Indlela yokwenza ngcono imishini ngokunemba kwe-shaft gear hob hob

Ukuhlaziywa kokunemba kwemishini kwe umphini igiya ukugcoba

| Ngokuhlaziywa kokunemba kwemishini kwe-shaft gear hobbing, kuthinta izici ezithinta ukunemba kwemishini ye-hobbing, ukuze kuthuthukiswe ikhwalithi yokucubungula kwe-hobbing. |

Igiya le-shaft liyingxenye ebaluleke kakhulu ku-gearbox, futhi ukunemba kwayo komshini kuthinta ngqo ikhwalithi ye-gearbox. Njengamanje, indlela yomshini yamazinyo egiya esetshenziswa yithi yindlela yokuhobha nokushefa. Ukuze ukhiqize amagiya anembe kakhulu ngokugoqa nokushefa, kuyadingeka ukukhulisa izinga lokugoqa nokushefa. Ukunemba kokushefa kuncike kakhulu ekunembeni kwe-saddle hobbing, ngakho-ke ezinye izinto ezingamaphutha ku-hobbing kumele zilawulwe ngokuqinile ukuze kukhiqizwe amagiya ekhwalithi ephezulu. I-Hobbing iyindlela evame ukusetshenziswa yokucubungula igiya.

Emshinini wokuhobha onembe kakhulu, i-hob enembayo ingasetshenziswa ukulungisa amazinyo egiya ngokunemba okungu-4-5. Emshinini ojwayelekile wokuhobha, kungenziwa amazinyo ayi-8 anemba kuphela nge-hob enembayo evamile. Ukunemba kwezinyo legiya le-gear shaft ngu-8-7-7, futhi inqubo yokubhoboza isekelwe ikakhulukazi ezimbobeni ezimbili ezimaphakathi nobuso bokuphela. Ngakho-ke, umthombo wephutha we-hobbing uyahlaziywa, futhi indlela yokuqinisekisa nokwenza ngcono ukunemba komshini iphethwe kahle. Baluleke kakhulu.

Ukunemba kwamazinyo we-shaft ikakhulukazi kuhlobene nokunemba kokunyakaza, ukunemba kokuqina, nokunemba kokuxhumana. Lawula ubude bomugqa ojwayelekile ojwayelekile kanye nobubanzi begiya lendandatho kwinqubo ye-hobhob

Ukuqinisekisa ukunemba kokunyakaza, iphutha lephrofayili yokulawula izinyo kanye nokuphambuka kwengxenye eyisisekelo kusetshenziselwa ukuqinisekisa ubushelelezi bomsebenzi, nephutha lokuphonsa izinyo lilawulwa ukuqinisekisa ukunemba koxhumana naye. Okulandelayo ukuhlaziywa kwezimbangela zamaphutha amaningi athambekele ekubambeni:

1.Iphutha lamagiya we-run gear radial runout (isb eccentricity geometric)

Irout gear radial runout isho ukwehluka okuphezulu kwephenyo ngokuhlobene ne-eksisi yamazinyo ebangeni lamagiya, iphenyo lisenkingeni yamazinyo noma kumazinyo egiya, futhi lihlangana nendawo yokuphakama kwamazinyo. Kubuye kube ukweqa kwendandatho yegiya maqondana nendawo emaphakathi yomgodi. Lokhu kwehlukahlukana kubangelwa iqiniso lokuthi izimbobo ezimbili ezimaphakathi zengxenye azihambelani noma ziphambuke kakhulu enkabeni yokuzungeza kwetafula lapho izingxenye zibekiwe. Noma ngenxa yokukhiqizwa kabi kwezimbobo eziphezulu neziphezulu, indawo yokuxhumana ayithintwanga kahle, okuholela ekugxekeni, ngakho-ke ubukhulu bendandatho kufanele buxazululwe ikakhulu kulezi zizathu ezingenhla.

2.Iphutha elijwayelekile lobude obujwayelekile (isb.

IHobbing ukusebenzisa umgomo wendlela yokwakha ukwenza imishini yamagiya. Uchungechunge lokudluliswa kwegiya kusuka kuthuluzi kuya kokungenalutho kwamazinyo kufanele kugcine ukunemba kokuhamba ngokuya ngesilinganiso esithile sokudlulisa. Kepha la maketanga okushayela akhiwe ngochungechunge lwezinto zokudlulisa.

Amaphutha azo okukhiqiza nawokuhlanganisa kumele agxiliswe ezingxenyeni zokugcina zeketango lokudlulisela phakathi nokunyakaza kokudlulisela, okuholela ekungafani kokunyakaza okuhlobene futhi kuthinte ukunemba komshini kwamazinyo egiya. Ushintsho lobude bomugqa ojwayelekile ojwayelekile yiphutha elikhulu elikhombisa ukusabalalisa okungalingani kwamazinyo egiya.

Leli phutha libangelwa ikakhulukazi ukunemba okungalingani kokujikeleza kwetafula legiya lezikelemu lomshini wokuhombisa, kanye nokugqoka kwesitimela esiyisiyingi setafula lomshini wokugaya, isondo le-indexing worm kanye nomhlahlandlela oyindilinga wetafula. Okubangelwa izimbazo ezihlukene, ngaphezu kwalokho, kunamaqhubu angathi sína endaweni yezinyo legiya elihlukanisiwe futhi ukuluma okuxekethile noma okuqine kakhulu kwesondo elilengayo nakho kuzothinta ukuhluka kokujwayelekile okuvamile.

3. Ukuhlaziywa kwephutha lokuma kwamazinyo

Iphutha lokuma kwezinyo libhekisela ebangeni elivamile phakathi kwamaphrofayili amabili anamazinyo afanelekile (angabandakanyi) avumela iphrofayili yangempela yezinyo engxenyeni yokusebenza enamazinyo.

Akunakwenzeka ukuthola iphrofayili ye-involute elungile ngokuphelele inqubo machining, futhi kuhlale kunamaphutha ahlukahlukene, ngaleyo ndlela kuthinte ukushelela kokudlulisela. Isiyingi esiyisisekelo segiya ukuphela kwepharamitha enquma ukuma kwezinyo elingenayo. Uma umbuthano wesisekelo ukhiqiza iphutha ngesikhathi senqubo ye-hobbing, isimo sezinyo kufanele sibe namaphutha. Ibanga eliyisisekelo lendilinga R= Isivinini sokuhamba kwehobhu / ithebula eligoba isivinini se-angular xcosao (i-ao i-engeli yezinyo yasekuqaleni ye-hob).

Ngesikhathi senqubo yokuhobha, umumo wezinyo ongenayo uqinisekiswa ngokuyinhloko ngokugcina isilinganiso esithile sejubane phakathi kwehobhu nokungenalutho. Kungabonakala ukuthi iphutha lephrofayili yezinyo linqunywa ngokuyinhloko iphutha lesimo sezinyo le-hob, futhi ikhwalithi yokugaya unqenqema lwe-hob ayilungile futhi iphutha lephrofayela yezinyo kulula ukwenzeka. Ngesikhathi esifanayo, ukuphuma kwe-radial kanye ne-axial turbulence (okungukuthi iphutha lokufaka) okukhiqizwa i-hob phakathi nokufakwa nakho kuba nomthelela ephutheni lephrofayela yezinyo. Amaphutha avamile womumo wezinyo a-asymmetrical, iphutha le-engeli yezinyo (ngaphezulu kwezinyo noma ukuqina), iphutha lomjikelezo, njalonjalo.

4. Ukuhlaziywa kwamaphutha esiqondisi sezinyo

Iphutha lezinyo izinyo ibanga lobuso bokugcina bemigqa emibili yamazinyo edizayini efaka umugqa wamazinyo woqobo ebangeni lobubanzi obugcwele bezinyo endaweni yenkomba ye-cylindrical surface. Imbangela enkulu yokungahanjiswa kahle kwamazinyo ukuthi indlela yokuphakela mpo yethuluzi lomshini nesiphathi sethuluzi kususwe ku-eksisi yengxenye, noma maphakathi nendawo ephezulu yesigxila somsila akuhambelani nendawo yokuzungezwa kwetafula , nephutha lokubala lesondo elenga umahluko lapho ugingqa igiya elinophephela emhlane, amaphutha wokukhiqiza nawokulungisa amakhulu ahlukile, makhulu kakhulu. Ngaphezu kwalokho, ukunemba kokukhiqizwa, ukufakwa nokulungiswa kwe-jig nokungenalutho nakho kungadala iphutha le-toothing.5. Ukuhlaziywa kwamazinyo okuba khona kwamazinyo

Kunezimo eziningana ekubukekeni kwamazinyo: izinwele zezinwele, ama-caries, i-fish phosphorus, izinyembezi.

Izimbangela eziyinhloko zokwahluka kobuso bamazinyo zimi ngale ndlela elandelayo: ukuqina kwethuluzi lomshini, ithuluzi nohlelo lomsebenzi alanele, igebe likhulu; isikhundla esihambisanayo se-hob nomsebenzi wokushintsha uyashintsha; i-hob ayisebenzi kahle, ingxenye yengxenye ayifani; imingcele yokusika ayikhethiwe. Ifanele

Xhumanisa nale ndatshana: Indlela yokwenza ngcono imishini ngokunemba kwe-shaft gear hob hob

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

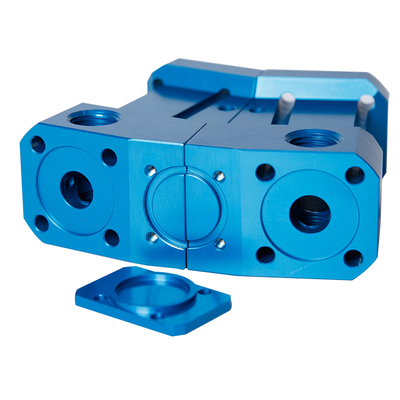

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi