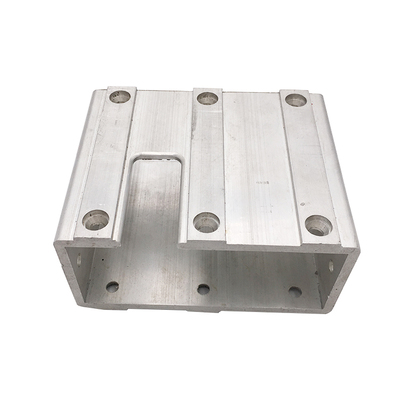

Machining Izici Futhi Material Ukukhethwa Indlela Of Cold elikhubazekile Isikhunta Steel

I-Cold Deformed Mold Steel

|

Ngokuthuthuka kwemboni yemishini yokwenza, izingxenye eziningi kakhulu ezikhiqizwa umsebenzi obandayo ziyafa ekukhiqizeni, futhi izinhlobo eziningi zokufa okubandayo ziyasetshenziswa. Ivolumu ebandayo iyafa UKWAKHA (ukucasula amakhaza, i-extrusion ebandayo, i-embossing, njll.); ishidi-insimbi uyanyathela (njengokwelula, ukuvala, ukusika, ukubhoboza, njll.); ukuginqika kwempahla (ukugoqa okubandayo, ukugoqa, njll.). Nakuba kunezinhlobo eziningi zesikhunta se-deformation esibandayo, izimo zokusebenza ezihlukene kanye nezidingo ezahlukene zokusebenza, izimo zokusebenza eziyisisekelo ziyefana: okungukuthi, insimbi ikhubazekile esimweni esibandayo, futhi ingaphansi kokugunda okukhulu, ingcindezi, amandla okugoba, Umthelela nokungqubuzana. |

Machining Izimpawu Of Cold Deformed Mold Steel

1. Ukuqina okuphezulu namandla aphezulu ukuqinisekisa ukuthi akulula ukukhiqiza inani elincane le-plastic deformation noma umonakalo lapho ubhekene nokucindezeleka okukhulu.

2. Ukumelana nokuhuzuka okuphezulu, okungaqinisekisa ukunemba kobukhulu besikhunta ngaphansi kwezimo eziphakeme zokuhuzuka, okubaluleke nakakhulu ekufeni okuqinile kanye nokufa kwesitembu esibandayo.

3. Ukuqina okwanele, ukuze kungabi lula ukuxebuka noma ukuwa lapho kusebenza ngaphansi komthwalo womthelela kanye nomthwalo oguquguqukayo.

4. Ukuguqulwa kokwelashwa kokushisa kufanele kube kuncane. Ngenxa yokuthi isikhunta esiningi sinezimbobo eziyinkimbinkimbi nokunemba okunembayo, ukuguqulwa kokwelashwa kokushisa kunzima ukukuqeda ngokugaya. Ngaphezu kwalokho, ezinye isikhunta se-deformation esibandayo kufanele sibe nokumelana nokushisa okwanele. Indlela yokukhetha impahla yesikhunta se-deformation ebandayo kanye nendlela efanele yokwelapha ukushisa ukuze uthuthukise impilo yesevisi yesikhunta yindaba ethintekayo kakhulu ekukhiqizeni. Ukwehluleka okuvamile kwesikhunta se-deformation ebandayo kufanele kube ukuguga, ukuguqulwa okuncane kwepulasitiki kanye nokwehluleka kokukhathala. Kodwa-ke, ekukhiqizeni kwangempela, ngaphezu kokuhluleka kokugqoka nokukhala, nokuhluleka kwasekuqaleni njengokuwa, ukuphuka, ukuqhekeka, njll, kuvamile. Njengoba sonke sazi, impilo yesevisi yesikhunta esigogekile siyisici esibanzi; ubuhlakani bokukhethwa kwezinto ezingavuthiwe, ikhwalithi ye-metallurgical yezinto zokusetshenziswa, ukuhlakanipha kokuklama nezinqubo zokukhiqiza, izimo zokusebenzisa, nezinga lobuchwepheshe labasebenzisi.

Ukukhethwa Kwensimbi Yesikhunta Epholile Ekhubazekile

- 1. Izimo zokusebenza zesikhunta, kufaka phakathi uhlobo lwemishini, imvamisa yomshini, izinto ezicutshungulwayo, ukugcotshwa nendawo ezungezile, njll.

- 2. ubunkimbinkimbi befomu lesikhunta kanye nezinqubo zomshini;

- 3.Iqoqo lokukhiqiza kanye nezidingo zobuchwepheshe;

- 4. Umthombo wezinto zokubumba kanye nezimo zomshini.

Izindleko zempahla yesikhunta esikhulu zivame ukubala ngaphezu kwe-50% yezindleko zesikhunta. Ukuze uthole isikhunta esinezimo eziyinkimbinkimbi kanye nezidingo zokunemba okuphezulu, insimbi yokubumba ene-deformation encane yokucisha kufanele isetshenziswe.

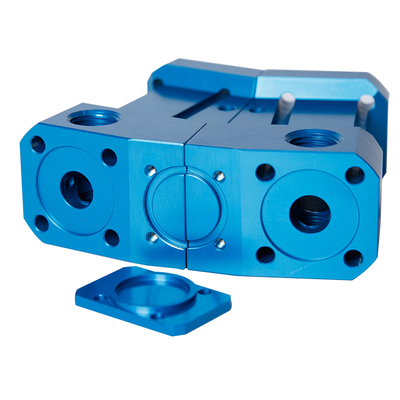

Ngokusho ukusetshenziswa langempela, evame ukusetshenziswa ebandayo isikhunta sikhubazekile steels machining insimbi eqinile ephansi, insimbi ekhubazekile ephansi, insimbi ekhubazekile encane, insimbi enamandla amakhulu, insimbi eqinile, kanye nensimbi yokubunjwa ekhubazekile engathinteki.

Xhumanisa nale ndatshana: Machining Izici Futhi Material Ukukhethwa Indlela Of Cold elikhubazekile Isikhunta Steel

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi Ukuhlinzeka ngezimpawu, ukusebenza okuphelele kokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi Ukuhlinzeka ngezimpawu, ukusebenza okuphelele kokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi