Ukuthola i-Coaxiality Method Yezingxenye Zomshini ze-PEEK

Isingeniso nokumelelwa okungokomfanekiso kobumbano

|

1. I-cooaxiality iyitemu lobuchwepheshe elenzelwe ukumelela ukubekezelelana kokuma nokubekezelelana kwesimo sezingxenye. Izinto ezifanele yi-eksisi ne-eksisi, imbobo nomgodi, ne-eksisi nembobo. Umugqa ofanayo oqondile noma ukugxila kuyadingeka, okusho ukulawula Ukuthi i-eksisi langempela liphambuka kangakanani kwi-eksisi eyisithenjwa! 2. Uphawu lwayo luchazwa njengemibuthano emibili: ◎ |

Imiphumela emibi engaba khona yamaphutha amakhulu wokukhohlisa

Iphutha le-cooaxiality ukungahambi kahle kwesikhungo sombuthano okuvezwe esigabeni esiphambanweni. Uma izingxenye ezinamaphutha amakhulu we-coaxiality zifakiwe futhi zisetshenziswa, kungenzeka zingabuthwa ngesikhathi somhlangano. Umshini ohlanganisiwe ungakhiqiza ukudlidlizela, ukuzamazama, umsindo ngezikhathi ezithile, ukuncela okungazinzile, ukulimala kwezingxenye zomshini, futhi kungadala umonakalo omkhulu. Uchungechunge lwezinkinga zokukhanda ezifana nezingozi zokuphepha, ngakho-ke ukulawulwa kobumbano bezingxenye bekulokhu kuyinto ebalulekile yokuhlolwa kwekhwalithi yePTJ Shop Plastics Machining.

Izinhlobo zezingxenye zesilinganiso se-coaxiality

Isilinganiso sokugxila kufanele senziwe ngezingxenye ezijikelezayo, njenge umphinis, igiyas, ibhasis nezinye izingxenye.Imishini yokuhlola

I-coaxiality kunzima ukuyikala. Izinsimbi esizisebenzisayo zifaka abalingisi bezithombe, izixhumanisi ezintathu, amamitha we-deflection, izinsimbi ezimise okwe-V, izinkomba zokudayela, kanye nezinto ezikhethekile zalapho.

Izindlela zokulinganisa

Ukutholwa kwe-coaxiality kuyinto yokuhlola esivame ukuyenza emsebenzini wokulinganisa. Okulandelayo isingeniso esifushane sendlela yokubona i-coaxiality ye-shaft negiya ekhiqizwa yinkampani.

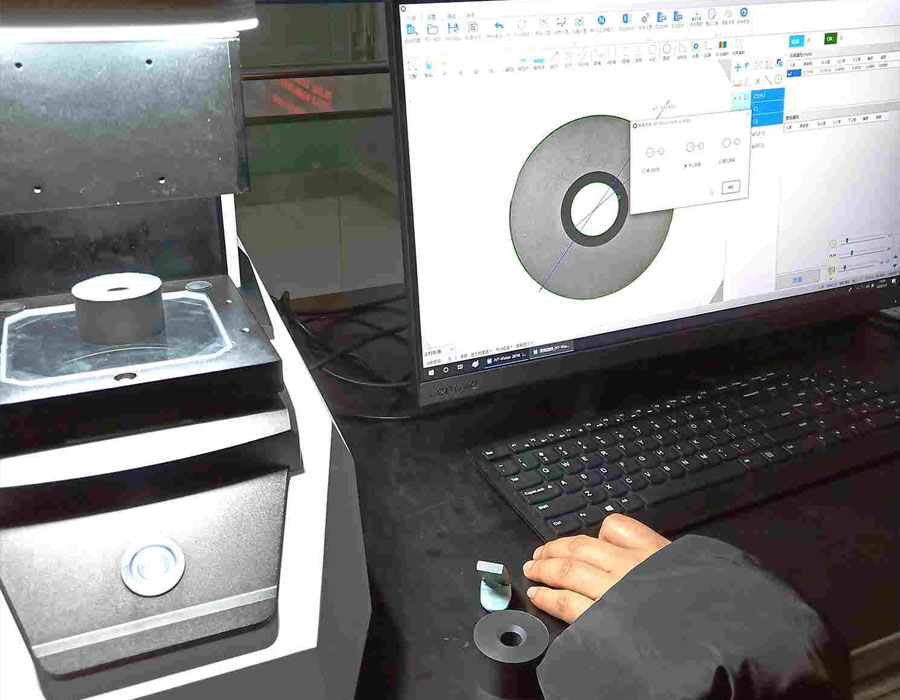

Indlela yokulinganisa ubumbano nomfanekiso wesithombe

- 1. Vula ikhompyutha bese ubeka ingxenye evivinyiwe ebhentshini lomsebenzi

- 2. Vula inkinobho ye-flash kukhompyutha bese ungenisa uhlelo

- 3. Chofoza umbuthano ongaphandle nomgodi wangaphakathi wento elinganisiwe negundane, bese uchofoza inkinobho yokulinganisa

- 4. Funda idatha coaxiality, urekhode, bese ugcwalisa umbiko test!

2.Indlela yokukala ukuhlangana ngezixhumanisi ezintathu (i-CMM)

- 1. Khomba umdwebo kuqala bese uthola uphawu.

- 2. Lungisa ifayela le- imidwebo yokubheka ingxenye ezolinganiswa kupulatifomu yokuxhumanisa emithathu bese uyilungisa ngokuqinile.

- 3. Vula izixhumanisi ezintathu, ulinganise ikhanda, vula ikhompyutha, thola isoftware yokulinganisa ehambisanayo, vula isoftware, bese uhlela.

- 4. Qala ukukala imikhiqizo, usungule uhlelo lokuxhumanisa, futhi ulinganise umbuthano ongaphandle.

- 5. Chaza ibhentshimakhi, hlaziya amasilinda alinganisiwe, bese uyabona ukubumbana.

- 6. Thekelisa umbiko wokuhlola.

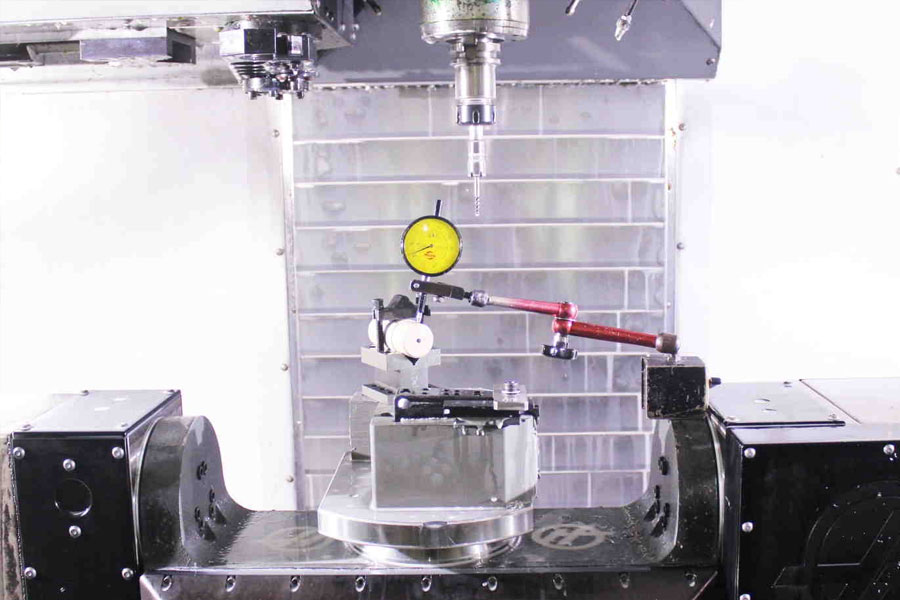

3.Indlela yokukala ubumbano nokuzamula

- 1. Geza isiqeshana sokuhlola ngamanzi afudumele bese usula ngendwangu eyomile.

- 2. Lungisa ibanga phakathi kwamathiphu amabili ozamule, acishe abe ngu-8 mm kufushane kunengxenye yeshafti ezolinganiswa. Qondanisa imbobo maphakathi nendawo yokuphela kocezu lokuhlola nethiphu engaguquki yozamula. Hudula okokusebenza ngesandla sakho sobunxele bese ucindezela ukuphambuka ngesandla sakho sokunene. Isibambo sethiphu yokuhamba ngakolunye uhlangothi lwe-pendulum senza ithiphu yokuhamba ihlehle emuva. Izandla ezingakwesobunxele nangakwesokudla ziyasebenzisana kahle, bese zicindezela ithiphu elihambayo lingene emgodini ophakathi ngakolunye uhlangothi lomsebenzi.

- 3. Zungezisa into ezohlolwa ngesandla, bese uyijika kalula, kepha igebe akumele likhulu kakhulu. Qiniseka ukuthi into iqinile. Ngaphandle kwalokho kuzodala imiphumela yokuhlola enganembile. Uma udinga ukulungisa ukunwebeka, sicela ubheke ku-Article 2 ngenhla.

- 4.Faka isibonisi sokudayela, isisekelo, nokuma, bese ulungisa inkomba yokudayela ukuze iphenyo lixhumane nengaphandle elinganisiwe lendawo yokusebenza, futhi kukhona ukuminyaniswa kombuthano ongu-0.5-1.

- 5. Kancane kancane nangokufanayo phendukisa okokusebenza ngesandla isonto elilodwa, futhi ubone ukuguquguquka kwesibonisi sokudayela, uthathe umehluko phakathi kwe-Mmax efundwayo ne-Mimin yokufunda njengephutha lokuhlangana kwesigaba, bese urekhoda imininingwane.

- 6. Hambisa ubakaki wesikhombi sokudayela, khetha indingilizi engaphandle, ujikeleze ingxenye ezolinganiswa, futhi ulinganise izindawo ezine ezihlukene ngokwendlela echazwe ngenhla. Thatha inani le-MAX lomehluko phakathi kwe-Mmax yokufunda ne-Mimin yokufunda njengephutha lengxenye ye-Coaxiality.

- 7. Qedela umbiko wokuhlola bese uhlela okokusebenza kokuhlola.

4. Indlela yokuthola ukuhlangana ngensimbi emise okwe-V

- 1. Geza isiqeshana sokuhlola ngamanzi afudumele bese usula ngendwangu eyomile.

- 2. Lungisa amabhlogo amabili amise okwe-V anokuphakama okufanayo nomkhawulo wokusika ofanayo. Beka amabhlogo alungiswe njenge-V kumbhalo wemabula noma etafuleni lomshini olicaba kakhulu.

- 3. Beka uphawu lokulinganisa lomsebenzi wokuhlola ozohlolwa emgodini omise okwe-V wensimbi

- 4. Faka igeji yokudayela, isisekelo setafula, nokuma kwemitha, lungisa igeji yokudayela ukuze iphenyo lixhumane nengaphandle elinganisiwe lomsebenzi, futhi kukhona ukuminyaniswa kombuthano ongu-0.5 --- 1

- 5. Cindezela phansi ngezandla zakho ujikeleze kancane futhi ngokufanayo umsebenzi wokusebenza isonto elilodwa, futhi ubone ukuguquguquka kwesibonisi sokudayela, uthathe umehluko phakathi kwe-Mmax efundwayo ne-Mimin yokufunda njengephutha lokuhlangana kwesigaba bese uqopha imininingwane.

- 6. Bese uhambisa isisekelo setafula, khetha indingilizi engaphandle, ujikeleze ingxenye ezolinganiswa, ulinganise izikhundla ezine ezihlukene ngokwendlela engenhla, bese uthatha inani le-MAX umehluko phakathi kwe-Mmax efundwayo ne-Mimin yokufunda njengokufanayo. Iphutha le-axiality

- 7. Qedela umbiko wokuhlola bese uhlela okokusebenza kokuhlola.

5. Indlela yokuthola ukuhlangana kwamathuluzi akhethekile

Indlela yokubala idatha nokubika ukugcwaliswa

- 1. Okokuqala bala inani lephutha le-coaxiality esigabeni esisodwa sokulinganisa, okungukuthi, Δ = Mmax-Mmin.

- 2. Thatha inani le-MAX lenani lephutha le-coaxiality elinganiswa esigabeni ngasinye njengephutha le-coaxiality yengxenye.

- 3. Qedela ukulinganisa ngokwezinyathelo ezingenhla bese ugcwalisa imininingwane efanele nemiphumela yokulinganisa ye-DUT embikweni wokuhlola ohambisanayo, bese usebenzisa lokhu njengesithenjwa ukuthola ukuthi ngabe iphutha lobumbano lwengxenye liyamukeleka yini.

Xhumanisa nale ndatshana: Ukuthola i-Coaxiality Method Yezingxenye Zomshini ze-PEEK

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi