Ukwakhiwa Kwama-Propeller Blades Nezici Zawo zeJiyomethri Esigabeni

Ukwakhiwa Kwama-Propeller Blades Nezici Zawo zeJiyomethri Esigabeni

| Njengoba i-propeller iyingxenye yefomu yamahhala, ukwakheka kwayo kuyinkimbinkimbi. Ukuhlela uhlelo lokuchofoza u-propeller, kufanele siqale sihlaziye izici zalo zejometri. |

Njengoba i-propeller yasolwandle iyingxenye yefomu yamahhala, ukwakheka kwayo kuyinkimbinkimbi. Ukuhlela uhlelo lokuchofoza u-propeller, kufanele siqale sihlaziye izici zalo zejometri. Ophephela bangempela, njengezikulufu, babenendawo eyodwa noma ezimbili ezijikajika umphini. Ukusebenza kwamuva kutholile ukuthi uma kuthathwa isigaba sendawo evunguza esikhundleni sombuthano ogcwele, ukusebenza kahle kuzokwanda. Kuthathe iminyaka engaphezu kwengu-100 yokwenza umkhuba ukukhiqiza ubujamo namuhla. Indlela eyinhloko yokwakheka kophephela yindlela yemephu, okungukuthi, ukwakhiwa kwenziwa ngemephu edwetshiwe ngokuya ngemiphumela yokuhlola yemodeli yokuhambisa. Ngokuya ngemephu yokuklama, i- iziphephelo zemishini ikakhulukazi iziphephela zohlobo lwe-B, iziphehli zohlobo lwe-AU, kanye nezihambisi zohlobo lwe-SSPA.

Ukwakheka Kwama-Propeller Blades

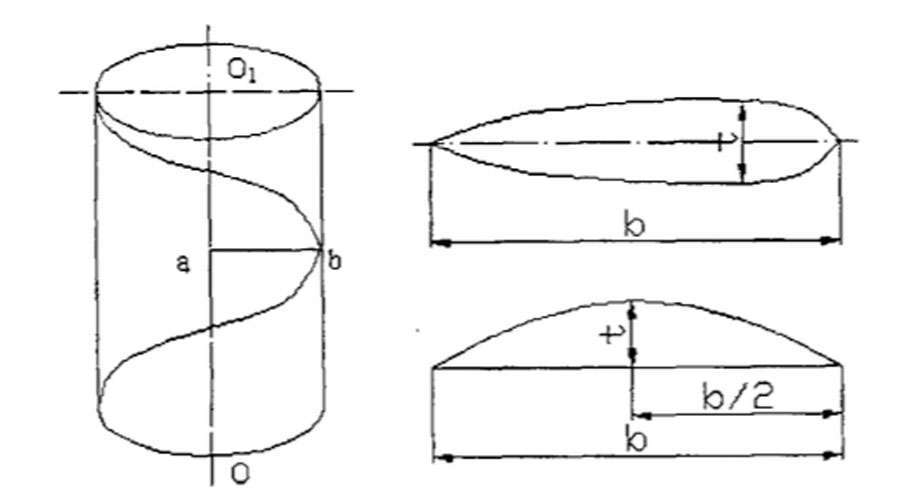

Indawo yokucindezela ye-propeller blade iyingxenye ye-spiral surface. Indawo ezungezayo yakhiwa ibha yebhasi ab ezungeza i-eksisi OO1 yehabhu lophephela, futhi ngesikhathi esifanayo ihambela phezulu ihambisana ne-OO1 ngesivinini esingaguquki, njengoba kukhonjisiwe ku-FIG. 1. Indawo yokunyakaza kwanoma yiliphi iphuzu emugqeni ojwayelekile i-spiral.

Uma ubhekwa ohlangothini lwe-eksisi, i-spiral iyi-arc. Uma ubhekwa ukusuka ohlangothini lwe-perpendicular kuya ku-eksisi, i-spiral iyi-sinusoid.

Ibanga phakathi kwanoma yiliphi iphuzu ku-helix efanayo ne-eksisi egxilile i-OO1 lihlala njalo. Ngakho-ke, uma indawo eyi-cylindrical yenziwa nge-radius ye-spiral njenge-radius (i-cylindrical centerline i-axis OO1), i-spiral ifakiwe endaweni eyi-cylindrical. Ukutshekela emuva kwebha kubizwa ngokuthi ukutshekela emuva, okuvezwa i-engeli yokutshekela emuva ε, ngokuvamile ε = 5 ~ 15 °.

Izici Zesigaba se-Blade

Ngoba ama-blade kufanele amelane nokujikijela kwephephela, kufanele abe nobukhulu obuthile. Ama-blades anokuqina okuphezulu endaweni esikiwe kuma-radii ahlukile, anqunywa ngokubala okulula.

Indawo eyi-cylindrical ene-radius R (isikhungo esihambisana nendawo ephakathi kwe-propeller shaft) i-tangent ku-blade, futhi isigaba esinqunyiwe siyindawo yokusika i-blade. Uma ubheka ohlangothini lwe-eksisi yophaphe, indiza esikiwe iyingxenye ye-arc ene-radius R, futhi ayiwona umugqa oqondile.

Ngokuvamile kunezinhlobo ezimbili zezingxenye ze-blade: i-airfoil ne-bow, njengoba kuboniswe kuMfanekiso 2. Ibanga b phakathi kweziphetho ezimbili zendiza e-tangent libizwa ngokuthi ububanzi be-chord bendiza ye-tangent, ebizwa nangokuthi ubude be-chord ye-tangent. indiza. Ubukhulu obukhulu besigaba bumelwe ngu-t.

Ubukhulu obukhulu besigaba esimise okwe-arch siphakathi nendawo, okungukuthi, b / 2. Ubukhulu obukhulu besigaba se-airfoil cishe ingxenye yesithathu yobubanzi be-chord kusukela onqenqemeni oluphambili, okungukuthi, cishe b / 3. isikhundla sobukhulu obukhulu besigaba ngasinye se-blade asishintshi.

Isilinganiso sobukhulu obukhulu kuya kububanzi be-chord sibizwa ngokuthi isilinganiso sogqinsi, futhi sivezwa ngo-δ, okungukuthi, δ = t / b. δ ikhombisa izinga lokukhuluphala nobuncane besigaba, futhi u-δ omkhulu ubonisa ukuthi ingxenye iwugqinsi futhi incane

Xhumanisa nale ndatshana: Ukwakhiwa Kwama-Propeller Blades Nezici Zawo zeJiyomethri Esigabeni

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi