Ukubaluleka Kwe-Cnc Machining Spacecraft Shell

I-Cnc Machining yeSpacecraft Shell

|

Ucwaningo olukule ndatshana lunokubaluleka okulandelayo ekusetshenzisweni okungokoqobo:

|

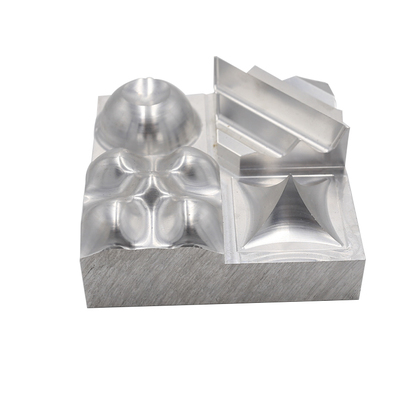

Izingxenye zegobolondo lemikhumbi-mkhathi ziyingxenye yesakhiwo somkhumbi-mkhathi. Ikakhulukazi amagobolondo ekhoni namakholomu anobubanzi obungaphansi kuka-1300mm nobude obungaphansi kuka-1700mm. Izinto ezisetshenziswayo ngokuyinhloko ziyingxube ye-aluminium eyakhiwe futhi yasakazwa, edlala indima yokuxhuma nokusekela. Ngokuhambisana nokuma kwento ngayinye esebenzayo yomkhumbi-mkhathi osemkhathini, ingaxhumanisa ukunyakaza. Njengoba izinhlobo ezahlukene zemikhumbi-mkhathi zenza imisebenzi eyahlukene, zithwala izingxenye ezisebenzayo ezihlukene, okuholela ezinhlotsheni ezihlukahlukene zezingxenye zegobolondo lemikhumbi-mkhathi. Njengoba kukhonjisiwe kuMfanekiso 1-1, kunezingxenye ezintathu zegobolondo lemikhumbi-mkhathi ejwayelekile. .

Phakathi nesikhathi "soHlelo Lweminyaka Emihlanu" lwe-13, ngokwanda okusheshayo kwemishini yasemkhathini, isidingo sezingxenye zamagobolondo emikhumbi-mkhathi sikhule kakhulu.

engeza. Uma kuqhathaniswa nemikhiqizo yemishini evamile, izingxenye zegobolondo lemikhumbi-mkhathi zinezici zamaqoqo amancane, izinhlobo eziningi, izikhathi zomjikelezo omfushane, nokushintshwa komkhiqizo ngokushesha. Phakathi nenqubo yokukhiqiza, izinkinga ezifana nokusatshalaliswa kwemisebenzi engalingani kanye nokushoda ngezikhathi ezithile kwezinsiza zokukhiqiza ziyaqhubeka nokuvela. Ngokwesiko Ukuguquguquka okuphansi, imodeli yokukhiqiza enkulu yenkampani ayikwazanga ukuhlangabezana nezidingo zamanje zokuthuthukiswa kwamamodeli amaningi kanye nokuthuthukiswa okuphezulu ngesikhathi esisodwa.

Namuhla, ngokuthuthuka okusheshayo kwemboni yokukhiqiza i-aerospace, indawo yokusebenzela yokukhiqiza yezingxenye zegobolondo lemikhumbi-mkhathi isifinyelele izinga elithile ledijithali. Ngokusetshenziswa kwezikhungo zemishini ye-CNC, ama-AGV aqondiswa ngokuzenzakalela nezinye izinsiza ze-hardware, amasistimu okugcina e-CNC, nezinhlelo zokwenziwa kokukhiqizwa kwedijithali , uhlelo lokutholwa kwedatha yomhlangano wokusebenzela kanye nenye isoftware yokuhlaziya ukuphathwa okusekelwe kusakhiwo "somugqa wokukhiqiza igobolondo ledijithali" iya ngokuya ngokuya iba khona. ephelele, ukusebenza kahle kwemishini kwezingxenye kuye kwaba ngcono kancane kancane, futhi ikhwalithi yomshini nayo iqinisekiswe kangcono. Nokho, inqubo yokuklama inqubo yomshini yezingxenye zegobolondo lemikhumbi-mkhathi isasebenzisa indlela evamile, incike kuphela ekwakhiweni kokwenziwa ingcweti, okukhawulela ukuthuthukiswa kwezinga lokukhiqiza. Ngemuva kokuhlaziywa, inqubo yendabuko yokwenza imishini.

Indlela yokuklama ngokuyinhloko inezihibe ezimbili ezilandelayo:

- (1) Izimfuneko zobuchwepheshe eziphakeme. Ukuhlelwa komzila wenqubo yokumaka kudinga ukucabangela izici ezihlukahlukene zomkhiqizo. Uma kuqhathaniswa neminye imikhiqizo eyimishini, izidingo zokwenziwa kwezingxenye zegobolondo lemikhumbi-mkhathi ziyinkimbinkimbi, zidinga ochwepheshe ukuba babe nezindawo ezigciniwe zolwazi lochwepheshe futhi bajwayele izinsiza zokukhiqiza zeshabhu. Ukwengeza, izici zomjikelezo omfushane nokushintshwa okusheshayo nazo zidinga abasebenzi benqubo ukuthi baklame ngokushesha umzila wenqubo ophumelelayo.

- (2) Ukusebenza kahle komklamo wenqubo kuphansi futhi izindleko ziphezulu. Lapho beklama umzila wenqubo, abasebenzi benqubo badinga ukufunda inombolo enkulu yezinkombandlela zokukhiqiza, imidwebo kanye namabhukwana okucubungula ukuze bathole ulwazi lwenqubo oluqukethwe ezingxenyeni. Imisebenzi inzima futhi miningi imisebenzi ephindaphindwayo. Ikakhulukazi, ukwakheka kwezingxenye zegobolondo lemikhumbi-mkhathi kuyinkimbinkimbi futhi inani lezici likhulu, futhi kunesidingo esiphuthumayo sobuchwepheshe obuhlobene ukusekela ukubuyiswa okusheshayo kolwazi lwenqubo.

Ngokuhlaziywa kwezinkinga ezikhona ezindleleni zokuklama zendabuko, kutholakala ukuthi izizathu ezibalulekile ezikhawulela ukwakheka okuphumelelayo nekhwalithi ephezulu yenqubo yomshini wezingxenye zegobolondo lemikhumbi-mkhathi yilezi:

- (1) Idatha yenqubo yomlando ayizange isetshenziswe ngempumelelo. Enqubweni yokuklama ingxenye nokukhiqizwa, kuzokwenziwa inani elikhulu ledatha yenqubo, futhi iningi lale datha yenqubo yomlando ayizange igcinwe futhi isetshenziswe ngokuphumelelayo, okuboniswa ngokuyinhloko: asikho isitoreji esimisiwe, okwenza kube nzima. ukuze abasebenzi bacubungule bathole ulwazi olufanele ukuze lusetshenziswe ngesikhathi senqubo yokuklama; Ukuntuleka kwezinqubo ezifanele zezinqubo zokumbiwa kwezimayini kuye kwaholela ekungakwazini ukusebenzisa kahle idatha yenqubo yomlando ukuze kuqondiswe ukuthathwa kwezinqumo ngokushesha kwezindlela zemishini.

- (2) Izinga lobuhlakani ekuhleleni umzila wenqubo liphansi. Ubuchwepheshe bamanje be-CAPP busesesigabeni sokuthuthuka nokwenza ngcono, futhi umzila wenqubo usahlelwa ikakhulukazi ngabasebenzi benqubo ngokusekelwe olwazini lwenqubo. Izingxenye zegobolondo le-Spacecraft zinezici zokuhlanganiswa okuphezulu kwezici. Nakuba imisebenzi nezakhiwo zezingxenye zihlukene, izici zezingxenye zinokufana okukhulu.

Ikakhulukazi yakhiwe ngaphezu kobumo begobolondo abavamile abangaphezu kwe-10, izimo zangaphakathi, amawindi, namagridi. Izici zomshini kanye nenombolo yezici ezingajwayelekile zokusebenzisa imishini. Ngesikhathi esifanayo, ngenxa yokufana kwezidingo zemishini ezifana nezinto kanye nokunemba kwezici ezijwayelekile zezingxenye, izindlela zomshini zezici zezingxenye ezahlukene zingasetshenziswa ukuze zisetshenziswe.

Ngakho-ke, ulwazi lwenqubo yokwenza imishini lungaxhunyaniswa ngokusekelwe ezicini zemishini, futhi izindlela zomshini kudatha yenqubo yomlando zingambiwa futhi ziqhutshwe kubasebenzi benqubo, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kokubuyiswa kwabasebenzi benqubo, futhi kwenze abasebenzi benqubo bakwazi uqondise ngokushesha nangempumelelo umsebenzi wokuklama.

Ukwengeza, ohlelweni lokuklama inqubo yokwenza imishini, abasebenzi benqubo akumele bacabangele ukuthi kungenzeka yini umzila wenqubo, kodwa futhi banciphise izindleko zomshini. Kodwa-ke, inani lezici zezingxenye zegobolondo lemikhumbi-mkhathi likhulu, futhi indawo yokusebenzela yedijithali inezinhlobonhlobo zemishini yokwenza kanye namakhono aqinile.

Ochwepheshe badinga ukukhetha izindlela ezifanele zokwenza imishini kanye nezinsiza zokukhiqiza zezici zomshini ngaphansi kwemingcele yemithetho yenqubo, futhi bazihlanganise zibe izinyathelo zenqubo. Izinyathelo zenqubo zihlelwa ngokunengqondo, ukuze zihlelwe zibe imizila yezinqubo ezongayo nezisebenzayo. Ngokusobala, uma kuqhathaniswa nezingxenye ezijwayelekile zomshini, umsebenzi wokuhlela umzila wenqubo yezingxenye zegobolondo lemikhumbi-mkhathi unzima kakhulu futhi udinga amakhono aphezulu ezisebenzi zenqubo.

Ngakho-ke, kungenzeka ukuthuthukisa isivinini sokuhlela umzila wenqubo futhi kuncishiswe umthwalo wokubala wabasebenzi benqubo ngokucwaninga kobuchwepheshe bokuhlela umzila wenqubo ngokusekelwe ku-algorithm ehlakaniphile.

Ngakho-ke, ukuze uvumelane nemodi yokukhiqiza "yezinhlobo eziningi, inqwaba encane" yezingxenye zegobolondo le-spacecraft, thuthukisa inqubo.

Ukusetshenziswa kwedatha yomlando kanye nezinga elihlakaniphile lokuhlelwa komzila wenqubo. Lesi sihloko sizothatha idizayini yenqubo yokwenza imishini yezingxenye zegobolondo lemikhumbi-mkhathi evamile njengesizinda socwaningo, futhi ihlaziye ulwazi lwenqubo yokwenza imishini phakathi nenqubo yokuklama kanye nobudlelwano obukhona phakathi kolwazi.

Qondisa ukumodela kwenethiwekhi yolwazi lwenqubo yokwenza imishini. Ngalesi sisekelo, i-rough set theory yethulwa emigodini yemithetho yesinqumo senqubo engase ibe khona kudatha yomlando wenqubo, ukuze kutholwe ngokushesha indlela yomshini wezici zomshini ngokuya ngemithetho yesinqumo sokubhekisela kubasebenzi benqubo. Okokugcina, funda indlela yokuhlela umzila wenqubo ngaphansi kwesithiyo semithetho yenqubo ukuze uthuthukise izinga elihlakaniphile lokuhlela umzila wenqubo. Ngokomkhuba wobunjiniyela, ngenxa yenani elincane lezingxenye ze-atypical nezici ze-atypical, ukusebenziseka kabusha akuphezulu.

Ngokusekelwe ekwakhiweni kwenqubo yokwenza imishini yezingxenye zegobolondo ezivamile zemikhumbi-mkhathi, leli phepha lihlela kabusha ubudlelwano bangaphakathi bolwazi lwenqubo yokwenza imishini futhi lisungula imodeli yenethiwekhi yolwazi lwenqubo ngefomu lenhlangano elicacile, elinikeza lula ukubuyisa nokusetshenziswa kabusha kolwazi lwenqubo; Inqubo yocwaningo Indlela yezimayini yemithetho yezinqumo ingasebenzisa ngokugcwele ulwazi olunobufakazi ukuze iqondise ukuthathwa kwezinqumo kwezindlela zomshini; ngcono izinga elihlakaniphile lokuklama inqubo ngokutadisha indlela yokuhlela umzila wenqubo ngokusekelwe ku-algorithm ethile yokuzivikela komzimba; futhi usebenzise lezi zindlela zethiyori ezingenhla kanye nokucwaninga nobuchwepheshe bobuchwepheshe Dala ithuluzi lokukhipha izici zokukhiqiza zezingxenye ezivamile zemikhumbi-mkhathi, ithuluzi lemithetho yesinqumo senqubo yezimayini kanye nokukhipha, kanye nethuluzi lokuhlela elihlakaniphile lemigudu yezinqubo ukuze kuthuthukiswe ukusebenza kahle kwenqubo yokuklama kanye nezinga lobuhlakani. izingxenye zegobolondo lemikhumbi-mkhathi ejwayelekile.

Amakhasi ahlobene:AIzingxenye ze-ircraft

Xhumanisa nale ndatshana: Ukubaluleka Kwe-Cnc Machining Spacecraft Shell

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi