Isicelo Of Laser Machining Ngo Imishini Ukukhiqiza

Isicelo Of Laser Machining Ngo Imishini Ukukhiqiza

|

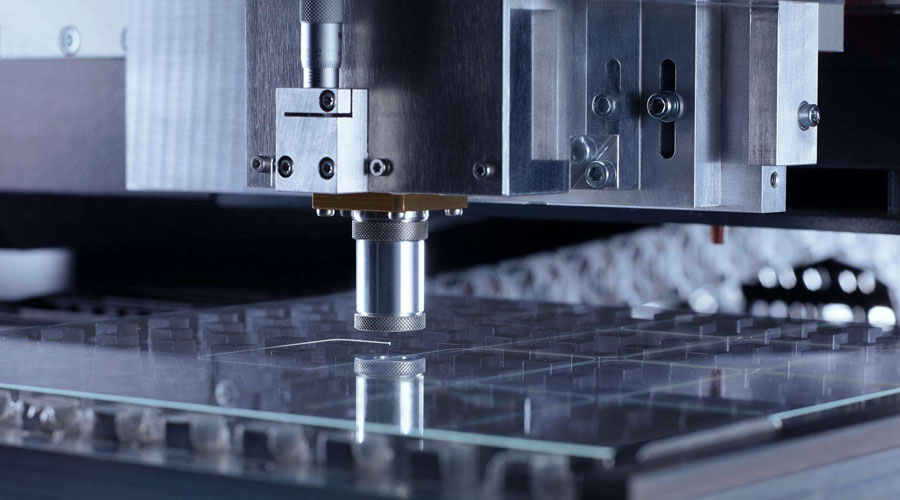

Umnyombo wobuchwepheshe bokucubungula i-laser ukuxhumana phakathi kogongolo lwe-laser nalolo lwazi. It ihlukaniswe laser ukucutshungulwa ezishisayo kanye photochemical ukusabela machining ngokuvumelana izindlela machining ezahlukene. Owokuqala usebenzisa umphumela oshisayo owenziwe ngogongolo lwe-laser ukwenza imisebenzi yokucubungula, kanti owokugcina usebenzisa ubukhulu obukhulu. Ama-photon anamandla amakhulu aqala ukusabela kwamakhemikhali ukuqedela ukucubungula. Ngokuthuthukiswa kobuchwepheshe besicelo se-laser, ukucutshungulwa kwe-laser sekuyiyona teknoloji eyinhloko yokusebenza kwezinhlelo ze-laser. Isetshenziswa kabanzi emkhakheni wokukhiqiza imishini futhi idlala indima ebalulekile. |

1.Characteristics laser machining ubuchwepheshe

Ukusika kwe-Laser ubuchwepheshe besimanje obuhlanganisa ubuhlakani nentuthuko, futhi buhlanganisa izimiso ze-laser, ubuchwepheshe be-CAD kanye nobuchwepheshe bokulawula izinombolo. Umgomo wobuchwepheshe bemishini ye-laser ukudlala indima ebonakalayo ebusweni bezinto ezibonakalayo ngenxa yokusebenza okuphezulu kwamandla okusebenza kwe-laser beam, futhi kubangele uchungechunge lwezinguquko ze-morphological ebusweni bento.

Ubuchwepheshe bemishini ye-laser bunezinzuzo zokunemba okuphezulu futhi akukho ukungcola, okungenakuqhathaniswa futhi okudlulwa ngobunye ubuchwepheshe bokukhiqiza imishini. Ngaphezu kwalokho, ubuchwepheshe bemishini ye-laser buhlanganisa imikhakha eyahlukene efana ne-electronics, izinto zokwakha, nokudluliswa kokushisa kobunjiniyela, ngezinga eliphezulu lobuhlakani.

Uma kuqhathaniswa nobunye ubuchwepheshe bemishini ekwenziweni kwemishini, i-laser machining imosha impahla encane, inempumelelo enkulu ekukhiqizeni ngezinga elikhulu, futhi ivumelana nezimo nezinto ezicutshungulwayo.

Ingasetshenziselwa ukukhiqizwa ngomshini kwezinto ezihlukahlukene ezikhethekile, kanye nokunye ukukhanda kwendabuko Izinto ezintsha ezingenakufinyelelwa ngobuchwepheshe nazo zicutshungulwa kusetshenziswa ubuchwepheshe be-laser machining. Izici eziyinhloko zobuchwepheshe bemishini ye-laser ekukhiqizeni imishini:

- (1) Amandla aphezulu, okokusebenza kungancibilika noma kufuthwe isikhashana ngemuva kokumunca ukushisa kwe-laser, futhi okokusebenza kungashintshwa ngokushesha noma ngabe iphuzu lokuncibilika kwento liphezulu.

- (2) Ikhanda le-laser ngeke lixhumane ngqo nomsebenzi, ngakho-ke ngeke zibe khona izinkinga zokugqoka.

- (3) Hhayi ukusebenza ngemishini kuphela kuma-static workpieces, kodwa futhi nokusebenza kokunyakaza, noma ngabe okokusebenza kuvaliwe kwezinye izinto.

- (4) Ngesikhathi machining laser, ugongolo laser ilawulwa ikhompyutha electronic, ezingasetshenziswa bona ukulungisa okucacile yomshini, futhi nezinga lokuzenzekelayo liphezulu.

- (5) Ukusetshenziswa kwe-Laser kungabona ukulawula ngomshini, futhi amarobhothi angasetshenziswa esikhundleni semishini ezindaweni lapho ukusebenza kwabantu kunzima.

2.Application laser machining e imishini yokukhiqiza

2.1 Ukuphathwa kwempahla

Laser machining ngokuvamile isebenzisa ukwelashwa ukushisa kanye ebusweni ukuqinisa ubuchwepheshe ukucubungula impahla. Lobu buchwepheshe obubili bungafudumeza ngokushesha okubonakalayo futhi buguqule ngokushesha i-morphology yayo lapho isondela endaweni encibilikayo, ngaleyo ndlela ifezekise inhloso ukwelashwa surface. Ubuchwepheshe bemishini ye-laser buyisandiso sobuchwepheshe bendabuko bokwelapha ukushisa. Ngemuva komshini we-laser, i-material inokumelana nokukhathala okuqinile nokumelana nokugqwala.

Impilo yesevisi nayo inwetshiwe, futhi zonke izici zokusebenza kwento zithuthukisiwe. Ukusetshenziswa komshini we-laser ebusweni bezinto zokusebenza kuzithuthukise kakhulu izakhiwo ezibonakalayo zezinto zokwakha, ezibaluleke kakhulu ekwenzeni ngcono ukuncintisana kwemakethe kwemikhiqizo.

Ubuchwepheshe be-laser bungasetshenziswa bubodwa noma buhlanganiswe nobunye ubuchwepheshe ukwakha imodi entsha yokwenza izinto. Ukuhlanganiswa kobuchwepheshe be-laser kanye nobuchwepheshe be-CAD kuvule insimu entsha yomshini wokukhiqiza impahla. Ubuchwepheshe be-CAD busebenzisa isistimu yekhompuyutha ukulawula inqubo yokuklama, ukuqedela umsebenzi wokuklama ingxenye, bese kusetshenziswa ubuchwepheshe be-laser ukucubungula ngokohlelo oluklanyelwe ukumodela. Imodeli yengxenye eyenziwe ngobuchwepheshe be-CAD inezici zokunemba nokuqondisa, okungenza kube lula ubunzima bokukhiqiza izingxenye eziyinkimbinkimbi.

Uma izinkinga zenzeka phakathi nenqubo yokuklama, zingashintshwa nganoma yisiphi isikhathi ukuze kuqinisekiswe ubuqotho bomkhiqizo. Ukukhiqizwa kwemishini kunezidingo eziqine kakhulu ezingxenyeni ngokwazo, futhi izidingo zokunemba ziqinile kakhulu. Ukucutshungulwa kwezinye izindawo ezigobile eziyinkimbinkimbi nakho kunzima. Ukusetshenziswa okuhlangene kobuchwepheshe be-CAD nobuchwepheshe be-laser kungaxazulula le nkinga kalula, kunciphise ubunzima bokukhiqiza, futhi kufinyeze umjikelezo we-R & D ukuze kuthuthukiswe ukusebenza kahle kokukhiqizwa komkhiqizo.

Ukushaya isibhakela kanye uyanyathela kuyingxenye ebalulekile yokwenza izinto ezibonakalayo. Izinhlobo ezijwayelekile zezimbobo zomshini zifaka izimbobo zikawoyela, izimbobo zokubopha, izimbobo zokubeka indawo, njll. Ikhwalithi ye- through-hole inomthelela omkhulu ekusebenzeni kwengxenye. Umthelela wokubhoboza we-laser machining ungcono kunowokubhoboza kwemishini evamile, futhi udonga lwembobo lushelela futhi luyindilinga, njengoba kuboniswe kuThebula 1. Ijika lokujula kwembobo kanye nobubanzi bembobo ngokuhamba kwesikhathi ngaphansi komshini we-laser uboniswa kuMfanekiso 1.

Kungabonakala ukuthi phakathi nenqubo yokumba i-laser, ukujula kwembobo kanye nobubanzi bembobo kuye kwanda kakhulu esigabeni sokuqala, futhi ngokunwetshwa kwesikhathi, Izinga lokukhula kwazo zonke liyancipha. Isizathu sokwehla kwejubane ukuthi amandla e-laser defocusing ayancipha, bese umthombo wokushisa we-laser uphendulelwa ngaphakathi kwento. Ngalesi sikhathi, inqubo laser

Xhumanisa nale ndatshana: Isicelo Of Laser Machining Ngo Imishini Ukukhiqiza

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi Ukuhlinzeka ngezimpawu, ukusebenza okuphelele kokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi Ukuhlinzeka ngezimpawu, ukusebenza okuphelele kokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi