Isendlalelo se-CNC esisebenza kahle kakhulu se-Flexible Wire Machining Cylinder Block And Cylinder Head

Nezimo Wire Machining eyisilinda Block Futhi eyisilinda Head

| Isixazululo esikhethekile se-CNC somugqa wokukhiqiza oguquguqukayo uyisisekelo sokufeza imishini esebenza kahle. Ake siqale ngomklamo oyisihluthulelo wezinjini ezinhlobonhlobo ezinhlobonhlobo nekhanda lesilinda zalapho kukhiqizwe kulayini ofanayo, futhi kuxoxwe ngomklamo obalulekile wezikimu zokuhlelwa kwesakhiwo ukwenza ngcono ukusebenza kahle nekhwalithi yemigqa yokukhiqiza. |

Ingxenye.1 Isakhiwo Esifanelekile Sokukhwabanisa

Inqubo ye-roughing iqeda inqubo elandelayo yokubeka imishini yokusebenza; indawo enkulu yemishini iyasuswa, kanti umugqa ovumelekile ubekelwe ukuqeda ukuqinisekisa usayizi wokugcina, ubucayi, nobukhulu bendawo ebusweni bemishini. Ngaphansi kwezimo zenqubo efanayo zamabhentshimakhi amaningi anemikhiqizo eminingi, ukucatshangelwa okubalulekile kungukuphazanyiswa kwemishini, ukusika ukusebenza kahle nokuqina kwekhwalithi yemishini. Lapho amabhentshi amabi emikhiqizo ehlukile, kuyadingeka ukufeza ukuhambisana ngomklamo omusha wesakhiwo.

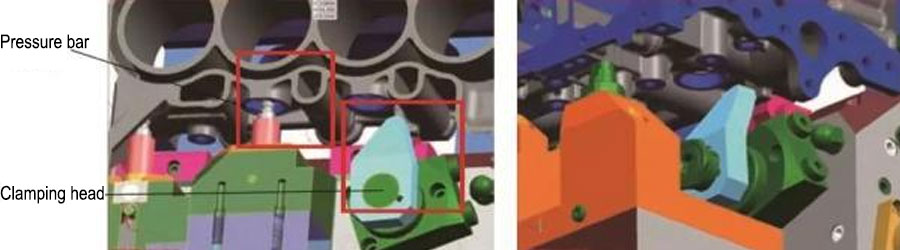

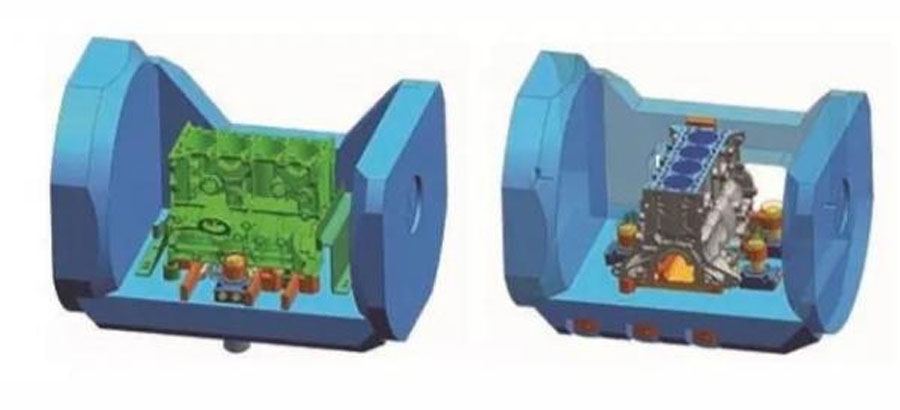

[1] isilinda block clamping scheme

Njengoba kukhonjisiwe kuMdwebo 1, imishini ekhohlakele ikakhulukazi ifaka imishini efana ne-cylinder block kanye negumbi lomlilo. Ngemuva kokuthi umsebenzi wokusebenzela uhleli phansi, uqinisa ikakhulu uqhubukusha induku ngesilinda samafutha ukucindezela imbobo yokususa isihlabathi yomzimba oyisilinda ukuze ucindezele ngokunembile ingxenye ekuqondisweni okuyireferensi, kepha induku icindezelwe ngenxa yomkhawulo wokusakaza, i-engeli yokusalungiswa ukusika umthwalo womthelela. Ukwephuka njalo kuthinta kakhulu ukusebenza kahle komkhiqizo.

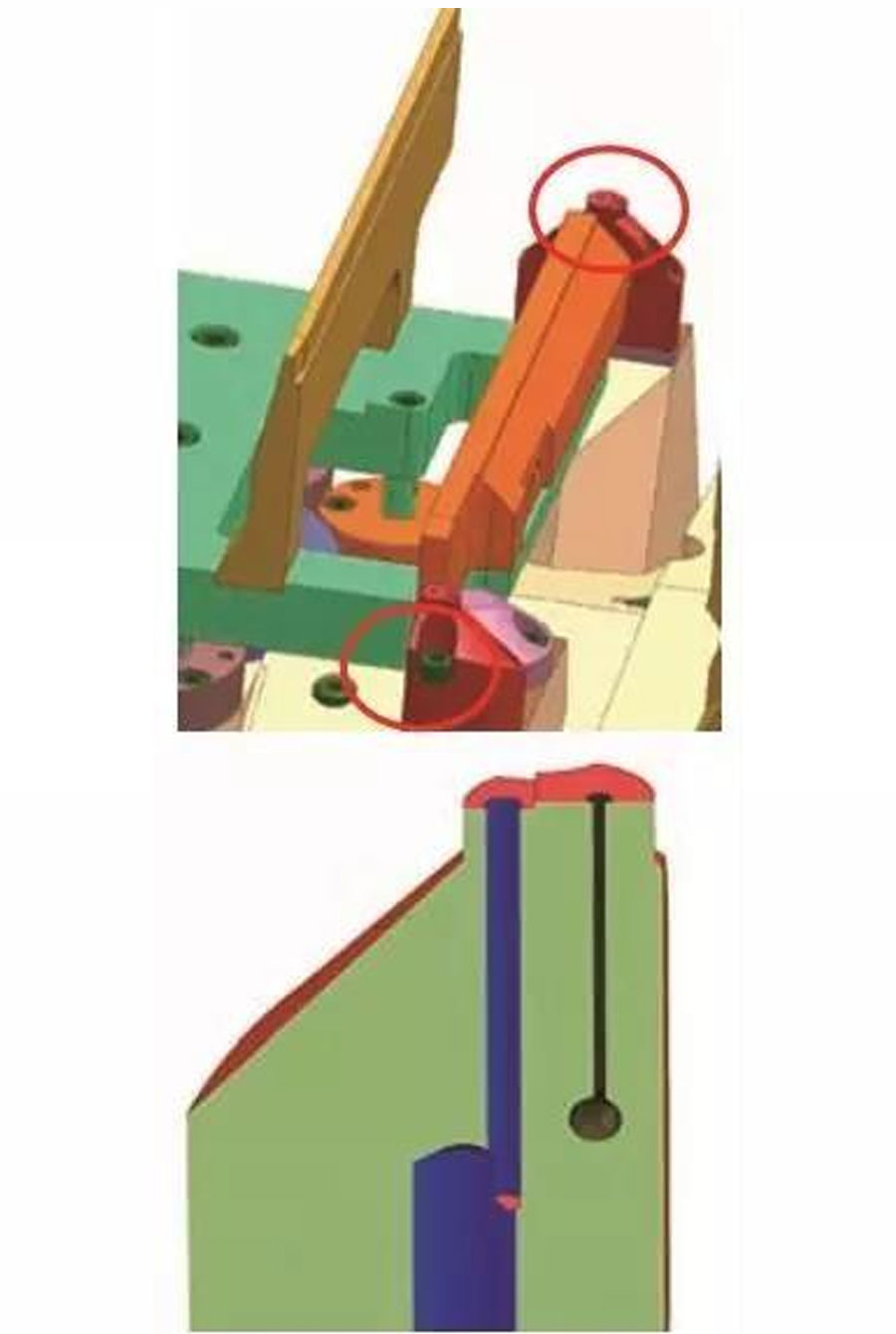

Kodwa-ke, ikhanda lokubamba kwenye indawo yokuma kule ndlela alikaze libhekane nenkinga yokuqhekeka. Ngokuhlela kabusha isakhiwo se-indent, njengoba kukhonjisiwe kuMdwebo 2, lolu hlelo lokusiza olusizayo lwenzelwe isakhiwo esifanayo, esixazulula ngempumelelo i-indenter Inkinga yokuqhekeka ngenxa yomthelela.

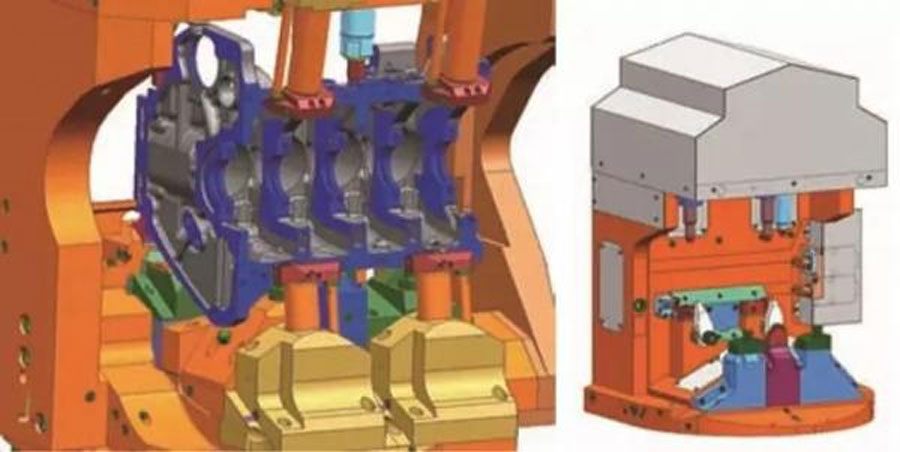

[2] Isixazululo sesibili sokuvumelanisa sijwayela ukukhiqizwa komugqa

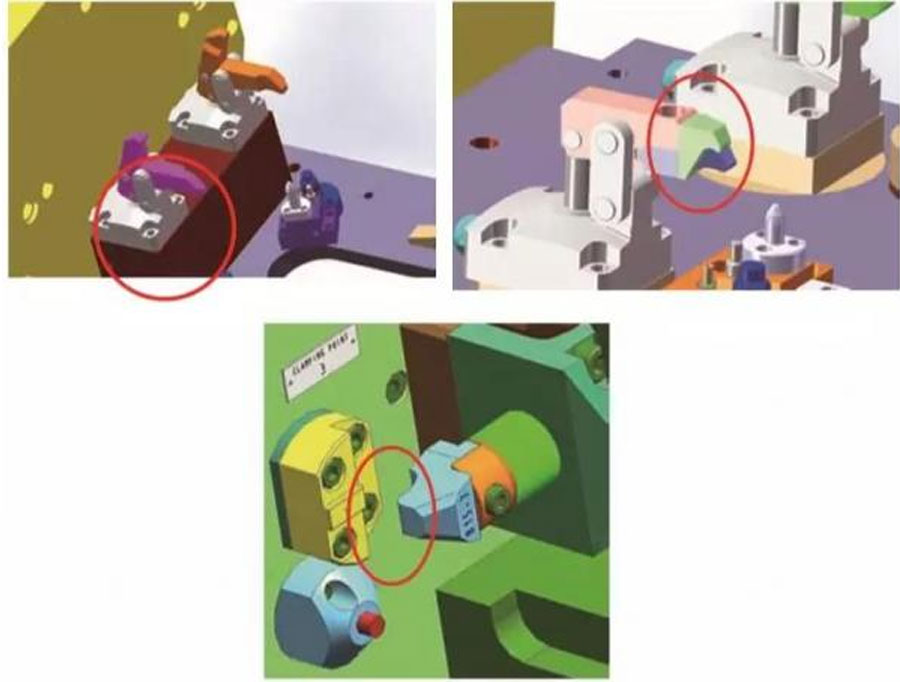

Amabhentshimakhi wokuma amabi we amakhanda eyisilinda zihluke kakhulu, futhi kuhlongozwa izixazululo ezintathu zokukhiqiza imikhiqizo ehlukahlukene kulayini:

1) Outsourced ukubona inqubo yenqubo izici;

2) Faka i-CNC;

3) Imishini efanayo ukulungisa imishini isikhungo.

Ngokushintsha idivayisi yokubeka noma ukusetha isikimu semishini ephindwe kabili, isikimu semishini ephindwe kabili sithandwa kwimodi yokukhiqiza ngobuningi ngemuva kokuhlolwa. Njengoba kukhonjisiwe kuMdwebo 3, ukwakheka kokuma kwezingxenye zekhanda lesilinda zamasilinda amakhulu nezincane kwehluka kakhulu: ukwakheka okuphindwe kabili komklamo designed wenzelwe umshini omncane wesilinda; Ⅱ yisikhundla esikhulu semishini yamasilinda, esifeza ngempumelelo ukulawulwa kwezindleko nokuqinisekiswa kwekhwalithi.

Ingxenye.2 Idizayini Yokuqedela Ukulungiswa Kususelwa ku- "One Side, Izikhonkwane Ezimbili"

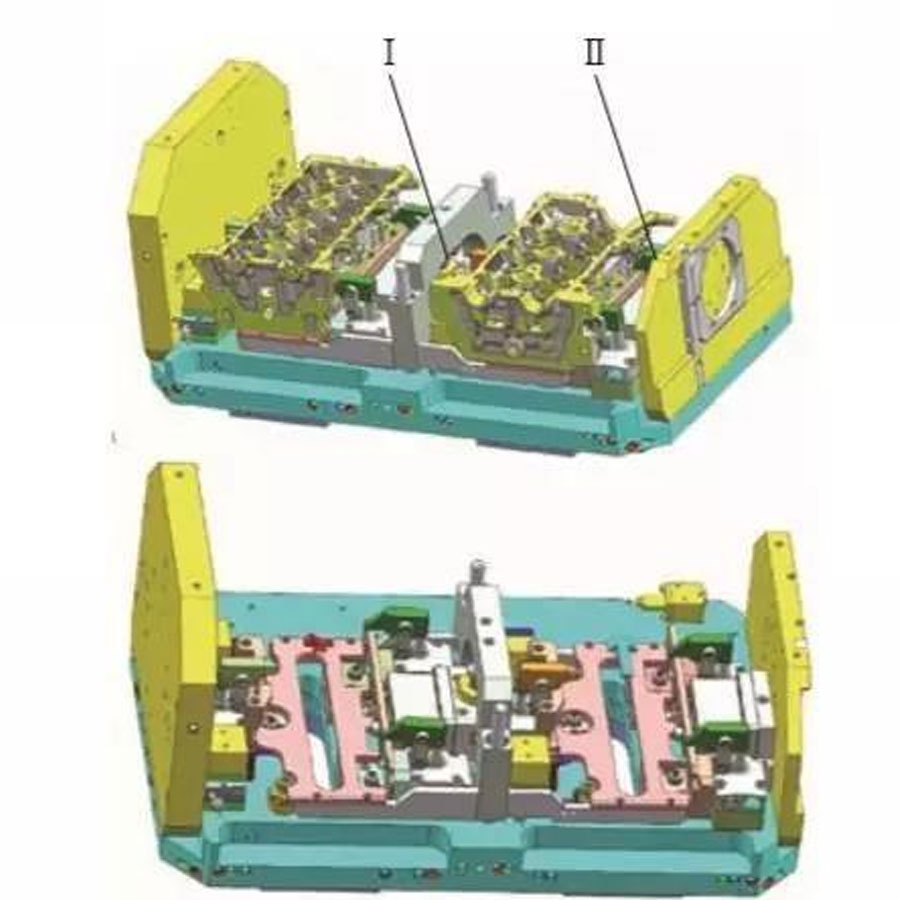

Isilinda ibhulokhi nesilinda ikhanda kuyizinto zemishini ejwayelekile ebhokisini. Ngesisekelo semishini, uhlelo lokubeka "uhlangothi olulodwa, izikhonkwane ezimbili" lusetshenziselwa ukufeza izindiza ezi-6 nokuqedwa kwesistimu yemigodi.

[1] Kusetshenziswa isibonisi se-eksisi ye-A / B

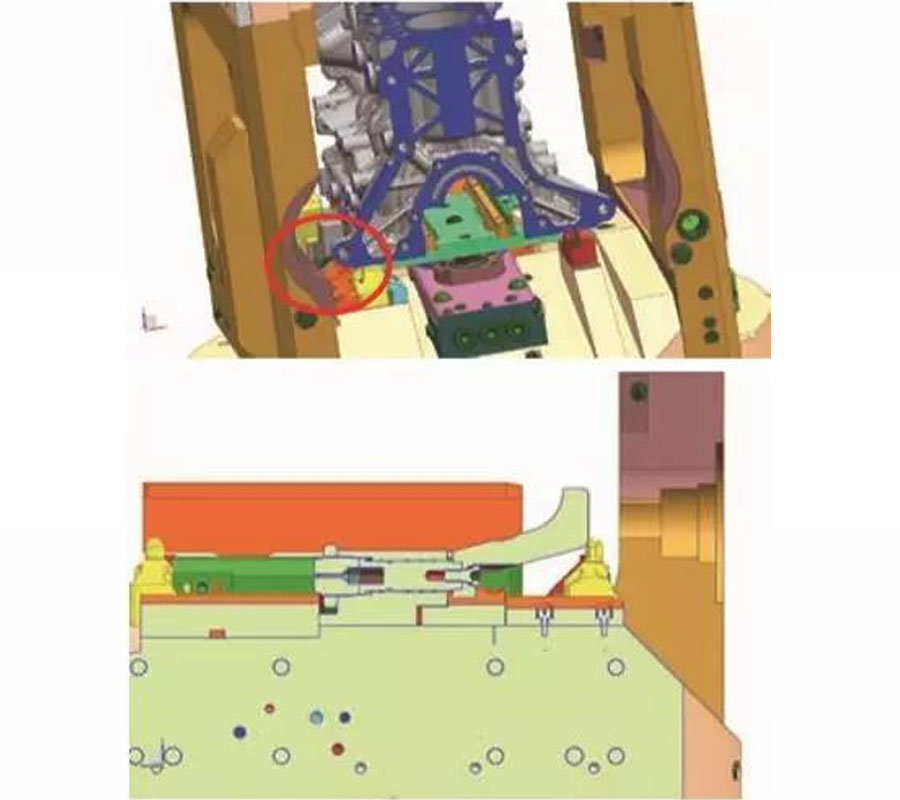

Ngokususelwa kunqubo yokudlulisela ye-B-axis, ulayini wokuqala wokukhiqiza we-cylinder block wonke usebenzisa isisombululo se-B-axis. Njengoba kukhonjisiwe kuMdwebo 4, ezinye izici zemishini ezifana ne-crankumphini izimbobo inzwa isikhundla kanye main eziveza izindawo ezihlanganisiwe zekhophethi kufanele ziphendulwe zime mpo ukuqedela ukwakhiwa.

Ngemuva kokuhlolwa kwemboni nokusetshenziswa okusebenzayo kwe-A-axis yekhanda lesilinda, umthwalo wemishini we-small-displacement cast iron cylinder block ngaphansi kwe-1.5L ungahlangabezana ngokugcwele nezidingo zenqubo ngokusebenzisa i-A-axis machining. Njengoba kukhonjisiwe kuMdwebo 6, ukusebenzisa ukuhlelwa kwe-B-axis ne-A-axis tandem kungabona kahle ukuthi indawo yokubeka ingxenye ihlala ibheke phansi, ngaphandle kwesidingo sokuyiguqula ime mpo. Akugcini nje kuphela isikhathi sokusebenza sabasebenzi, kunciphisa umthwalo womsebenzi, kepha futhi kugwema ukusika uketshezi kuketshezi ngesikhathi sokuguqula kubangela ukungcola endaweni yokusebenza.

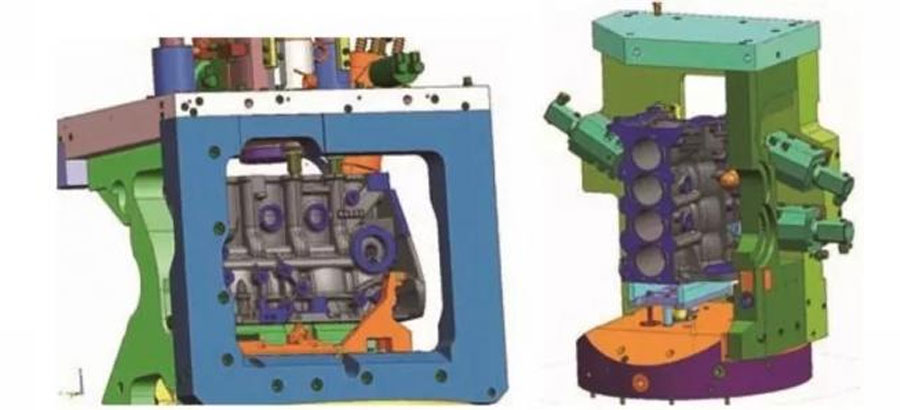

[2] Lungiselela ukuklanywa kwephoyinti lokuqinisa le-aluminium alloy fixture

I-lever-type force-kuongeza clamping mechanism isetshenziselwa ukuklama ukwakhiwa kwamakhanda e-aluminium alloy cylinder, angagcini nje ngokugwema ukusonteka kwamakhanda esilinda, kepha futhi ahlangabezana nezidingo zamandla emishini. Njengoba kukhonjisiwe kuMdwebo 6, iziteshi eziningi zisebenzisa ukwakheka okufanayo kwesakhiwo ukuhlangabezana nolayini wokukhiqiza. Ukuhlolwa kokuqina kwesikhathi eside. Ngenxa yomehluko omkhulu ebangeni lephoyinti lokuminyanisa, izinqubo zokubambanisa ezihambisanayo azikwazi ukufinyelelwa. Ngokuklama isakhiwo esisheshayo se-chuck, ukuhambisana kwezingxenye ezahlukahlukene kuyatholakala.

[3] Idizayini eqondile yesakhiwo sokuma endaweni

Ngokuya ngezidingo zokuklama eziphansi, i-CNC yakhelwe ukulayishwa okuzenzakalelayo. Ukuze kuqinisekiswe ukuthi abasebenzi bayacindezela futhi badonse izingxenye ezithile endaweni, ukwakheka kwedivayisi yokungeniswa komshini wethuluzi lomshini kubaluleke kakhulu.

Ngakho-ke, ukwakheka kukhonjisiwe kuMdwebo 7. Ngemuva kokuthi umsebenzi wokusebenza ufakwa endaweni yawo, indlela yangaphakathi yegesi yendlela yokuxhuma ixhunyiwe, futhi ingcindezi esiteshini ishintshelwa kunani elibekiwe, ukuze izingxenye zibhekwe zisendaweni . Ngokubhalela lesi siginali kumqondo wokuxhumeka wedivayisi, umshini awucubunguli lapho ingxenye ingekho ukuvimbela ingxenye ukuthi ingaweli emgqonyeni wemishini.

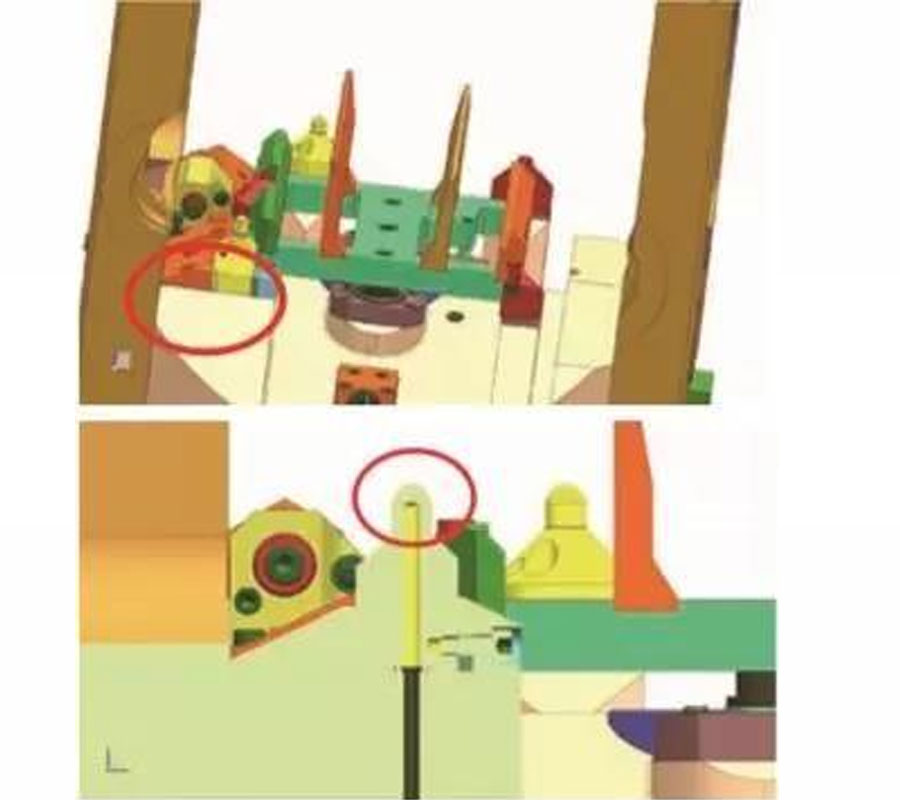

[4] Ukuma kwesakhiwo sokutholwa kwesakhiwo sokuthola igesi

Ngokuya ngesakhiwo sokuklanywa "sohlangothi olulodwa nezikhonkwane ezimbili", njengoba kukhonjisiwe ku-FIG. 8, "uhlangothi olulodwa" ludlulisa amaphuzu wokubeka ama-3 noma ama-4; "Izikhonkwane ezimbili" ziyizingxenye zokubeka iphini kanye nedayimane.

[5] Idizayini yesakhiwo sephoyinti

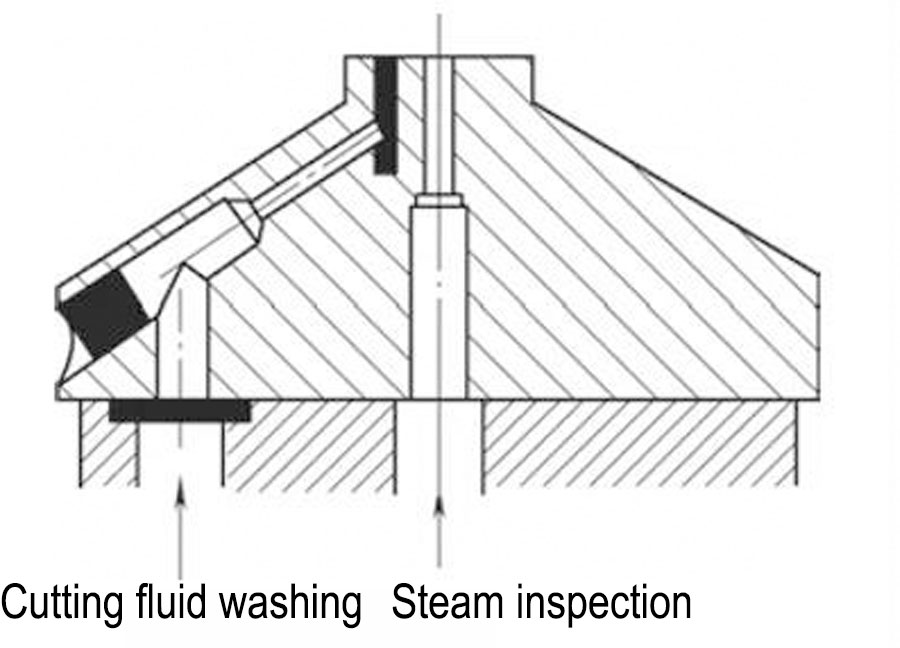

Njengoba kukhonjisiwe kuMdwebo 9, ukuqapha okungangeni emoyeni nokusika imishini yokuwasha uketshezi kuyasetshenziswa endaweni ngayinye yokumisa: ngesikhathi senqubo yokubeka, ukungasebenzi kahle kwemishini okubangelwa ukufakwa kwensimbi endaweni yokuma kuvinjelwe ukuthi kungagezwa; ngesikhathi semishini, ukuhlolwa komoya kuhlola yonke ingxenye yokufuduka.

Ingxenye.3 Ukwakhiwa kwemidlalo yezici ezibalulekile

Imishini yiyo yonke i-CNC, ikakhulukazi ebheka ukuguquguquka kokukhiqizwa nokwethulwa kwemikhiqizo emisha ngokuzayo. Kodwa-ke, amandla esikhathi eside wokusebenza kwemishini ebalulekile awakwazi ukuhlangabezana nezidingo zenqubo, njengokuma okuyisidina kwemigodi ye-crankshaft.

[1] Idizayini yokuboniswa kwesiteshi esikhethekile

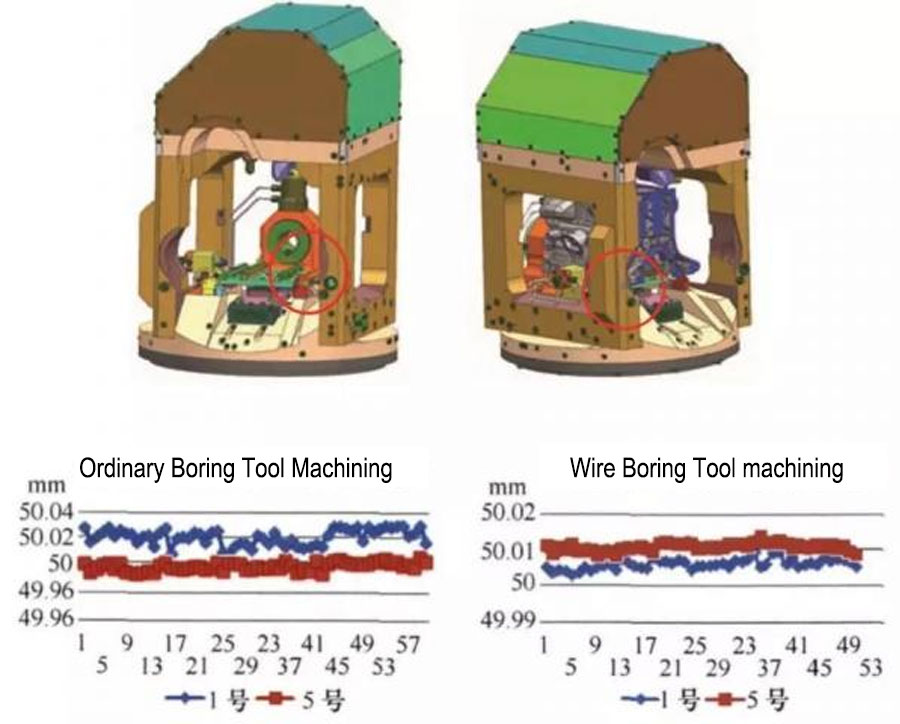

Imbobo ye-crankshaft yebhulokhi yesilinda icutshungulwa yithuluzi elikhethekile elicefe elinezici ezikhethekile zomshini, elingabheki nje kuphela ukuguquguquka kwe-CNC, kepha futhi liqinisekisa ukuzinza komshini okhethekile. Ukuqina kubangela ukwehluka kwesikhundla. Kodwa-ke, ithuluzi eliyisicefe linezidingo eziqinile enkabeni yokuphakelayo, futhi uhlelo lokuma olususelwa ekubambisaneni komgodi wepini lunomphumela othile wegebe.

Ukususa igebe, njengoba kukhonjisiwe kuMdwebo 10, kufakwa isilinda sokuphusha ohlangothini lwengxenye. Ngemuva kokuthi umsebenzi wokusebenza uhleli phansi, ingxenye idudulelwa eceleni ngenduku yokusunduza ukuqeda umphumela ongaba khona wegebe ukuqinisekisa ukugxila. Ngokusebenzisa isisombululo se-wire-boring cutter solution ekhethekile ku-CNC, umehluko wesikhungo phakathi kwengaphambili nangemuva komgodi we-crankshaft yathuthukiswa ngempumelelo kusuka ku-0.025mm kuya ku-0.01mm.

[2] Idivayisi yokulinganisa on-line yamathuluzi esiteshi asemqoka

On-line uphenyo asetshenziselwa machining izici ezibalulekile izingxenye ibhokisi-like, futhi ngenkuthalo angenele inqubo ukuthuthukisa machining amakhono. Njenge-cylinder block thrust surface, i-cylinder block cylinder ikhanda lokushisa ikamelo elingaphezulu nezinye izici ezibalulekile zokutholwa kwemishini, ukuze kuqinisekiswe ikhono losayizi wemishini, ngokusebenzisa isilinganiso se-probe ukufezekisa isinxephezelo sokugqoka ithuluzi. Ukuze uvikele ithonya lokunamathisela ngensimbi ye-probe, i-aluminium shavings, nokuguquguquka komzimba komzimba, njll. usayizi.

Ukulungiswa okukhethekile kwezingxenye zebhokisi kuthuthukiswe ngempumelelo futhi kwasetshenziswa kulayini wokukhiqiza wemizimba yamasilinda kanye namakhanda amasilinda. Ngaphandle kokuthi ezinye izingxenye zokunamathela nokuqondisa kudingeka zishintshwe ngesandla, amadivayisi wokuma awadingi ukuthi aguqulwe, angaqaphela ukukhiqizwa okusemgqeni kwezigaba ezinkulu ezintathu zemikhiqizo. Ukusetshenziswa okuxubekile kwezimbazo ze-A / B kususelwa ohlangothini olulodwa nezikhonkwane ezimbili kufinyeza kahle isikhathi sosizo lokukhiqiza futhi kuthuthukise ukusetshenziswa kwe-ergonomics, ikakhulukazi ukusetshenziswa komqondo womshini okhethekile ekwakhiweni kwezinsiza ze-CNC, okuthuthukisa ngempumelelo isikhathi eside machining amakhono izici ezibalulekile.

Xhumanisa nale ndatshana: Isendlalelo se-CNC esisebenza kahle kakhulu se-Flexible Wire Machining Cylinder Block And Cylinder Head

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ inguchwepheshe Cnc Machining Isitolo uneminyaka engu-12 enolwazi kuzingxenye ezingokwezifiso ezingekho ejwayelekile.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ inguchwepheshe Cnc Machining Isitolo uneminyaka engu-12 enolwazi kuzingxenye ezingokwezifiso ezingekho ejwayelekile.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi