla, okulandelayo kuyisibonelo. Uthi lokuphotha (oluboniswe ngenhla), izingcezu ezingama-40 ngeqoqo ngalinye, okokusebenza okungu-20Cr, ngaphandle kwemicu yangaphakathi nangaphandle engu-S0.9 ~ C59. Inqubo ye-carburizing inzima kakhulu, futhi umdwebo wenqubo kumele udwetshwe ngenqubo yokuganga (okufanekiselwa).

Ukwakhiwa kokucaciswa kwenqubo ezingxenyeni ze-shaft kuhlobene ngqo nekhwalithi yomsebenzi, ukukhiqizwa kwabasebenzi kanye nezinzuzo zezomnotho.

Ingxenye ingaba nezindlela zokucubungula ezahlukahlukene, kepha yinye kuphela yazo enengqondo kakhulu. Ekubunjweni kwe- inqubo machining incazelo, amaphuzu alandelayo kufanele aqashelwe.

- 1.Ekuhlaziyweni kwenqubo yezingxenye zokudweba, kuyadingeka ukuqonda izidingo zobuchwepheshe zezici zesakhiwo, ukucacisa, okokusebenza, ukwelashwa kokushisa, njll, nokufunda umdwebo womhlangano womkhiqizo, umdwebo womhlangano wezinto kanye nenqubo yokwamukela.

- 2.Umzila wokucubungula wezingxenye ze-carburizing ngokuvamile: ukusika → UKWAKHA → ukujwayela → ukujija → ukuqeda semi → ukuqeda ukukhishwa kwekhabhoni (engxenyeni engadingi ukuthuthukisa ubulukhuni) → ukucima → ukuchusha, ukubhola noma ukugaya iGroove → ukugaya okunamandla → ukuguga okushisa okuphansi → ukuqeda okuncane → ukuqeda izinga lokushisa eliphansi → ukuqeda.

- 3.Ukukhethwa kwesithenjwa esibi: Uma kukhona indawo engenamishini, indawo engeyona imishini kufanele ikhethwe njengereferensi enokhahlo. Okwenziwe izimbazo okudingeka kwenziwe ngomshini kuzo zonke izindawo, indawo encane ilungiswa ngokuvumelana nesabelo semishini. Futhi ukhethe indawo ebushelelezi, vumela isango. Khetha indawo eqinile nethembekile njengesethenjwa esibi, kuyilapho ireferensi ekhululekile ingasetshenziswa kabusha.

- 4.Ukukhethwa kwesilinganiso esihle: ukuhlangabezana nomgomo wokuqondana okuyisisekelo, ngangokunokwenzeka ukukhetha isisekelo sokuklama noma ibenchmark yomhlangano njengebhentshi lokuma. Ngokuhambisana nomgomo wokumaka. Sebenzisa ireferensi efanayo yokuma ngangokunokwenzeka ekusebenzeni okuningi. Ngokusemandleni, ireferensi yokuma iqondane nesethenjwa sesilinganiso. Ukukhethwa kobuciko obuphezulu, obuzinzile futhi obunokwethenjelwa yisilinganiso esihle.

Uthi lokuphotha Machining Inqubo

1.Ukuguqula

Isisetshenziswa senqubo: CA6140, Mohs No. 3 reamer, Mohs No. 3 plug gauge 1: 5 ring gauge

Inqubo yokuqukethwe: ngokusho komdwebo wenqubo ukuguqula konke kube ngosayizi

- (1) Umgodi wesikhungo φ2 umbiwe ekugcineni.

- (2) 1: 5 taper kanye Mohs 3 # kwangaphakathi Isigaxa umbala test, contact ebusweni> 60%.

- (3) Ububanzi obungaphandle bombuthano wangaphandle ngamunye ozobekwa phansi abungeqi ku-0.1 lapho kugadla khona ubukhulu bembobo ephakathi nendawo.

Qaphela: Ekugcineni hlola

2.Ukucima

Inqubo okuqukethwe: ukwelashwa ukushisa S0.9-C59

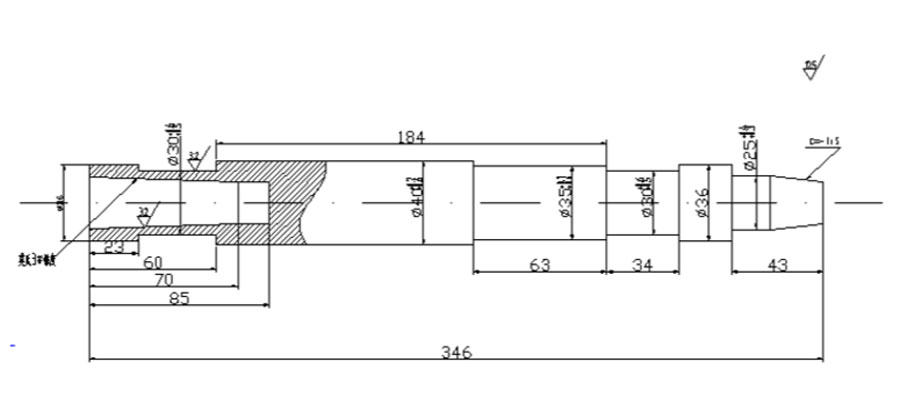

3.Kuguquliwe

Inqubo yokuqukethwe: i-deturningbonization. Ukuphela okukodwa kuboshiwe, ukuphela komunye kugxile

- (1) Ubuso bokugcina bokujika buqinisekisa ukuthi ubude besinyathelo sokuphela kwesokudla esingu-φ36 kuze kube sekupheleni komphando kungama-40

- (2) Drilling isikhungo imbobo φ5B uhlobo

- (3) U-U-turn

- (4) Ubuso bokuphenduka bokujika, thatha ubude obuphelele obungu-340 ngosayizi, qhubeka ubhoboze ujule uye kuma-85, 60 ° chamfer

4.Ukuguqula

Imishini yokucubungula: CA6140

Inqubo yokuqukethwe: isiqeshana esisodwa nesihloko esisodwa

- (1) Ukuguqula i-M30 × 1.5-6g kwesobunxele ngentambo ububanzi obukhulu kanye ne-ф30JS5 kuye ku- +30 + 6.0 +5 .0 ++

- (2) Ukuguqula u-to25 kuya ku -25 + 0.2 + 0.1 ubude obungu-43

- (3) Ukuguqula u-35 kuya ku-353 + 0.4 + 0.3

- (4) Ukuguqula ukugaya isondo okweqile

5.Ukuguqula

Inqubo yokuqukethwe: U-turn, isiqeshana esisodwa nesihloko esisodwa

- (1) Ububanzi obukhulu bomucu we-M30 × 1.5-6g kanye no-J30JS5 kuye ku- φ30 + 0.6 + 0.5

- (2) Ukuguqula u-40 kuya ku-40 + 0.6 + 0.5

- (3) Ukuguqula isondo lokugaya ngaphezulu kwe-slot

6.Ukugaya

Inqubo okuqukethwe: Milling 19 + 0.28 izindiza ezimbili ngosayizi

Ukwelashwa kwe-Heat

Inqubo yokuqukethwe: ukwelashwa kokushisa i-HRC59

8.Ucwaningo

Inqubo yokuqukethwe: Ukugaya imbobo yesikhungo sokugcina emibili

9.Ukugaya kwangaphandle

Imishini yokucubungula: M1430A

Inqubo yokuqukethwe: amathiphu amabili aphezulu, (elinye icala livinjiwe ngesigaxa)

- (1) ukugaya amaqhafuqhafu outer40 yangaphandle, kusale u-0.1 kuye ku-0.15

- (2) ukugaya okumile φ30js isiyingi sangaphandle ukuya ku- outer30t + 0.1 + 0.08 (izindawo ezimbili) ukugaya isinyathelo

- (3) Okubi okugaya u-1: 5 taper, kushiye isabelo sokugaya

10.Internal ukugaya

Imishini yokucubungula: M1432A

Inqubo yokuqukethwe: sebenzisa i-V-shaped fixture (ukubeka esiyingini sangaphandle se-ф30js5)

Isigaxa sangaphakathi esingu-3 sikaMomo (sifanisa kabusha i-Mohs 3 # cone plug) isibonelelo sokuqeda 0.2 ~ 0.25

Ukwelashwa kwe-Heat

Inqubo yokuqukethwe: ukwelashwa okuguga okushisa okuphansi (ukubhaka), kuqeda ukucindezeleka kwangaphakathi

12.Ukuguqula

Imishini yokucubungula: Z-2027

Inqubo yokuqukethwe: kuboshwe ngakolunye uhlangothi futhi kugxilwe ekugcineni

- (1) Drilling hole10.5 imbobo, ukuma nomhlahlandlela emkhonweni, intambo hhayi ukuhlasela

- (2) U-turn, ukubhola φ5 thepha intambo yangaphakathi engu-M6-6H

- (3) 60 ° isikhungo imbobo ukuvulwa

- (4) Ukubhoboza imbobo yomkhono we-drill ф10.5 × 25 (intambo ayishintshi)

- (5) 60 ° isikhungo imbobo, ebusweni roughness 0.8

13.Izimpahla

Inqubo yokuqukethwe:

- (1) Faka ukuthepha umshini eziveza umkhono ungene emgodini we-taper

- (2) Ukuhlasela ngentambo yangaphakathi engu-M12-6H kusayizi

14.Ucwaningo

Inqubo yokuqukethwe: Imbobo yesikhungo sokucwaninga i-Ra0.8

15.Ukugaya kwangaphandle

Inqubo yokuqukethwe: into yokusebenza ikhinjiwe phakathi kwalezi ziqongo ezimbili

- (1) Ukugaya okuhle φ40 no-35φ25 umbuthano wangaphandle ngosayizi

- (2) Ukugaya iM30 × 1.5 M30 × 1.5 ngentambo yesobunxele ububanzi obukhulu bube ngu-30-0.2-0.3-

- (3) Ukuqeda okungama-ф30js5 amabili kuya ku-ф30 + 0.04 + 0.03

- (4) Ukugaya okuhle 1: 5 taper ngosayizi, hlola ngendlela yokufaka imibala ngokusho kwendawo yokuthinta kukhulu kuno-85%

16.I-grinding

Inqubo okuqukethwe: workpiece clamping eziqongweni ezimbili, ukugaya intambo

- (1) Mill M30 × 1.5-6g intambo yesobunxele ngosayizi

- (2) Ukugaya intambo engu-M30 × 1.5-6g kusayizi

17.Ucwaningo

Inqubo okuqukethwe: Lapping isikhungo imbobo Ra0.4

18.Ukugaya kwangaphandle

Imishini yokucubungula: M1432A

Inqubo yokuqukethwe:

- (1) ukugaya Fine, workpiece clamping phakathi eziqongweni ezimbili

- (2) Ukugaya okuhle 2-φ30-0.003-0.007 ngosayizi, naka ukubekezelelana kwejometri

19. Ukugaya kwangaphakathi

Imishini yokucubungula: MG1432A

Inqubo yokuqukethwe:

I-workpiece ifakwe kwisakhiwo esenziwe ngo-V, futhi indawo engaphakathi ye-Mohs 3 imiswe ngesisekelo sombuthano wangaphandle ongu-1 – ф30 (ukwehlisa, ukubeka nge-2 – ф30js5 isiyingi sangaphandle), futhi indawo yokuxhumana yokuhlola imibala inkulu kune 80%. Idinga "1" kanye "2"

Okuvamile

Inqubo yokuqukethwe: ukuhlanza nokugcoba uwoyela olwa nokugqwala, isitoreji esime mpo silenga ku-workpiece

Amanye amaphuzu ekusetshenzisweni komshini kushaft:

- Imigodi emibili yesikhungo isetshenziswa njengereferensi yokuma, ehambisana nomgomo oshiwo ngenhla wenkomba yokuqondanisa kanye nokuma kwezilinganiso.

- 2.Ingxenye yokuqala isebenzisa umbuthano wangaphandle njengesethenjwa esibi, ubuso bokugcina bemoto nomgodi ophakathi nendawo wokuprakthiza, bese isiyingi sangaphandle semoto esime kahle sinezimbobo zombili zesikhungo njengereferensi yokuma, futhi imbobo ye-taper icutshungulwa ngombuthano wangaphandle wemoto enjengesithenjwa sokuma, okuyisimiso senkomba efanayo. Imishini ine-datum yokuma enembile kakhulu kunangesikhathi esisodwa. Cha. 3 Izidingo zokunemba kwesigaxa se-Mohs ziphakeme kakhulu. Ngakho-ke, isakhiwo esenziwe ngo-V siyadingeka ukufeza imfuneko yokubekezelelana kwejometri nombuthano wangaphandle we-2-ф30js5 njengesethenjwa sokuma. Lapho isigaxa singaphakathi emotweni, uhlangothi olulodwa lubhajwe ngozipho, bese kuthi uhlangothi olulodwa lugxile ohlakeni oluphakathi nendawo, futhi isiyingi sangaphandle sisetshenziswa futhi njengesethenjwa esihle.

- 3. Lapho kuqedwa futhi kuqedwa isiyingi esingaphandle, kusetshenziswa ipulaki lesigaxa, futhi imbobo emaphakathi yesigaxa isetshenziswa njengereferensi yokuma yokuqedela indawo engaphandle eyisiyingi.

Ngezidingo zokufaka izigaxa:

- Ipulaki le-1.Cone linokunemba okuphezulu, okuqinisekisa ukuthi indawo yokuthinta iplagi yesigaxa inezinga eliphakeme lokugxila nomgodi wayo wethiphu.

- I-plug ye-cone akufanele ithathelwe indawo ngemuva kokufakwa ukunciphisa iphutha lokufaka elidalwe ukufakwa okuphindaphindwayo.

- 3. Ububanzi bangaphandle bobubanzi obungaphandle bepulaki lesigaxa kufanele benziwe ngasekupheleni komphetho ukuze kususwe futhi kususwe isigaxa.

- I-4 imishini shaft i-carburized futhi iqine insimbi engu-20Cr low-carbon alloy, futhi into yokusebenza ayidingeki ukuthi iqine (M30 × 1.5-6g kwesokunxele, M30 × 1.5-6g, M12-6H, M6-6H), kusale ukususwa kwekhabhoni okungu-2.5-3mm ungqimba ebusweni. .

- 5.After intambo icishiwe, ayikwazi ukucutshungulwa ku-lathe. Uma intambo iqale yajijwa bese icinywa, intambo izokhubazeka. Ngakho-ke, intambo ngokuvamile ayikuvumeli ukuqina, ngakho-ke ungqimba lwekhabhoni kufanele lushiywe kububanzi nobude besabelo esinezintambo ku-workpiece. Kwemicu yangaphakathi, ungqimba we-3 mm decarburization nawo kufanele ushiywe ku-orifice.

- 6.Ukuze kuqinisekiswe ukunemba komgodi wesikhungo, umgodi ophakathi nendawo yokusebenza awuvunyelwe ukuba uqine. Ngalesi sizathu, ubude bento engenalutho bungu-6 mm.

- 7.Ukuze uqinisekise ukunemba kokugaya kombuthano wangaphandle womsebenzi, inqubo yokugaya imbobo yesikhungo kufanele ihlelwe ngemuva kokwelashwa kokushisa, futhi kudingeka indawo enobuso obuhle. Lapho indingilizi yangaphandle ingumhlabathi, ukuzungeza okuthinta okokusebenza ikakhulukazi kungenxa yobumbano lwezimbobo ezimbili eziphezulu nephutha lokuzungeza lomgodi ophezulu.

- 8.Ukuze uqede ukucindezela kokugaya, inqubo yokuguga yokushisa okuphansi (ukubhaka) ihlelwe ngemuva kokugaya okunzima.

- 9.Ukuze uthole umbuthano ongaphandle wokunemba okuphezulu, ukugaya kufanele kuhlukaniswe kube ukugaya okunokhahlo, ukuqeda semi, nokugaya okuhle. Ukugaya okuhle kuhlelwe kumshini wokugaya ophakeme kakhulu.

Xhumanisa nale ndatshana: Izibonelo eziningiliziwe ze-Shaft Machining Technology

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi