Imfihlo! Inqubo ye-CNC machining yehabhu yonke yama-aluminium

2019-03-22

Ihabhu lamasondo, okungukuthi, ukuma kwangaphakathi kwesondo lisetshenziselwa ukuxhasa umphongolo wesondo, futhi nendawo ibuthene ku umphini. Amasondo avamile wezimoto anamasondo wensimbi namasondo e-aluminium alloy. Amasondo ensimbi anamandla amakhulu futhi asetshenziswa kakhulu emalolini amakhulu;

uma udinga ukubheka izifundo zamacala we-ptj, chofoza isondo hub.

Kodwa-ke, amasondo ensimbi anesisindo esisindayo futhi anomumo owodwa, ongahambelani nomqondo wekhabhoni ephansi nemfashini namuhla, futhi kancane kancane ithathelwa indawo amasondo e-aluminium alloy.Izinzuzo zamasondo e-aluminium alloy

- (1) Uma kuqhathaniswa namasondo ezimoto zensimbi, izinzuzo zamasondo e-aluminium alloy zisobala: ukuminyana kuncane, cishe u-1/3 wensimbi, okusho ukuthi ivolumu efanayo yamasondo e-aluminium alloy azoba 2/3 alula kunamasondo ensimbi. Izibalo zikhomba ukuthi ikhwalithi yezimoto isiyonke yehliswe ngo-10%, futhi ukusebenza kahle kukaphethroli kungakhuphuka ngo-6% kuye ku-8%. Ngakho-ke, ukukhushulwa kwamasondo e-aluminium alloy kubaluleke kakhulu ekongeni ugesi, impilo ephansi yekhabhoni.

- (2) Ukuqhutshwa kokushisa kwe-aluminium kuphakeme, kanti ukuhanjiswa kwensimbi okushisayo kuphansi, ngakho-ke ngaphansi kwezimo ezifanayo, ukusebenza kokushiswa kokushisa kwamasondo e-aluminium alloy kungcono kunamasondo wensimbi.

- (3) Isitayela futhi enhle. I-aluminium alloy ingaguga futhi iqiniswe, futhi isaladi le-aluminium ingxube ngaphandle kokwelashwa kokuguga linamandla aphansi futhi kulula ukucutshungulwa, futhi isondo le-aluminium ingxubevange ngemuva kokwelashwa okungahambisani nokugqwala nombala kufakwe umbala futhi kuhle.

Ukuhlaziywa Kokwakhiwa Kwezimoto Ezingamasondo zeAluminium

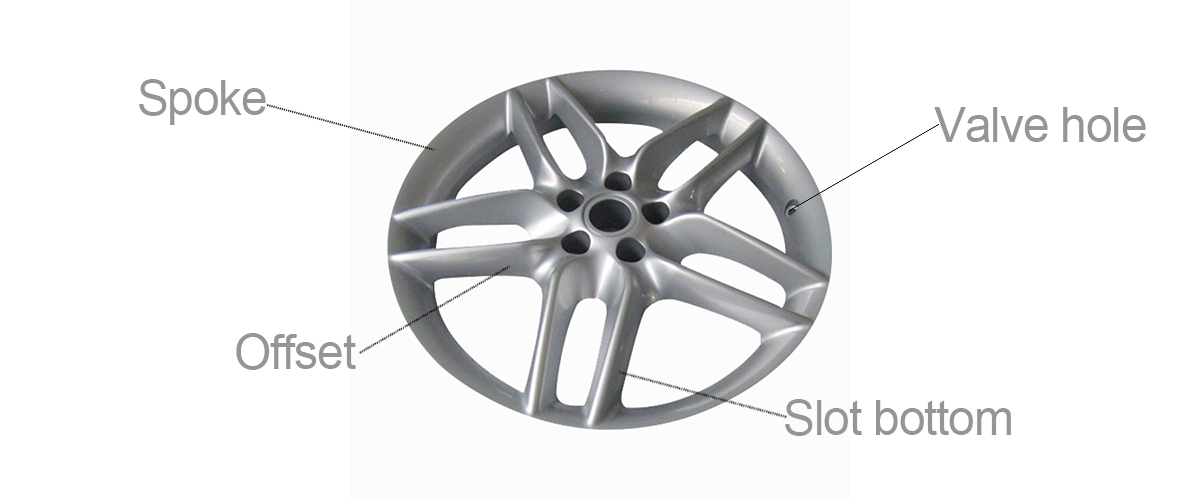

Ukuze kuhlangatshezwane nezidingo zokusetshenziswa kwemisebenzi kanye nemakethe, ihabhu le-aluminium alloy hub linezinhlobonhlobo zemiklamo yokwakha enjengokuhlanganiswa okuhlanganisiwe nokwenziwa kwezinto eziningi; kukhona ama-spokes abanzi, ama-spokes amancane, ama-spokes amaningi, ama-spokes ambalwa neminye imiklamo yokuklama. Ngezizathu zokuphepha, ukubukeka nokwakheka kwesondo le-aluminium alloy kumele kususelwe kuzidingo zokuphepha nokusetshenziswa okusebenzayo. Ezimotweni ezijwayelekile zabagibeli, amasondo we-aluminium alloy ahlanganisiwe anele ukuhlangabezana nezidingo zabo zokusebenza.Isakhiwo sehabhu lezimoto siboniswa kuMdwebo 1. Singahlukaniswa sibe izingxenye ezimbili: irimu nehabhu. Ukuhlaziywa kokusebenza kwengxenye ngayinye kukhonjisiwe esithombeni esingezansi.

Izidingo zokusebenza kwamasondo e-aluminium alloy yezimoto

Kunezinhlobo eziningi nezakhiwo zamasondo e-aluminium alloy, futhi izidingo zawo ziyahlukahluka kuye ngohlobo lwemoto nemodeli. Kodwa-ke, amandla nokunemba yizidingo eziyisisekelo kakhulu. Ngokuya ngocwaningo lwemakethe, ihabhu lamasondo kufanele libe nalezi zakhiwo ezilandelayo:- 1) Okuqukethwe, ukwakheka nosayizi kunembile futhi kunengqondo, futhi ukusebenza kwesondo kungasetshenziswa ngokuphelele futhi kungashintshaniswa nesondo, elinokuguquguquka kwamazwe omhlaba;

- 2) Uma ushayela, ama-oscillation e-longitudinal ne-lateral mancane, futhi ukulahleka nesikhathi se-inertia kuncane;

- I-3) Ngesisindo esanele, ukuqina nokuqina okunamandla ngaphansi kwesisekelo sokunciphisa isisindo;

- 4) ukuhlukaniswa okuhle nge-shaft nesondo;

- 5) inokuqina okuhle kakhulu;

- I-6) Inqubo yokukhiqiza ingahlangabezana nezidingo zekhwalithi yomkhiqizo ozinzile, izindleko eziphansi, izinhlobo eziningi, nokukhiqizwa okukhulu.

Xhumanisa nale ndatshana: Imfihlo! I-CNC-Machining-Process yawo wonke amasondo e-aluminium hub

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

Imisebenzi Yethu

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

Case Studies

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

Uhlu lwezinto

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi

Izingxenye zegalari