Ukufakwa komsebenzi kanye nezinsiza zalo

Ukufakwa Kokusebenza Kanye Nezinto Zayo

|

Indlela yokukhweza eqondile I-workpiece ibekwe ngqo etafuleni lomshini noma isilinganisi esijwayelekile (njengezinsimbi ezijwayelekile ezifana ne-three-jaw chuck, i-four-jaw chuck, i-flat-nose impintshisi, i-electromagnetic chuck, njll.), Futhi kwesinye isikhathi iyabopheka ngaphandle ukuthola okunye okulungile, ngokwesibonelo I-chuck yomhlathi emithathu noma i-electromagnetic chuck isetshenziselwa ukufaka okokusebenza; kwesinye isikhathi kuyadingeka ukuvumelanisa okokusebenza ngokuya ngendawo ethile noma ulayini wombhali kulowo msebenzi, bese uwubopha, njengokufaka okokusebenza kusihlunu semihlathi emine noma etafuleni lomshini. |

Ukufakwa komsebenzi

Ukubeka isikhundla: Ngaphambi kokuchofoza, ubuciko bokubekwa kumele bubekwe etafuleni lomshini noma isibonisi ukuze kube nokuma okulungile.

Ngemuva kokuthi umsebenzi ubekiwe kahle, udinga ukuboshwa ukuze uvimbele ukuthi ungaphambuki endaweni efanele ngenxa yamandla okusika, amandla adonsela phansi namandla angenawo amandla ngesikhathi senqubo yokusika.

Ukufakwa: yonke inqubo kusuka ekubekeni kuye ekubambeni komsebenzi.

Lapho ufaka into yokusebenza, imiswa kuqala kuqala bese ibambeka. Lapho ufaka okokusebenza ku-chuck emithathu yomhlathi, ukubeka nokubopha kwenziwa ngasikhathi sinye.

Indlela yokufaka

(1) Indlela eqondile yokufaka

I-workpiece ibekwe ngqo etafuleni lomshini noma i-fixture ejwayelekile (njengezinsimbi ezijwayelekile ezifana ne-three-jaw chuck, i-four-jaw chuck, i-flat-nose pliers, i-electromagnetic chuck, njll.), Futhi kwesinye isikhathi iyabambeka ngaphandle kokuthola enye eyiyo , isibonelo I-chuck emihlathini emithathu noma i-electromagnetic chuck isetshenziselwa ukufaka okokusebenza; kwesinye isikhathi kuyadingeka ukuvumelanisa okokusebenza ngokuya ngendawo ethile noma ulayini wombhali kulowo msebenzi, bese uwubopha, njengokufaka okokusebenza kusihlunu semihlathi emine noma etafuleni lomshini.

Lapho ufaka okokusebenza ngale ndlela, kuthatha isikhathi ukuthola ukuqondanisa, futhi ukunemba kokuma kuxhomeke kakhulu ekunembeni kwamathuluzi noma okokusebenza okusetshenzisiwe, nasezingeni lobuchwepheshe labasebenzi. Ukunemba kokuma akulula ukukuqinisekisa futhi umkhiqizo uphansi, ngakho-ke imvamisa ifaneleka kuphela ezingxenyeni ezizodwa zokukhiqizwa kweqoqo elincane.

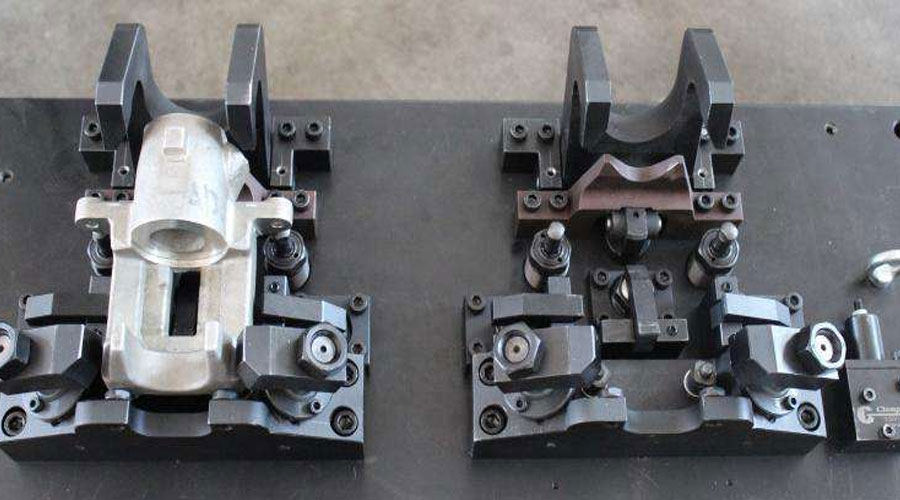

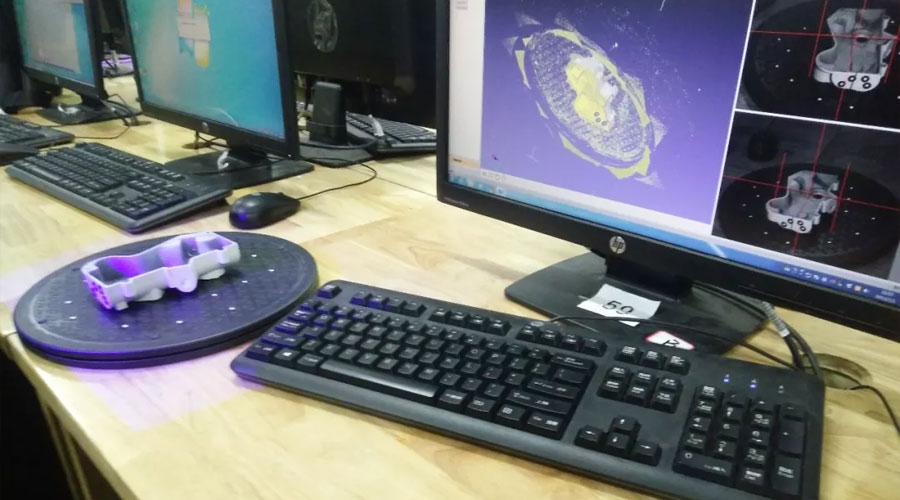

(2) Indlela yokufaka ekhethekile

Isimboni senzelwe ngokukhethekile futhi senzelwe ukwenziwa kwengxenye ethile. Ngaphandle kokulungisa, ungaqinisekisa ngokushesha nangokwethenjelwa indawo elungile yesihlobo somsebenzi kuthuluzi lomshini nethuluzi, futhi ungacindezela ngokushesha.

Ukusetshenziswa kwe-special zalapho ukucubungula ubuciko bokusebenza abunakuqinisekisa kuphela ukunemba kwemishini, kepha futhi kuthuthukise ukusebenza kahle kokukhiqiza, kepha akukho ndawo yonke. Ukuklanywa, ukwenziwa nokugcinwa kokukhethekile zalapho kudinga utshalomali oluthile, ngakho-ke kuphela ekukhiqizeni i-batch noma ekukhiqizeni ngobuningi lapho imiphumela emihle ingatholakala.

Ukuhlukaniswa nokwakheka kwamathuluzi wemishini yomshini

I-jig ne-fixture yethuluzi lomshini lingahlukaniswa ngemidlalo ejwayelekile, izinto ezikhethekile, izinto ezihlanganiswayo, izinto ezijwayelekile ezilungiswayo nezilungiselela iqembu ngokuya ngobubanzi bokusetshenziswa kwazo.

Ngokusho kwethuluzi lomshini elisetshenzisiwe, izinto ezihlanganisiwe zingahlukaniswa zibe yimishini yokubopha, izinto zokwenza umshini wokugaya, imishini yemishini yokubhola (idrayivu iyafa), imishini yomshini oyisidina (iyafa iyisicefe) igiya ukulungiswa kwemishini.

Ngokusho komthombo wamandla odala amandla okubambelela, isimbembembe singahlukaniswa sibe sesandla sombhalo, isakhiwo somoya, isibonisi se-hydraulic, isilinganisi sikagesi, isilinganisi se-electromagnetic nesifutho se-vacuum.

Isakhiwo esikhethekile ngokuvamile sakhiwa izingxenye ezilandelayo:

(1) Isikhundla sokubekwa

Isakhiwo sixhumana nendawo ekhethiwe yokubheka indawo yomsebenzi ukuze kutholakale indawo efanelekile yomsebenzi.

Lapho okokusebenza kubekwe endizeni, sebenzisa isipikili esisekelayo kanye nepuleti elisekelayo njengezinto zokubeka

Lapho ubeka indawo yokusebenza ngaphandle kwendawo eyindilinga, ibhlokhi elimise okwakwa-V nomkhono wokuma kusetshenziswa njengezinto ezihleliwe

Lapho okokusebenza kumiswe ngembobo, i-mandrel yokuma kanye nephini yokubeka kusetshenziswa njengezinto zokubeka.

(2) mshini clamping

Umshini obopha futhi uqinise into yokusebenza ngemuva kokuma ukuvimbela ukuthi okokusebenza kungahambi ngenxa yamandla okusika namanye amandla angaphandle.

Izindlela ezivame ukusetshenziswa zokuqinisa zifaka amapuleti okucindezela u-screw, amapuleti wokucindezela eccentric, izindlela zokuthambeka kwe-wedge, izindlela zokuqinisa i-hinge, njll.

(3) Umhlahlandlela

Ingxenye esetshenzisiwe ukusetha ithuluzi futhi liqondise ithuluzi lisebenze ngendlela efanelekile yemishini

Imikhono ye-Drill nemikhono yomhlahlandlela isetshenziswa kakhulu emishini yemishini yokubhola nemishini yemishini eyisicefe, namabhulokhi wokusetha amathuluzi asetshenziswa kakhulu emishini yomshini wokugaya.

(4) izingxenye Clamping nezinye izingxenye

Izingxenye Clamping kukhona izingxenye inkomba lwemidlalo. Yisebenzise ukuxhuma nokulungisa into yokuma, indlela yokubamba kanye nomhlahlandlela, njll., Ukuyenza iphelele, bese ufaka isethi kuthuluzi lomshini.

Ngokuya ngezidingo zemishini yokusebenza, kwesinye isikhathi kunendlela yokufaka izinkomba, okhiye bokuqondisa, insimbi yebhalansi nezingxenye zokusebenza kulungiselelo.

Isimbembimbimbimbimbimbimbimbimbimbimbimbimbzi size sibe nokuqina okwanele, futhi isakhiwo kufanele sihlangane, umumo kufanele ube lula, nocezu lomsebenzi kufanele lulayishwe futhi luthululwe futhi ukususwa kwe-chip kufanele kube lula.

Amabhentshimakhi nokukhethwa

Ekuklanyweni nasekusebenzeni ngomshini kwezingxenye, amaphuzu athile, imigqa nezindawo kuvame ukusetshenziselwa ukuthola ubudlelwano bejometri phakathi kwezakhi. Lawa maphuzu, imigqa nezindawo kubizwa ngokuthi ama-datum.

Ibhentshimakhi: Kuhlukaniswe ngezigaba ezimbili: ibhentshimakhi yokuklama kanye nebhentshimakhi yenqubo.

(1) Isisekelo sedizayini

Isisekelo sokwakhiwa yisisekelo esisetshenziswa kumidwebo yengxenye ngesikhathi sokwakhiwa.

Ngokuya ngesisekelo sedizayini yokunquma usayizi nobudlelwano bokuvumelana phakathi kwezakhi zejometri

(2) Inqubo yokulinganisa

Inqubo yebhentshimakhi ibhentshimakhi esetshenzisiwe enqubeni yezingxenye zokukhiqiza nemishini yokuhlanganisa. Inqubo amabhentshimakhi ahlukaniswe ngamabhentshi wokuma, ama-benchmark wokulinganisa namabhentshimakhi womhlangano, asetshenziselwa ukubeka, ukukala nokuhlola okokusebenza nokuhlangana kwezingxenye ngesikhathi semishini yokusebenza.

Isethenjwa sokumiswa: ubuso bento yokusebenza ukunquma isikhundla esihlobene nomsebenzi wokusebenza kuthuluzi lomshini nethuluzi ngesikhathi semishini.

Isethenjwa esibi: Isethenjwa sokuma esisetshenziswe kunqubo yokuqala yindawo engaxutshiwe engenalutho.

I-fine datum: I-datum yokuma esetshenzisiwe kuzinqubo ezalandelayo yindawo eyenziwe ngomshini.

(3) Inkomba embi

Ukukhethwa kwesethenjwa esinolaka kufanele kuqinisekise ukuthi zonke izindawo ezenziwe ngomshini zinesabelo esanele semishini, futhi indawo ngayinye eyenziwe ngomshini inokunemba kwesikhundla esithile endaweni engenamshini.

Izimiso ezithile zokukhethwa kwayo zingokulandelayo:

- 1) Khetha indawo engaxhunywanga njengereferensi enokhahlo. Uma kunezindawo ezimbalwa ezingacacisiwe engxenyeni, kufanele ukhethe indawo edinga ukunemba okuphezulu kokuphakama nendawo ngomshini oyisithenjwa.

- 2) Khetha indawo edinga isabelo semishini efanayo njengesithenjwa esibi, ukuze kuqinisekiswe ukuthi ubuso obusetshenziswa njengesethenjwa esibi bufana nemishini.

- I-3) Ukuze izingxenye zenziwe ngomshini kuzo zonke izindawo, ubuso obunomkhawulo omncane nokubekezelelana kufanele kukhethwe njengereferensi enzima yokugwema imfucuza ebangelwa umkhawulo onganele.

- 4) Ukuze wenze indawo yokusebenzela ibe nokuzinza okuqinile nokunokwethenjelwa, kuyadingeka ukuthi ireferensi ekhethiwe ekhululekile ibushelelezi futhi ibushelelezi ngangokunokwenzeka, cha UKWAKHA i-flash, ukusika okhuphuka esangweni noma okunye ukukhubazeka kuvunyelwe, futhi kunendawo yokusekela eyanele.

- 5) Ngokuya ngosayizi ofanayo, ireferensi eyindilinga ivame ukusetshenziswa kanye kuphela. Lokhu kungenxa yokuthi ireferensi eyindilinga ngokuvamile imbi kakhulu. Uma isethenjwa esifanayo esishubile sisetshenziswa kaninginingi, iphutha lesikhundla phakathi kwamasethi amabili ezindawo ezenziwe ngomshini lizoba likhulu impela. Ngakho-ke, ireferensi eyindilinga Ngokuvamile, ayinakusetshenziswa kabusha.

Isethenjwa esihle Ukukhethwa kwesithenjwa esihle kufanele kuqinisekise ukunemba kwemishini nokunamathela okunokwethenjelwa nokulula.

Izimiso ezithile zokukhethwa kwayo zingokulandelayo:

- 1) Ngokusemandleni akho, khetha indawo enosayizi omkhulu njengereferensi ngokunemba ukuze uthuthukise ukuzinza nokunemba kokufakwa.

- 2) Umgomo wokuqondana kokulinganisa, ngangokunokwenzeka, khetha ibhentshimakhi yokuklama njengebhentshi lokuma, isib. Lokhu kungagwema ukubeka amaphutha okubangelwa ukungahambi kahle kwesethenjwa sokuma kanye nesethenjwa sokwakhiwa.

- 3) Isimiso esihlanganisiwe sokwenza benchmarking. Kwezinye izindawo eziqondile ezingxenyeni ezithile, ukunemba kwesikhundla okuvamisile ngokuvamile kunezidingo eziphakeme. Lapho uqeda lezi zindawo, ireferensi efanayo yokuma kufanele ikhethwe ngangokunokwenzeka ukusiza ukuqinisekisa ukunemba kwesimo somunye phakathi kwendawo.

- 4) Isimiso sokubhekisela kokunye. Lapho ukunemba kwesikhundla phakathi kwezindawo ezimbili ezakhiwe ngomshini ku-workpiece kuphakeme kakhulu, indlela yokusebenzisa imishini ephindaphindwayo yomabili ngomshini ingasetshenziswa.

- 5) Isimiso esizimele. Lapho ezinye izinqubo zokuqedela indawo zidinga umkhawulo omncane futhi ofanayo (njengokugaya ujantshi), indawo okumele yenziwe ngomshini ingasetshenziswa njengereferensi yokuma, ebizwa ngokuthi umgomo wokuzikhomba. Ukunemba kwesikhundla ngalesi sikhathi kufanele kuqinisekiswe inqubo edlule.

Xhumanisa nale ndatshana: Ukufakwa komsebenzi kanye nezinsiza zalo

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi