Imishini Ephumelelayo Yezingxenye Zezindiza zeTitanium

Imishini Ephumelelayo Yezingxenye Zezindiza zeTitanium

|

Ingxubevange yeTitanium inezinzuzo zokuminyana okuncane nokumelana nokugqwala, futhi isetshenziswa kakhulu ekwakhiweni kwezindikimba zezindiza, kepha ithambekele ekuguqukeni ngesikhathi semishini ye-cnc, futhi ukunemba kwemishini kunzima ukukuqinisekisa. Ngakho-ke, kuyadingeka ukusebenzisa ubuchwepheshe besimanje obuthuthukile kanye nengqalasizinda ephelele ukwakha izinqubo ezisebenzayo zemishini, futhi ekugcineni kuthuthukise ukusebenza kahle kwemishini kanye nekhwalithi ngokusebenzisa Ukufakwa kwe-CNC imishini. Ukuhlaziywa okujulile kuhlanganiswe ne-titanium ingxubevange machining izindlela kuhloswe ngazo ukwenza ngcono ukusebenza kahle kwemishini yezingxenye ezihlobene |

Njengohlobo lwezingxenye ezibonakalayo ezinamandla amakhulu, izingxenye ze-titanium alloy zinenani lesicelo eliphakeme ngokwedlulele ku- izingxenye zezindiza inkambu. Izindlela zokwenziwa zendabuko azisafanele izidingo zokukhiqiza zezakhiwo zesimanje zezindiza. Ngakho-ke, ukusetshenziswa kwezingxenye ze-titanium alloy kungahlangabezana nezidingo zokuthuthukiswa kwezindiza ngezinga elikhulu kakhulu. Izingxenye ze-Titanium alloy zisetshenziswe kabanzi ekwakheni izindiza. Isibonelo, ngezikulufo namantongomane kungasetshenziswa ukulungisa amafreyimu amakhulu we-fuselage, nezingxenye ezibalulekile ezifana nezinsimbi zenjini nokwehla igiya kungenziwa ngezinto ze-titanium alloy.

Izinkambu zohlelo lokusebenza nezinzuzo zezingxenye ze-titanium alloy

1.1 Inkambu yesicelo sezingxenye ze-Titanium

Thatha izindiza zabagibeli ze-B777 njengesibonelo. Ukusetshenziswa kwe-titanium alloy castings ekwakheni ifreyimu yokufaka izindiza. Kungabonakala ukuthi lapho kwenziwa izindiza zombuso, ubuchwepheshe bokusetshenziswa kwezingxenye ze-titanium alloy buvuthiwe ngokwanele. Ngaphezu kwalokho, izingxenye ze-titanium alloy nazo zibaluleke kakhulu ekuthuthukiseni imboni yezindiza. Isibonelo, inkampani yase-European Doncasters isebenzisa ubuchwepheshe be-centrifugal casting ukusebenzisa i-titanium alloy ukubhuleka torque.

1.2 izinzuzo zesicelo sezingxenye ze-titanium alloy

Izingxenye ze-Titanium alloy zinezinzuzo ezilandelayo zobuchwepheshe:

- Okokuqala, asikho isidingo sokusebenzisa isikhunta phakathi nenqubo yokubumba;

- Okwesibili, asikho isidingo sokutshala amandla amaningi nezimali esigabeni sokuqala sokulungiselela;

- Okwesithathu, ingathuthukisa ngempumelelo ukusebenza kahle kwezinto ezibonakalayo. Izingxenye ze-Titanium alloy azithuthukisi nje kuphela ukuphepha kokusebenza kwezakhi zezindiza, kepha futhi zinciphisa inani lezingxenye ezixhunyiwe, zisindisa ngempumelelo isikhathi somhlangano wezandla, futhi zifeze umphumela wezindlela ezimbili zokuthuthukiswa kwemali engenayo nekhwalithi.

Izici zezingxenye ze-titanium alloy

2.1 akulula ukukhubazeka

Izinto ze-Titanium alloy zinamandla aphezulu namandla okushisa, futhi zinobuningi obuphansi. Uma kuqhathaniswa nezinto zensimbi, kungu-60% kuphela wobuningi bensimbi. Lokhu kwenza i-titanium alloy material ngaphandle kwezinkinga ze-deformation ngisho nasemazingeni aphezulu okushisa we-300 ° C kuye ku-500 ° C. Isakhiwo se-titanium alloy sohlobo oluthile lwenjini yezindiza sicutshungulwa yi-TC4 titanium alloy UKWAKHAs. Ubunzima bungu-19.987kg, ububanzi bungu-600mm, ubude bube ngu-2800mm, kepha ubukhulu bodonga bungu-1.50mm kuphela.

2.2 ukumelana nokushisa okuphansi

Ingxubevange yeTitanium inokumelana nokushisa okuphezulu okuphansi, okungukuthi, isengakwazi ukugcina izakhiwo zayo zokwenziwa ngaphansi kwezimo zokushisa eziphansi noma eziphansi kakhulu. Kuyinto ebonakalayo enokuqina okuqinile kokushisa okuphansi. Ngokuya ngezivivinyo ezihlobene, kuyaziwa ukuthi ingxubevange ye-titanium iku -196 ° C. Ngezansi, amandla we-tensile σb yi-1207Pa.

2.3 ukumelana nokugqwala okuqinile

Izingxenye ze-Titanium alloy zingasetshenziswa kabanzi emkhakheni wezindiza, isizathu esibaluleke kakhulu ukuthi sinokumelana nokugqwala okukhulu. Lapho indiza indiza phezulu kakhulu, izinto ezisemoyeni zizoba nomthelela othile owonakalisayo ebusweni bendiza. Izingxenye ze-Titanium alloy zingabhekana ngempumelelo nalokhu kubuyela emuva futhi ziqinisekise ukuphepha kwendiza.

2.4 Ngezici zamakhemikhali

Ama-alloys weTitanium angaphendula ngezinto ezahlukahlukene zensimbi. Ngosizo lokuphendula kwamakhemikhali, izakhiwo zemishini yama-titanium alloys zingandiswa. Isibonelo, endaweni yokushisa ephezulu engaphezulu kuka-600 ° C, ama-titanium alloys angaphendula nge-oxygen ukuze enze ungqimba lwe-oxide olufanayo.

2.5 conductivity ezishisayo ongaphakeme

Ukusetshenziswa kwezingxenye ze-titanium alloy ezindizeni kunganciphisa ngempumelelo amathuba okwehluleka kwezingxenye zendiza, futhi kugweme ukuqhutshwa kokushisa okweqile kwezingxenye zendiza ezithinta ukusetshenziswa okuvamile kwezinye izingxenye.

2.6 Modulus encane yokuqina

Ngenqubo yokusebenzisa izingxenye ze-titanium alloy, ungazicubunguli zibe izingxenye ezincane. Lokhu kungenxa yokuthi i-modulus nokunwebeka kwe-titanium alloy incane kakhulu futhi kulula ukuyikhubaza. Ngaphezu kwalokho, kufayela le- umshini we-titanium inqubo, ngenxa yokubuyela emuva okukhulu kwe-titanium alloy, kulula ukugqoka ithuluzi.

Izinyathelo Zokumaketha Nokusetshenziswa Kwezingxenye Zezindiza zeTitanium

Imboni yezindiza yaseChina ikubheka kakhulu ukusetshenziswa kwezinto zokusetshenziswa, kanti ukugxila kwe-R & D kugxile ekwakhiweni kwenqubo nasekusebenziseni ukuze kuthuthukiswe ukusebenza kwezindiza.

3.1 Nweba umkhakha wokusetshenziswa kwe-titanium alloy castings

Uma kuqhathaniswa nezinye izingxenye ze-titanium, indlela yokukhipha utshalomali inezinzuzo zayo ezihlukile:

- Usayizi wokulingisa unembile, ingaphezulu libushelelezi, futhi ubukhulu buphansi;

- Ingasakaza ukujikijela okuyinkimbinkimbi;

- Ngenkathi kuthuthukiswa izinga lokusetshenziswa kwempahla eluhlaza, kungabuye kuthuthukise ukuguquguquka kokukhiqiza nokuzivumelanisa nezimo.

Kodwa-ke, kunqubo yokufaka isicelo, amandla ama-titanium alloys awakwazi ukuhlangabezana ngokugcwele nezidingo zokwakhiwa kwezindiza. Ngakho-ke, ukugcizelela kufanele kubekwe ekuthuthukiseni amandla we-tensile alloys we-titanium ngesikhathi socwaningo nentuthuko. Ijubane lokuthuthuka lobuchwepheshe bokuphonsa ngokunemba kwe-titanium alloy ezweni lami belilokhu landa ngokuqhubekayo eminyakeni yamuva. Ngalesi sizathu, i-diagonal overrunning clutch isetshenziswe kabanzi emkhakheni wezindiza. Ngenxa yezidingo eziphakeme zezindiza zezingxenye ze-titanium alloy, izinga lokwakheka kwezingxenye zezindiza zezwe lami le-titanium alloy liphansi kakhulu. Ngakho-ke, isayensi nobuchwepheshe kufanele busetshenziselwe ukuthuthukisa izinga lokusakaza, ukunciphisa izindleko zokukhiqizwa komkhiqizo nemijikelezo yokukhiqiza, nokufeza izinhloso zokukhiqiza ngobuningi. .

3.2 Yehlisa izindleko zentuthuko

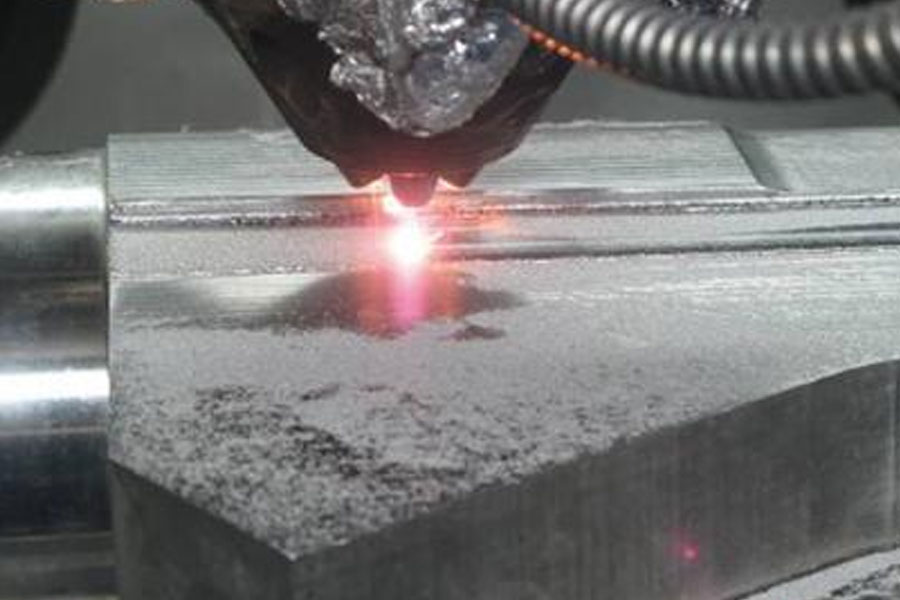

Ngesisekelo sekhwalithi ephezulu yamandla we-laser kanye ne-prototyping esheshayo, ubuchwepheshe be-titanium alloy powder laser ukwakha busetshenziswe kabanzi. Lobu buchwepheshe busebenzisa i-high-energy laser beam ukuncibilikisa i-titanium alloy powder bese buyiqinisa ku-substrate ngokuma kwamaconsi amancane, bese bencika kubuchwepheshe bokulawula ikhompyutha ukwenza ikhanda le-laser lihambe liphindelela, ngaleyo ndlela ligcine ungqimba ngongqimba, futhi ekugcineni thola imodeli yezingxenye ze-titanium alloy edingekayo.

Okwamanje, ukusebenza okuphelele kwesakhiwo se-titanium alloy kuthuthukiswe kakhulu, futhi isisindo sengxenye uqobo sehliswe kakhulu, esithandwe yinkambu yezindiza. Ngokuhambisana nesimo sangempela, izindleko ze-Nb, Mo futhi izinto ze-V kuma-titanium alloys zibiza kakhulu, okuholela ezindlekweni eziphezulu zempahla eluhlaza.

Ngakho-ke, izindiza ze-aviation titanium ezinokutshalwa kwezindleko eziphansi zihehe ukunakwa okukhulu. Njengamanje, abacwaningi bathole ukuthi izakhi ze-Fe zingasetshenziswa ukufaka esikhundleni sezinto ezibiza kakhulu ze-Nb, Mo ne-V, ezingagcini ngokuqinisekisa ukusebenza kwezinto, kepha futhi zinciphise ngempumelelo Izindleko zokufaka zezinto zokusetshenziswa ze-titanium alloy.

3.3 Indlela yokusabalalisa nokuvikela indawo

Ekuhlaziyweni kwengqimba engaphezulu ye-BT3-1 ne-OT4-1, kungaphethwa ngokuthi ukusatshalaliswa kwe-hydrogen kusendlalelo sobuso kuyinkimbinkimbi, futhi okuqukethwe yi-hydrogen kuzokhula kancane kancane, futhi lapho kufinyelela inani eliphakeme, izokwehla ngokufanele. Njengamanje, i-laser enezinhlangothi ezintathu ezakha ubuchwepheshe kanye nezingxenye ze-titanium alloy zihlanganiswe ngempumelelo, nezikhulu ezinkulu ze-titanium alloy main eziveza izingxenye zezindiza zenziwe.

3.4 Thuthukisa ukusetshenziswa kwensimbi yesici sokushisa okushisayo okushisayo

Indlela ephumelela kakhulu yokwandisa isici sokusetshenziswa kwensimbi ukusebenzisa i-low-oxidation kanye nokushisa okungeyona i-oxidation. Okwezinsimbi ze-titanium, ukushisa okungenalutho ngomoya owomile kungaxazulula le nkinga ngempumelelo. Ngokuya ngocwaningo oluhlobene, lapho kufudunyezwa esithandweni sikagesi, izinga lokushisa kufanele lilawulwe ku-950 ℃ ~ 980 ℃. Ngaphezu kwalokho, ngokwenza izivivinyo ku-BT20 naku-OT4-1 (TC1), ukufudumeza wonke amasampula futhi kufe kubunjwe ngokufanayo, kungatholakala ukuthi indawo yoboya obungenawo oksijini obugcwele obushisayo obungenalutho ibonisa umphumela obushelelezi, oholela isiphetho sokuthi ungqimba we-oxide kanye nesimo sokugcwaliswa kwegesi kunethonya elibalulekile kuzakhiwo zemishini.

Isiphetho

Ngokwesimo sokuthuthuka okuqhubekayo kwesayensi nobuchwepheshe, amabhizinisi amaningi aqedile ukuguqulwa kwawo, futhi imboni yezwe lami le-aluminium nayo ithole imiphumela emihle. Enqubweni yokuthuthuka kwezomnotho ngokushesha, imboni ye-titanium alloy iyaqhubeka nokukhula ibhekise emandleni avuselelekayo, inika amandla izingxenye ze-titanium alloy ukuthi zisetshenziswe ngempumelelo emikhakheni eminingi, zibeka isisekelo esiqinile sokuthuthukiswa kokongiwa kwamandla kanye nokwehlisa ukungcola.

Xhumanisa nale ndatshana: Imishini Ephumelelayo Yezingxenye Zezindiza zeTitanium

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi