Uhlelo Lokuhlanganisa Umshini we-CNC

Uhlelo Lokuhlanganisa Umshini we-CNC

|

Ngesikhathi sokubhala a Ukufakwa kwe-CNC Uhlelo, ukuze kunqunywe ukuma okuhlobene kwethuluzi nendawo yokusebenza, indlela yokuhamba yethuluzi kumele ichazwe ngephoyinti lokukhomba ithuluzi lomshini nohlelo lokuxhumanisa. |

Ukudidiyela uhlelo nokuqondiswa kokunyakaza

1. Umgomo wokunquma uhlelo lokuxhumanisa

- 1) Isisekelo sethuluzi elihamba ngokuhlobene nomsebenzi omile Lesi simiso sichaza ukuthi noma ngabe ithuluzi lomshini we-CNC liyinhlangano yokunyakaza noma ukunyakaza komsebenzi, lolu hlelo lubhaliwe ngokuya ngethuluzi lapho kuqhutshwa uhlelo, ukuze imishini ithuluzi lomshini we-CNC linganqunywa ngqo ngokuya ngomugqa wokuchofoza wenqubo yokudweba okuyingxenye.

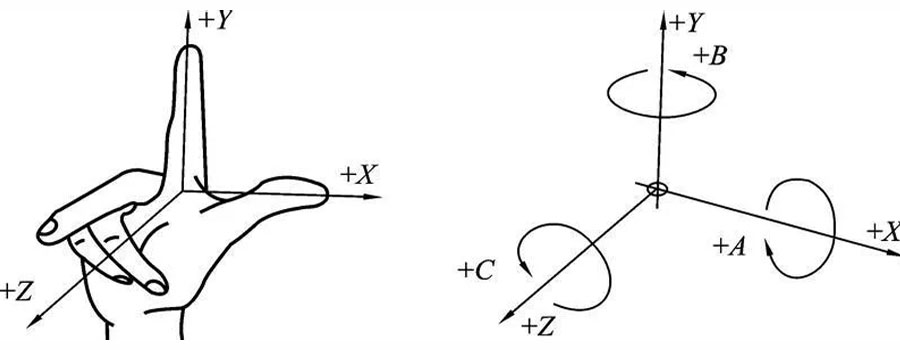

- 2) Incazelo yohlelo lokuxhumanisa olujwayelekile Uhlelo lokuxhumanisa olujwayelekile uhlelo lokuxhumanisa olunxande, njengoba kukhonjisiwe kuMdwebo 2-1-1 (a), ngokuya ngohlelo lokuxhumanisa lwesandla sokunxele, isithupha, umunwe wenkomba nomunwe ophakathi kwesokudla kumele u-X, Y no-Z ngokulandelana Ukuqondiswa kwamazembe wokuxhumanisa amathathu; njengoba kukhonjisiwe kuMdwebo 2-1-1 (b), ukuqondiswa kokujikeleza kungokomthetho wesandla sokudla, iminwe emine ilandela inkomba yokujikeleza kwe-eksisi, kanti isithupha ne-eksisi yokuxhumanisa kusendleleni efanayo njengokujikeleza okuhle kwe-eksisi, futhi okuphambene nalokho Ukuzungezisa okuphindayo kwe-eksisi, A, B, no-C kulesi sibalo kufanekisela izinkomba zokujikeleza ezizungeze ama-axes amathathu wokuxhumanisa we-X, Y, no-Z, ngokulandelana.

- I-3) Incazelo yokuhle nokubi kwe-axis yokuxhumanisa Ukuqondiswa okwandisa ibanga phakathi kwethuluzi nendawo yokusebenza kucaciswa njengokuqondiswa okuhle kwe-eksisi, futhi okuphambene nalokho njengokuqondiswa okungalungile kwe-eksisi.

2. Indlela yokunquma ama-axes wokuxhumanisa wethuluzi lomshini.

I-eksisi engu-Z imele okuyinhloko umphini edlulisa amandla okusika. I-eksisi ye-X ifana nendiza yokubamba yomsebenzi. Ngokuvamile, isikhundla esivundlile siyathathwa. Ngokwemvelo, ukuqondiswa kwe-Y axis kunganqunywa.

1) Uhlelo lokuxhumanisa i-Lathe

I-axis yokuxhumanisa i-axis ihlangana ne-axis eyinhloko ye-lathe, futhi ukuqondiswa kokuhamba kwe-lateral kwethuluzi kuyisiqondiso se-X yokuxhumanisa i-axis

2) Qondisa izinhlelo zamathuluzi omshini we-CNC

Amasistimu amabili axhumanisa amathuluzi omshini we-CNC

Uhlelo lokuxhumanisa ithuluzi lomshini we-CNC lunesistimu yokuxhumanisa ithuluzi lomshini nohlelo lokuxhumanisa lomsebenzi, lapho uhlelo lokuxhumanisa lomsebenzi lubizwa nangokuthi uhlelo lokuxhumanisa uhlelo.

Isistimu yokuhlanganisa ithuluzi lomshini

Isistimu yokudidiyela ithuluzi lomshini i-XYZ iwuhlelo lokuxhumanisa olubekwe umenzi ethuluzini lomshini, futhi umsuka walo iphoyinti eligxilile ethuluzini lomshini, elisetshenziswa njengendawo eyinkomba yokunyakaza yezingxenye ezihambayo zethuluzi lomshini we-CNC. Umsuka uwukuhlangana kobuso bokugcina be-chuck kanye ne-axis ye-spindle; emshinini wokugaya oqondile we-CNC ojwayelekile, imvelaphi iyisiphambano sezikhundla ezidlulele lapho izingxenye ezihambayo zihamba zibheke kolunye uhlangothi lwezimbazo eziqondisa u-X, Y, no-Z, okungukuthi, ibhentshi lomsebenzi kulesi simo Ekhoneni elingaphambili kwesokunxele. .

Uhlelo lokudidiyela ucezu lokusebenza Inhloso yokusetha uhlelo lokudidiyela i-workpiece XpYpZp iwukuba lula ukuhlela. Isimiso sokubeka imvelaphi yesistimu yokuxhumanisa i-workpiece kufanele ikhethwe ngokusemandleni ngesisekelo sokuklama kanye nesisekelo senqubo ye-workpiece.

Isiqondiso se-axis yokuxhumanisa yesistimu yokuxhumanisa i-workpiece ihambisana nesiqondiso se-axis yokuxhumanisa yesistimu yokuxhumanisa ithuluzi lomshini. Kulathe ye-CNC, njengoba kukhonjisiwe ku-Fig. 1, i-Op point yomsuka ivamise ukusethwa empambanweni yobuso bokuphela kwesokudla besiqephu sokusebenza kanye ne-axis yokuphotha. Emishinini yokugaya ye-CNC, njengoba kukhonjisiwe kuMfanekiso 2, imvelaphi ye-eksisi ye-Z ivamise ukusethwa phezulu kwendawo yokusebenza.

Kuma-workpieces angama-asymmetric, imvelaphi yezimbazo zika-X kanye no-Y ngokuvamile zisethwe ekhoneni elingaphambili elingakwesokunxele le-workpiece; kuma-workpieces alinganayo, X Umsuka we-eksisi ye-Y ngokuvamile umiswa empambanweni ye-symmetry eksisi yomsebenzi.

Ukuxhumanisa okuphelele nokuhlobene

1) Ukubhalwa ngokuphelele kokuxhumanisa

Inani lokuxhumanisa lesimo sokunyakaza kwamathuluzi livezwa njengebanga elihlobene nomsuka wokuxhumanisa. Lokhu kumelwa kokuxhumanisa kubizwa ngokuthi ukumelwa okuphelele kokuxhumanisa. Iningi lezinhlelo ze-CNC zisebenzisa uhlelo lokuxhumanisa oluphelele ngemiyalo ye-G90.

2) Isihlobo sokuxhumanisa esihlobene

Inani lokuxhumanisa lesimo sokunyakaza kwamathuluzi livezwa njengokukhuphuka okuhlobene nokulungiswa kwesikhundla sangaphambilini, okungukuthi, umehluko phakathi kwenani eliphelele lokuxhumanisa lephoyinti eliqondiwe nenani eliphelele lokuxhumanisa lephoyinti lamanje.

Iningi lezinhlelo ze-CNC zisebenzisa umyalo we-G91 ukukhombisa izinhlelo zokuxhumanisa ezihlobene. Ezinye izinhlelo ze-CNC zisebenzisa i-X, Y, ne-Z ukukhombisa amakhodi wokuxhumanisa ngokuphelele, kanti u-U, V, no-W bakhombisa amakhodi wokuxhumanisa ahlobene. Izinhlobo ezimbili zohlelo lokuhlelwa kokuboniswa.

Xhumanisa nale ndatshana: Uhlelo Lokuhlanganisa Umshini we-CNC

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi