I CNC Machining ka Fan Inaliti Model Cavity Futhi Core

I CNC Machining ka Fan Inaliti Model Cavity Futhi Core

|

Kungumsebenzi onzima futhi onzima kakhulu wokucubungula umgodi nomgogodla phakathi nokukhiqizwa kwesikhunta sepulasitiki, okubandakanya inqubo ye-CNC ne-EDM. Uhlelo lwe-CNC lwendlela yamathuluzi kuwumsebenzi osemqoka kuyo yonke inqubo yokukhiqiza enquma ikhwalithi ye-CNC nobunzima be-EDM. Leli phepha laxoxa ngokusetshenziswa kwesoftware yeCimatron ekusetshenzisweni komgogodla nomgogodla we-fan injection injection, futhi yahlaziya inqubo machining, Bese igxile ekuchazeni ukugcwaliseka kwemishini yayo emibi futhi emihle. Ekugcineni, ngokusebenzisa ukulingiswa kwendlela yamathuluzi kufakazele ukuthi indlela inengqondo. |

Njengamanje, ukukhishwa kwemigodi yesikhunta sekuyinsimu ebalulekile Ukufakwa kwe-CNC, ikakhulukazi machining of ingaphakathi isikhunta ukwakha izingxenye isondelene kakhulu Ukufakwa kwe-CNC. Esikhathini machining izingxenye ingaphakathi isikhunta ukwakha, kubalulekile ukuba zidlule izinqubo ezintathu: umkhiqizo-ntathu imodeli ukumodeliswa, umkhiqizo eqhekeza futhi electrode eqhekeka okusekelwe umkhiqizo ezintathu-ntathu imodeli, futhi ithuluzi indlela ukulungiselela esekelwe isikhunta cores kanye electrode eyenziwe ukuhlukana. Isoftware engavuleki ye-3D CAD / CAM. Njengamanje, isoftware enkulu ye-CAD / CAM ingayibona imisebenzi emithathu yokumodela, yokuhlukanisa nokuqaqa ama-electrode, nezindlela zokwenza izinhlelo, ezinjengePro / E, UG, MasterCAM, Cimatron, njll. Phakathi kwazo, iPro / E idume kakhulu ngokumodela nokuqhekeka. Okwe-machining, i-MasterCAM ne-Cimatron zithandwa kakhulu. Le ndatshana izothatha isibonelo se-fan mold cavity cavity machining, futhi yethule ezinye izimo zangempela zokusebenzisa i-Cimatron ukucubungula izingxenye zokwakha isikhunta, ukuze kunikezwe izinkomba zesikhunta se-mold kanye ne-core machining.

2 Isingeniso sezinto zokwakha

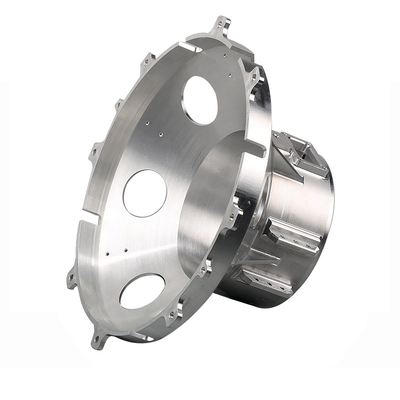

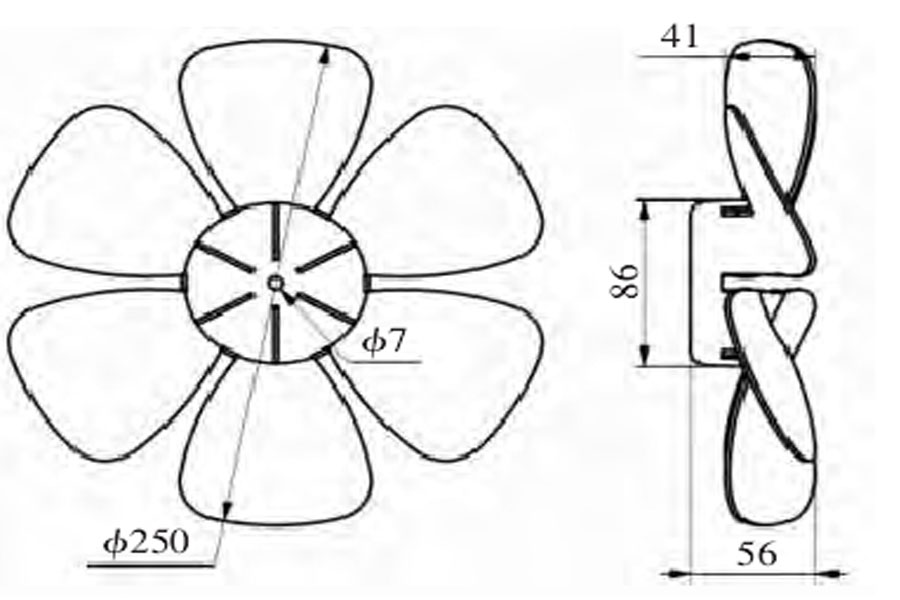

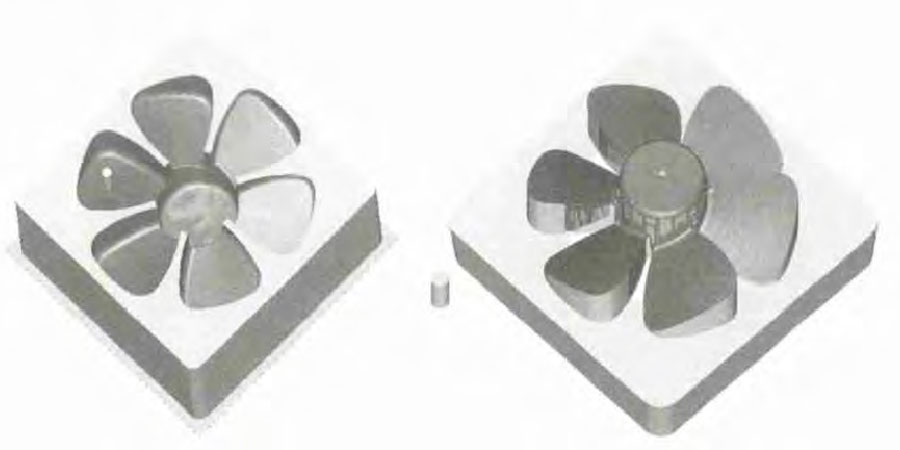

Njengoba kukhonjisiwe kuMdwebo 1, ingxenye yepulasitiki iyinhlangano kagesi ye-ABS blade epulasitiki enobubanzi besayizi ka-250 × 250 × 50mm. Ukumodela kugcwaliswa kakhulu ku-Pro / E ngokuqina ebusweni ukuze kube umzimba oqinile, bese usebenzisa i-Pro / Isikhunta ku-Pro / E Imodyuli iyabona ukuhlukaniswa, nomphumela ohlangothini ntathu womgodi nomgogodla ngemuva kokuhlukaniswa kukhonjisiwe kuMdwebo 2.

Izidingo zobuchwepheshe:

- ABIzinto ezibonakalayo ABS;

- Ubukhulu bodonga lwengxenye yepulasitiki bungu-2mm;

- Ingxenye yepulasitiki akumele ibe nezimbobo, imifantu nokunye ukukhubazeka;

- Ubuso bengxenye yepulasitiki akumele ibe nama-burrs (i-flash);

- Usayizi wokuvula ukhonjelwe kumodeli ye-3D.

Ukuze ulwelwesi isikhunta ingxenye plastic, it is ikakhulukazi edingekayo ukuze umshini lwalugobile ebusweni ukuma blade, kanye nokugcina mpo kanye nokunemba kwangaphakathi umgodi ohlangothini odongeni, ukuze kuqinisekiswe ukuxhumana okuseduze phakathi komgogodla , futhi lapho kwakhiwa ingxenye yepulasitiki Ngakho-ke ngeke kube khona ukukhanya. Ngaphezu kwalokho, ukuze kwenziwe lula ukufakwa kodonga olungaphandle lomgodi nomgogodla, umgodi ojiyile uvame ukucutshungulwa umumo wesigaxa, ukuze udonga lohlangothi nendawo engezansi kungabi okungaqondile, kepha ithambeka eliwumqansa engela ethile mpo, mayelana 1 ° ~ 5 °, kudingeka sinake ngesikhathi machining. Okulandelayo inqubo yokuhlaziya ngomshini womgodi.

Le ngxenye eyakha isikhunta idinga ukuthi icutshungulwe izinhlangothi ezimbili, ngaphambili nangemuva. Uhlangothi olungaphambili lugaya ngaphakathi ingaphakathi lesikhala nangaphezulu ekugcineni. Ngokubekwa, udonga lohlangothi olungaphandle kufanele lusolwe ngokunemba. Ngemuva kokuthi uhlangothi lwangaphambili lucutshunguliwe, okokusebenza kuphenduliwe, indawo engezansi iyasongwa, bese kuthi umsele onqenqemeni wodonga lohlangothi olungaphandle ucutshungulwe.

Isikhunta isikhunta ngokuvamile yensimbi pre-lukhuni nge ubulukhuni 38 ~ 45HRC, okuyinto has a ubulukhuni ephakeme. Lapho ukhetha ithuluzi, kufanele ucabangele ukusebenzisa ummese wensimbi we-tungsten noma ummese onengubo ekhethekile.

Maphakathi, kunezingqimba zezimbambo ezibanzi eziyi-6 2mm, ezijule kancane, futhi zingacutshungulwa ngommese omncane wokwephula ummese, ongashiyelwa imishini ye-EDM.

3 Machining ubuchwepheshe ukuhlaziywa

Ukuze kwenziwe imishini yesikhunta sesikhunta, kufanele kukhethwe into efanelekile engenalutho yensimbi engenalutho yokugaya i-CNC, futhi umkhawulo we-0.1 ~ 0.2mm uzobekelwa ukugaya nokugaya ngesandla nge-grinder. Ngezindawo eziwumngcingo nezijulile emgodini, kuyadingeka ukukhetha ukukhishwa kwemishini kagesi nokupholisha mathupha ngemuva kokugaya kwe-CNC. Intambo yomgodi ocutshunguliwe ingathathwa ngesandla ngemuva kokulawulwa kwangaphambi kokulawulwa kwamanani. Ngenxa yokuthi izinhlangothi zangaphambili nezingemuva zomgodi nezinhlangothi ezizungezile ziyizindawo zokumatanisa, umgodi nengqikithi kucutshungulwa kuzindlela zombili zangaphambili nangemuva. Uhlangothi lwangemuva (okungukuthi ezansi) kufanele lucutshungulwe kuqala ukuqedela ukugaya indawo engezansi engezansi nezindonga zohlangothi ezizungezile, ikakhulukazi Isimo sokugcina sangaphansi komgodi siyisicaba, futhi kulula ukubopha ngemuva kokukhanda. Ngemuva kokuqeda ukubuyiswa komhlaba okuphambene nalokho, phendulela umsebenzi wokusebenzela imishini, ukugaya ingxenye eyakhiwe yomgodi, uma udonga lwangaphandle lomgodi lunendawo esalungiswa, kuyadingeka ukuthi ucabangele ukusebenzisa isikhungo semishini noma umshini wokugaya we-CNC nge ithebula le-electromagnetic adsorption.

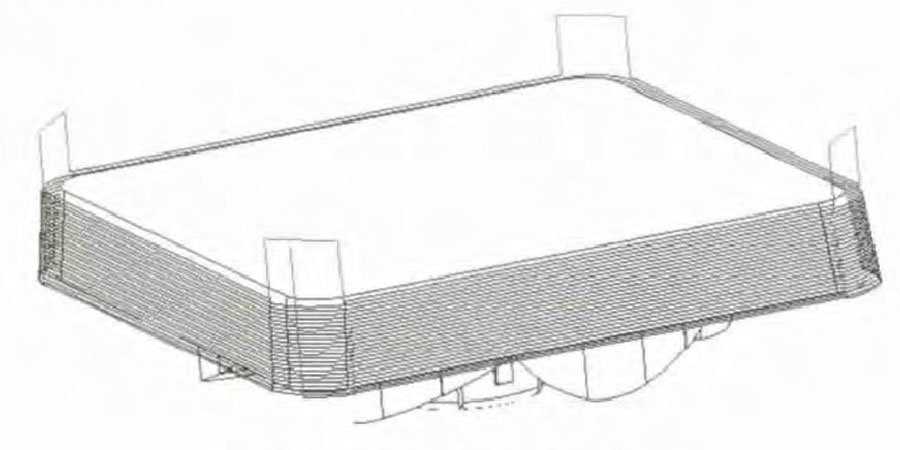

Ukulungiswa kwale ndlela yokusetshenziswa kwemishini kwenziwa ngesoftware ethandwa kakhulu yeCimatron. Ngaphambi kokwenza izinqubo ezithile zemishini ku-Cimatron, amafayili webhizinisi lomgodi ku-Pro / E kufanele aguqulwe abe amafayili wefomethi ye-iges, bese efakwa ku-Cimatron ukuhleleka kokuhlelwa. Kunqunywa ukuthi emgodini nasemgudwini oyinhloko womgogodla we-fan mold, uhlelo lokuxhumanisa lusethelwe ebusweni bokugcina nangaphezulu, futhi ukuphela komugqa ubheke ohlangothini lwe-Z-axis lubheke ngaphandle. Isixhumi esibonakalayo sohlelo lwendlela yethuluzi leCimatron siboniswa kuMdwebo 3 [2].

Lapho ingaphakathi lesikhunta licutshungulwa yi-CNC milling, imvamisa ifaka imishini enokhahlo, ukuqeda semi, nokuqeda. Umgomo wokugudluza ukususa insimbi eyeqile ngendlela efanele ngangokunokwenzeka, ngakho-ke kuthenjwa ukukhetha ithuluzi losayizi omkhulu, kepha usayizi wethuluzi mkhulu kakhulu, okungaholela ekwandeni kwevolumu engacutshungulwanga; umsebenzi wokuphothula semi uwukususa okusele ekugudwini Isinyathelo; ukuqeda ikakhulu kuqinisekisa usayizi nekhwalithi yendawo yezingxenye. Ukucabangela ukusebenza nekhwalithi, inqubo ye-CNC machining ihlelwe njengoba kukhonjisiwe kuThebula 1 [3].

4 Ukulungiswa kwendlela yamathuluzi okweqa

Emgodini kanye nomgogodla wesikhunta sabalandeli, kusetshenziswe izikhala zesikwele, futhi ivolumu eningi idinga ukususwa, ikakhulukazi ingqikithi icishe ibe yingxenye. Imishini ibaluleke kakhulu.

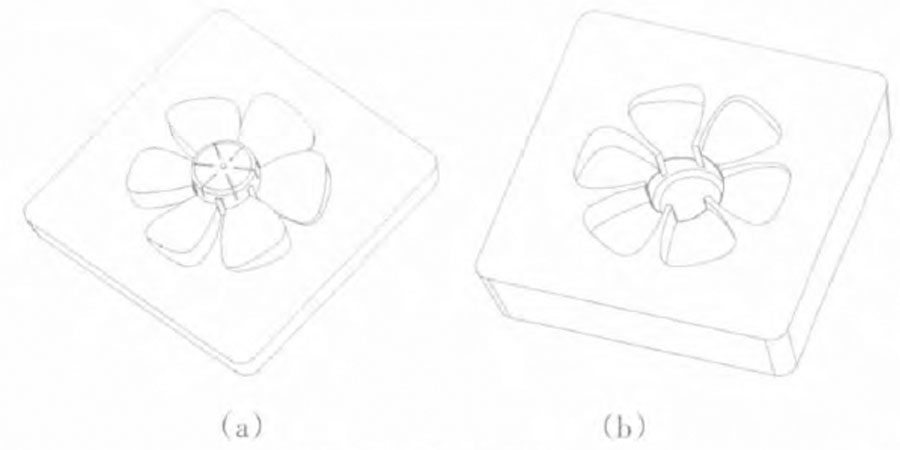

(1) 2.5-eksisi umgodi Milling.

2.5 I-eksisi umgodi wokugaya umyalo wokugaya osetshenziswa ngakubili kumyalo we-Cimatron, ongacutshungulwa ngaphakathi kwebanga elithile le-contour. Lo myalo usetshenziselwa indawo yetafula ngokuya ngqo ku-eksisi ye-Z emgodini. Njengoba kukhonjisiwe kuMdwebo 4a, kungukugaya okunzima kwepulatifomu yangaphandle yomngcele we fan. Uhla lwentaba yokugaya yilona uhla oluphakathi konqenqema olungunxande kanye neplamu liqhakaza ukunquma kwentaba yangaphakathi. Inani eliphakeme le-eksisi engu-Z lingu-0, futhi inani eliphansi lingu -55mm, kusukela ngaphandle kuye ngaphakathi. Ngomshini wokusika indandatho, umkhawulo u-0.6mm. Bheka inketho ukuhlanza igebe phakathi kwemigqa. Umphumela wokugcina ukuthi yonke indlela yethuluzi iyaqhubeka, cishe ayinamathuluzi angenalutho, futhi kunamakheshi ambalwa wamathuluzi. Kuyindlela ephumelelayo yethuluzi.

(2) 3D ahlabayo isiyingi nge ivolumu Milling.

Ukuze ingxenye udonga umgodi phakathi komgodi nengaphakathi, ngoba ebusweni lwalugobile kuyinto kuqhathaniswa eziyinkimbinkimbi, volumetric Milling 3D ahlabayo isiyingi eyamukelwa. Ivolumu yokugaya indandatho yokusika kwe-3D isetshenziselwa ukufeza inhloso yokususa ivolumu engalingani ezansi. Isihluthulelo ukukhetha "umugqa wemishini" kanye "nengxenye yendawo". Umdwebo 4b yiyona ndlela eyinhloko yokugaya ivolumu yendlela yethuluzi lokusika indandatho ye-3D. Khetha yonke indawo njenge "part surface", thatha imajini ibe ngu-0.6mm, bese usebenzisa ithuluzi lokudweba ukwakha indingilizi enobubanzi obungu-251mm njengentaba. Inzuzo yalokhu ukuthi ingasetshenziswa njengentaba. Kwenza indlela yethuluzi ingaguquki kakhulu, ibe namathuluzi amancane angenalutho, futhi ngasikhathi sinye, futhi ingasusa ezinye izindawo ezingacutshungulwanga phakathi kwamakhasi amabili. Uma kukhethwe iphrofayili emiswe okwenziwe ngeplamu, lo mphumela awukwazi ukutholwa. Umdwebo 5 ukhombisa ithuluzi lokusika eliyindilinga le-3D lokugaya ivolumetric cavity. Umugqa weplamu ukhethelwa ngqo umugqa, futhi zonke izindawo zengxenye yengxenye zikhethiwe. Njengoba ivolumu yokususa ingaphakathi komugqa weplamu, indlela yethuluzi nayo ibumbene kakhulu futhi kunamathuluzi ambalwa angenalutho.

5 Ukulungiswa kwendlela yethuluzi lokuqeda

Kunezindlela eziningi zokuqedela umgodi womgogodla nomgogodla, ikakhulukazi usebenzisa izindlela ezi-3 ezilandelayo:

(1) Ukuzisika okuyindilinga kwe-2.5-axis cavity milling.

Ukuqedwa kwendiza kutholakala ikakhulukazi ngokusebenzisa into ethi "3D cutting cutting" engaphansi kwe-2.5-axis cavity milling. Umdwebo 6 ukhombisa indlela yokugaya emihle yengxenyekazi eyinhloko yomngcele. Ngenkathi igaya indiza, umugqa ojikelezayo wengxenye eyakhiwe nawo wenziwa. Ekugayeni okuhle, kubhekwa indawo yokuqhekeka, kusetshenziswa ummese oyisicaba onobubanzi be-mm6mm, kanti imajini ingu-0.15mm.(2) Surface Milling izingxenye nge lula milling.

Isetshenziselwa ukucubungula ngokunemba kwendawo eguqulwe ngokushelela, futhi indlela yethuluzi ekhiqizwayo ibuye iguquke kahle ngokuya ngokuqondiswa kobuso, futhi uhla lokugaya lungaphakathi kobuso. Okungukuthi, kusetshenziswa ukugaya okulula, futhi kukhethwa intaba emide yodonga lohlangothi oluzungezile ukuze kugaywe, isiqondiso siyisiyingi esizungezile, kanti imajini ingu-0.15mm.(3) Qeda ukugaya konke ngokugaya indawo egobile.

Ubuso bokugaya nokuqeda ukugaya kusetshenziselwa ikakhulukazi ukugaya indawo enesakhiwo esiyinkimbinkimbi, futhi ububanzi bezintambo kufanele kukhethwe. Khetha zonke izindawo njenge- "part surface" bese uthatha imajini njengo-0.15mm. Ekujuleni, kufanele usebenzise ithuluzi lokudweba ukudala imibuthano emibili enobubanzi obungu- φ251mm no φ20mm njengomugqa wemishini, ukuze indlela yethuluzi lokuchofoza ibushelelezi. Emgodini, udinga kuphela ukukhetha umugqa omise iplamu.6 Imiphumela yokuqinisekiswa kwebhizinisi

Udonga ohlangothini lomgogodla lunikeza umphumela wokuthambisa owehlelayo, futhi udonga lwehlangothini lomgodi luwumphumela wokuqonda odongeni oqondile. Esikhathini machining ethize, it kukhethwe ngokuvumelana nezidingo design isikhunta.

Amazwi okuphetha ayi-7

I-machining ye-mold mold ye-fan inobunzima obuphakathi ekusetshenzisweni kwesikhunta sesikhunta, esingabonisa zonke izici zomshini wokubumbela isikhunta, futhi inokubaluleka okujwayelekile komeleli. Kuleli phepha, kusukela ekuhlaziyweni kwenqubo ye-CNC machining ye-fan mold mold machining, ukugcwaliswa kwemishini emibi nokuqedela kanye nokuhlaziywa kwamaphoyinti ayo abalulekile futhi anzima, kunikezwa indlela ye-CNC yokugaya imishini yesikhunta jikelele. Ukuma komgodi wesikhunta kuyahlukahluka kakhulu. Emshinini we-CNC, iprosesa kufanele lihlele ngokufanelekile izinqubo zokuchofoza ngokuya ngezimo ezithile zento yokwenza imishini, kuhlanganiswe nezinzuzo zesoftware ye-CAM, ukuze kuhlanganiswe izindlela zokwenza kahle kakhulu nezisezingeni eliphakeme.

Xhumanisa nale ndatshana: I CNC Machining ka Fan Inaliti Model Cavity Futhi Core

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.CNC machining ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindeka kwensimbi nepulasitiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.CNC machining ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindeka kwensimbi nepulasitiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi