Yini ukukhwabanisa kwezinto zensimbi?

Ukukhohliswa Kwezinto Zensimbi

|

Isici esinomthelela omkhulu ekwakhiweni kwensimbi ukwakheka kwensimbi uqobo. Uma ubungcweti bungcono, mancane amathuba okuthi aqhekeze ngesikhathi UKWAKHA. I-plasticity yensimbi ihlobene kakhulu nokwakheka kwensimbi. Lapho izinhlamvu ze-crystal zicwenga, ukwakheka kufana kakhulu futhi i-plasticity ingcono. Ngakho-ke, ukukhwabanisa kwensimbi kungathuthukiswa ngokucwenga izinhlamvu ze-crystal kanye nesakhiwo esifanayo. Izinto zensimbi zingashintsha ukwakheka kwazo ngaphandle kokuqhekeka ngesikhathi sokucindezela ingcindezi. Kubandakanya imishini efana nesando UKWAKHA, ukugoqa, ukuzelula, nokukhipha endaweni eshisayo noma ebandayo. Ukukhwabanisa ikakhulukazi kuhlobene nokwakheka kwamakhemikhali ezintweni zensimbi. |

I-Essence Of Metal

1.1 Ithonya lokwakheka kwamakhemikhali

Izinsimbi ezinezingoma ezahlukahlukene zamakhemikhali zinokukhohlisa okungafani Ngokuvamile, izinsimbi ezimsulwa zinokukhohliswa okungcono kunama-alloys; ukwehla kwengxenyenamba yekhabhoni yensimbi yekhabhoni, kuba ngcono ukukhiqizwa lapho insimbi iqukethe izinto eziningi ezakha i-carbide (chromium, tungsten, molybdenum, vanadium, njll.), Ukukhwabanisa kuncishisiwe kakhulu.1.2 Ithonya lesakhiwo sensimbi

Isakhiwo sensimbi sihlukile, futhi ukukhwabanisa kwaso nakho kuhluke kakhulu. Lapho i-alloy isesigabeni esisodwa isakhiwo sesisombululo esiqinile (njenge-austenite), ukukhwabanisa kuhle; lapho insimbi inesakhiwo sensimbi (njenge-cementite), ukukhwabanisa kubi. Isakhiwo sekholomu ekhonjiwe nezinhlamvu ezimahhadla azibumbeki kalula njengeyunifomu nesakhiwo esihle ngemuva kokucindezelwa ngomshini.

Izimo machining

Ukushisa kwe-2.1

Ukwandisa izinga lokushisa lapho insimbi ikhubazekile kuyindlela ephumelelayo yokuthuthukisa ukukhwabanisa kwensimbi. Ngesikhathi sokushisa kwensimbi, njengoba izinga lokushisa lokushisa landa, ukuhamba kwama-athomu ensimbi kuyanda, ukukhanga phakathi kwama-athomu kuyehla, futhi ukushelela kulula ukwenzeka. Ngakho-ke, i-plasticity ithuthukisiwe, ukumelana ne-deformation kuyancipha, futhi ukukhwabanisa kuthuthukiswe kakhulu. Zonke zenziwa emazingeni okushisa aphezulu.Isivinini se-Deformation

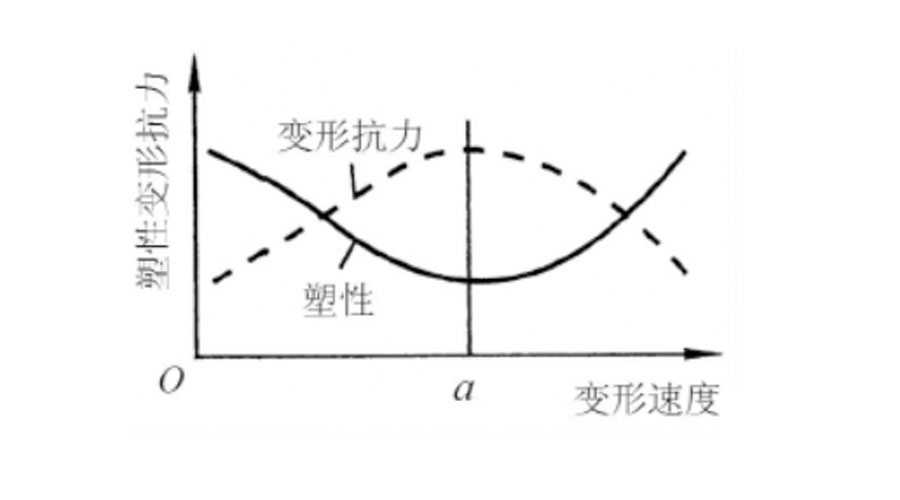

Isivinini sokumosheka yizinga lokuguquguquka ngesikhathi ngasinye. Umphumela wejubane lokumosheka ekwentekeni kwensimbi ukhonjisiwe kuMdwebo 2. Kungabonakala embonweni ukuthi ithonya lawo ekuthambekeni kwezinto liyaphikisana. Ngakolunye uhlangothi, njengoba ijubane lokukhubazeka landa, ukuvuselelwa nokuvuselelwa kabusha sekwephuze kakhulu ukunqoba lo msebenzi owenziwa uqine isikhathi, ukuze ubukhulu bensimbi banciphe, ukumelana ne-deformation kuyanda, nokukhohlakala kwehle (khomba isibalo kwesobunxele). Ngakolunye uhlangothi, ngenqubo yokuguquguquka kwensimbi, ingxenye yamandla asetshenzisiwe ekusetshenzisweni kwepulasitiki iguqulwa ibe amandla okushisa, okulingana nokushisa insimbi, ukuze ipulasitiki yensimbi inyuke, ukumelana ne-deformation kuyehla, futhi ukukhwabanisa kuyathuthukiswa (khomba isibalo ngakwesokudla). Lapho ijubane lokusonteka likhula, umphumela wokushisa uyabonakala.Umdwebo 2 Umphumela wejubane lokusonteka ku-plasticity nokumelana ne-deformation

Indlela ye-2.3 (isimo sokucindezeleka)

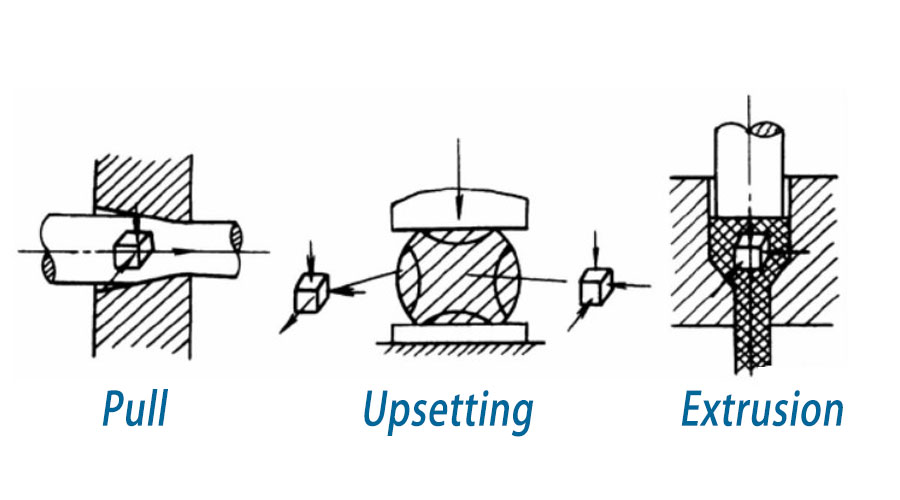

Imodi ye-deformation yehlukile, futhi isimo sokucindezeleka kwangaphakathi sensimbi ekhubazekile sihlukile. Isibonelo, esimweni sokuchithwa kwe-extrusion, kusesimweni sokuminyaniswa ngezindlela ezintathu; esimweni sokudweba, kusesimweni sokucindezelwa kwezindlela ezimbili kanye nesimo sokucindezela sendlela eyodwa; lapho kucasula, isimo sokuxineka sengxenyeni emaphakathi yokungabi nalutho ukucindezelwa okunezindlela ezintathu, kanti ingxenye engaphezulu iyaphezulu naphansi futhi iyashuba Ingcindezi ecindezelayo, futhi i-tangential ingukuqina kokuqina, njengoba kukhonjisiwe kuMdwebo 3.

Xhumanisa nale ndatshana: Yini ukukhwabanisa kwezinto zensimbi?

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi