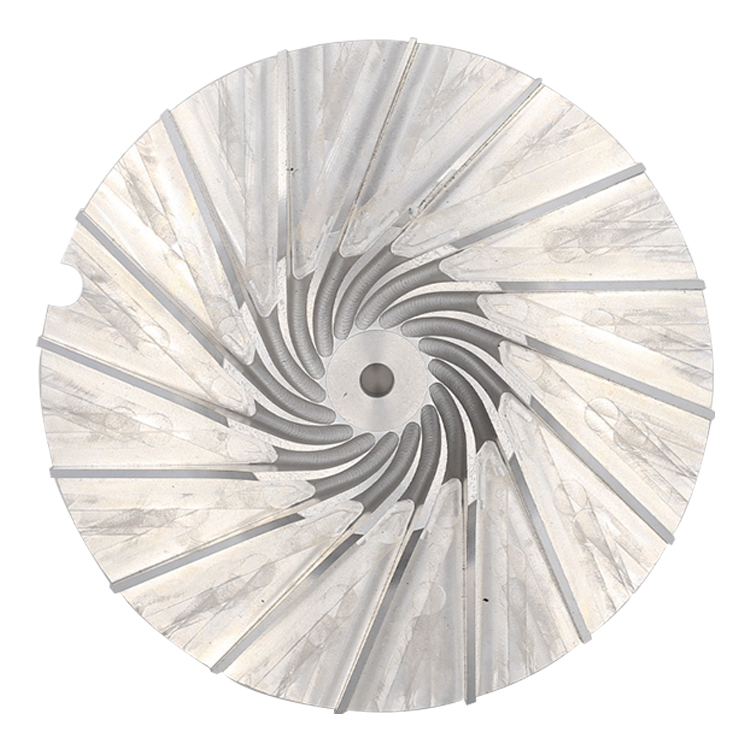

Uhlobo lwe-Aluminium: Uhlelo lokusebenza lwe-Aluminium alloy cnc machining

|

|

|

|

Aluminium ingxubevange CNC MachiningAluminium ingxubevange isingeniso:

I-Aluminium alloy ingenye yezinto ezisetshenziswa kakhulu ezakhiwe ngensimbi embonini futhi isetshenziswe kakhulu ezindizeni, esikhaleni sendawo, ezimotweni, ekukhiqizeni imishini, ezimbonini zasolwandle nakwamakhemikhali.

Ubuningi be-aluminium emsulwa bincane (ρ = 2.7g / cm3), okucishe kube yi-1/3 yensimbi.

I-aluminium alloy inokuqina okuphansi, kepha amandla aphakeme, asondele noma adlula insimbi esezingeni eliphakeme, i-plasticity enhle, ingacutshungulwa ibe ngamaphrofayili ahlukahlukene, ine-conductivity enhle kakhulu kagesi, i-conductivity eshisayo kanye nokumelana nokugqwala. Isetshenziswa kabanzi embonini futhi isetshenziswa isibili kuphela kunensimbi. .

I-aluminium alloy inokuqina okuphansi, kepha amandla aphakeme, asondele noma adlula insimbi esezingeni eliphakeme, i-plasticity enhle, ingacutshungulwa ibe ngamaphrofayili ahlukahlukene, ine-conductivity enhle kakhulu kagesi, i-conductivity eshisayo kanye nokumelana nokugqwala. Isetshenziswa kabanzi embonini futhi isetshenziswa isibili kuphela kunensimbi. . |

Xhumanisa nale ndatshana: I-aluminium alloy cnc machining application

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi