Ukusetshenziswa Kwesistimu Ye-AC Servo Ku-Shelf Cold Roll Owenza Umugqa

Ukusetshenziswa Kwesistimu Ye-AC Servo Ku-Shelf Cold Roll Owenza Umugqa

|

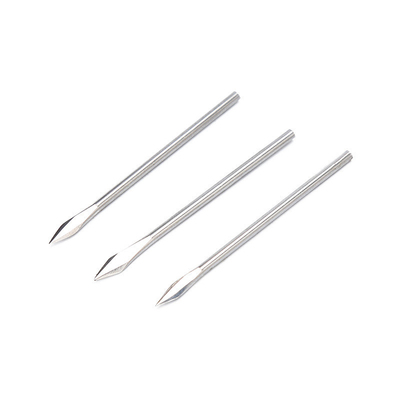

Ukwethulwa kwenqubo yangaphambi kokubhoboza kanye nobuchwepheshe be-hydraulic stop shear emgqeni wokukhiqiza owenziwe ngokubanda wekholomu yokubeka akugcini nje ukwandisa ububanzi bokuklama kanye nokunemba kokukhiqiza kokuma kwekholomu ye-rack, kodwa futhi kuhlangabezana nezidingo idizayini kanye nokuhlanganiswa kwesistimu yesakhiwo sensimbi yokubeka, futhi ithuthukisa .Indlela yokwakheka kwesakhiwo sensimbi yeshalofu, ikakhulukazi uma uhlelo lwendlu yokugcina impahla enezinhlangothi ezintathu lukhuphuka futhi luthuthuke kabanzi ezweni lethu, lubeka phambili izidingo eziphakeme ekunembeni kwendawo yembobo. kanye nokulawula ubude bekholomu yeshalofu. |

1.2 Lesi sihloko sihlaziya futhi sidingide ngamathuluzi okulawula okusika ngaphambi kokubhoboza kanye ne-hydraulic cut-off yekholomu yeshalofu ebandayo eyakha umugqa wokukhiqiza usebenzisa isimiso sokulawula i-servo ye-AC, futhi ilwela ukufeza inhloso kanye nezidingo zokulawula ukunemba kwesikhundla esiphezulu ezindaweni eziningi ezibandayo. izikhathi zokugoba. Khuthaza ontanga.

2. Isimiso sokusebenza seshalofu elibandayo lokugoba umugqa wokwakha

2.1 Inqubo yokukhiqiza eyisisekelo kanye nokwakheka kwemishini yomugqa wokwenza umqulu obandayo weshalofu:

2.1.1 Inqubo ejwayelekile yokukhiqiza yezingxenye zeshalofu yilena: ukuqaqa, ukulinganisa, ukuphakela i-servo, ukubhoboza, ukubumba, ukugingqa, ukuqondisa, ukusika-ubude, ukupakisha, ukwelashwa ngemva kokufafaza, njll.;

2.1.2 Izinto zokusebenza ezihambisanayo yilezi: i-uncoiler, umshini wokulinganisa, idivayisi yokuphakela i-servo, umshini wokucindezela, isigayo esigoqayo esibandayo esiqondisa isisetshenziswa sokusika se-hydraulic kanye ne-hydraulic station baler noma ezinye izisetshenziswa ezisizayo + uhlelo lokulawula ugesi, njll.

2.2 Umgomo oyisisekelo wesistimu yokulawula i-servo ye-AC yomugqa wokwenza umqulu obandayo weshalofu:

Njengoba kuboniswe kuMfanekiso 1.

2.3 Uhlelo lwakhiwe izingxenye ezinhlanu, okuyikhompyutha, ikhadi lokulawula idrayivu ye-servo, isistimu yokulawula isivinini se-servo ye-AC, ukutholwa kwezinzwa kanye nempendulo, kanye nesistimu yokukhishwa kwesenzo esiyinhloko. Uhlelo oluyinhloko lokulawula ngamakhulu ambalwa K, olusebenza ngaphansi kwesistimu yokusebenza ye-DOS, i-microcomputer yokulawula eyinhloko ixhunywe ekhadini lokulawula idrayivu ye-servo ngokusebenzisa imbobo yokuphrinta LP1, futhi ithumela imiyalo yesikhundla noma isivinini ngomugqa wedatha, ukulungiswa okuguquguqukayo noma ukusetha imingcele yokulungiswa kwe-PID, bheka Ngemva kwesibalo, futhi wenze ukuguqulwa kwedijithali-kuya-analogi, khipha isignali ye-analog engu-±10V ngebhodi lokulawula elihambisanayo bese ushayela i-servo motor ngemva kokukhuliswa yi-AC servo amplifier. I-semi-closed-loop noma isistimu yempendulo yokulawula ukuma kwe-loop evaliwe ikhuliswa yi-motor umphini ukuphela. I-quantitative photoelectric encoder inikeza amasignali ukuze aqedele impendulo yendawo yesistimu ye-servo yendawo. I-elementi yezinzwa kusimo sempendulo ye-loop-encoder photoelectric encoder idlulisa izinguquko zesikhathi sangempela zokugudluzwa kwezingxenye ezihambayo kusayithi ngendlela yama-pulses ahluka wesigaba A no-B. Ukubalwa kwe-Encoder pulse kwenziwa esiteshini sokulawula ukuze kutholwe ulwazi lwendawo yedijithali. Ngemuva kokuthi ikhompuyutha encane yokulawula ibale ukuchezuka phakathi kwendawo enikeziwe nendawo yangempela, isu elihambisanayo lokulawula i-PID liyamukelwa ngokuya ngebanga lokuchezuka, futhi umsebenzi wokulawula wedijithali uguqulelwa ku-analog ngokuguqulwa kwedijithali-kuya-ku-analogi. Lawula i-voltage bese uyikhiphela ku-servo amplifier, futhi ekugcineni ulungise ukunyakaza kwemoto, ugcwalise inani elifiswayo lokulawula ukuma kwempendulo evaliwe ephindaphindiwe, futhi uqaphele iphutha elincane kanye nokunemba okuphezulu kokuma kumgomo wokulawula; bese uhlelo lokulawula oluyinhloko lukhipha ukusebenza kwesistimu yokukhishwa kwesenzo esiyinhloko esisizayo ukuze kuqedelwe isenzo esithile sokubhuleka esisebenza ngomshini, ukunyakaza kokushaya ngesibhakela, ukunyakaza kokushefa kwe-hydraulic stop, njll.

2.4 Izici eziyinhloko zale yunithi: izindleko eziphezulu zokutshala izimali zesikhathi esisodwa, amandla amakhulu e-AC servo anemikhawulo ethile, kodwa izindleko zokusebenza zakamuva ziphansi, ikakhulukazi izinga lokukhiqiza eliphezulu lezingxenye zeshalofu, ukunemba okuphezulu komkhiqizo, ububanzi bohlelo lokusebenza kanye nokwengezwa okuphezulu. inani lokuphumayo .

3. Ukuhlaziywa kanye nesimiso sokusebenza sokuphakelayo okuzenzakalelayo kanye nedivayisi yokubhoboza

3.1 Ithuluzi lokuphakelayo elizenzakalelayo lenqubo yokubhoboza ngaphambilini yomugqa wokukhiqiza ogobayo obandayo wekholomu yeshalofu yakhiwe ipheya eliphezulu nangaphansi lamaroli aqondisayo angu-φ75. Amandla amakhulu okusebenza avela ku-AC servo motor, encike ekungqubuzaneni phakathi kwepuleti lezinto ezibonakalayo namarola angumhlahlandlela angaphezulu naphansi. Ukuphakela ngenkani, izimbobo zokusabalalisa insimbi ye-strip zekholomu yeshalofu zigxivizwa emshinini wokunyathelisa. Idizayini eyinhloko iboniswa kuMfanekiso 2. Le divayisi ekuqaleni yayiklanywe njengesistimu yokulawula i-servo engu-3.7KW yaseProuder, USA. Kamuva, ngenxa yokuthuthukiswa kwemikhiqizo emisha, umthwalo wokudlulisa umsebenzi wanda, futhi Ngokwesimiso sokusebenza esiboniswe kuMfanekiso 2, ukulawulwa kwesikhundla phakathi kwengxenye yokulawula amandla kanye nokulawulwa kwe-AC servo kubonakala ikakhulukazi ngesignali ye-analog ± 10V. , awukho umkhawulo wamandla ohlelweni lwe-AC servo, futhi ingashintshwa ngokomgomo. Isilawuli se-AC servo esisekelayo kanye ne-AC servo motor ye-5KW servo amplifier model MR-J2S-series ye-Mitsubishi Corporation, futhi ngokuya ngezidingo zokunemba kokukhiqizwa kwezingxenye zeshalofu elihambisanayo kanye nokunqunywa kokunemba kokulawula i-servo: ±0.1, bese Isilinganiso sesiyingi serola yokulinganisa kububanzi bokunemba sicishe sibe: 1178. Izishumeki ezijikelezayo ezingaphezu kuka-1200PPR kufanele zisetshenziswe, futhi izidingo zokulawula ukunemba kwendawo zingafezwa kahle eminyakeni emine eyakamuva yohlelo lokusebenza.

3.2 Isistimu ye-servo ye-Mitsubishi MR-J2 inezici zokusabela okuhle komshini, ukuzinza kwesivinini esiphansi, nokulungiswa kwesimo esifanele okuhlanganisa nezinhlelo zemishini. Impendulo yefrikhwensi yesivinini ingaphezulu kuka-550HZ, efaneleke kakhulu izikhathi zokuma ngesivinini esikhulu. Okokusebenza okunomzuzwana okhuphukile wokulayisha we-inetia ratio kanye nokuqina okungekuhle.

3.3 Umshini wokuphakela othomathikhi ngokuyinhloko wakhiwe isakhiwo esiboniswe kuMfanekiso 3. (1) Inzwa ye-photoelectric 1# ngokuyinhloko ibuyisela isimo sebhande lensimbi elingena endaweni yokusebenza yomshini wokunyathelisa, njengalokhu: impahla eningi, ukuntuleka kwezinto. , njll.; ⑵I-servo motor iqondiswa phansi nge- igiya ibhokisi Irola yokuphakelayo idlulisa amandla okudlulisa. I igiyaisilinganiso sokudluliswa kwebhokisi i kanye nesivinini semoto sinquma isivinini sokuphakela kanye nokuma kwesistimu; (3) Isishumeki esijikelezayo sikala isignali yendawo edluliswa irola ewumhlahlandlela engenhla ngokunyakaza ngento yeshidi. ⑷ Ibhuleki lomshini libona ukuma Isikhundla sangemuva sigxilile; ⑸inzwa ye-photoelectric 2# ibona ukudluliswa kwesignali yendawo edingwa ukulawulwa komsebenzi womshini wokunyathelisa; ⑹isikhunta esingenhla nesingezansi siyakubona ukubhoboza kwendawo yembobo; ukufanisa i-punching tonnage yomshini wokucindezela kuyadingeka, ukufaniswa kokunemba kwethuluzi lomshini noma isikhunta, njll.

3.4 Inani elithile lesinyathelo sokuphakela sefa ngalinye linqunywa i-PC ebeka inombolo ye-pulse count ehambisanayo noma ukuqhathaniswa kwenani lokuguqulwa kobude, futhi ihlanganiswa impendulo yokulinganisa yokwenziwa kwesishumeki se-engeli esixhunywe kurola womhlahlandlela ophezulu, ukuze kubonakale. i uyanyathela Okuphakelayo kwesinyathelo okulungisekayo, okunembayo okuphezulu, nokungaqoqiwe uyanyathela kwempahla yeshidi. Iphutha elinqwabelene lisingathwa i-algorithm yesinxephezelo sephutha esethwe kuhlelo noma ukulungiswa mathupha ukuze kuqinisekiswe ibanga lembobo lekhwalithi ephezulu yekholomu yeshalofu. Ukuzijwayeza kuye kwabonakala kuwusizo kakhulu.

3.5 Umshini wokuphakelayo ozenzakalelayo ohlelweni lwemishini unqoba ukushiyeka kokuphakela mathupha kwekholomu yeshalofu ibhande lensimbi eliyisicaba elivula ngaphambili. Inezici zokusebenza okulula, umsebenzi othembekile, nokunemba kokulawula okuphezulu. Kungathuthukisa kakhulu ukukhiqiza kwezabasebenzi. Ingakwazi ukufeza izikhathi ezingu-70 ngomshini wokunyathelisa onesivinini esikhulu nokunemba okuphezulu. Imvamisa yokusebenza ingahlukaniswa ibe izingxenye ezimbili, futhi ingcindezi yokusebenza ingafinyelela ngaphezu kwe-2500KN, engakha uhlelo lokusebenza oluzimele.

4. Ukuhlaziywa kanye nesimiso sokusebenza sedivayisi yokusika ishalofu

4.1 Umgomo oyisisekelo wokulawula uyafana futhi wabelana ngesistimu ebumbene. Izici zayo yilezi: isignali yenombolo yendawo yembobo kukholomu yeshalofu ikalwa ngeswishi yesithombe kagesi ekhanyayo. Ngenani elithile lezimbobo, uhlelo lokulawula oluyinhloko lwangaphakathi luguqula inombolo yemodi yokulinganisa izimbobo ibe imodi yokulinganisa ubude, futhi ngokufanayo luqedele impendulo yendawo kanye nokulawula ukuma kwesistimu ye-servo yendawo. I-microcomputer yokulawula eyinhloko ibala ukuchezuka phakathi kwendawo enikeziwe kanye nendawo yangempela, futhi ikulungise ngesikhathi. I-AC servo motor iyanyakaza futhi iqedele ukuma kwevelu efiselekayo, ukunyakaza okuyinhloko kuyama futhi kuholele idivayisi yokunqanyulwa kwe-hydraulic ukulawula i-solenoid. I-valve ukukhiqiza ukulandelana komsebenzi okusikiwe;

4.2 Umehluko omkhulu phakathi kwemodi yokulawula ye-hydraulic cut-off kanye nemodi yokulawula yokugunda okundizayo: ①Ukunemba kokulawula kwe-hydraulic cut-off kuphezulu, futhi ukunemba kokulawula okuphezulu yilokhu: ± mayelana no-0.1mm futhi alikho iphutha elikhulayo, okuyi- ikakhulukazi kuboniswa kusishumeki sesithombe sikagesi esikhulayo Ukunemba okuphezulu nokulawula izidingo zokulandelana, isisetshenziswa sokutshala imali ngesikhathi esisodwa siphezulu; kodwa isivuno sokuqala siphezulu, izinga lokusetshenziswa kwezinto ezibonakalayo liphezulu, futhi isilawuli sokugunda esindizayo sidinga ukwandisa ukulandelela nokusetha kabusha idivayisi, futhi uhlelo lokulawula lulula; ②Esimisweni sokulawula, i-hydraulic stop Shear inemba ngokuphelele yokulawula, alikho iphutha lomehluko wejubane, njll., ukugunda okundizayo kuwukunemba kokulawula okuhlobene, okuyiphutha elihlobene phakathi kwendawo yokugunda kanye nokunyakaza kwendawo yokusebenza, ngenxa ukungaqiniseki komthetho wokusebenza kwejubane noma ukuguquguquka kokumelana neyunithi kanye nomthwalo womsebenzi. Isivinini esiyinhloko sokunyakaza sokulawula i-shear endizayo sihlala njalo, esivumelana nokusetha nokulungiswa kwemingcele yokusebenza yemishini yokushisela esekelayo. Ijika eliyinhloko lokunyakaza kwemodi yokulawula i-hydraulic stop shear iyinkimbinkimbi kakhulu futhi iphakeme Ukuguqulwa kwesivinini esiphansi kanye nezimo zokumisa ukunyakaza ngezinye izikhathi zinesikhathi eside sokulinganisa; ④Ukusebenza kahle kokukhiqiza kuyehluka kakhulu, futhi ukusebenza kahle kokukhiqiza kwe-shear endizayo kuphezulu, futhi kulula ukulawula ukukhiqiza; ⑤Izidingo zokunakekelwa kwemishini nokulawula ukusebenza zihluke kakhulu. ⑥Imodi ye-hydraulic cut-off isiza kakhulu ekuxazululeni iziphambeko ezisikiwe ezifana nokusikwa nokubopha kabusha amaphrofayili akhiwe ngendlela ebandayo. Kafushane, kuyadingeka ukwakha nokukhetha izindlela zokusebenza zokulawula imishini ngokwezici zemikhiqizo ebandayo ukuze kutholwe inzuzo enkulu.

5 Izinkinga ezimbalwa ezibalulekile ekwakhiweni kwesistimu yokulawula

5.1 Lawula ukunemba kwesignali yokokufaka: Isilinganiso sesiyingi serola yokulinganisa ukuya ebangeni lokunemba lokulinganisa ekugcineni sinquma ukunemba kokulawula ukukhiqiza komkhiqizo. Umkhiqizo onesilinganiso esikhulu kufanele ukhethwe ngangokunokwenzeka, futhi impahla ye-roller yokulinganisa efanele kanye nokuxhumana phakathi kwe-roller yokulinganisa kanye nengxenye ebandayo kufanele kukhethwe. I-Damping kanye ne-elastic coefficient yokwandisa i-coefficient yokungqubuzana nokucindezela kokuxhumana ukuze kuvinjelwe amaphutha okushelela enqubweni yokulinganisa.

5.2 Ukulawula ukunemba kwesignali yokuphumayo: Umehluko ku-algorithm yokulawula i-loop ye-PID inquma ukunemba kokulawula kanye nemiphumela etholwe ukulawula kwe-PID. Isibonelo, indlela yesisombululo inendlela yokuphendula yesinyathelo, futhi izici ezintathu zesenzo zamukelwa ngokuvumelana nezici zokulawula: 1), kuphela Kukhona ukulawula okulinganayo; 2), ukulawula kwe-PI; 3), ukulawulwa kwe-PID; futhi wenze ukubala kwe-PID ngokwesimo sesivinini kanye nefomula yokubala ehlukile yenani elilinganisiwe, futhi wenze izibalo zesenzo esihle nesibi nokulawula ngaphansi kwezidingo zokunemba ezihambisanayo.

5.3 Ukushuna amapharamitha esistimu ye-PID: I-microcomputer yokulawula eyinhloko ithumela amapharamitha e-PID ekhadini lokulawula ukuze ibone ukuthi amapharamitha anikeziwe ayahlangabezana yini nezimfuneko zesistimu yokulawula. Le nqubo idinga ukwenziwa ngokulungisa ipharamitha. Umsebenzi oyinhloko wokushuna ipharamitha ukunquma K, A, B kanye Nesibali sikhathi sesampula. I-proportional coefficient K iyanda, ukuze uhlelo lwe-servo drive luzwele futhi luphendule ngokushesha. Kodwa-ke, uma inkulu kakhulu, izobangela i-oscillation futhi isikhathi sokulungisa sizoba side; i-coefficient A ehlanganisiwe izokwanda, Ingasusa iphutha lesimo sohlelo, kodwa ukuzinza kuyancipha; isilawuli esihlukanisayo esingu-B singathuthukisa izici eziguqukayo, sinciphise i-overshoot, futhi sifinyeze Isikhathi sokulungisa isikhathi. Inqubo ethile yokushuna idinga ukuthuthukisa i-algorithm yokulawula kanye nendlela yokushuna ipharamitha yedivayisi ye-PID yeluphu yendawo yedijithali ukuze yakhe imingcele yokujwayela endaweni kanye nezilungiselelo zangempela zokulungisa endaweni, futhi ziyisethwe ngokwehlukana ngokuya ngemikhiqizo ehlukene noma umthwalo. izimo, ngaphandle kwalokho inqubo yokulawula isikhundla izokwakhiwa kalula. I-oscillation phenomenon. Njengoba kuboniswe ekulungiseni okuvulekile okusethiwe ohlelweni lokuklama.

5.4 Ukunemba kwemishini kwesistimu kulawulwa ngaphakathi kwebanga elithile lamaphutha, futhi ukunemba kokulawula ugesi kungathuthukiswa. Ihlanganiswe nesistimu ye-AC servo drive esebenza kahle kakhulu, ingahlangabezana nezidingo zokulawula indawo enembayo izikhathi eziningi, futhi ithuthukise ukusebenza kahle kokuma kwesikhundla. Nokunemba.

5.5 Uhlelo oluyinhloko wuhlelo lokulawula i-AC servo olusekelwe endaweni yokuthuthukisa i-PC. Imisebenzi esemqoka yilena: inkhulumomphendvulwano yomshini womuntu ukulungisa idatha yokukhiqiza umkhiqizo, izilungiselelo zepharamitha yedivayisi kanye nokusetha ipharamitha ye-PID, njll.; ukubona ukudluliswa kwedatha nokucutshungulwa phakathi kwe-PC namamojula, kanye ne-algorithm yokulawula iluphu ye-PID nokulawula ukunyakaza kwe-servo motor, ukubona isenzo semishini ehlukahlukene ehlobene, njll. Okunye okufana: ukusetha nokulungiswa kwebanga lesinyathelo sokugxiviza, i ukulungiswa okuhambisanayo kwenombolo ye-pulse ephumayo ngayinye ngaphansi kwenani elithile lobude, ukunemba kokulawula komshini wokunyathelisa, ukunemba kokudla kwe-servo kanye nokusetha nokulungiswa kwevelu yobude bokudla kwe-servo konke kuwumklamo ovulekile.

5.6 Idizayini yohlelo oluyinhloko icabangela izingxenye zohlelo oluyisixwayiso zokwehluleka kwezinye izinto zokusebenza, okuthuthukisa kakhulu ukusebenza kwezisetshenziswa kanye nokulawulwa kwekhwalithi yokukhiqiza umkhiqizo, futhi kunciphisa isikhathi sokuhlolwa kokuhluleka kwemishini ngokwezinga elithile.

6 isiphetho

6.1 Uhlelo lokusebenza olusebenzayo lubonisa ukuthi ukukhethwa kwesistimu ye-servo ye-AC enengqondo ingahlangabezana nezidingo zesistimu yokulawula ngesivinini sokuphendula esisheshayo, ukunemba kwesivinini esikhulu, nokuqina okuqinile. Ukunemba kwangempela kokulawula indawo yohlelo lokusebenza kufika ku-0.1mm futhi kungagwema amaphutha anqwabelene. Lolu hlelo lokulawula lungasetshenziswa ekukhiqizeni uchungechunge olunembayo lokuvula olunembayo lwemikhiqizo yensimbi eyakhiwe ngendlela ebandayo, ikakhulukazi imikhiqizo efana namakholomu eshalofu, okungukuthi, umugqa wokukhiqiza owenziwe ngokubanda wezinto ezimile zensimbi ezakhiwe ngokubanda kanye nezimbobo ezishaywe ngaphambili. izikhundla zembobo enembe kakhulu emaceleni.

6.2 Uhlelo lwe-AC servo olusetshenziswa eshalofini elibandayo lwakha umugqa wokukhiqiza lungafinyelela ukunemba kokulawula isikhundla esiphezulu; futhi imodi yangaphambi kokubhoboza kanye nemodi ye-hydraulic stop shear ingasetshenziswa ngokuzimela, njengenqubo yokukhiqiza ishalofu yeshalofu, ayikho imodi yangaphambi kokubhoboza, njll.

Xhumanisa nale ndatshana: Ukusetshenziswa Kwesistimu Ye-AC Servo Ku-Shelf Cold Roll Owenza Umugqa

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Isitolo se-PTJ CNC sikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zemishini, ukunemba nokuphindaphindwa kwensimbi nepulasitiki. 5-eksisi CNC Milling etholakalayo.Machining ephezulu lokushisa ingxubevange ububanzi inclouding machining we-inconel,machining machining,Imishini ye-Geek Ascology,Carp 49 machining,I-Hastelloy machining,Imishini yeNitronic-60,Imishini ye-Hymu 80,Ithuluzi Steel machining, njll.,. Ilungele ukusetshenziswa kwe-aerospace.Ukufakwa kwe-CNC ikhiqiza izingxenye ezinezakhiwo ezinhle kakhulu zomshini, ukunemba nokuphindeka kwensimbi noplastiki. I-3-axis & 5-axis CNC milling etholakalayo.Sizohlela amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi