Inqubo Yokucwaninga Ngokudalwa Kokuhlelwa Kwemishini ye-NC Machining

Inqubo Yokucwaninga Ngokudalwa Kokuhlelwa Kwemishini ye-NC Machining

|

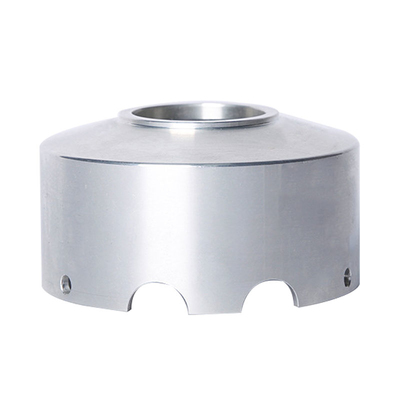

Ngenxa yokuhlushwa okuhlobene, ukusebenza kahle okuphezulu, ukuguquguquka okuphezulu, ukunemba okuphezulu, kanye nokuvumelana okuhle kwezinqubo zokucubungula ithuluzi lomshini we-CNC, ukucindezela okukodwa kungaqedela ukugaya, ukubhola, isidina, ukuqhathanisa, ukuthepha nezinye izinqubo nokucubungula izingxenye eziningi; |

Ukuchaza indlela efanayo yokuchofoza ku-clamping njengenqubo ejwayelekile, bese kudalwa futhi kwakhiwa i-CNC inqubo machining ihlukile ekwakhiweni kobuchwepheshe obujwayelekile bombhede wokucubungula ishidi. I-GroupTechnolgy ingenye yezinhlelo zokukhiqiza ze-CNC ezisekelayo. I-Ring, inomsebenzi wayo obalulekile, ukunikeza ukudlala okugcwele kuzici zamathuluzi womshini we-CNC, inqubo yesayensi nenengqondo yokwakha kuyisihluthulelo. Inqubo enengqondo nengokwesayensi yokuhlela kanye nokuklama kuzokhulisa kakhulu umkhiqizo, kunciphise imijikelezo yokukhiqiza, futhi kunciphise izindleko zokukhiqiza jikelele. Okulandelayo yingxoxo ngemigomo ye Ukufakwa kwe-CNC ukudala ubuchwepheshe.

1 Izici ze-CNC machining technology

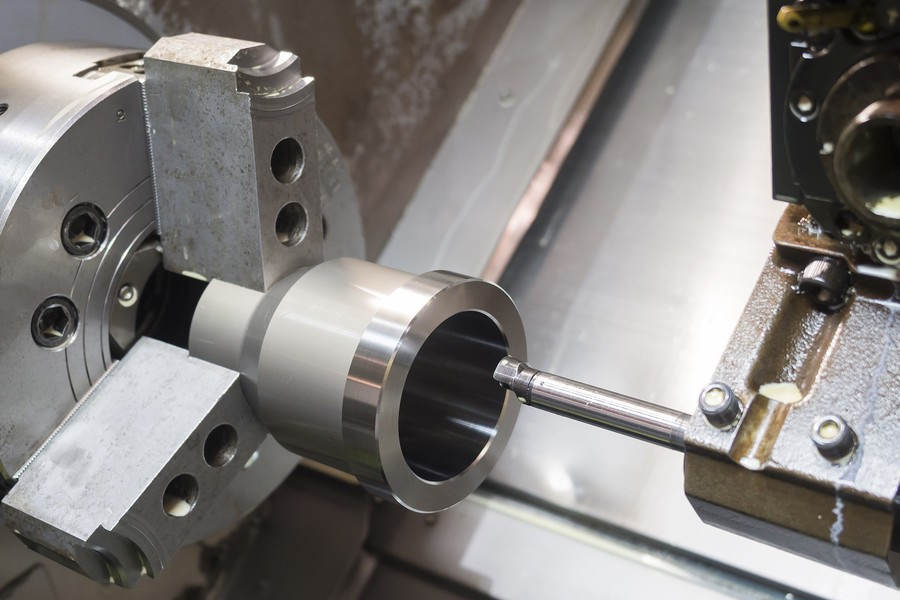

I-CNC machining technology inezici ezilandelayo: ukunemba okuphezulu kwemishini. Ngokuvamile, ukunemba kwengxenye esetshenzisiwe kungatholakala ngokucubungula kwesikhathi esisodwa kuthuluzi lomshini we-CNC, ngaphandle kwesidingo sokucubungula okunzima nokuhle.

Ukuqinisa isikhathi esisodwa komsebenzi kungagcwalisa ukucubungula izingxenye eziningi namaphrofayli, futhi kuqede konke ukucutshungulwa kokuqukethwe, ikakhulukazi amathuluzi womshini we-CNC anezinhloko zamandla amaningi kanye nama-axes angaphezu kwamane.

Ngoba amathuluzi adingekayo ekusetshenzisweni ngakunye kokufakwa ngaphambili afakwa kumagazini wethuluzi, ngakho-ke, ukumiswa kwamathuluzi, ukufakwa nokusetshenziswa akudingeki kuphazamise inqubo yokuchofoza lapho kusetshenzwa into yokusebenza kuthuluzi lomshini we-CNC, ukuze inqubo yokuchofoza iqhubeke .

Ngoba inqubo yokwenza imishini ichazwa ngezinqubo ezijwayelekile lapho kusetshenzwa ubucwebe kumathuluzi womshini we-CNC, ukubambeka kwezinto zokusebenza, imishini nokusetshenziswa kwamathuluzi, kanye nokuzimisela kwemizila yokucubungula kwehlukile kunalokho kwamathuluzi wemishini ejwayelekile.

Ngenxa yokuhlungwa okuhlobene kwezinqubo zenqubo ye-CNC machining, okuqukethwe kwenqubo (okufana nethuluzi lendlela, indlela yokusika, imingcele yokusika, ukulandelana kokusebenza, ukumiswa kwamathuluzi nokulandelana kokusebenzisa, njll. ukwakheka okuningiliziwe, futhi Uma sekusunguliwe, akunakuguqulwa kalula.

2 Imithetho Yesinqumo ye-CNC Machining Process

Ukwakhiwa kobuchwepheshe be-CNC kulungisa imininingwane edingekayo yenqubo yokwenziwa kwezinhlelo ze-CNC machining, futhi inqubo yenqubo yenqubo ye-CNC iyisimiso nendlela yokwenziwa kwenqubo ye-CNC, futhi kuyisisekelo sohlelo lweCAPP oluchaza inqubo ye-CNC machining. Ngenxa yezici zobuchwepheshe bokucutshungulwa kokulawulwa kwamanani okushiwo ngenhla, kunqunywa ukuthi ohlelweni lwe-CAPP olukhiqizayo, isinqumo senqubo yokulawula izinombolo sihlukile kunqubo yenqubo yokucubungula yethuluzi lomshini elijwayelekile. Umthetho wesinqumo wobuchwepheshe bokulawulwa kokulawulwa kwamanani kuhlelo lokukhiqiza lweCAPP ungafingqwa kanjena: Amathuluzi womshini we-CNC angasetshenziswa kanye lapho uqedela ukwenziwa kwephrofayili yokuchofoza nokuma endaweni yokusebenza enezidingo zokunemba. Ngakho-ke, ukusungulwa kochungechunge lwendlela yokuchofoza ehlobene nephrofayili yomsebenzi nendawo kuhlukile kunalokho kwamathuluzi wemishini ejwayelekile. Thatha ukugaya njengesibonelo. Isibonelo, ngesici esithile, iphrofayili nokuma kwendlela yokucubungula isikhundla kufanele kuhlukaniswe kube ukususwa kwe-margin semi-finish milling * ukugaya okuhle kwinqubo yokwenza izinqumo okujwayelekile, ngenkathi kwenziwa izinqubo zenqubo ye-CNC, kuyalinganiswa ngokubanzi njengoba CNC Milling. Ukuthi nje ekwakhiweni kohlelo lwe-CNC, ithuluzi lihlukaniswe ngamaphasi amaningi noma lathathelwa indawo ngamathuluzi ahlukile futhi lisika inani elifanayo.

Uma ithuluzi lomshini we-CNC linamakhanda amaningi wamandla noma ama-axes wokuxhumanisa angaphezu kwamasentimitha angu-0, umsebenzi ungabophezelwa kanye ukuqedela imisebenzi yokucubungula engaqedwa ngamathuluzi wemishini ejwayelekile yokuqinisa okuningi. Ngakho-ke, enqubweni yokulawula izinombolo yokwenza izinqumo, okuqukethwe kwenqubo kunganqunywa ngokuya ngemisebenzi yokucubungula engaphothulwa ekubambeni okukodwa.

Njengoba ukumiswa, ukufakwa kanye nokusetshenziswa kwamathuluzi e-CNC machining kwehlukile kunalawo amathuluzi wemishini ejwayelekile, inqubo yokwenza izinqumo kufanele ilandele ukumiswa kwamathuluzi, ukusetshenziswa kokulandelana kanye nezimo zokushintsha amathuluzi ngesikhathi senqubo yenqubo. Akunakuhlanganiswa kufane kumathuluzi wemishini ejwayelekile. Okuqukethwe kwezinyathelo zenqubo kungahlanganiswa kwenziwe isinyathelo senqubo efanayo kuthuluzi lomshini we-CNC.

Ukulandelana kwezinqubo zenqubo yokwenza izinqumo zamathuluzi womshini we-CNC kufanele kuvumelane nezimpawu zekhompiyutha yethuluzi lomshini we-CNC kanye nezimpawu zokulungiswa kwethuluzi, ukuguqulwa kwethuluzi nokuhleleka kokusetshenziswa. Lokhu kuyiqiniso ikakhulukazi kumathuluzi omshini we-CNC anezinhloko zamandla amaningi kanye nezimbazo ezingaphezu kwezine.

Okuqukethwe kwenqubo yokulawulwa kwamanani kudinga ukuchazwa ngokuningiliziwe. Isinqumo senqubo kufanele silandele imithetho eningiliziwe yenqubo nokuqukethwe kwesinyathelo, okungukuthi, ukukhethwa okuzenzakalelayo nokufaniswa kwamathuluzi omshini, amathuluzi, imingcele yokusika, kanye nomzila wethuluzi esinqumweni senqubo, ukuze inqubo ngemuva kwesinqumo Okuqukethwe mfushane futhi inemininingwane.

Kungabonakala kulokhu okungenhla ukuthi umehluko phakathi kwemithetho yesinqumo yenqubo yemishini ye-CNC kanye nenqubo yesinqumo yenqubo yamathuluzi wemishini ejwayelekile ibonakala kakhulu ku: a) Imithetho yesinqumo yokwehlukaniswa kwezigaba zokucubungula yehlukile; imithetho yezinqumo yenqubo nenqubo yezinyathelo yehlukile emithethweni yezinqumo eyabelwe amandla;) inqubo nenqubo yokucubungula Imithetho yesinqumo yokuhlanganisa nokuhlunga yehlukile; d) Izidingo eziningiliziwe nezifushane zezinqubo nezinyathelo zehlukile; imithetho yesinqumo yamathuluzi okusika, imingcele yokusika, nemizila yokusika yehlukile.

3 Imodeli yokudala inqubo yenqubo

Ukusungulwa kwemodeli yokudala inqubo ye-CNC (2) kufaka phakathi: ukudala isamukeli somsebenzi esingachaza ngokuphelele futhi sigcine izici zento esetshenzisiwe, futhi sivumele uhlelo lwazi isimo esihlosiwe sengxenye yomkhiqizo (njengezinto ezibonakalayo, i-geometry) Ubukhulu , ukuma nokubekezelelana kwesimo, isikhundla esihambisanayo nezidingo zokunemba, njll.).

Yakha isisekelo solwazi sezingxenye zendlela yokuhlukanisa nokuqonda izingxenye ezahlukahlukene ezizocutshungulwa.

Dala inqubo yolwazi yenqubo yezingqinamba ezidinga ukuhlangatshezwa lapho kuklanywa izingxenye zokucubungula ubuchwepheshe.

Dizayina isihleli esitholayo esingaqhubeka ngokuthola futhi sibuyekeze okuqukethwe kusisekelo solwazi sezingxenye nesisekelo solwazi lwenqubo.

Indlela yezinombolo yokulawula imishini ngokuya ngephrofayili yesici sale ngxenye isetshenziselwa ukusungula imishini yokulawula izinombolo eyindala ye-CNC-ME. Okwakudala kuyinhlangano yesici semininingwane yokulawulwa kwemishini yokulawulwa kwezinombolo enengxenye yengxenye njengomongo. Kungumyalo oyisisekelo wenqubo ye-CNC machining futhi kwenziwa ngenqubo ye-CNC machining Kwakhiwa ngokufanisa ubudlelwane obuhambisanayo phakathi kwendlela ye-CNC machining, inqubo yemingcele kanye nezici eziyingxenye emithethweni. Lapho ingxenye inqunywa, sebenzisa isici ngasinye sesici (njengokuma, ukucacisa, okokusebenza, njll.) Kwengxenye njengegama elingukhiye ukusesha isisekelo solwazi oluhambisanayo ukuthola uhlelo lobuchwepheshe bokucubungula.

4 CNC inqubo yokwenza imishini inqubo yokudala

Inqubo yokudala inqubo ye-CNC (efana no-4, 5, 6) ihlukaniswe ngezigaba ezintathu: "phambili ngokuqondakalayo", "ukubuyisela emuva kugxilwe", kanye "nokwenza inqubo yomzila".

Inqubo ehlukile eya phambili yisigaba sokubola ingxenye ibe yinto ngayinye yesici. Ngokuthwebula imininingwane yolwazi lwesici sengxenye, ukwahlulela uhlobo lwesici, ukufunda imingcele yesici, nokufanisa nokwenza ngcono indlela yokusebenzisa i-NC yesici ngasinye kumthetho wenqubo ye-NC, ngakunye kunqunywa. Isici sokuchazwa kwamanani wokulawulwa kwamanani (i-CNC-ME) ukubuyisela emuva ukuhlushwa yizinyathelo zenqubo kanye nezinqubo ezakhiwe ukuhlanganiswa kwezinhlobonhlobo zokulawulwa kokulawulwa kwamanani okuyi-CNC-ME ngokuya ngezimpawu zokucutshungulwa kwedatha kuze kube yilapho kwenziwa inqubo yokucubungula izinombolo. Ngemuva kokunqunywa kwendlela yokulawulwa kwamanani yesici ngasinye, ngokuya ngokusebenza okucacile, indlela yokubambelela, ukulandelana kokulandelana, nemingcele yemidwebo yommese yethuluzi lomshini wokulawula amanani

Xhumanisa nale ndatshana: Inqubo Yokucwaninga Ngokudalwa Kokuhlelwa Kwemishini ye-NC Machining

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi