Inqubo ye-Cnc Machining ye-Spiral Bushing

Inqubo ye-Cnc Machining ye-Spiral Bushing

|

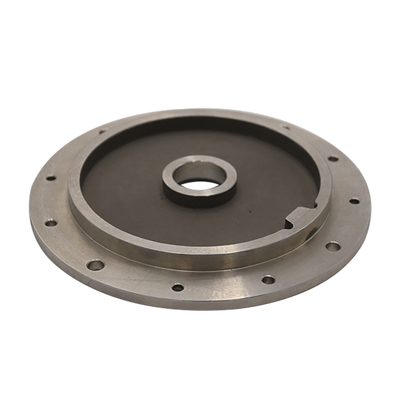

The Ukufakwa kwe-CNC wemishini kanye ne-anticorrosive spiral ibhasis isetshenziselwa ukwenziwa kwasendaweni kwezingxenye zemishini engenisiwe, futhi kuhlongozwa umbono omusha ohluke ngokuphelele kumishini yendabuko, ongahlinzekela Ukufakwa kwe-CNC kanye nomklamo wohlelo lwe-CNC wezingxenye eziyinkimbinkimbi. Isikulufu sokusheshisa esinesiphelo esikabili umphini Umkhono uyingxenye ebalulekile yenduku ye-extruder ye-pelletizer efektri yepulasitiki. Ingxenye yokuqala ingeniswa ivela phesheya. Ukuze kuhlangatshezwane nezidingo zokwenziwa kwasendaweni kwemishini engenisiwe, ifekthri yemishini yahlola futhi yadweba le ngxenye. Umumo othize we-spiral bushing umelelwa imigqa emibili ezungeza endaweni eyi-cylindrical, iphimbo lakhona elishintsha ngokusheshisa okulinganayo nebanga eliphakathi komugqa ozungezayo kanye nesiphetho esingakwesokudla, futhi umugqa ngamunye ozungezayo wakhiwe izingxenye ezinhlanu ezishintshayo. ngesimo. Lolu hlobo lwendawo egobile eyi-spiral inomumo oyinkimbinkimbi ngokukhethekile kanye nezidingo zokunemba eziphakeme kakhulu. Indawo egobile enjalo kunzima ukuyiqeda ngezindlela ezijwayelekile zokuwenza. |

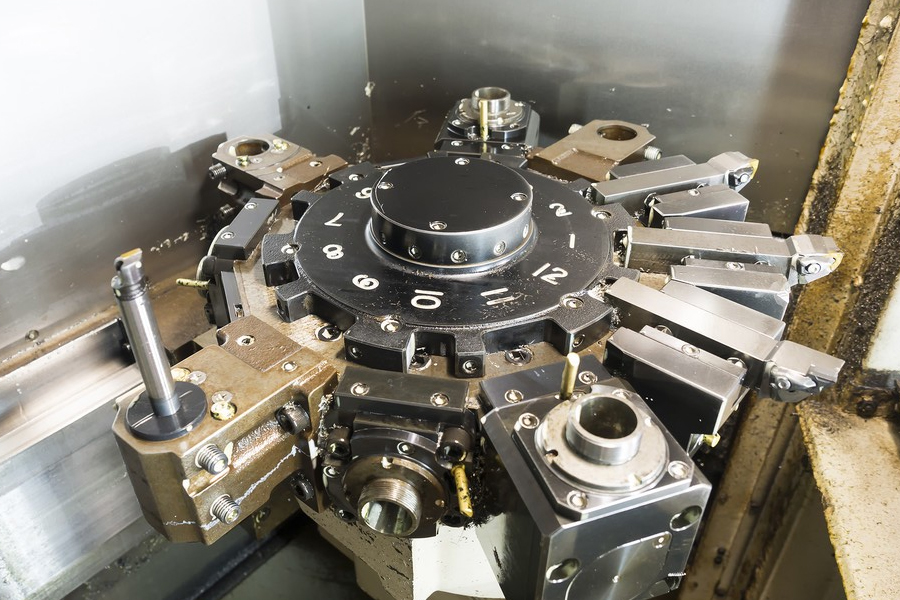

Amathuluzi omshini we-CNC amathuluzi esimanjemanje ahlanganisa ubuchwepheshe obuningi obuthuthukile futhi angabona ukwenziwa kwe-CNC kwezindawo ezigobile eziyinkimbinkimbi. Ngokukhipha, ukusesha kwekhompuyutha okunohlangothi olulodwa lwezibalo zezibalo kunquma indawo yokuguquguquka, kuhlukanise indawo eqhubekayo eyinkimbinkimbi ibe amaphuzu amaningana okulawula ukuma kwamathuluzi, futhi kufane nakakhulu ijika eliqhubekayo ukuze kuzuzwe ukulawula okuqhubekayo. Ngokusekelwe kumodeli onjalo wezibalo, kwahlanganiswa uhlelo lwe-NC, futhi i-spiral axis efanelekayo yagaywa kusetshenziswa umsebenzi wokuxhumanisa wama-axis amane wethuluzi lomshini wesikhungo somshini.

Imodeli yezibalo ye-spiral bushing kanye nokuhlaziywa kwezinombolo okuhlobene. I-spiral bushing yasekuqaleni ithengwa kwamanye amazwe. Inqubo yokuklama ayaziwa. Uma ukuma kwe-spiral kanye nokuma kwendawo egobile kushintsha ngesikhathi sokukhiqiza, izakhiwo zemishini yepulasitiki zizoshintsha ngesikhathi sokukhipha. Ngakho-ke, landela ngokuqinile Usayizi wokuhlola nokubhala imephu kungacutshungulwa ukuze kuhlangatshezwane nezidingo zokuqala zokuklama nokusetshenziswa.

11. Imodeli yezibalo Ngokwemiphumela yokuhlola kanye nemephu yegumbi lokuklama lefektri yemishini, umugqa ovunguzayo uhambisana nesikwele X: ibanga phakathi kwesikhungo somugqa ovunguzayo kanye nendawo yokugcina kwesokudla yengxenye, mm; Njengoba kukhonjisiwe, endaweni ye-inflection u-a ukuya ku-b, ububanzi obuzungezayo bushintsha ukusuka ku-22mm ukuya ku-34mm; endaweni ye-inflection c kuya ku-d, ububanzi be-spiral buyashintsha ukusuka ku-34mm ukuya ku-45mm. Umgomo wethu ukukhipha insimbi phakathi kwama-spiral amabili futhi sigcine ukuzungeza Sicabanga ukuthi ububanzi bokuzungeza bunguziro futhi ububanzi bethuluzi bunguziro, okuhambisanayo noma yimuphi u-A unalo: Okubonisiwe kungenye ye-spirals: 1, 5 indlela yesikhungo samathuluzi; unqenqema lwe-spiral lapho i-arc engu-R30 ikhona; iyisikhungo se-spiral; 4 unqenqema lwe-spiral lapho i-R 16 arc ikhona.

12 Ukunqunywa kwenani lesinxephezelo samathuluzi kucabangela ububanzi obuzungezayo kanye nerediyasi yethuluzi. Noma yiliphi iphuzu endleleni yamathuluzi lithi: centre=/+Ax, okungukuthi, kukhona ukuxhumana phakathi kwephuzu elisendleleni yamathuluzi kanye nephuzu eliphakathi nendawo yokuzungeza. Inqobo nje uma iphuzu eliphakathi nendawo yokuvunguza liwumsuka wemephu, futhi inani lesinxephezelo lengezwa kumanani ayo adidiyelwe X, Y, Z, izixhumanisi zephuzu elihambisanayo endleleni yamathuluzi zingatholakala. Ukusebenzisa u-A njengokuguquguquka ukubala i-trajectory ephakathi yesisiki sokugaya, kukhona: R: i-radius yomsiki webhola; H: ububanzi bezinyo; M: umkhawulo; umthambeka wephuzu I, I=(A), inani elithi I lilingana nephuzu elilodwa ku-Order derivative derivative; R, irediyasi yomsebenzi.

13 Ukuze kuhlaziywe izinombolo, umsuka wemephu wephuzu u-a. Ngokwemodeli yezibalo esiyisungulile, a kanye no-a banobudlelwano obulandelayo obuhambisanayo. Ngemva kuka-a, yenza ama-tangents A no-B. Umthambeka we-tangent ngu-1 = I ngiyijika kuleli phuzu. Okuphuma kuqala kokuthi, isikhungo se-milling cutter sitholakala endaweni engu-a2, a2a, AB.

Imajini, M=0; K: ukwehla kwaleli phuzu.

Sebenzisa uhlelo lwe-QuickBASIC ukuze unqume isikhawu sosesho, khetha usayizi wesinyathelo esifanele, bese wenze usesho lwe-dimensional eyodwa izikhathi eziningi. Iphuzu elihambisana nezibalo zokulinganisa indawo egobile engu-1.4 lingatholakala. Njengoba singekho i-milling cutter engu-R30, i-arc surface ka-R30 idinga ukugaywa nge-radius encane. Ummese ufakiwe, futhi ummese webhola ukunoma iyiphi indawo. M=R―R(R―r)cos9AZ, =―Rsin0+1.5―Indawo yokusebenza ye-arc radius, R=Z-isinxephezelo sesiqondiso; M―surplus.

2 Uhlelo lokulawula izinombolo kanye nomphumela wokucubungula

Ngokusho kokuhlaziywa okungenhla nokubala, uhlelo lokucubungula izinombolo luhlanganiswa ngendlela yepharamitha. Uhlelo luhlanganisa izingxenye ezi-3:

- (1) Uhlelo lokucubungula lwendawo egobile lapho i-arc engu-R30 ikhona;

- (2) Uhlelo lokucubungula lwendawo egobile lapho i-arc engu-R16 ikhona;

- (3) Uhlelo lokucubungula lokugaywa ingxenye emaphakathi yama-spiral amabili. Ukuze kube lula kubasebenzi abafanelekile, yizinqubo zokucubungula kuphela zendawo egobile lapho i-R 16 arc itholakala khona ezisohlwini: Sisebenzisa amasethi amathathu angenhla ezinqubo ze-NC ekusebenzeni, futhi inani le-84cl70S560e9Ar liphinde lisetshenziswe ukufaka esikhundleni semishini. ngomkhono ovunguzayo kanye neyunithi yokuqhekeka kwe-anti-corrosion. Inhloso yokuhlaziya imbangela yokugqwala kwegobolondo lokushintsha ukushisa iqinisekisa ukusebenza okuvamile kwemishini yokukhiqiza futhi inikeza ulwazi lokusingatha izingozi zemishini ngaphansi kwezimo ezifanayo zokusebenza.

Embonini ye-petrochemical, ukushisa kwemfucuza kawoyela ngamunye we-distillate embhoshongweni wokulungisa kuvame ukusetshenziselwa ukushisisa izinto ezingavuthiwe zezimboni ezidinga ukushiselwa ukuze kufezwe inhloso yokonga amandla kanye nokunciphisa ukusetshenziswa. Isishintshi sokushisa se-H204 seyunithi yokuqhekeka eyi-catalytic ye-Qingdao Petrochemical Plant sisebenzisa udaka lukawoyela ngaphansi kombhoshongo wokuhlukanisa ukushisa amanzi athambekele ukuze kufezwe injongo yokukhiqiza isitimu. Kusukela kwaqala ukusetshenziswa umshini wokushisisa ngo-1992, ukuvuza kwamagobolondo kwenzeka kabili kusukela ngo-1996 kuya ku-1997. Isikhathi phakathi kwalokhu kusetshenziswa okubili okungaphansi kwesigamu sonyaka kwaba nomthelela omkhulu ekusebenzeni okuvamile kokukhiqiza futhi kwenyusa izindleko zokukhiqiza. Ukuze kuxazululwe le nkinga ngokuyisisekelo, kuyadingeka ukuhlola izimbangela zokugqwala kwayo ukuze kunikezwe umuthi ofanele wokuxazulula le nkinga.

Uphenyo lwasendaweni lokuvuza kwegobolondo lesishintshi sokushisa luseduze ne-flange yebhokisi lepayipi kanye nomthungo wokushisela wegobolondo. Umgodi wokugqwala omncane wabonwa ngemuva kokupholisha endaweni, omise okwe-strip eduze komthungo wokushisela, nendawo engaba ngu-2cm2. Kukhona ezinye ezi-4 I-crack i-perpendicular weld ye-circumferential, enobubanzi obungaba ngu-0.2cm kanye nobude obungaba ngu-40 ~ 60cm. Ezintathu zazo zingena endaweni yokushisela futhi zigqekeze igobolondo.

Ngesikhathi esifanayo, sakhipha izingcezu ezimbili zenhlabathi egobolondweni le-heater ka-November 30, 1996, futhi inzika yayiqinile futhi ishwabene. Ucezu olulodwa ngokuyisisekelo alumhlophe-olumhlophe ngempahla emnyama phezulu, ugqinsi olungaba ngu-15mm. Olunye ucezu luhlukaniswe izingqimba ezimbili, ungqimba olungezansi lubomvu-nsundu, ugqinsi olungaba ngu-20mm, kanti ungqimba olungaphezulu lumpunga-mhlophe futhi lunezimbotshana, ugqinsi olungaba ngu-10mm, futhi kukhona izinto ezimnyama phezulu. Ngemuva kokuhlolwa, lezi zinsalela zombili zikhipha igesi ku-asidi. Zombili izinsalela ziyancibilika emanzini. Ngemva kokuncibilika, phansi kuba yinhlabathi enodaka ethambile, futhi ingxenye engaphezulu iwungqimba lwamafutha amnyama. Ukuhlaziywa kwe-X-ray diffraction kwezinsalela ezimbili kwembula ukuthi iningi lenhlabathi kwakuyi-chloride, i-hydroalkali ne-ferrite. Idatha yokuhlaziya ikhonjiswe kuThebula 1. Ikolishi Lobunjiniyela, futhi manje iHhovisi Leselula le-Qingdao Petrochemical Plant lisebenza ekuphathweni kwemishini. Ucingo: Lokhu kukhombisa ukuthi ukwakheka kohlelo kuba yimpumelelo kakhulu. Ngesikhathi esifanayo, umklamo wohlelo >ublishingHouse.Allrightsreserved. Inkinga enzima okunzima ukuyifinyelela ngezindlela ezijwayelekile zomshini. Indawo evunguzayo ecutshungulwa izindlela zemishini ye-CNC inokunemba okuphezulu, ukungaguquguquki okuhle kanye nendawo kuphela Ingafakwa futhi ipholishwe ngendlela efanele nge-fitter.

Isiphetho se-3

Umkhono ovunguzayo oyinkimbinkimbi kangaka uyingxenye yokuqala emishinini ethengwa kwamanye amazwe, futhi ayivamile ekucutshungulweni kwangempela. Ukungenisa uchungechunge olulodwa kudinga imali eningi yangaphandle futhi kudinga ukubhukhwa kusenesikhathi. Amathuluzi omshini wesikhungo somshini we-MITSUBISHI kwakuyimishini esanda kuthunyelwa evela emazweni angaphandle yifektri yethu ngaleso sikhathi, futhi kwakunzima kakhulu ukubona ukwenziwa kwasendaweni kwezihlahla ezivunguzayo. I-CNC machining ye-4 spiral bushings iqediwe ngokusebenzisa lolu hlelo, futhi isimo sokusebenzisa sihle. Indlela yokusungula imodeli yezibalo, indlela yokubala yangempela yokuxhumana phakathi kwethuluzi nesiqeshana sokusebenza, indlela yokulungiswa kwe-omni-directional yethuluzi ngokuhlobene nomsebenzi, kanye nendlela yokulinganisa indawo, inganikeza ireferensi yesikhathi esizayo. idizayini yohlelo lomumo oyinkimbinkimbi.

Xhumanisa nale ndatshana: Inqubo ye-Cnc Machining ye-Spiral Bushing

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. I-3, i-4 ne-5-axis ngokunemba okusheshayo kwezinsizakalo ze-CNC kufaka phakathi ukugaya, ukuphendukela kokucaciswa kwamakhasimende, Izinsimbi ezinamandla zensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi