I-CNC Machining Technology ye-Sealing Pipe Taper Thread

I-CNC Machining Technology ye-Sealing Pipe Taper Thread

|

The Ukufakwa kwe-CNC Kuxoxwa ngobuchwepheshe bokubekwa uphawu kwamapayipi we-pipe taper, kuchazwa izindinganiso zamanje zemicu yamapayipi amaShayina, izici, ukuhlaziywa kwenqubo kanye nokuklanywa kohlelo lokufaka imicu yamapayipi wokufaka uphawu kuyachazwa ngokuningiliziwe, futhi ukucubungula kuhlanganiswe nezibonelo ezithile. Ubuchwepheshe buhlaziyiwe ngokuhlelekile ukuze kunikezwe inkomba yezidingo zamaqembu afanele. |

Ukufakwa uphawu kwepayipi ngentambo njengamanje kuyindlela ephumelela kakhulu yokuxhuma ipayipi, okusetshenziswa kancane kancane kunqubo yokuthuthwa kuketshezi nokufakwa uphawu kwegesi. Ukuze uthuthukise ikhwalithi yokuxhumeka kwepayipi lokufaka uphawu, kuyadingeka ukwenza ukucutshungulwa kokulawulwa kwamanani ocingweni lwe-pipe taper, okudinga ukuthi samukele ubuchwepheshe obusebenzayo ukwenza umsebenzi ohambisanayo. Ngokususelwa kulokhu, lo mbhalo uxoxa ngobuchwepheshe bemishini be-CNC bensimbi engu-55 ° evaliwe yompompi wepayipi, okukholelwa ukuthi iyasiza ezidingweni zamaqembu ahlobene.

1. Izici ezisebenzayo zentambo yepayipi evaliwe engama-55 °

Emucwini wepayipi ovalwe ngama-55 °, asikho isidingo sokwengeza noma iyiphi i-sealant, engagwema ngempumelelo ukuvuza kwe-sealant. Imicu esentambo yokufaka uphawu ehlanganisiwe ihlukaniswe ngemicu yangaphakathi eyindilinga nemicu eyindilinga yangaphandle. Lapho ingcindezi ingaphansi kuka-5 × 105MPa, intambo yangaphakathi eyindilinga ingasetshenziselwa ukuxhumana, ukuze uxhumano luqine kakhulu; ngenkathi intambo eyindilinga yangaphandle ivame ukusetshenziswa ngaphansi kwezinga lokushisa eliphakeme kanye nengcindezi ephezulu. Lolu hlobo lwentambo lulungele kakhulu ukusetshenziswa emapayipini, kumaqhude nakwezinye izesekeli ezixhunywe yimicu, futhi ukubekwa uphawu kwalo kuhle kakhulu, futhi kuvame ukusetshenziselwa ukuthutha oketshezi [1].

2. 55 ° wokufaka uphawu kwepayipi ngentambo ye-CNC inqubo machining

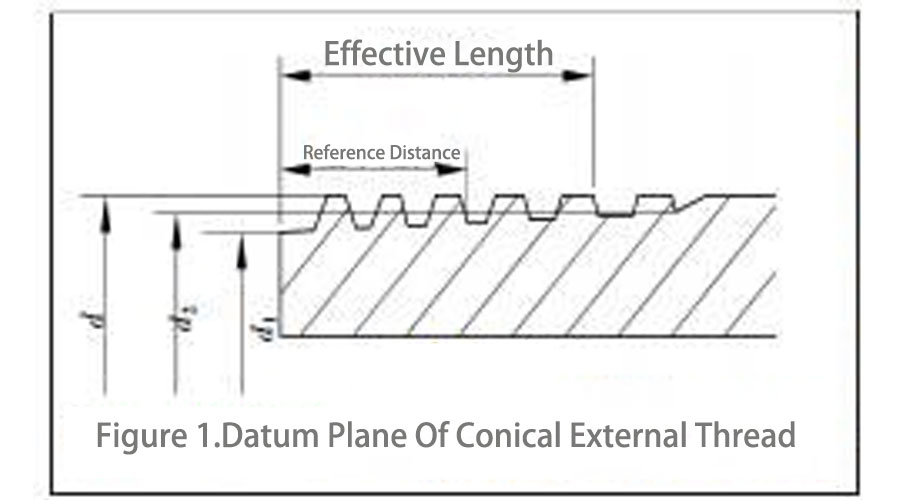

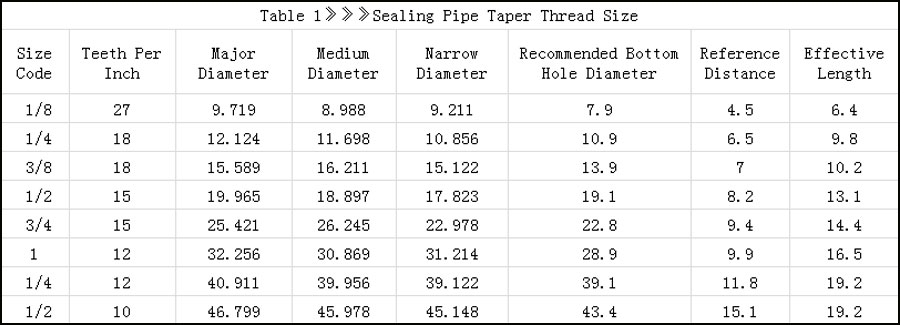

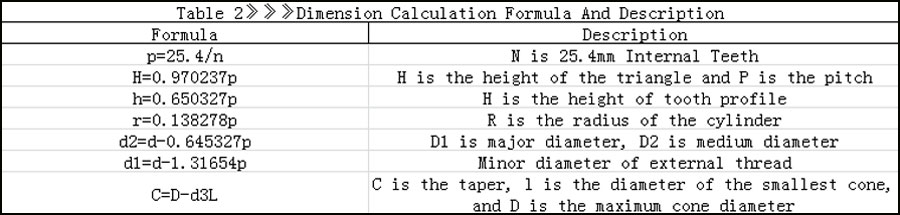

Umucu we-taper wepayipi uhlukaniswe kakhulu ube yizinhlobo ezimbili: isigaxa nesilinda, kuyilapho intambo yetaper yepayipi langaphandle ingenaso isilinda. Ngokuklama isilinganiso sephrofayili ye-taper yesigaxa sepayipi kuye ku-1: 16, ibanga eliphakathi kwendawo eyisisekelo nokuphela kwepayipi nobude obusebenzayo kufanele bahambisane namazinga ahambisanayo. Ngokuya ngokuhlaziywa okuhlanganisiwe komdwebo 1, Ithebula 1 kanye neThebula 2, ngokuya ngemininingwane etafuleni kanye namafomula ahlobene, kungabalwa usayizi wentambo kunqubo yokuphatha.

3. Ukunqunywa kwamapharamitha womyalo wokujika kwentambo

3.1 Ububanzi obuphezulu bezintambo

Ngenqubo yokusika intambo, ububanzi obuphezulu bomucu wokugcina owenziwe ngomshini bunwetshwa ngoplastikhi ngenxa yokukhishwa kwethuluzi, okuzoba nomthelela omkhulu emhlanganweni wentambo nokusetshenziswa okujwayelekile. Abasebenzi bokucubungula kumele baqale babheke le nkinga ngenkathi kusetshenzwa. . Futhi ngaphambi kokusika intambo, kunqubo yokwenza imishini eyindilinga, kufanele kususwe enye impahla, isilinda sangaphandle sincishiswe sibe sincane, bese kuthi isilinda yangaphakathi isikwe ibe nkulu, futhi ukusika kuvame ukulawulwa ngaphakathi kuka-0.2 ~ 0.3 mm.

Ukuphakama kwephrofayili ye-3.2

Ukuphakama kwephrofayili yezinyo akukwazi ukuba ngaphansi kuka-0.6495 p, futhi ukujula kwamazinyo esiqondisweni sobubanzi kungasethwa cishe ku-1.3 p.

3.3 Ukujula okunomugqa okusikiwe

Kunezindlela ezimbili zokucubungula ukucutshungulwa kwentambo kulesi sigaba. Enye ukusebenzisa izinto zensimbi ezisheshayo ukucubungula ngejubane eliphansi; okunye ukusebenzisa ukucubungula okusheshayo nge-carbide namathuluzi aboshwe. Inqubo yokuhlela kumele isuselwe kulokho okwenziwe yithuluzi. Setha ijubane lokujikeleza [2-3]. Futhi i-CNC machining imvamisa ijubane eliphezulu imishini. Ngesikhathi senqubo yokwenza imishini, inani lokusika kokuqala licishe libe ngu-0.5 p, bese kuthi izikhathi ezingama-0.7 ukusika kwangaphambilini kwehle. Ukujula okusikiwe kokusika okukodwa kufanele kube ngaphansi kuka-1, futhi ukusika okuncane okusikiwe okukodwa akufanele kube ngaphansi kuka-0.1.

I-3.4 Thread start and end ubukhulu be-axial

Lapho uchwepheshe efaka intambo ku-lathe ye-CNC, ngenxa yezici ezithile zomshini we-servo motor, ngenkathi kucutshungulwa intambo, ithuluzi kufanele lifinyelele kusivinini sokuphakelayo esishiwo kusuka esimweni sokuqala sokuma, noma ukwehla ngqo kusuka kokucacisiwe isivinini sokuphakela ku-Zero, kudingeka ukuthi kube nenqubo yokuguquka ohlelweni lokushayela, futhi kunenqubo yokusheshisa enqubeni yokuqala, kanye nenqubo yokwehlisa inqubo yokumisa. Kule nqubo, iphimbo alinembile. Ngakho-ke, lapho kwenziwa ukujika kwentambo, isigaba sokuqalisa sokusheshisa esihambisanayo nesigaba sokuhoxiswa kokunciphisa kufanele sisethwe kuzo zombili izinhlangothi, futhi amanani ezindawo zombili kufanele akhethwe ngokufanele, ngaphandle kwalokho ithuluzi lizosika lapho kusheshiswa noma kuncipha, okuzokwenza ukuthi indlela zenzeka. Ukulimala nokukhiqiza imikhiqizo engekho ezingeni. Kukhona ukuhlangana okuhle phakathi kwamanani wezingxenye zokusheshisa nezokwehlisa kanye nezici ezinamandla, intambo yokuphamba nokunemba kohlelo lokushayela ithuluzi lomshini. Ngakho-ke, ochwepheshe kufanele basethe ngempumelelo inani lezigaba ezimbili ngokuya ngezimpawu zomshini wohlelo lokushayela lwe-servo. Ngokuvamile, isigaba sokuqala sokusheshisa sikhulu kunezikhathi ezi-2 zokuhola; isigaba sokuhlehla sokuhlehla siphakathi kuka-1 no-1.5 izikhathi zomholi [4]. Ngaphezu kwalokho, ngenkathi kusetshenziswa umjikelezo osethinini, kufanele kuqashelwe ukuthi ukugcotshwa kwendawo yokuqala kukhulu kunobubanzi bezintambo, ukuvimbela imihuzuko ebusweni bomshini lapho ithuluzi lihoxiswa [5] .4. Indaba eyisibonelo

4.1 Ukuhlaziywa kwenqubo

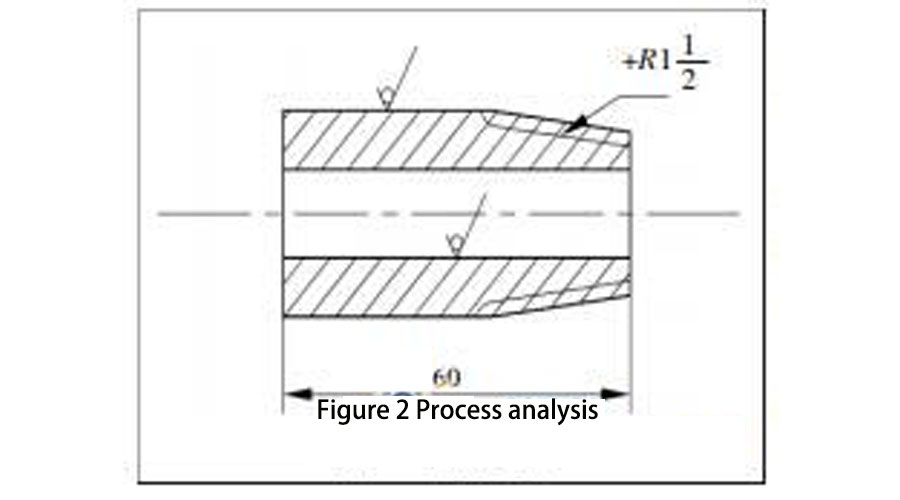

Kungabonakala kusuka kuMdwebo 2 ukuthi ububanzi bangaphandle nomgodi wangaphakathi wesigaxa sepayipi awucubungulwanga futhi awacutshungulwa. Umsuka wohlelo lokuxhumanisa ipayipi lesigaxa sepayipi lenzelwe ngqo empambanweni yomugqa ongakwesokudla ekugcineni kwentambo yesigaxa sepayipi nolayini ophakathi nendawo. Ngemuva kwalokho sebenzisa i-chuck centering ukubopha ukuphela kwesobunxele kwento yesigaxa sepayipi, bese usetha ubude bokunweba bube cishe ama-60 mm. Okokuqala, uchwepheshe angasebenzisa indlela yokusika isilingo ukwenza ukusethwa kwamathuluzi, bese esebenzisa ithuluzi lokujika langaphandle elingu-90 ° ukwenza umshini ububanzi obukhulu bentambo ngemuva kokuphothula [6]; okwesibili, ngaphambi kokusebenzisa ithuluzi lokuguqula intambo elingu-55 ° ukucubungula intambo ye-taper pipe, okokuqala Umehluko we-radius phakathi kwendawo yokuqala nendawo yokuphela kobubanzi obuncane besigaxa sepayipi ubalwa, futhi nenani lamazinyo lilawulwa phakathi kuka-3 no 4 ngesikhathi sokucubungula; ekugcineni, ingxenye isikwa ngqo yithuluzi lokusika lombuthano ongaphandle, futhi ubude bulawulwa ku-60 kuye ku-65 mm.

Kungabonakala kusuka kuMdwebo 2 ukuthi ububanzi bangaphandle nomgodi wangaphakathi wesigaxa sepayipi awucubungulwanga futhi awacutshungulwa. Umsuka wohlelo lokuxhumanisa ipayipi lesigaxa sepayipi lenzelwe ngqo empambanweni yomugqa ongakwesokudla ekugcineni kwentambo yesigaxa sepayipi nolayini ophakathi nendawo. Ngemuva kwalokho sebenzisa i-chuck centering ukubopha ukuphela kwesobunxele kwento yesigaxa sepayipi, bese usetha ubude bokunweba bube cishe ama-60 mm. Okokuqala, uchwepheshe angasebenzisa indlela yokusika isilingo ukwenza ukusethwa kwamathuluzi, bese esebenzisa ithuluzi lokujika langaphandle elingu-90 ° ukwenza umshini ububanzi obukhulu bentambo ngemuva kokuphothula [6]; okwesibili, ngaphambi kokusebenzisa ithuluzi lokuguqula intambo elingu-55 ° ukucubungula intambo ye-taper pipe, okokuqala Umehluko we-radius phakathi kwendawo yokuqala nendawo yokuphela kobubanzi obuncane besigaxa sepayipi ubalwa, futhi nenani lamazinyo lilawulwa phakathi kuka-3 no 4 ngesikhathi sokucubungula; ekugcineni, ingxenye isikwa ngqo yithuluzi lokusika lombuthano ongaphandle, futhi ubude bulawulwa ku-60 kuye ku-65 mm.

4.2 Uhlelo lwe-CNC machining lokufaka uphawu ngentambo ye-taper thread

Uhlelo lwe-CNC machining lokufaka uphawu kwepayipi ngentambo lumi kanje:

- O0001;

- I-G40 G99 T0101 M03 S600;

- I-G00 X55 Z5;

- G71 U1.5 R1;

- I-G71 P10 Q20 U0.3 W0.05 F0.15;

- I-N10 G00 X47;

- G01 Z0 F0.1;

- X48.5 Z-23;

- I-N20 X55 F0.5;

- I-G70 P10 Q20;

- I-G00 X100 Z100;

- T0202 M03 S200;

- I-G00 X55 Z8;

- I-G92 X46 Z-25 R-0.75 F2.309;

- x45.5;

- X45 .;

- x44.7;

- x44.4;

- x44.2;

- x44.1;

- x44.05;

- I-G00 X100 Z100;

- T0303 M03 S400;

- I-G00 X55Z 5;

- Z-64;

- G01 X29 F0.1;

- X55 F0.3;

- I-G00 X100 Z100;

- I-M05;

- I-M30;

I-5.Conclusion

Ngamafuphi, imishini esebenzayo ye-CNC nokuphathwa kwentambo yesigaxa sepayipi akukwazi nje ukuthuthukisa ukunemba kwentambo, kepha futhi kuthuthukisa kakhulu ukusebenza kahle kokucutshungulwa komshini. Ngakho-ke, ukucubungula kokulawulwa kwamanani kwentambo ye-paper taper kungathuthukisa kakhulu ikhwalithi yokuxhuma kwepayipi elivalwe. Ngaphezu kwalokho, abasebenzi bezokuphatha kufanele basebenzise ubuchwepheshe obusezingeni eliphezulu bokucutshungulwa kokulawulwa kwamanani, ukuze kukhuthazwe ukuthuthukiswa okuqhubekayo kobuchwepheshe bokulawulwa kokulawulwa kwamanani.

Xhumanisa nale ndatshana: I-CNC Machining Technology ye-Sealing Pipe Taper Thread

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi