Ukuqhathanisa okuhlobene kwezinqubo ezijwayelekile zokusika zensimbi

Ukuqhathanisa Izinqubo Zokusika Kwensimbi

|

Ekukhiqizeni, ngokuthuthukiswa kwesayensi nobuchwepheshe, izinhlobo zezinqubo zokusika zensimbi bezilokhu zicebiswa ngokuqhubekayo. Okuvamile kakhulu ukusika kwe-laser, ukusika amanzi, ukusika i-plasma, nokusika ucingo. Ngo machining yethu yangempela, ukukhetha inqubo efanele ngokuya ngezinto ezahlukene noma izidingo machining ingafinyelela kangcono machining imiphumela. |

Ukuqhathanisa Ibanga Lokufaka

- The ukusika kwe-laser umshini unezinhlobonhlobo zezicelo. Ingasika insimbi nokungeyona insimbi. Ukusika okungezona izinsimbi, njengendwangu nesikhumba, kungasebenzisa imishini yokusika i-CO2, futhi ukusika izinsimbi kungasebenzisa imishini yokusika i-fiber laser. Ipuleti deformation lincane.

- Ukusika amanzi ukusika okubandayo, akukho ukusonteka okushisayo, ikhwalithi enhle yokusika ebusweni, akukho machining wesibili okudingekayo, futhi ukwenziwa kwemishini yesibili kulula uma kunesidingo. Ukusika amanzi kungabhoboza futhi kusike noma iyiphi impahla, ngejubane lokusika okusheshayo nosayizi wemishini oguqukayo.

- Ukusikwa kwe-Plasma umshini ungasetshenziselwa ukusika izinto ezahlukahlukene zensimbi ezifana nensimbi engagqwali, i-aluminium, ithusi, i-cast iron, i-carbon steel, njll. Ukusika i-Plasma kunemiphumela ebonakalayo yokushisa, ukucacisa okuphansi, futhi akulula ukwenza imishini yesibili endaweni yokusika.

- Ukuzisika kwentambo ingasika kuphela izinto ezisetshenziswayo, futhi ukusika okupholisayo kuyadingeka ngesikhathi sokusika, ngakho-ke akukwazi ukusika izinto ezifana nephepha nesikhumba okungahambisi, ukwesaba amanzi, nokwesaba ukusika ukungcoliswa kwesipholisi.

Ukuqhathanisa Ukusika Ubukhulu

- Ukusetshenziswa kwezimboni kwe i-laser-cut i-carbon steel ngokuvamile ingaphansi kwama-20mm. Amandla okusika ngokuvamile angaphansi kwama-40mm. Izinsimbi zezimboni ezingenazinsimbi ngokuvamile zingaphansi kwe-16mm, futhi umthamo wokusika ngokuvamile ungaphansi kuka-25mm. Futhi njengoba ukushuba komsebenzi kukhula, isivinini sokusika sincipha kakhulu.

- Ukusika okusika amanzi ingaba obukhulu kakhulu, i-0.8-100mm, noma izinto ezijiyile.

- Ukusikwa kwe-Plasma ubukhulu bungu-0-120mm. Isistimu yePlasma enezinga eliphakeme lokusika lekhwalithi engaba ngu-20mm iyona ebiza kakhulu.

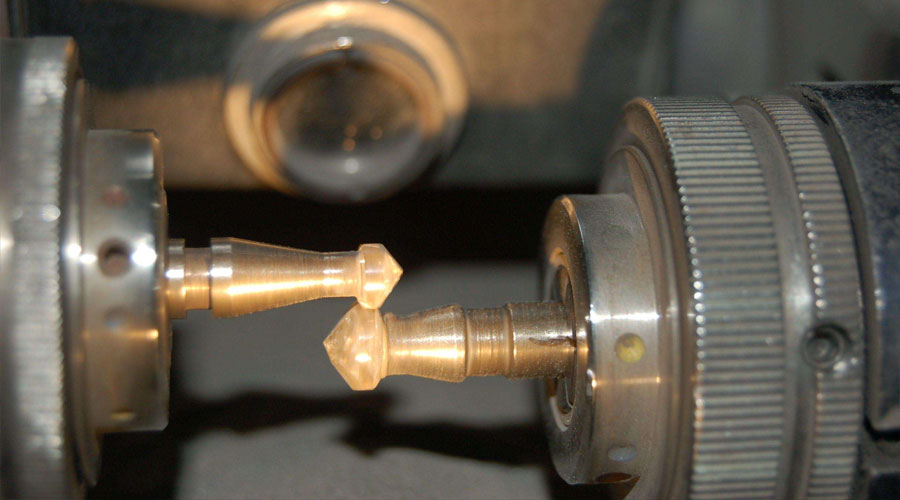

- The ukusika ucingo ukushuba ngokuvamile kungama-40 ~ 60mm, futhi ubukhulu obukhulu bungafika ku-600mm.

Ukuqhathanisa Ukusika Ijubane

- Ngamandla we-1200W, ipuleti lensimbi engu-2mm elincane elingasikiwe linganqunywa ngejubane lama-600cm / min. Ipuleti le-resin le-polypropylene elijiyile elingu-5mm lingasikwa ngejubane le-1200cm / min. Ukusebenza kahle kokusika okutholwe ukusika ngocingo lwe-EDM imvamisa kungamamilimitha angama-20 kuye kwangama-60 ngomzuzu, kanti okuphezulu kakhulu kungafinyelela amamitha ayisikwele angama-300 ngomzuzu. Ngokusobala, ijubane laser ahlabayo iyashesha futhi ingasetshenziswa ekukhiqizweni.

- The ukusika amanzi ijubane lihamba kancane futhi alifanele ukukhiqizwa ngobuningi.

- Ukusikwa kwe-Plasma inejubane lokusika elihamba kancane nokunemba okuphansi. Kukufanele kakhulu ukusika amapuleti awugqinsi, kepha ubuso bokugcina bunomthambeka.

- Ukuze machining yensimbi, ukusika ucingo inokunemba okuphezulu, kepha ijubane lihamba kancane. Kwesinye isikhathi ezinye izindlela zidinga ukuphoqwa futhi kufakwe imicu ukusika, futhi usayizi wokusika ukhawulelwe kakhulu.

Ukuqhathanisa Ukusika Ukunemba

- The ukusika kwe-laser imbobo incane, izinhlangothi zombili zesikhala ziyafana futhi zibheke phezulu, futhi ukunemba okuyisilinganiso sengxenye yokusika kungafinyelela ku-± 0.2mm.

- I-Plasma ingafinyelela ngaphakathi kwe-1mm.

- Ukusika amanzi ngeke kubangele ukusonteka okushisayo, futhi ukunemba ngu- ± 0.1mm. Uma kusetshenziswa umshini wokusika amanzi onamandla, ukunemba kokusika kungathuthukiswa. Ukunemba kokusika kungafinyelela ku-± 0.02mm, kuqeda umthambeka wokusika.

- Ukunemba kocingo lokusika imvamisa kungu-± 0.01 ~ ± 0.02mm, futhi okuphezulu kakhulu kungafinyelela ku-± 0.004mm.

Ukuqhathanisa Ububanzi beSlit

- Ukusika kwe-Laser kunemba kakhulu kunokuzisika kwe-plasma, futhi isinqe sincane, cishe ngo-0.5mm.

- Ukusikwa kwe-Plasma Isikhala sikhulu kunokusika kwe-laser, cishe u-1-2mm.

- Ukusika amanzi ama-slits angaba ngu-10% amakhulu kunobubanzi bethumbu lommese, imvamisa u-0.8-1.2mm. Njengoba ububanzi bepayipi le-trowel bukhula, ukusika kukhula kukhulu.

- Ububanzi besikhala se- ukusika ucingo incane kunazo zonke, imvamisa izungeze u-0.1-0.2mm.

Ukuqhathanisa kwekhwalithi yokusika engaphezulu

Ubukhulu besimo se- ukusika kwe-laser ayifani neyokusikwa kwamanzi. Okukhulu kakhulu kokuqukethwe, kusobala kakhulu.

Ukusika amanzi ayishintshi ukuthungwa kwento ezungeze umthungo wokusika (i-laser ingeyokusika okushisayo futhi iguqula ukuthungwa kwendawo yokusika).

Ukuqhathanisa Izindleko Zokufaka Zokukhiqiza

- 1) Izinhlobo ezihlukile ze ukusika kwe-laser imishini inamanani ahlukene. Eshibhile njengemishini yokusika i-carbon dioxide laser ibiza kuphela ama-20,000 kuye kwangama-30,000, kanti abizayo njengemishini yokusika i-fiber ye-1000W manje ibiza ngaphezulu kwesigidi. Ukusika kwe-Laser akunakho okudlekayo, kepha izindleko zokutshala imali ziyizinto eziphakeme kakhulu kuzo zonke izindlela zokusika, futhi ayiphakeme kancane, futhi izindleko zesondlo nazo ziphakeme impela.

- 2) Ukusikwa kwe-Plasma umshini ushibhile kakhulu kunomshini wokusika we-laser. Ngokuya ngamandla nomkhiqizo womshini wokusika we-plasma, intengo iyahluka, futhi izindleko zokusebenzisa ziphakeme. Ngokuyisisekelo, inqobo nje uma ikwazi ukuqhuba izinto eziqhubayo, ingasika.

- 3) Izindleko ze- ukusika amanzi imishini ingeyesibili kuphela ekusikeni i-laser, ukusetshenziswa kwamandla okuphezulu, izindleko zokusebenzisa nokugcina kahle, futhi ijubane lokusika alisheshi njengeplasma, ngoba yonke imihuzuko iyalahlwa, futhi uma isiqediwe, ikhishelwa emvelweni. Ngakho-ke, ukungcoliswa kwemvelo okubangelwa nakho kubucayi kakhulu.

- 4) Ukuzisika kwentambo ngokuvamile cishe amashumi ezinkulungwane. Kodwa ukusika izintambo kunezinto ezisetshenziswayo, i-molybdenum wire, i-cooler yokusika nokunye. Kunezinhlobo ezimbili zezintambo ezivame ukusetshenziswa ekusikeni izintambo. Enye intambo ye-molybdenum (i-molybdenum iyigugu), esetshenziselwa imishini ehamba ngokushesha. Inzuzo ukuthi i-molybdenum wire ingasetshenziswa kabusha izikhathi eziningi. Enye i-copper wire (eshibhe kakhulu kunocingo lwe-molybdenum) ), Isetshenziselwa imishini yokuhamba kancane, okubi ukuthi ucingo lwethusi lungasetshenziswa kanye kuphela.

Ngaphezu kwalokho, imishini yokuphakela ngokushesha ishibhile kakhulu kunemishini edla kancane. Intengo yocingo olulodwa oludla kancane ilingana nezintambo ezi-5 noma ezi-6 ezidla ngokushesha.

Xhumanisa nale ndatshana: Ukuqhathanisa okuhlobene kwezinqubo ezijwayelekile zokusika zensimbi

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

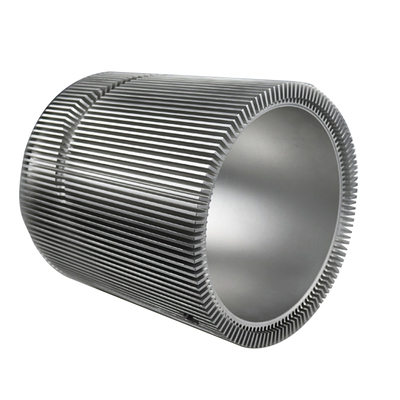

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi