Yini i-Inconel 625

Incazelo Ka-Inconel 625

|

I-Inconel625 yisisombululo esiqinile esiqinise i-nickel esekwe nge-superalloy ene-molybdenum ne-niobium njengezinto eziqinisa kakhulu. It has omuhle ukugqwala ukumelana kanye namachibi ukusebenza. Inezakhiwo ezinhle zokuqina nokuqina kokukhathala kusuka ekushiseni okuphansi kuye ku-980 ℃, futhi ingukumelana nosawoti okumelana nosawoti endaweni enenkungu. |

Ngakho-ke, ingasetshenziswa kabanzi ukwenza izingxenye zenjini ye-aero, izingxenye zesakhiwo se-aerospace nemishini yamakhemikhali. I-alloy inokusebenza okuhle nokucutshungulwa kwe-welding, futhi ingakunikeza amapuleti ahlukahlukene, imigoqo, amapayipi, izintambo, imichilo kanye UKWAKHAs.

Ingxubevange 625 ingxubevange emelana nokugqwala, emelana ne-nickel. Amandla amahle nobulukhuni be-625 alloy endaweni ephansi yokushisa-1093 ° C ibanga lokushisa lisuselwa kumphumela wesisombululo esiqinile se-reflexory metal colium ne-molybdenum ku-nickel-chromium matrix. Amandla amahle kakhulu okukhathala nokumelana nengcindezi yokugqwala kokuqhekeka kwe-625 alloy inzuzo kusuka ku-chloride ion kulokho okusetshenziswayo.

Inconel 625 isicelo

Ingxubevange engu-625 isetshenziselwa ukukhiqiza izivikelo zokushisa, amapayipi omoya enjini yenjini ephendulwa, amashubhu omlilo wangaphakathi, izinduku zokujova uphethiloli, imishini yezimboni zamakhemikhali kanye nezicelo ezikhethekile zamanzi olwandle.

Inconel 625 Corrosion ukumelana

Ingxubevange engu-625 ingamelana nezindawo ezahlukahlukene ezonakalisayo. Ezixazululweni ze-alkaline, amanzi olwandle, amanzi ahlanzekile, usawoti ongathathi hlangothi nomoya, okubalulekile kunokugqwala okuncane. Izakhi ze-Nickel ne-chromium zinikeza amandla we-antioxidant. I-Nickel ne-molybdenum inikeza ukumelana nokugqwala ngamagesi angenayo i-oxidizing. I-Molybdenum ingavimbela ngempumelelo ukugqwala nokugqwala kwezinsika. Ukumelana nokuqhekeka kokugqwala kwe-chloride kubaluleke kakhulu. Emazingeni okushisa aphezulu, i-625 alloy ayijwayele ukuqhuma noma i-oxidation.

Izakhiwo zomzimba

Ubuningi: 8.44

Ukushisa okumaphakathi okumaphakathi: 0.098 btu / lb / ° F

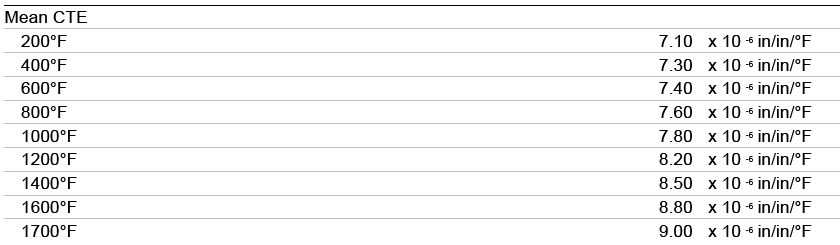

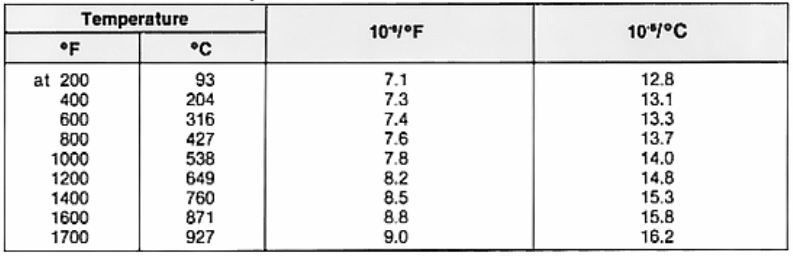

Isilinganiso se-coefficient yokunwetshwa okushisayo

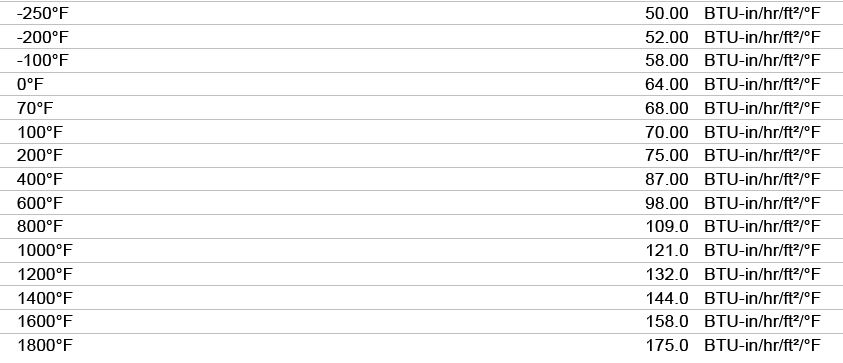

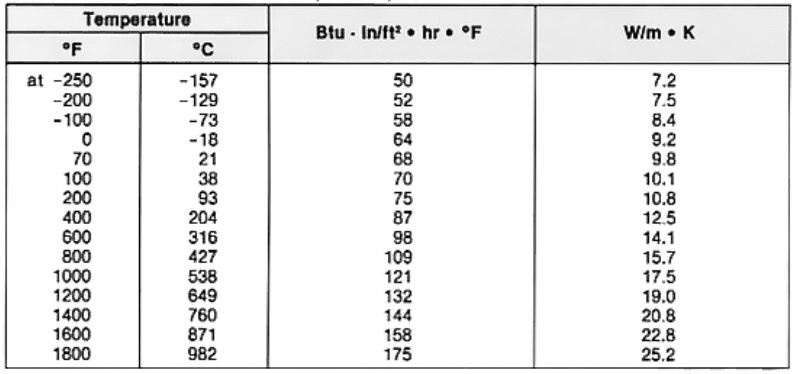

Inconel 625 conductivity ezishisayo

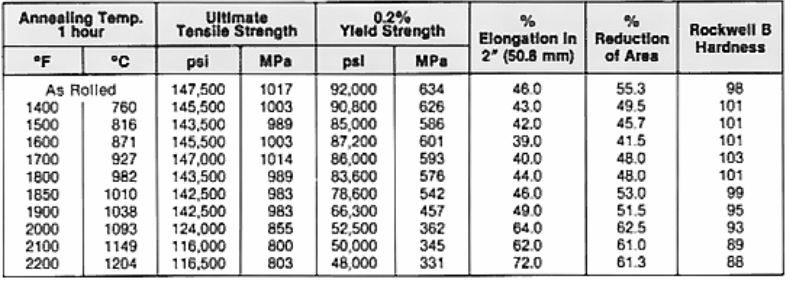

Impahla ye-Inconel 625 iphathwa ukushisa ngo-1149 ° C ngehora elilodwa

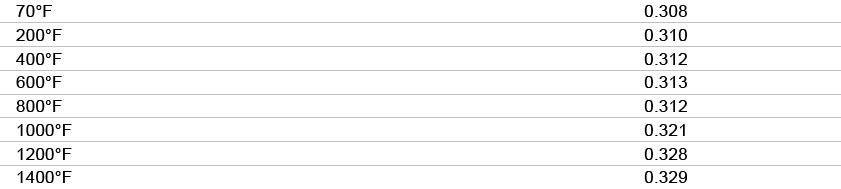

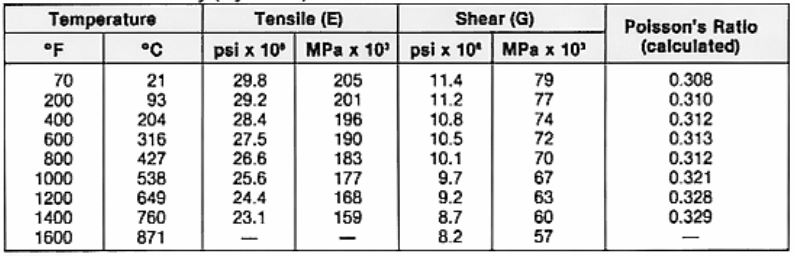

Isilinganiso sika-Inconel 625 Poisson

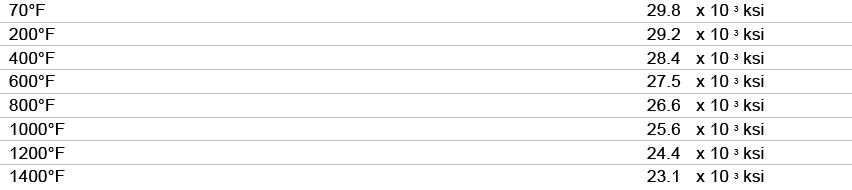

I-Modulus yokuqina (E)

I-Modulus ye-elasticity (enamandla)

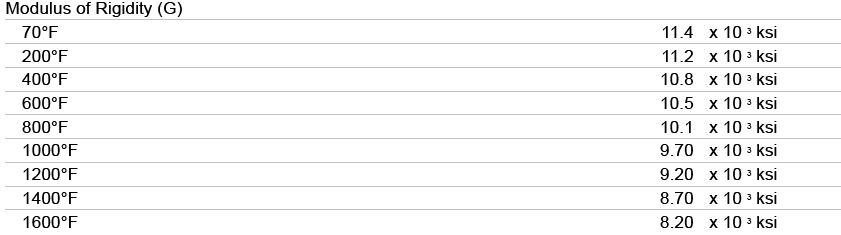

Imodi yokuqina (G)

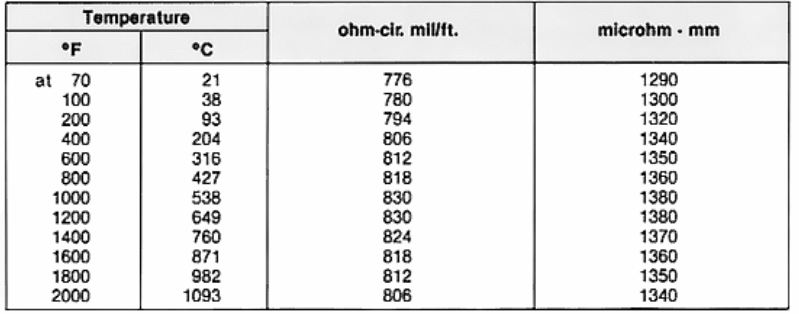

Ukumelana ne-Inconel 625

Ukushisa okuphathekayo kulashwa ngo-1149 ° C ngehora elilodwa

Ukushisa kwe-Curie: < -320 ° F

Ibanga lokuncibilika: 2350-2460 ° F

Magnetic

Ukufuduka kweMagnetic (200 Oe): 1.0006Mu

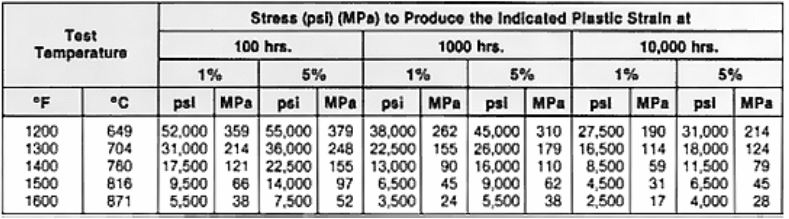

Ukusebenza kwe-Inconel 625 Creep

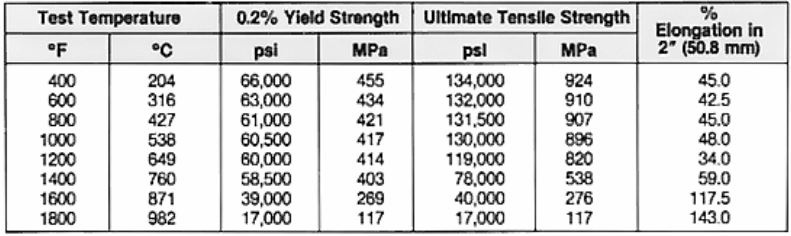

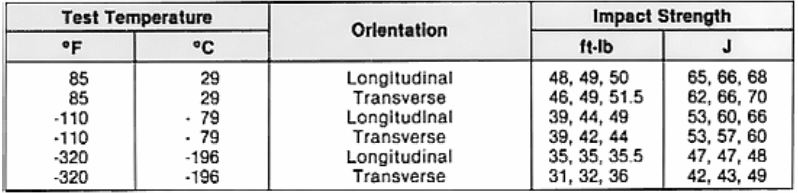

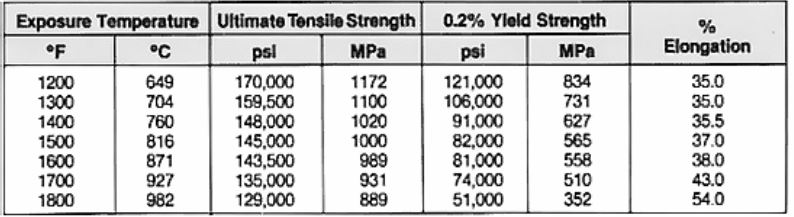

Izici eqine at lokushisa ephakeme

Umphumela wokushisa okuncishisayo

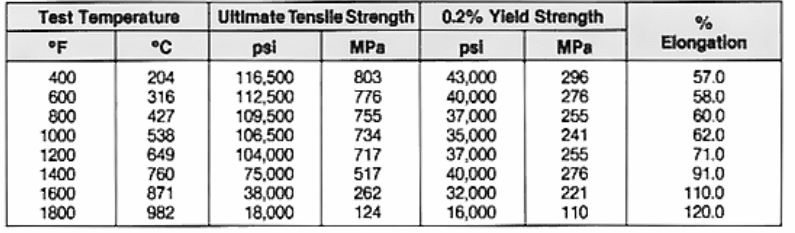

Izici eqine at lokushisa ephakeme

Inothi yokuhlola imbobo yokhiye

Izakhiwo eziqinile ekamelweni lokushisa

Amandla eqine ekamelweni lokushisa

Ukugoqa okushisayo, ukufaka isixazululo esiphansi, amahora ayi-100 ezingeni lokushisa elisohlwini lwethebula elingezansi

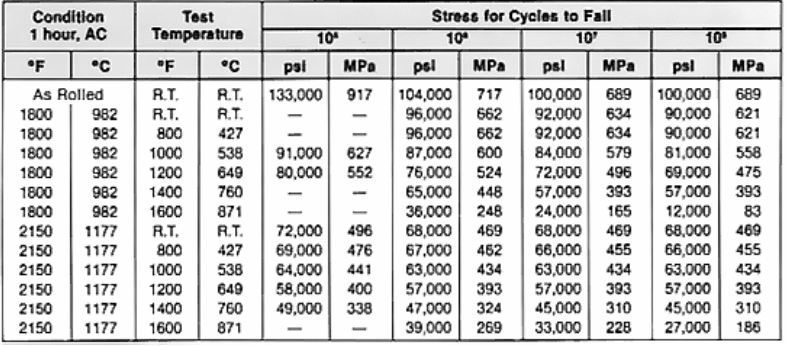

Ukuzungeza ukukhathala kwegongolo

ukwelashwa ukushisa

Kunezindlela ezintathu eziyisisekelo zokwelashwa kokushisa kwe-625 alloy:

1.Ukufakwa kwesisombululo esiphakeme: 1093-1204 ° C, ukucima umoya noma ukucima ngokushesha

2. Ukuncishiswa kwesisombululo esiphansi: 927-1038 ° C, ukucima umoya noma ukucima ngokushesha

Ukukhululeka kwengcindezi: 3 ° C, ukucima umoya

Isikhathi sokwelashwa kokushisa sincike kwinani lezinto zokwakha nobukhulu besigaba esiphambanweni. Isikhathi sokwelashwa kokushisa kwezindlela 1 no-2 imvamisa ihora elingu-1 / 2-1, kanti isikhathi sokwelapha ukushisa kwendlela yesi-3 ngamahora angu-1-4.

Lapho izinga lokushisa elisebenzayo lingaphezu kuka-816 ° C futhi ukumelana okuhamba kancane kubaluleke kakhulu, Indlela 1 ivame ukusetshenziselwa ukucubungula okokusebenza. Izigayo zensimbi zizophinda zisebenzise ukuxazulula isixazululo esiphakeme ukwenza izinto zithambe futhi kube lula ukuzibandayo noma ukudweba okubandayo.

Indlela 2 iyindlela esetshenziswa kakhulu yokwelapha ukushisa. I-1038 ° C ingakwandisa ukusebenza okuphelele kwamandla we-tensile namandla wokuqhekeka. Ngasikhathi sinye, i-ductility nobulukhuni ngaphansi kwezinga lokushisa eliphansi nakho kuhle kakhulu.

Lapho izinga lokushisa elisebenza lingaphansi kuka-649 ° C, lapho izidingo zokumelana nokukhathala, amandla okuqina, amandla wokukhiqiza kanye nokuqina kwento kuphezulu, Indlela yesi-3 inconyelwa ukwelashwa kokushisa. Izinto eziphathwayo zine-ductility enhle kakhulu nobulukhuni endaweni ephansi yokushisa. Uma kudingeka okusanhlamvu okuminyene, okokusebenza kuzoba namandla amahle okukhathala, amandla okuqina futhi kuveze amandla emvelweni ongaphansi kuka-816 ° C. Kwesinye isikhathi indlela yesi-3 nayo ingasetshenziswa.

Ukucubungula okushisayo

Izinga lokushisa lomlilo eliphakeme lokucubungula okushisayo lingu-1149 ° C. Qaphela ukugwema ukuqongelela kokushisa okungqubuzanayo okungadala ukushisa okungaphezulu kwe-1149 ° C. Ingxubevange engu-625 iyoba lukhuni ngaphansi kuka-1010 ° C. Uma ingaphansi kwaleli zinga lokushisa, Umsebenzi wokusebenza udinga ukuvuselelwa. Kunconywa ukwenza umfaniswano wokufaka ukugwema ukwakheka kwe-crystal okuxubile. Izinga eliqediwe lokufaka cishe i-15-20%.

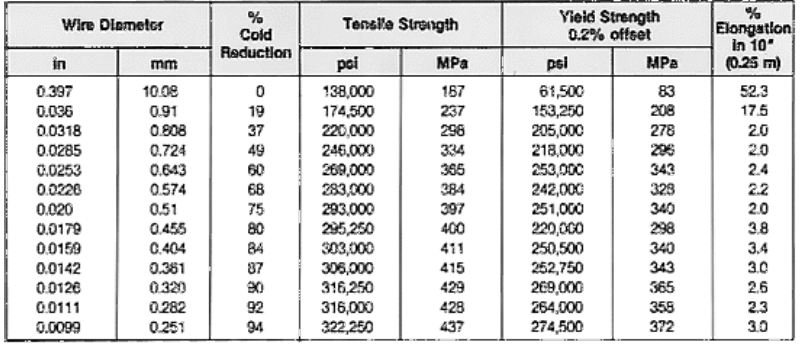

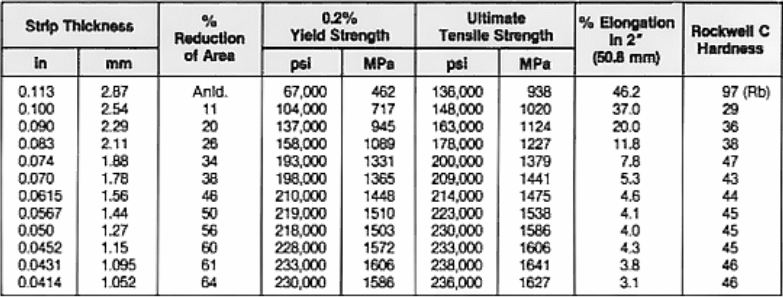

Icubungula Cold

Ingxubevange engu-625 ilungele izindlela ezahlukahlukene zokusebenza ezibandayo. Ngemuva kokusebenza okubandayo, into yokusebenza iba lukhuni futhi ingabuyiselwa ekuthambekeni kwayo ngokuncishwa.

Umthelela womsebenzi obandayo

Ngaphambi kokusebenza okubandayo, umucu ufakwe ku-1019 ° C

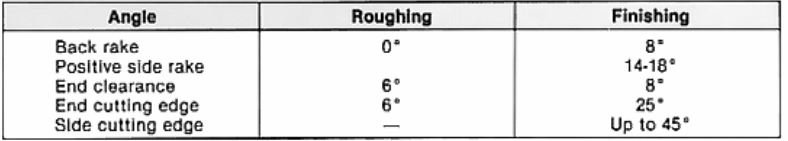

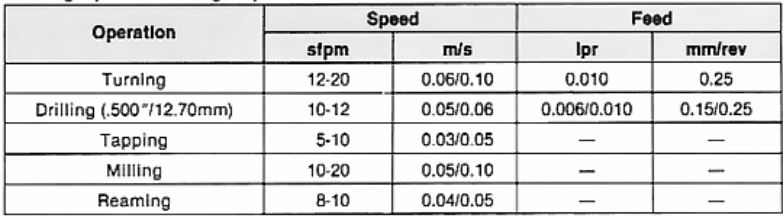

Ukusebenza komshini

Ngokuvamile kunconywa ukusebenzisa isivinini sokusika esiphansi, amathuluzi aminyene, imishini esindayo, okupholisa okwanele, nokuphakelayo okuphoqiwe ukucubungula ingxubevange engu-625.

Ukuvula amathuluzi wokusika asheshayo

Izinga lokushisa lomlilo eliphakeme lokucubungula okushisayo lingu-1149 ° C. Qaphela ukugwema ukuqongelela kokushisa okungqubuzanayo okungadala ukushisa okungaphezulu kwe-1149 ° C. Ingxubevange engu-625 iyoba lukhuni ngaphansi kuka-1010 ° C. Uma ingaphansi kwaleli zinga lokushisa, Umsebenzi wokusebenza udinga ukuvuselelwa. Kunconywa ukwenza umfaniswano wokufaka ukugwema ukwakheka kwe-crystal okuxubile. Izinga eliqediwe lokufaka cishe i-15-20%.

Ijubane lokusika insimbi ephezulu

I-engeli yethuluzi le-carbide incane kunaleyo yethuluzi le-HSS, futhi ijubane lokusika liyashesha.

Kunconywa ukusebenzisa uketshezi lokusika olususelwe kwisulfure. Ngemuva kokuchofoza, kuyadingeka ukuthi uhlanze kahle okokusebenza ukuze ugweme ukuletha ukungcola okungaphezulu kunqubo elandelayo yokwelashwa kokushisa.

Welding

Ukushisela igesi kungasetshenziselwa ukushisela, i-tungsten electrode noma i-electrode yensimbi engasetshenziswayo. Akukho ukwelashwa kokushisa ngemuva kokushiswa okudingekayo ukugcina ukumelana nokugqwala. Ngaphambi kokushisela, naka ukuhlanza indawo yokushisela bese uqondanisa umthungo wokushisela. Indawo yokushisela ewugqinsi isebenzisa indlela yokushisela emise okwe-U.

Xhumanisa nale ndatshana: Yini i-Inconel 625

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi