Inqubo yokusika ye-Titanium alloy TC11 Precision

Inqubo yokusika ye-Titanium alloy TC11 Precision

|

Ingxubevange yeTitanium inezici zobuningi obuphansi, amandla aphezulu, namandla athe xaxa kunensimbi yamandla e-ultra-high; nokuqina okuhle kokushisa, ukumelana nokugqwala, amandla okushisa aphezulu; ekushiseni okungu-300 ~ 500 ℃, amandla ayo acishe aphindwe izikhathi eziyi-10 kune-aluminium alloy, njll. Isetshenziswe kabanzi emikhiqizweni ye-aerospace, yezindiza neyemishini. Ikakhulu, (α + β) titanium alloy ingacinywa futhi igugile ukuqinisa i-alloy, futhi amandla ngemuva kokwelashwa kokushisa athuthukiswa ngo-50% kuya ku-100% uma kuqhathaniswa nesimo sokuncishwa. Futhi ine esivelele ongaphakeme lokushisa ukumelana futhi ukumelana esivelele amanzi olwandle ukugqwala futhi hot usawoti ukucindezeleka ukugqwala, futhi lisetshenziswa kabanzi. |

Kodwa-ke, ngoba ingxubevange ye-titanium ine-coefficient encane yokusika (i-coefficient ye-deformation ingaphansi noma icishe ibe ngu-1), inqubo yokusika ye-chip ebusweni be-rake inyusa indlela yokushayisana okungahambisani, okusheshisa ukugqoka kwamathuluzi; Okwamanje, izinga lokushisa lokusika liphezulu, amandla okusika makhulu, futhi Ukubonakala kongqimba lokungcola okonakele kwenzeka ngoba umshini we-titanium inomsebenzi omkhulu wamakhemikhali futhi unesibopho sokuthola ukusabela kwamakhemikhali okunolaka ngokungcola okuhlukahlukene kwegesi, okufana no-O, N, H, C, njll., okuhlasela isendlalelo sokusika se-titanium alloy, kubangele ukuqina nobulukhuni bendawo ungqimba ukwandisa. Abanye basenokwakheka kwe-TCI ne-TiN ungqimba lwendawo eqinile; ekushiseni okuphezulu, ungqimba olungaphezulu luhlelwe ngo-α-ungqimba ne-hydrogen embrittlement ungqimba nezinye izingqimba zokungcola eziguqulwe ngaphandle. Ukwakheka kwezingqimba ezingalingani zomhlaba, ukugxila kwengcindezi okuncane, ukunciphisa ukukhathala kwezingxenye, ukulimala okukhulu kunqubo yokusika, nokubukeka kokuqhekeka, ukugawulwa nokuchithwa; ubumbano olukhulu. Ngesikhathi sokusika, ama-titanium chips nezindawo ezisikiwe Kulula ukuluma nedatha yethuluzi, futhi kuvela ukuvela kommese okunzima, okuholela ekugqokeni okukhulu kokubopha; futhi ukushiyeka okufana nokungazinzi kwelungiselelo le-titanium alloy kuletha ubunzima obuningi ekusikeni, ikakhulukazi ukusika okuhle, ngakho-ke kubizwa nangokuthi insimbi yokwenza kabi. Ngakho-ke, ingxoxo yezobuchwepheshe ye-titanium alloy cutting cutting machining ngumbuzo odinga ukusingathwa ngokuphuthumayo.

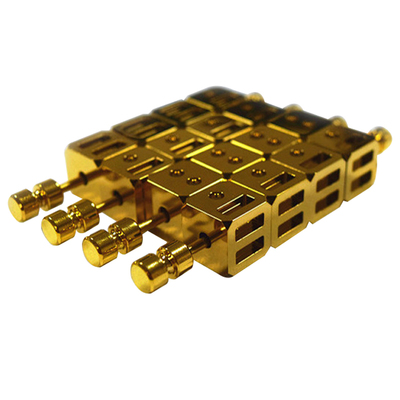

Indlu yamapayipi omsila (njengoba kukhonjisiwe kuMdwebo 1) iyingxenye ebalulekile yokusebenza kumkhiqizo efektri yombhali. Ngoba kuyadingeka ukwamukela ukushisa okuphezulu kanye nengcindezi ezimeni zokusebenza, izidingo zomsebenzi wazo zingamandla we-Rm ≥ 1030MPa, ukunwebeka A ≥9, ukuze kwaneliswe izidingo zayo zokusebenza, i-titanium alloy TC11 isetshenziselwa ukuhlela umkhiqizo, iyindonga ejwayelekile emincane umphini ingxenye ye-tubular. Ngemuva kokuhlelelwa kokusebenza kahle kobuchwepheshe bayo bokusika, ukusikwa okuhle kwe-titanium alloy TC11 kwaqedwa.

1.Titanium Ingxubevange TC11 Cutting Izici

I-TC11 titanium alloy iyinhlobo (α + β) yohlobo lwe-Ti alloy. Ukuhlelwa kwaso kuhlanganiswe isigaba esigcwele i-hexagonal α nesigaba se-cubic body esigxile emzimbeni. Uma kuqhathaniswa nezinye izinsimbi, ukuthungwa kubaluleke kakhulu futhi i-anisotropy inamandla, okuletha ubunzima obukhulu ekukhiqizeni nasekusebenzeni kwama-titanium alloys. . Inqubo yokusika izici zayo zimi kanje:

- (1) Amandla okusika aphezulu nokushisa okuphezulu okusika. Ngoba ingxubevange ye-titanium inokuqina okuphansi namandla amakhulu, okuphakelayo okusikayo kunokucindezeleka okukhulu kwe-shear nomsebenzi omkhulu wokwenza ipulasitiki, ngakho-ke amandla okusika aphezulu futhi izinga lokushisa lokusika liphakeme.

- (2) Umsebenzi onzima uqina. Ngaphezu kokuguquguquka kwepulasitiki, ama-titanium alloys asebenza kanzima ngenxa yokuhogela umoya-mpilo ne-nitrogen emazingeni okushisa aphezulu okusika, ukutholakala kwesisombululo esiqinile ku-voids, kanye nemiphumela ephikisanayo yezinhlayiya zobulukhuni obuphezulu kuthuluzi.

- (3) Ummese wenduku olula. Ama-alloys weTitanium anokuhlangana okuqinile kwamakhemikhali emazingeni aphezulu okushisa, kuhambisana namandla amakhulu okusika, kuqhubeka nokukhuthaza ukugqokwa kwamathuluzi.

- (4) Ukugqokwa kwamathuluzi kunzima. Hlukanisa ukugqoka kuyisici esibalulekile sokugqokwa kwamathuluzi lapho usika ama-titanium alloys.

Ukuhlaziywa Kweworkpiece

Isixazululo se-3.Technical

3.1 Umgwaqo Wezobuchwepheshe

Umgwaqo wobuchwepheshe usekelwe esimisweni esithi "ukujiya kuqala, bese uqeda, ngaphakathi bese ngaphandle" ukunciphisa ukusonteka ngesikhathi sokuqeda nokwenza ngcono ukunemba kwemishini. Enqubweni yokuqala yokukhiqizwa kwesivivinyo, imigwaqo yobuchwepheshe yilena: ukungabi nalutho, ubude bemoto, ukuma kokujika okunzima, ukubhola, okuyisidina, ukunemba kokuma, ukuqeda ukuma.

Ingxubevange yeTitanium ine-conductivity empofu yokushisa, ubuningi obuphansi nokushisa okuthile, kanye namazinga okushisa aphezulu okusika; inokusondelana okunamandla kwamakhemikhali nethuluzi, futhi kulula ukunamathela ummese, okwenza ukusika kube nzima. Ukuhlolwa kuqinisekisile ukuthi lapho amandla amakhulu e-alloy titanium ayanda, amandla ayo asebenza kabi kakhulu. Ngakho-ke, kuyadingeka ukukhetha ama-alloys anzima asuselwe ku-tungsten-cobalt anokuhlangana okuncane kwamakhemikhali, ukuqhuba okuhle kokushisa namandla amakhulu ku inqubo machining.

Imoto erhabaxa yi-YG8, imoto eqeda semi ngu-YG6, kuthi eyokuqeda kube yi-YG3X. I-drill yenziwa ngosimende we-carbide twist drill (YG6 cemented carbide).

3.2 Ngokungabaza

- (1) Lapho kusetshenziswa i-hard alloy twist drill ekushayeni, izinga lokushisa lokusika liphakeme ngokufanele, i-drill bit igqoke kakhulu, futhi ukucindezela okushisayo kwenqubo yokuchofoza kuthinteka ngqo, okuthinta ngqo ukunemba kokuqeda okulandelayo.

- (2) I-workpiece ine-deformation enkulu, futhi ubukhulu bemishini bunzima ukulawula.

- (3) Isimo se-out-of-coaxiality sinzima, isilinganiso esifanelekile sendawo yokusebenza siphansi, futhi isilinganiso esifanayo esifanelekile singama-50% kuphela.

- (4) Amandla wokukhiqiza awekho phezulu, ukugqokwa kwamathuluzi kukhulu, futhi izindleko zokukhiqiza zinkulu.

3.3 Uhlelo lokwelashwa

3.3.1 Khetha ithuluzi elifanele kusuka ekuqaleni

Ngemuva kokufunda inqubo yedatha nemishini, kwanqunywa ukuthi kusetshenziswe i-Kenner HTS-C umshini wohlobo lwe-drill bit (jet suction drill) wokubhola; le ncanyana inganikeza ukupholisa okunamandla futhi ifakwe i-PVD enamathelayo efakwa kuyo yonke ingxubevange eqinile efakwa kanye nemitshingo ye-chip kanye ne-carbide drill. Ngemuva kocwaningo, i-drill isebenzisa okufakwa kwe-KC720 ne-KC7215 (okufakwa ngaphambili nangemuva) okukhethekile ezintweni ezinzima ukwenza umshini ukubhola ama-titanium alloys. Amandla okukhipha andiswa ngama-60%, futhi umsebenzi wokusebenza ngemuva kokubhola awukhiqizi ukushisa nokusonteka. Awukho umphumela wokucindezeleka ngesikhathi semishini, futhi akukho ukungcola kwemvelo ezungezile, njengoba kukhonjisiwe kuMdwebo 2.

3.3.2 Ukuhlaziywa kwezimbangela zokusonteka nezindlela zokulwa

Isizathu esiyinhloko sokushintshwa kwenqubo yokwenza imishini kungenxa yokuthi ingxubevange ye-titanium ihlela ukucindezeleka. Esigabeni sokuqala senqubo yokukhiqizwa kwesivivinyo, yize ubuchwepheshe bamukela ubuchwepheshe bemishini bokukhahlela kuqala, bese buqedela, bese ngaphakathi nangaphandle, kepha abuzange bucabangele ngokuphelele izinto ezingazinzile zelungiselelo le-titanium alloy, ezakha ukubukeka kokuguqulwa komsebenzi Kunzima ukulawula usayizi ngesikhathi semishini. Ungakunciphisa kanjani ukusontwa kwe-titanium ingxubevange machining inqubo kuya okungenani kuyinkinga enzima.

Ngemuva kokuhlolwa okuphindiwe, singeza inqubo yokuguga yokuguga ngemuva kokucubungula okunzima kwento yokusebenza. Ngaphandle kokunciphisa ukusebenza ngomshini kokwenza umsebenzi, izinhlamvu ziyacolisiswa, bese kufinyelelwa kulungiselelo elihle ukuqeda ukucindezeleka kwangaphakathi nokwenza ilungiselelo lifinyelele esimweni esizinzile.

Izinga lokwelashwa kokushisa limi kanje: izinga lokushisa lokuguga lingu-530 ℃, futhi isikhathi sokubamba ngu-4 ~ 6h. Qinisekisa ukuthi i-Rm≥1030MPa ne-A≥9%. Ngemuva kwamaqoqo amaningi wokuhlola, i-Rm eqine amandla ingaphezulu kwe-1030 MPa, futhi i-elongation A ingaphezu kuka-9%.

3.3.3 Izizathu Zokuphuma Kwenhlangano kanye Nezinyathelo Zokuphikisa

Kuhloswe ngezinga eliphansi le-workpiece elibangelwe ubumbano obumbene, ukuhlaziywa okuqhubekayo kwedatha yomsebenzi kanye nobuchwepheshe bemishini kutholakale ukuthi lo msebenzi uyishubhu enezindonga ezincanyana, okuyinsimbi ejwayelekile ekhubazekayo futhi enzima ukwenza umshini. Uma nje ukuqina kwazo zonke izinhlelo zobuchwepheshe kuthuthukisiwe, iTalente ukuphatha ngempumelelo imibuzo yalo yokwenza izinto.

- (1) Ngesikhathi sangaphakathi imbobo machining, inqubo yezobuchwepheshe isethwe ngokunengqondo. Isinyathelo sobuchwepheshe esinokuqina okuthile sisetshenzisiwe njengesithenjwa sokubekwa nokuma kwendawo yokusebenza, ebhekane ngempumelelo nenkinga yokukhubazeka kwembobo yangaphakathi ngesikhathi semishini, njengoba kukhonjisiwe kuMdwebo 3.

- (2) Enkambeni yomshini wangaphandle wokumaketha, kwamukelwa indlela yokugcwalisa izinto ezilwa nokudlidliza, okungukuthi, ngesikhathi senqubo yokuqedela eseqedile yomsebenzi, ingxenye yokuqinisa igcwele iphedi eqinile yokuvikela ukusonteka komsebenzi; imbobo yangaphakathi yomsebenzi igcwele okuthambile Ishubhu enjoloba eguquguqukayo noma impahla eyenziwe ngegwebu iyenza ingene odongeni lwayo lwangaphakathi ngesikhathi senqubo yokwenza imishini, bese ifinyelela kumphumela wokunezela ukuqina kozosebenza, njengoba kukhonjisiwe kuMdwebo 4.

- (3) Ukuze kuqinisekiswe ubumbano lomsebenzi, isethi yokuma ngaphezulu zalapho kuhlelwe ngesikhathi sokugcina sokuqedela ukwenza ngcono ukuqina komsebenzi, njengoba kukhonjisiwe kuMdwebo 5.

Ngemuva kwalokho, ukubumbana kobuciko bokusebenza kubi. Ngakho-ke, ekuhleleni kwe-fixture, ukuze kuqinisekiswe ukuqina komsebenzi, kusetshenziswe idivayisi yokubeka ngaphezulu. Akugcinanga lapho kuphela yonke imbobo yangaphakathi yomsebenzi isetshenziswe njengesethenjwa sokuma, yize ukubukeka kokuma kwenzeka ngokwethiyori, kepha empeleni, kuzenelise ngokuphelele izidingo zento yokusebenza. . Bheka Umfanekiso 6.

Ngokuya ngezici ezibalulwe ngenhla ze-TC11 titanium alloy ngesikhathi senqubo yokusika kanye nendlela i-alloy enzima ukusika ngayo, futhi ihlobene nezindlela zemishini kanye nesipiliyoni sedatha enzima ukwenza umshini ekukhiqizeni, ubuchwepheshe bokusika imishini umgwaqo wabhalwa kusukela ekuqaleni ngale ndlela elandelayo: ukusika okuthe xaxa- —Ukubhoboza — Ngaphakathi nangaphandle kwemoto enolaka — Ukuhlolwa kokuguga nokusebenza kwemishini — Isilinganiso semoto — Imbobo yangaphakathi yemoto eqediwe, Imbobo enkulu yemoto eqediwe— Ukuma kwangaphakathi kwemoto eqediwe — Isimo semoto eqediwe Semi —— Umphathi Jikelele uPing, isiphetho esincane semoto enhle —— Isimo semoto esihle.

Indlu yomsila wepayipi yezingxenye ze-titanium alloy ezicutshungulwa ngale ndlela yezobuchwepheshe ihlangabezana ngokugcwele nezidingo zokuhlela, futhi isilinganiso esifanelekayo sezingxenye sifinyelela ngaphezu kuka-98%. Inkinga yokusikwa okuhle kwe-titanium alloy kusingathwa ngayo ngempumelelo.

I-4.Conclusion

I-Titanium alloy ine-machinability empofu, ngakho-ke ukuthi ungayithuthukisa kanjani futhi uyenze ngcono kanjani ukusebenza kwayo ngemishini inkinga enzima. Lo mbhalo uhlaziya izindlela zokusika zensimbi yegobolondo lomsila wezingxenye ze-titanium alloy, uqeda ukusikwa okuhle kwezingxenye ze-titanium alloy, futhi kusingathwa ngempumelelo ubunzima bemishini njengokuguqula ukusonteka nokugqokwa kwamathuluzi kwezingxenye zodonga lwe-titanium alloy TC11. Ngolwazi oluthe xaxa nokuqonda ubuchwepheshe bemishini yezingxenye ezincane ezinamadonga e-titanium alloy, ithole isipiliyoni esithile sokwenza imishini yesikhathi esizayo kwezingxenye ze-titanium alloy.

Xhumanisa nale ndatshana: Inqubo yokusika ye-Titanium alloy TC11 Precision

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi