Isimo Futhi Ithemba Of Laser Precision Machining Technology

Isimo Futhi Ithemba Of Laser Precision Machining Technology

|

Laser impahla machining kuhilela anhlobonhlobo. Sintering, isibhakela, ukumaka, ukusika, i-welding, ukuguqulwa komhlaba kanye nokufakwa kwemishini yamakhemikhali konke kuthathe i-laser njengomthombo wamandla obalulekile. |

Ugongolo lwe-laser lungagxila kusayizi omncane kakhulu, okwenza lube lufanele ngokukhethekile ukulungisa okucacile. Sihlukanisa ubuchwepheshe bamanje be-laser machining emazingeni amathathu ngokuya ngosayizi wento esetshenzisiwe kanye nezidingo zokunemba kwemishini:

- Technology Ubuchwepheshe be-laser machining bezinto ezinkulu, ezinamapuleti awugqinsi (amamilimitha amaningana kuya kumashumi wamamilimitha) njengento eyinhloko, nokunemba kwayo kwemishini ngokuvamile kusezingeni lemilimitha noma le-sub-millimeter;

- Ubuchwepheshe be-machining be-Precision laser, obunamapuleti amancane (i-0.1 kuye ku-1.0mm) njengeyona nto eyinhloko yokwenza imishini, futhi ukunemba kwayo kwemishini ngokuvamile kulandelana ngama-microns ayishumi;

- Technology Ubuchwepheshe be-Laser microfabrication, kumafilimu ahlukahlukene anobukhulu obungaphansi kuka-100μm njengento eyinhloko yokwenza imishini, ukunemba kwayo kwemishini ngokuvamile kungaphansi kwama-microns ayi-10 noma ngisho ne-sub-micron level.

Kumele kuqashelwe ukuthi embonini yemishini, ukucacisa ngokuvamile kusho okuncane kobuso obukhulu kanye nohlu oluncane lokubekezelelana (kufaka phakathi isikhundla, ukuma, usayizi, njll.). Kodwa-ke, igama elithi "ukucacisa" kule ndatshana lisho igebe elincane endaweni esetshenziswayo, okusho ukuthi usayizi womkhawulo ongacutshungulwa mncane. Kulezi zinhlobo ezintathu ezingenhla ze-laser machining, ubuchwepheshe be-laser machining bezingxenye ezinkulu buye bukhula ngokwengeziwe futhi nezinga lezimboni beliphezulu kakhulu.Imibhalo eminingi ibuyekeziwe; i-laser micro machining technology efana ne-laser trimming, i-laser precision etching, i-laser Direct technology yobuchwepheshe nayo isetshenziswe kabanzi embonini, futhi kunemibiko eminingi ehlobene. Le ndatshana izogxila kubuchwepheshe be-laser precision machining. Ukuze kube lula, izinhloso zemishini zokunemba ngemishini okukhulunywe ngazo ngezansi zikhawulelwe emapuleti amancane (0.1-1.0mm).

1. Ukuqhathanisa phakathi laser ngokunemba machining nezindlela machining bendabuko

Ngokuthuthuka kobuchwepheshe, izinhlobo zobuchwepheshe bokuchofoza ngokunemba ziya ngokuya zanda.

Laser ngokunemba machining inezici ezilandelayo ezibalulekile:

- Scope Ububanzi be-laser precision machining bubanzi, kufaka phakathi cishe zonke izinto zensimbi nezingezona ezensimbi. Ngenkathi i-electrolytic machining ingacubungula kuphela izinto ezisetshenziswayo, imishini ye-photochemical ilungele kuphela izinto ezonakalisayo kalula, futhi ukwenziwa kwe-plasma kunzima ukucubungula izinto ezithile zokuncibilika okuphezulu.

- ② Kunezici ezimbalwa ezinomthelela kukhwalithi ye-laser ngokunemba machining, futhi ukunemba kwemishini kuphezulu, futhi ngokuvamile kungcono kunezinye izindlela zendabuko zemishini ngokujwayelekile.

- ③ Ngokombono womjikelezo wokuchofoza, i-electrode yethuluzi le-EDM idinga ukucacisa okuphezulu, ukulahleka okukhulu, nomjikelezo omude wokusebenzisa; ukwakheka kwesikhunta se-cathode se-machining cavity kanye nephrofayili ye-machining ye-electrolytic inkulu, futhi umjikelezo wokukhiqiza nawo umude; Izinqubo ziyinkimbinkimbi; i-laser precision machining ilula, ububanzi bokusikwa kulula ukulungisa nokulawula, isivinini semishini siyashesha, futhi umjikelezo wemishini mfushane kunezinye izindlela.

- ④Laser ngokunemba machining kungokwalabo non-contact machining, ngaphandle force mechanical. Uma kuqhathaniswa ne-EDM ne-plasma arc machining, indawo ethintekayo ekushiseni kanye nokusonteka kuncane kakhulu, ngakho-ke kungacubungula izingxenye ezincane kakhulu.

Ngamafuphi, i-laser precision machining technology inezinzuzo eziningi kunezindlela zendabuko zemishini, futhi nethemba layo lokusebenza libanzi kakhulu.

2. Isingeniso esivame ukusetshenziswa imishini laser ngokunemba machining

Amalaza avame ukusetshenziselwa ukunemba kwemishini ahlanganisa: amalaser e-CO2, amalaser e-YAG, ama-laser omhwamuko wethusi, ama-excimer lasers, namalaser e-CO, njll. Ukuze uthole izici zawo ze-laser, bona imibhalo ukuze uthole imininingwane.

Phakathi kwazo, ama-laser anamandla e-CO2 kanye nama-laser we-YAG aphezulu asetshenziswa kakhulu kubuchwepheshe bemishini ye-laser enkulu; ama-lasers omhwamuko wethusi nama-lasers e-excimer asetshenziswa kabanzi kubuchwepheshe be-laser micro-machining; amalaser e-YAG amaphakathi nanamandla aphansi ngokuvamile asetshenziselwa ukunemba kwemishini .

3.Ukusetshenziswa kwe-laser precision machining nokuthuthuka kweChina nokwamanye amazwe

Isimo se-International

3.1.1 Laser ngokunemba imishini

Ngokuthuthuka kobuchwepheshe, indlela yendabuko yokushaya ayikwazanga ukuhlangabezana nezidingo ezikhathini eziningi. Isibonelo, izimbobo ezincane ezinobubanzi bamashumi ama-micrometer ambalwa zicutshungulwa kuma-alloys e-tungsten carbide aqinile; izimbobo ezijulile ezinobubanzi bama-micrometer angamakhulu amaningana zicutshungulwa ngokubomvu okuqinile futhi okuphahlazeka nesafire, njll., okungeke kufinyelelwe ngezindlela ezivamile zemishini. Ubuningi bamandla osheshayo be-laser beam bufinyelela ku-108 W / cm2, ongashisa ukwaziswa kufinyelele endaweni yokuncibilika noma iphuzu lokubilisa ngesikhathi esifushane ukufezekisa ukugcwala ezintweni ezingenhla. Uma kuqhathaniswa ne-electron beam, i-electrolysis, i-spark kagesi, ne-mechanical drilling, i-laser drilling inekhwalithi enhle, ukunemba okuphindiwe okuphezulu, ukuguquguquka okuqinile, ukusebenza kahle okukhulu, izindleko eziphansi, kanye nezinzuzo ezibalulekile eziphelele zobuchwepheshe nezomnotho. International ngokunemba laser imishini ifinyelele ezingeni eliphezulu kakhulu. Inkampani yaseSwitzerland isebenzisa ama-lasers wombuso oqinile ukubhoboza izimbobo ezinhlangothini zamabhanoyi ezindiza, ezingacubungula ama-microholes anobubanzi obusuka ku-20 μm kuye ku-80 μm, futhi isilinganiso sobubanzi ukuya ekujuleni singafinyelela ku-1: 80 (bona Umfanekiso 1 (a)) . Ugongolo lwe-laser lungabuye lucubungule izimbobo ezahlukahlukene ezimise okwembobo ezinjengezimbobo eziyimpumputhe (bheka uMdwebo 1 (b)) nezimbobo eziyizikwele ezintweni eziqhekekile ezinjengobumba, ezingatholakali ngemishini ejwayelekile.

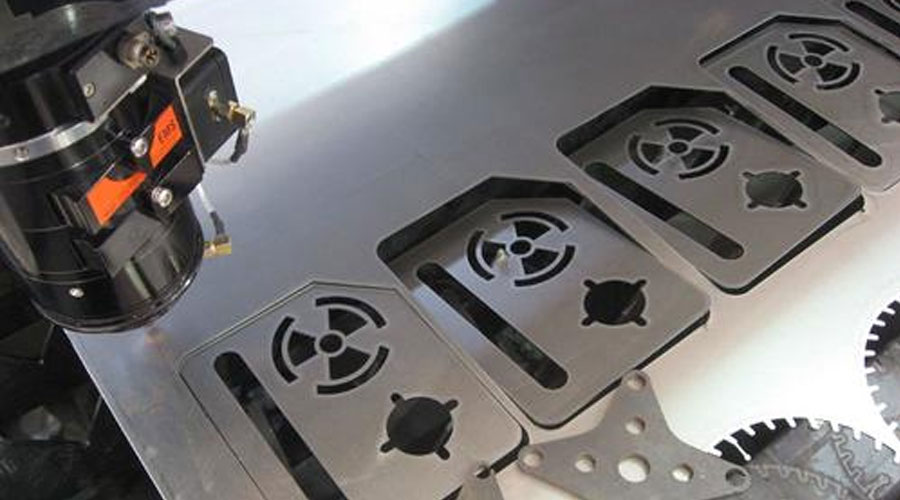

3.1.2 Ukusika ngokunemba kwe-Laser

Uma kuqhathaniswa nendlela yokusika yendabuko, ukunemba ukusika kwe-laser kunezinzuzo eziningi. Isibonelo, ingenza ukusikeka okuncane, cishe akukho zinsalela zokusika, indawo encane ethintekile ekushiseni, umsindo wokusika ophansi, futhi ungagcina u-15% kuye ku-30% wezinto ezibonakalayo. Ngenxa yokuthi i-laser ayikhiqizi umfutho womshini nengcindezi entweni esikwayo, ilungele ukusika izinto ezinzima neziqinile ezifana nengilazi, i-ceramics kanye ne-semiconductors.Ngaphezu kwalokho, indawo ye-laser incane futhi imbobo incane, ngakho-ke ikakhulukazi efanelekayo izingxenye ezincane. Uhlobo ngokunemba ahlabayo. Inkampani yaseSwitzerland isebenzisa ama-lasers wombuso oqinile ukusika ngokunemba, futhi ukunemba kwayo kobukhulu kufinyelele ezingeni eliphezulu kakhulu.

Uhlelo lokusebenza olujwayelekile lokusika ngokunemba kwe-laser ukusika ama-stencil e-SMT kumabhodi esekethe aphrintiwe (bona Umfanekiso 2). Indlela yendabuko yokwenza isifanekiso se-SMT iyindlela yokufaka amakhemikhali. Ububi bayo obubulalayo ukuthi usayizi olinganiselwe womshini akumele ube ngaphansi kogqinsi lwepuleti, futhi indlela yokuhlanganisa amakhemikhali inenqubo eyinkimbinkimbi, umjikelezo omude womshini, kanti indawo edlayo ingcolisa imvelo.

Ukusebenzisa i-laser machining akukwazi nje ukunqoba lezi zinkinga, kodwa futhi kucubungule kabusha isifanekiso esiqediwe.Ikakhulukazi, ukunemba kwemishini kanye nokushuba kwegebe kungcono kakhulu kunokuqala (bheka uMdwebo 3). Iphansi kancane kuneyangaphambili. Kodwa-ke, ngenxa yokuqukethwe okuphezulu kwezobuchwepheshe kwayo yonke isethi yemishini esetshenziselwa umshini we-laser kanye nenani eliphezulu, izinkampani ezimbalwa kuphela emazweni ambalwa njenge-United States, Japan, neJalimane ezingakhiqiza wonke umshini.

3.1.3 Ukushisela kwe-Laser ngokunemba

Ukushisela i-Laser kunendawo emincane kakhulu ethinteke ekushiseni kanye nomthungo omncane we-weld. Ikakhulu, ingakwazi ukuhlanganisa izinto zokuncibilika okuphezulu nezinsimbi ezingafani ngaphandle kwesidingo sezinto ezengeziwe. Ukusetshenziswa kwamazwe omhlaba kwe-YAG lasers okuqinile kwe-seam welding kanye ne-welding yamabala kufinyelele ezingeni eliphezulu. Ngaphezu kwalokho, izintambo eziholayo zesekethe ephrintiwe zifakwa nge-laser, engadingi ukusetshenziswa kokugeleza, futhi enganciphisa ukushaqeka okushisayo ngaphandle kokuthinta ukufa kwesifunda, ngaleyo ndlela iqinisekise ikhwalithi yesifunda esihlanganisiwe (bheka Umfanekiso 4) .

3.2 Isimo esikhona eChina

Ngemva kweminyaka engaphezu kwengu-20 yemizamo, mayelana nobuchwepheshe be-laser precision machining kanye nemishini ephelele, nakuba i-China iye yasetshenziswa ku-ceramic laser scribing kanye ne-laser spot welding yezingxenye zensimbi ezincane, i-seam welding kanye ne-air-tight welding, kanye nokumaka, njll.

Kodwa-ke, kubuchwepheshe be-laser precision machining, inqubo yokusika nokunamathisela kwethempulethi yesekethe ye-microelectronic enokuqukethwe okuphezulu kobuchwepheshe kanye nemakethe yesicelo ebanzi, izimbobo, izimbobo ezingaboni kanye nezimbobo ezimise okukhethekile, izikhala zokucaciswa okuhlukahlukene nosayizi emashidini e-ceramic futhi aphrintiwe. amabhodi wesifunda Ukunemba kwe-laser machining nezinye izici kusesesigabeni socwaningo nentuthuko, futhi akukho sibonelo sezimboni esihambisanayo esivelile.

Iningi labasebenzisi e-China livamise ukusebenzisa izifanekiso ezingenisiwe noma ukwenza imishini e-Hong Kong nakwezinye izindawo.Intengo ephezulu kanye nomjikelezo omude kuthinte kakhulu umjikelezo wokuthuthukiswa komkhiqizo. Eminyakeni yamuva, izinkampani ezimbalwa ezinkulu zamazwe ngamazwe zibone imakethe enkulu yaseChina engase ibe khona embonini ye-laser machining. , Isiqalile ukumisa amagatsha eChina. Kodwa-ke, izindleko eziphezulu zokukhiqiza zenyusa izindleko zomkhiqizo futhi zisalokhu zenza amabhizinisi amaningi abathene amandla.

4. Intuthuko Yezentuthuko kanye Nethemba Lobuchwepheshe be-Laser Precision Machining Technology

Amalaser ekhwalithi ephezulu, asebenza kahle, azinzile, athembekile, futhi ashibhile ayizimfuneko zokuphromotha nokusebenzisa ukunemba kwemishini. Enye yezindlela zokuthuthuka zemishini yokunemba kwe-laser ukwenziwa kwemishini emincane yamasistimu. Eminyakeni yamuva nje, ama-laser e-diode-pumped athuthuke ngokushesha. Inochungechunge lwezinzuzo ezifana nokusebenza kahle kokuguqulwa okuphezulu, ukuzinza okuhle komsebenzi, ikhwalithi enhle ye-beam, nosayizi omncane. Kungenzeka ibe i-laser eyinhloko yesizukulwane esilandelayo somshini wokunemba we-laser.

Ukuhlanganiswa kwezinhlelo zemishini kungenye inkambiso ebalulekile ekuthuthukisweni kwemishini yokunemba kwe-laser. Hlela futhi uthuthukise ubuchwepheshe bemishini yokunemba kwe-laser yezinto ezihlukahlukene; sungula isofthiwe yokulawula esebenziseka kalula, ezinikele efanele ukwenziwa kwemishini enembayo nge-laser, futhi yengeze ngesizindalwazi senqubo ehambisanayo; hlanganisa isilawuli, inqubo kanye ne-laser ukuze kuzuzwe ukubona, Ukuhlanganiswa komshini, ugesi kanye nomshini wezinto ezibonakalayo kuwumkhuba ongenakugwemeka ekuthuthukisweni kwemishini yokunemba kwe-laser.

Yize i-China inegebe elikhulu nelomhlaba jikelele maqondana nobuchwepheshe bemishini ye-laser nemishini, uma siqhubeka nokwenza ngcono ikhwalithi ye-laser ugongolo nokunemba kwemishini ngokuya ngohlobo lwangempela, kuhlangene nokucwaninga kobuchwepheshe bemishini yokusebenza, sizohlala ngokunemba kwe-laser imakethe yemishini ngangokunokwenzeka. Futhi kancane kancane ukungena emkhakheni we-laser micro-machining, kungakhuthaza ukuthuthukiswa okusheshayo kwe ukusika kwe-laser ubuchwepheshe, futhi ekugcineni wenze laser ngokunemba machining embonini enkulu.

Xhumanisa nale ndatshana: Isimo Futhi Ithemba Of Laser Precision Machining Technology

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi