Isistimu Yokulawula Isoftware Yezingxenye Ezi-Circular ze-CNC eziguqula

Isistimu Yokulawula Isoftware Yezingxenye Ezi-Circular ze-CNC eziguqula

|

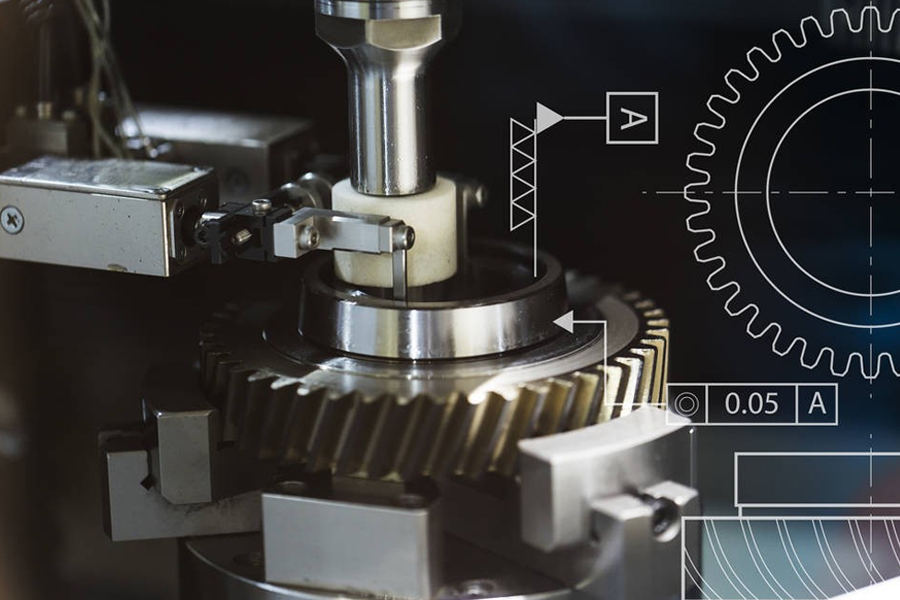

IPiston yingxenye ebalulekile yenjini yomlilo yangaphakathi futhi iyingxenye ejwayelekile engeyona eyindilinga. Izinga lokubambisana phakathi kwepiston ne-cylinder yisimo esibalulekile sokukala ikhwalithi yenjini. Kulezi zinsuku, i-convex ejwayelekile ye-ellipse piston icutshungulwa ngabakhiqizi abaningi besebenzisa indlela yokuphrinta. Kodwa-ke, njengoba uhlelo olunzima lokuphrinta ludinga ukusebenzisa ingcindezi yemishini noma ye-hydraulic ukufeza ukulandelela okulandelwayo, kunzima ukuqhubeka nokwenza ngcono ukusebenza kahle kwephrofayili, futhi ukuphrinta Ukwenziwa kwemishini kunzima futhi izindleko zokukhiqiza ziyabiza. Ngakho-ke, kuyadingeka ukuklama uhlobo olusha lwensimbi ye-CNC ukuhlangabezana nemishini ekhethekile ye-convex ne-piston eyindilinga eguquguqukayo. |

IPiston yingxenye ebalulekile yenjini yomlilo yangaphakathi futhi iyingxenye ejwayelekile engeyona eyindilinga. Izinga lokubambisana phakathi kwepiston ne-cylinder yisimo esibalulekile sokukala ikhwalithi yenjini. Kulezi zinsuku, i-convex ejwayelekile ye-ellipse piston icutshungulwa ngabakhiqizi abaningi besebenzisa indlela yokuphrinta. Kodwa-ke, njengoba uhlelo olunzima lokuphrinta ludinga ukusebenzisa ingcindezi yemishini noma ye-hydraulic ukufeza ukulandelela okulandelwayo, kunzima ukuqhubeka nokwenza ngcono ukusebenza kahle kwephrofayili, futhi ukuphrinta Ukwenziwa kwemishini kunzima futhi izindleko zokukhiqiza ziyabiza. Ngakho-ke, kuyadingeka ukuklama uhlobo olusha lwensimbi ye-CNC ukuhlangabezana nemishini ekhethekile ye-convex ne-piston eyindilinga eguquguqukayo.

Ukuthuthukiswa kobuchwepheshe bezimoto ezihambisanayo nezimpawu zokuphendula imvamisa kwenza lokhu kudingeka kwenzeke. Ngesikhathi sokucubungula, izingxenye ezicutshungulwayo zifakwa kuthebhuleni yethuluzi lomshini bese zijikeleza ngesipikili, futhi ithuluzi lifakwa ku-motor eqondile, futhi i-motor eqondile ilinganiselwa Izingxenye ezenziwe ngomshini ziphindaphinda kabusha. Ngenxa yesimo esiyinkimbinkimbi ngokwedlulele sesikhungo esiyindilinga esiyindilinga esiguquguqukayo, inani lemininingwane edinga ukucutshungulwa phakathi kokufakwa lukhulu, futhi ijubane lokuphendula nalo lifuna kakhulu.

Ngaphezu kwalokho, lapho kucutshungulwa i-piston, izinhlobo ezimbili zama-motors zidinga ukulawulwa ngasikhathi sinye, enye i-servo yesikhundla, kanti enye iyimoto ekhethekile yomugqa we-servo yokucubungula izingxenye ezingezona eziyindilinga. Isoftware ejwayelekile ye-CNC ayikwazi ukuhlangabezana nale mfuneko ekhethekile yama-machining piston. Uhlelo lwesoftware olwethulwe kule ndatshana lwamukela uhlelo lwe-C nolimi lomhlangano oluxubekile, futhi lwamukela ukwakheka okuzimele okuzimele, okuxazulula kangcono ubudlelwano phakathi kokujikeleza kwe-spindle nethuluzi lokudla okuphakelayo.

1 Ukwakheka okuphelele kohlelo

Umphathi walesi simiso usebenzisa ukulawula kwezimboni okungu-586, futhi isoftware yohlelo igcinwa kwi-hard disk ye-microcomputer. Ngemuva kokuthi uhlelo luqalisiwe, umsebenzisi angenza imisebenzi ehlukahlukene ngemenyu. Uhlelo lunemisebenzi ye-CNC efana nokufunda uhlelo lokucubungula, ukuhlanganisa, ukulingisa, ukudala idatha yokucubungula i-piston, ukulawula imoto eqondile, ukuhlanganiswa, i-M, S, T ukuthola isikhundla, njll.

Isoftware yesistimu isebenzisa ukwakheka okulandelanayo nokuhlelekile. Isoftware yohlelo ingahlukaniswa ngamamojula amaningi ngokuya ngemisebenzi, futhi imodyuli ngayinye ingahlelwa futhi ihlanganiswe ngokuhlukile. Imininingwane idluliswa phakathi kwabo ngamapharamitha noma amafayela wedatha, futhi ukungezwa, ukuguqulwa, nokususwa kwemojuli akuthinti amanye amamojula. Isoftware yohlelo ihlukaniswe ungqimba lwesixhumi esibonakalayo, ungqimba lokuhlanganiswa, ungqimba lokulawula nolwelwesi olusizayo, futhi ukusebenza kwengxenye ngayinye kuzimele ngokwedlulele.

2 Ukwakheka kwesistimu nezimpawu

Kungabonakala ukuthi uhlelo luqukethe amamojula ayisithupha, asetshenziswa kakhulu ekwenzeni imishini. Kodwa-ke, intengo imvamisa iphindwe ka-5 kuye kwengu-10 leyo yama-lathes ajwayelekile. Uma ukushayisana kwenzeka ngesikhathi sokucubungula, okokukhanyisa kuzolimaza ukunemba komkhiqizo futhi kudale udoti. Esimweni esinzima, ithuluzi lomshini lizolimala, lidale ukulahleka okukhulu kwezomnotho kanye nokulimala komuntu.

Ngemuva kokubuka kanye nokuhlaziya, umbhali wafingqa amathuba amaningi wokushayisana ngezihlakala ze-CNC, nezindlela eziphakanyisiwe zokugwema ukushayisana lapho uhlela izihibe ze-CNC.

1 Uma usebenzisa umyalo we-G00, ukushayisana kungenzeka kakhulu. Njengoba kukhonjisiwe, into yokusebenza idinga ukudilizwa, umsuka wensimbi yokusebenza ungakwesokudla, futhi iphuzu lokushintsha ithuluzi kulapho ukuqedwa kwe-groove kuqediwe, ukonga isikhathi, ngifuna ithiphu yethuluzi lisuke ekuqaleni iphuzu fl. Lapho ufinyelela iphuzu lokushintsha ithuluzi> 1, sebenzisa ingxenye yohlelo ye-N150G00X80Z50 ukuqedela ukuhoxiswa kwethuluzi. Uma indlela ibhekwa njengomugqa oqondile, kubonakala ngathi akunankinga, kepha indlela yangempela yetiphu ngu-B nolayini (njengokusebenza kosizo lwesikhathi. Kulesi simiso, umsebenzisi angaqala, ngokuya ngezidingo ezithile komdwebo wengxenye, ukufakwa kwedatha ehlukahlukene nokusebenza komsebenzi ngamunye kwenziwa kusendlalelo esibonakalayo ngendlela yenkulumompikiswano yomshini womuntu. Kusendlalelo sokuhlanganiswa, okokufaka kolwazi okwenziwe ngumsebenzisi kuyahlanganiswa ukukhiqiza ikhodi eqondisiwe , okubandakanya ukuguqulwa kwefomethi yohlelo lomthombo we-NC, ukuguqula ukuxhumanisa, ukutholwa kwephutha, ukulawula ukubalwa kwedatha kanye nokufakwa ohlwini kwejika, ukuhlangana okungahambi kahle, njll.; kusendlalelo sokulawula, uhlelo lokulawula lunikezwa imiyalo yokuxhumanisa imisebenzi yengxenye ngayinye yohlelo ; kusendlalelo esisizayo, Inikeza imisebenzi ehlukahlukene yokusiza evumelana nomsebenzi wesistimu nokusebenza komsebenzisi. Uhlelo lonke lilawulwa ikhibhodi negundane. Ukukhetha imenyu, abasebenzisi badinga kuphela ukucindezela i-cu i-rsor, i-hotkey noma igundane. Ngaphezu kwalokho, uhlelo futhi lunemisebenzi enamandla kakhulu yehluzo enikeza ukubonisa okucacile kwedatha yokufaka ye-piston, umsebenzi wokulingisa onamandla wendlela yokuhamba kwamathuluzi, futhi ifomu enembile likhombisa idatha yokufaka nomdwebo wethuluzi la). Ngokusobala, ithuluzi kumele libe uma ngabe indawo yesinyathelo yomsebenzi ishayisana, okokusebenza nethuluzi kuzolimala, nokunemba kwethuluzi lomshini kuzolimala.

Umehluko phakathi komyalo wokumiswa kwephoyinti G00 nomyalo wokuhumusha oqondile G01 akusona isivinini kuphela, kodwa into ebaluleke kakhulu ukuthi umugqa wangaphambili awulona umugqa oqondile, kanti owokugcina kufanele afinyelele ekugcineni ekugcineni umugqa. Uma kuyiphutha ukuthi i-G00 kufanele ifike ekugcineni ngendawo eqondile, kuyingozi kakhulu. Ukuhamba kwethiphu yethuluzi okusuka endaweni yoqobo kuye endaweni yamaphoyinti okuyalwe kubhulokhi le-G00 imvamisa kuyizingxenye ezimbili zomugqa oqondile ezinama-engeli ahlukile, okungukuthi, idinga ukujika kanye ngenkathi ihambela, futhi izinkomba ze-X ne-Z kokuthunyelwe kwamathuluzi zombili kusethwe ngokuya ngezilungiselelo zazo. Ukuhamba ngejubane, ngakunye kuze kuphele iZengtong kuleyo ndlela.

Ukwenza i-retract, indlela yokuhamba yethuluzi iyakhonjiswa ku-Figure lb, ukuze ukushayisana kungagwemeka.

I-track egijimayo inika amandla abasebenzisi ukuthola amaphutha wokusebenza ngesikhathi.

3 Isifingqo

Uhlelo lusebenzisa indlela yokwakha ephezulu phezulu, isikhombimsebenzisi esibonakalayo, umsebenzi wosizo wesikhathi sangempela, umsebenzi wokufanisa imidwebo, umsebenzi we-alamu, njll. . Ukusebenza kahle kwethuluzi lomshini kunciphisa izindleko zokukhiqiza. Uhlelo luhlolwe ngempumelelo emafemini amathuluzi wemishini eminingana.

Xhumanisa nale ndatshana: Isistimu Yokulawula Isoftware Yezingxenye Ezi-Circular ze-CNC eziguqula

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi