Kungani usebenzise inconel 718 ekwenzeni izingxenye zezindiza

Kungani usebenzise inconel 718 ekwenzeni izingxenye zezindiza

|

Kudala, abantu baqala ukusebenzisa izindlela zokuhlanganisa ukucubungula ulimi nokukhomba kumadiski e-turbine kagesi. I-blade igxiliswe kudiski ye-turbine ngolimi nasemgodini. Kodwa-ke, ukugoqa izikhumba kuzodala ushintsho ekwakhiweni kobuso nangaphansi kwezingqimba zediski ephendulwa, okuzothinta ukumelana nokukhathala kwesondo. |

Ngakho-ke, ekwakhiweni kokwenza kahle kwenqubo ye-broaching, kubaluleke kakhulu ukudweba umdwebo wesakhiwo se-metallographic onokwethenjelwa futhi omningi we-tenon groove ecutshungulwa ngokubhulabhula. Kulesi sihloko, sisebenzise ukuhlolwa kwesibonakhulu esibonakalayo kanye nokuskena i-electron microscopy ukuze sihlaziye ukwakheka kwe-metallographic yezingxenye ezingaphezulu nezingaphansi komhlaba ze-tenon grooves ye-Inconel-718 alloy disk yezinjini zegesi yezimboni. Okugxilwe kakhulu ekutadisheni izici zokukhubazeka okubangelwa ukubhoboza i-tenons nemifantu phezulu kanye ne-underlayer yesondo. Ngesikhathi esifanayo, ucwaningo luphinde lwathola usayizi wezinto ezingavuthiwe γ ", γ 'kanye no-δ ebusweni bolimi nomsele. Uma usebenzisa imodeli ye-FEM esekelwe ezintweni ezibonakalayo ukuze ubikezele impilo yokukhathala yediski yesondo, kuyadingeka ukufaka lezi zici ezibalulekile zesakhiwo se-metallographic. Ocwaningweni lwesakhiwo senhlangano, sithole amaphutha afana nokuklwebheka nokuhlanekezela. Ngokulandelayo, siqhathanise imingcele yesici (usayizi nokuma) kwala maphutha namazinga omklamo anikezwe umkhiqizi wenjini yegesi.Ukwengeza, izindawo ezithintekile ngokubroaching kanye nokuqhathaniswa kwezinto zokuqala kukhombisa ukuthi ingxenye yevolumu yezinhlamvu ezingu-δ inezinguquko ezisobala. Lezi zinguquko zihlobene nokukhiqizwa kokushisa okungqubuzanayo ngesikhathi sokuphefumula. Ekugcineni, ngokuqhathanisa nokwangempela. izinto zokwakha, siqhathanise ubulukhuni besakhiwo se-microstructure sesakhiwo se-metallurgical endaweni ye-broaching. Imiphumela yezinguquko yafundwa.

I-Inconel-718 alloy iyingxube ye-Ni-Fe-Cr yokushisa ephezulu eyasungulwa yi-International Nickel Corporation ngeminyaka yawo-1950. Lena ingxubevange eqinisa imvula engabonisa ingcindezi yesivuno esikhulu kanye nokumelana okuqinile nokukhathala nokukhasa. Ngenxa yokumelana kwayo ne-oxidation ephezulu namandla aphezulu ezindaweni zokushisa okuphezulu, i-Inconel-718 alloy isetshenziswa kabanzi embonini ye-aerospace, ikakhulukazi njengempahla yamasondo enjini ye-turbine. Ngokuvamile, isondo nensingo kuxhunywe ndawonye ngethanoni emise okwesihlahla ubude, futhi inqubo yokuphefumula iwukhiye wokulungisa i-longitudinal tree-shaped tennon slot. Ngokuvamile, ukukhathazeka kwawo wonke umuntu umphumela wamazinga okushisa nokushuba ekushintsheni kosayizi wokusanhlamvu ngesikhathi sokushisa okushisayo. I-Broaching izophinde idale izinguquko kusakhiwo se-metallographic ebusweni nangaphansi kwesondo, okuzothinta ukumelana nokukhathala kwesondo. Kodwa-ke, ezincwadini, kunamaphepha ambalwa mayelana ne-broaching ye-Inconel-718 alloy wheels Ukuhlaziywa kwekhwalithi nokulinganisa kwezinguquko ku-microstructure.

Inhloso yalolu cwaningo ukuchaza kanye nokulinganisa ukwakheka kwe-metallographic kwendawo engaphezulu nendawo engaphansi ye-longitudinal dendritic groove yesondo le-Inconel-718 alloy. Ikakhulukazi, incazelo kanye nokuhlaziywa komthamo weziphambeko ezibangelwa inqubo ye-broaching ebusweni nangaphansi kwesendlalelo esingaphansi kwediski yesondo kwabhalwa, futhi usayizi wokusanhlamvu nezici zokusanhlamvu zendawo yomshini zafundwa.

Indlela Yokuhlola

Sibambe ingxenye yesondo le-Inconel-718 alloy ukuze senze ucwaningo (Umfanekiso 1). Njengoba kuboniswe ku-Figure 2, sisebenzisa indlela ye-EDM ukuthatha amasampula e-metallographic kusukela kokuqala, okuphakathi nomsila we-slot ye-tenon ephakathi.

Ukuze kuhlangatshezwane nezidingo zokuhlaziywa kwe-metallographic, ngemva kokuba isampula isilungisiwe, izohamba ngenqubo ezenzakalelayo yokugaya nokupholisha. Uma kusenziwa isihlabathi kuzosetshenziswa i-sandpaper engu-320, 400, 600 kanye ne-1200. Ngemva kokupholishwa, isampula izopholishwa kuboya be-MD ngokumiswa kwedayimane okungu-1 μm njengoketshezi lokupholisha imizuzu emi-2. Ukuze ukwazi ukubuka imingcele yokusanhlamvu ngesibonakhulu se-electron yokuskena (SEM), isampula izobhalwa kusixazululo se-oxalic acid ku-voltage engu-4V imizuzwana engu-20-40. Ukuze uthwebule izici ze-γ 'kanye no-γ' ngokuchazwa okuphezulu, isampula idinga ukufakwa igalvanic kusisombululo sevoltheji engu-10V (8ml H2SO4 kanye ne-100ml H2O) imizuzwana engu-20, kanye nesibonakhulu se-electron yokuskena efakwe isibhamu esikhipha umoya wokuskena. (FEG).

Uma uhlaziya ukukhubazeka nge-SEM, isampula idinga ukufakwa ugesi kusixazululo se-voltage 3V (5g CuCl2, 100ml HCL kanye ne-ethanol engu-100ml) imizuzwana engu-10. Sebenzisa indlela yomehluko wobude ukuze uthole usayizi wokusanhlamvu. Sebenzisa i-ASTM ukuze uthole ingxenye yevolumu yezinhlamvu ezihlukene: I-E562 ithatha ukuthi ingxenyenamba yendawo ilingana nengxenye yevolumu. Ubukhulu bezinhlamvu ezahlukene bulinganiswa ngesofthiwe yokuhlaziya isithombe se-Clemex. Ukuze uthole umphumela wezibalo omele, okungenani imidwebo ye-metallographic eyisi-6 kufanele isetshenziselwe ukucacisa ubukhulu nezici zezinhlamvu ezahlukene.

Okungenani amasampuli angu-5 esampula ngayinye kufanele athathwe ukuze kukale ubulukhuni be-Rockwell A, bese kubalwa inani elimaphakathi kusampula ngayinye. Ezivivinyweni, ibanga eliphakathi kokuklwebheka livamise ukuba likhulu kunobukhulu obuphindwe ka-5 kobubanzi bemihuzuko. Ukuze kuqhathaniswe namanani obulukhuni ezincwadini, amanani obulukhuni be-Rockwell A adinga ukushintshwa abe ubulukhuni be-Vickers, i-ASTM: E140.

Ukuhlaziywa Kwesici

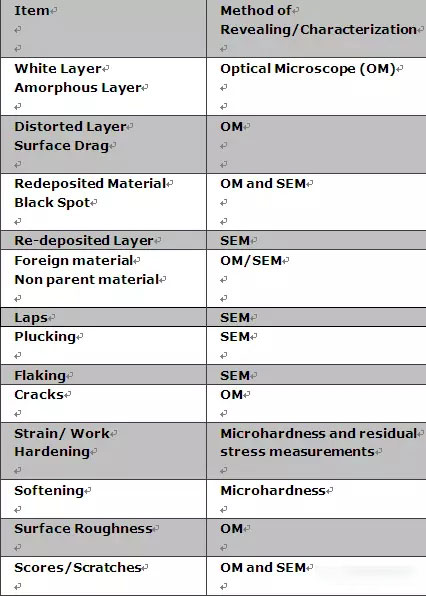

Kulolu cwaningo, sihlaziye ngokuhlelekile amaphutha emugqeni ophakathi wolimi ne-groove. Ngokunembe kakhudlwana, siqaphele futhi salinganisa isiqalo, maphakathi nesiphetho se-broaching. Ithebula 1 libonisa izinhlobo ezihlukene zokukhubazeka ezifakwe emiseleni yobude be-dendritic yamasondo ahlanganisiwe we-Inconel-718 alloy. Kufanele kukhulunywe ukuthi kumasampula ocwaningo, asizange sibone iziphambeko ezifana nongqimba olumhlophe, ungqimba olunganqamuki lokuya esikhathini, i-biomass yesibili, amabala amnyama, ukunqwabelana kabusha, izinto zangaphandle, nemifantu.

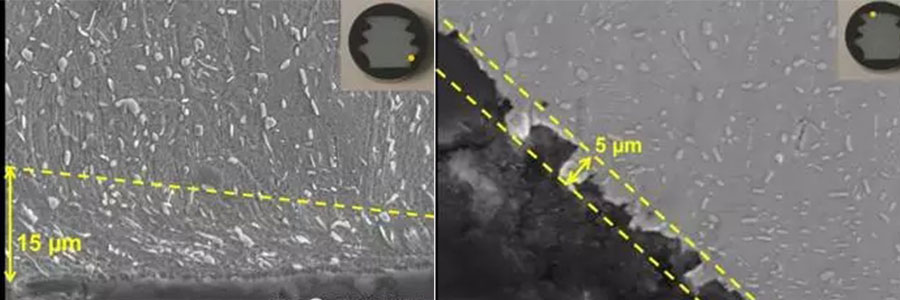

Izibalo 3 kuya ku-6 zibonisa ezinye zeziphambeko ezibonwayo. Umfanekiso wesi-3 ubonisa ukuguguleka, njengezimbobo ezincane ezivela endaweni esebenza ngomshini. Ngempela, ukunwaya yikona okuvame kakhulu endaweni. Wonke umuntu uyazi ukuthi ingxubevange ye-Inconel-718 iqina ngomshini ngenxa yokuqina kwayo ngokushesha komshini ngesikhathi sokucubungula. Izinto ezisetshenziswayo ezihlukene kanye nezimo ze-broaching, ingaphezulu le-alloy liyoba nokwanda kokugqoka ohlangothini, ukugoba nokubhoboza. Nokho, kuwo wonke amasampula ocwaningo, ukujula okuphezulu okwamukelekile kokuguguleka bekukuncane kunokwaklanywa. Ngokufanayo, njengoba kuboniswe kuMfanekiso 4, isithombe sesendlalelo esisontekile siyaboniswa. Kulesi sendlalelo (7 μm ububanzi), isigaba sika-δ sinohlelo olukhethekile. Lesi senzakalo sitholakala kalula phezulu kolimi kanye ne-groove, okungenzeka ihlobene nokucindezeleka okubangelwa ukubhoboza kule ndawo.

Indawo eqinile yolimi kanye ne-groove (Umfanekiso 5) isekuqaleni nasekupheleni kokubhoboza. Ngokufanayo, njengoba kuboniswe kumfanekiso wesi-6, kukhona iphutha elibizwa ngokuthi ukuhlukaniswa kwezinto ezingaphelele, okufana nokuphuka kwezinto ezibonakalayo, kodwa akuzange kuwele ebusweni besondo. Lesi simo sikhona kuwo wonke amasampula. Amaphutha anjalo anobude obuyi-25 μm, futhi izici zabo (usayizi kanye ne-morphology) ziyahlukahluka. Lesi sici sisuka kukhwalithi ye-broaching, futhi umphumela wawo empilweni ye-roulette kusazoqhutshekwa kufundwe.

Xhumanisa nale ndatshana: Kungani usebenzise inconel 718 ekwenzeni izingxenye zezindiza

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi