New Technology Of Die-Ekubunjweni Isikhunta Surface Ukwelashwa

New Technology Of Die-Ekubunjweni Isikhunta Surface Ukwelashwa

|

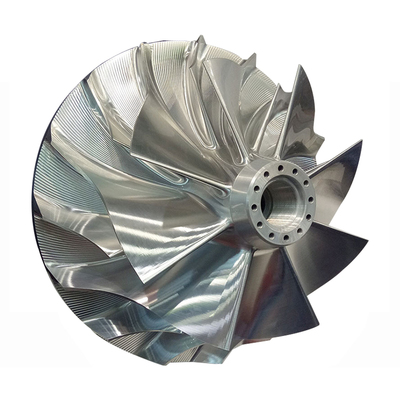

Isikhunta sokuphonsa sigaba esikhulu sesikhunta. Ngokuthuthuka okusheshayo komkhakha wezimoto nezithuthuthu emhlabeni, imboni yokulingisa ifake inkathi entsha yentuthuko. Ngasikhathi sinye, izidingo eziphakemeyo zibekwa phambili zezakhiwo eziphelele kanye nokuphila kwesikhunta sokufa. |

Kunobuchwepheshe obuhlukahlukene bokulungiswa kwesikhunta bokufa obusaqhubeka buvela, kepha ngokujwayelekile bungahlukaniswa ngezigaba ezintathu ezilandelayo:

- Ubuchwepheshe 1.Improved bendabuko inqubo ukwelashwa ukushisa;

- Ubuchwepheshe bokuguqulwa kwe-2.Surface, kufaka phakathi ukwelashwa kokushisa okushisayo komhlaba, ukuqiniswa kwesigaba sendawo yokuqinisa, ubuchwepheshe bokuqinisa inhlansi kagesi, njll

- Ubuchwepheshe 3.Coating, kuhlanganise Plating electroless, njll

Izikhunta ezi-die-casting ziyisigaba esikhulu sezikhunta. Ngokuthuthuka okusheshayo komkhakha wezimoto nezithuthuthu emhlabeni, imboni yokulingisa ifake inkathi entsha yentuthuko. Ngasikhathi sinye, izidingo eziphakemeyo zibekwa phambili zezakhiwo eziphelele kanye nokuphila kwesikhunta sokufa. ULuo Baihui, uNobhala-Jikelele we-International Mold Association, ukholelwa ukuthi kusenzima ukuhlangabezana nezidingo zokusebenza ezikhula njalo ezincike kuphela ekusetshenzisweni kwezinto zokwakha ezintsha. Ubuchwepheshe obuhlukahlukene bokwelashwa kwendawo kumele busetshenziswe ekwelapheni okungaphezulu kwesikhunta sokufa ukuze kufezekiswe ukusebenza kahle kwesikhunta sokufa. , Ukunemba okuphezulu nezidingo zokuphila ezinde. Phakathi kwesikhunta esihlukahlukene, izimo zokusebenza zesikhunta sokuphonsa zibuhlungu kakhulu. Ukufakwa kwe-die ukugcwalisa isikhunta sensimbi ngensimbi encibilikisiwe ngaphansi kwengcindezi ephezulu nesivinini esikhulu futhi ukufa-okusakaza. Ixhumana kaningi nensimbi eshisayo ngenkathi isebenza. Ngakho-ke, isikhunta sokufa sidingeka ukuba sibe nokukhathala okuphezulu, ukushisa okushisayo, ukumelana nokugqoka, nokumelana nokugqwala. , Ubulukhuni be-Impact, ubulukhuni obomvu, ukukhululwa okuhle kwesikhunta, njll. Ngakho-ke, izidingo zobuchwepheshe bezokwelapha ebusweni bezikhunta zokufa ziphakeme kakhulu.

Ubuchwepheshe obuthuthukisiwe benqubo yokwelashwa kwendabuko

Inqubo yendabuko yokwelapha ukushisa kwezibungu ezifayo iyacisha, futhi kamuva ubuchwepheshe bokwelapha obungaphezulu sebuthuthukisiwe. Ngenxa yezinhlobonhlobo zezinto ezingasetshenziswa njengezikhunta ezibulalayo, ubuchwepheshe obufanayo bokwelashwa kwendawo kanye nenqubo esetshenziswa ezintweni ezihlukene kuzoveza imiphumela ehlukene. U-Schoff uphakamisa ubuchwepheshe bokwelashwa kwangaphambili kwe-substrate ye-mold substrate kanye nobuchwepheshe bokwelapha obungaphezulu.

Ngesisekelo sobuchwepheshe bendabuko, ubuchwepheshe bokucubungula obufanele bezinto ezihlukahlukene zokubunjwa kuhlongozwa ukuthuthukisa ukusebenza kwesikhunta nokwandisa impilo yesikhunta. Esinye isiqondiso sokuthuthukiswa kokuthuthukiswa kobuchwepheshe bokwelapha ukushisa ukuhlanganisa ubuchwepheshe bendabuko bokwelapha ukushisa nobuchwepheshe obuthuthukisiwe bokwelashwa kwendawo ukuze kwandiswe impilo yesevisi yesikhunta esibulalayo.

Isibonelo, indlela yokwelapha ukushisa ngamakhemikhali i-carbonitriding, i-NQN ehlanganiswe nenqubo evamile yokucisha kanye neyokushisa (okungukuthi i-carbonitriding-quenching-carbonitriding composite composite, ayitholi nje kuphela ubulukhuni obuphezulu bobuso, kodwa futhi nongqimba olusebenzayo lokuqina.

Ukujula kuyanda, ukusatshalaliswa kwegradient yokuqina kwesendlalelo esingenisiwe kunengqondo, ukuzinza kwesimo sezulu kanye nokumelana nokugqwala kuyathuthukiswa, ukuze ngenkathi isikhunta se-die-casting sithola ukusebenza okuhle okuyisisekelo, ikhwalithi ephezulu nokusebenza kuthuthukiswa kakhulu.

Ubuchwepheshe bokuguqulwa komhlaba

Ubuso bokusabalalisa obushisayo bokushisa

Lolu hlobo lubandakanya i-carburizing, i-nitriding, i-boronizing, i-carbonitriding, i-sulfur carbonitriding nokunye.

I-Carburizing ne-carbonitriding

Inqubo ye-carburizing isetshenziswa emsebenzini obandayo, oshisayo kanye nokuqinisa indawo yokubunjwa kwepulasitiki, okungathuthukisa impilo yesikhunta. Isibonelo, isikhunta se-die-casting esenziwe ngensimbi engu-3Cr2W8V siqale sishiswe, bese sicinywa ku-1140℃, bese sishiswa kabili ku-1150℃. Ukuqina kobuso bungafinyelela ku-HRC550~56, okwandisa ukuphila kwezinsimbi ezingenayo i-die-casting nama-alloys azo izikhathi ezingu-61–1.8. .

Lapho kungcwatshwa i-carburizing, izindlela eziyinhloko zenqubo zifaka i-powder carburizing, i-gas carburizing, i-vacuum carburizing, i-ion carburizing, kanye ne-carbonitriding eyenziwe ngokungeza i-nitrogen emkhathini we-carburizing. Phakathi kwazo, i-vacuum carburizing kanye ne-ion carburizing ubuchwepheshe obuthuthukiswe eminyakeni engama-20 edlule. Lobu buchwepheshe bunezici ze-carburizing esheshayo, i-carburizing efanayo, i-carbon concentration gradient ebushelelezi, kanye nokuguqulwa okuncane kwendawo yokusebenza. Izosetshenziswa ebusweni besikhunta, ikakhulukazi isikhunta esinembayo. Dlala indima ebaluleke kakhulu ekwelapheni okungaphezulu.

Ubuchwepheshe bokunwetshwa okushisayo bokushisa kwe-nitriding nokuhlobene

Lolu hlobo lubandakanya i-nitriding, i-ion nitriding, i-carbonitriding, i-oxygen nitriding, i-nitriding yesulfure ne-ternary sulphur carbon nitriding, i-oxygen, i-nitrogen nesibabule. Lezi zindlela zinobuchwepheshe bokucubungula obulula, ukuzivumelanisa nezimo okuqinile, izinga lokushisa eliphansi lokusabalala, imvamisa i-480 ~ 600 ℃, ukusonteka okuncane kwendawo yokusebenza, ikakhulukazi efanelekile ekuqiniseni ubuso kobuciko besikhunta, nobulukhuni obuphezulu besendlalelo se-nitride, ukumelana okuhle kokugqoka, ne-Anti enhle ukusebenza -sticking.

3Cr2W8V steel die-casting isikhunta, ngemva kokucisha kanye nokushisa kanye ne-nitriding ku-520~540℃, impilo yesevisi yinde ngokuphindwe izikhathi ezi-2 kuya kwezingu-3 kunezibunjwa ezingafaki i-nitriding. Izibunjwa eziningi ezisafufusa ezenziwe ngensimbi ye-H13 e-United States zidinga ukufakwa i-nitrided, futhi i-nitriding isetshenziswa esikhundleni sokufudumeza okwesikhathi esisodwa. Ukuqina kwendawo kuphezulu njenge-HRC65~70, kuyilapho umnyombo wesikhunta unobulukhuni obuphansi kanye nokuqina okuhle, ukuze kutholwe ukuhlanganisa okuhle kakhulu.

Izakhiwo zemishini. Inqubo ye-nitriding iyinqubo evame ukusetshenziswa ekwelapheni okungaphezulu kwesikhunta esibulalayo. Kodwa-ke, lapho ungqimba olumhlophe oluncane oluncane lubonakala ongqimbeni olune-nitrided, alukwazi ukumelana nomphumela wokushintshana kokucindezeleka okushisayo, futhi kulula ukukhiqiza imifantu emincane nokunciphisa ukumelana nokukhathala okushisayo. Ngakho-ke, ngesikhathi senqubo ye-nitriding, inqubo kufanele ilawulwe ngokuqinile ukuze kugwenywe ukukhiqizwa kwezingqimba eziphukayo. Amazwe angaphandle ahlongoza ukusebenzisa izinqubo zesibili neziningi ze-nitriding. Indlela ye-nitriding ephindaphindiwe ingabola ungqimba olumhlophe lwe-nitride olumhlophe oluthambekele kuma-microcracks ngesikhathi senkonzo, lwandise ukushuba kongqimba lwe-nitriding, futhi ngasikhathi sinye yenze isikhunta sibe nongqimba oluqinile lwezinsalela zokucindezeleka, ukuze ukuphila isikhunta singathuthukiswa kakhulu. Ngaphezu kwalokho, kunezindlela ezifana ne-salt bath carbonitriding kanye ne-salt bath sulfur nitrocarburizing.

Lezi zinqubo zisetshenziswa kabanzi emazweni angaphandle futhi azivamile ukubonwa eChina. Isibonelo, inqubo ye-TFI + ABI icwiliswa kubhavu osawoti we-alkaline oxidisa usawoti ngemuva kwe-nitrocarburizing kubhavu kasawoti. Ubuso bento yokusebenza benziwe i-oxidized futhi buvela bumnyama, futhi ukumelana kwayo nokugqoka, ukumelana nokugqwala nokumelana nokushisa kuthuthukisiwe. Impilo ye-aluminium alloy die-casting die ephathwa ngale ndlela inyuswa ngamakhulu amahora. Esinye isibonelo inqubo ye-oxynit eyenziwe eFrance, lapho i-nitrocarburizing elandelwa yi-nitriding isetshenziswa kwizikhunta zensimbi ezingafaki insimbi ezinezici eziningi.

Xhumanisa nale ndatshana: New Technology Of Die-Ekubunjweni Isikhunta Surface Ukwelashwa

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi