Ubunzima nezixazululo zokusika kwe-laser kwamapuleti ensimbi awugqinsi

Ubunzima nezixazululo zokusika amapuleti ensimbi awugqinsi

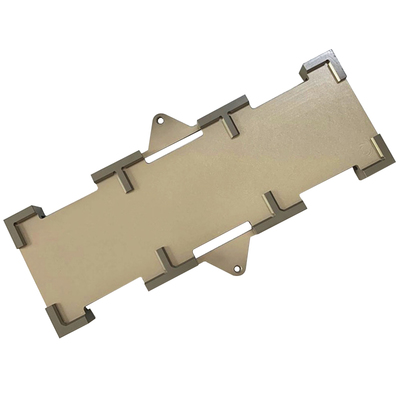

| Umshini wokusika we-cnc awunankinga yokusika amashidi ensimbi angaphansi kuka-10 mm ubukhulu. Kodwa-ke, uma kuzosikwa ipuleti lensimbi elijiyile, kuvame ukudingeka ukusiza i-laser enamandla amakhulu ngokukhipha okungaphezu kuka-5 kW, futhi nekhwalithi yokusika nayo incishiswe kakhulu. Ngenxa yezindleko eziphakeme zamadivayisi we-laser anamandla amakhulu, imodi ye-laser yomkhiqizo nayo ayifanele ukusika i-cnc, ngakho-ke indlela yokusika yendabuko ayinayo inzuzo lapho usika amapuleti aminyene. |

Ubunzima bezobuchwepheshe obulandelayo bukhona ngokuba khona kwensimbi ukusika kwe-laser imishini yokusika amapuleti aminyene:

1. Inqubo yokusha komlilo e-quasi-steady-state kunzima ukuyigcina.

Enqubeni yokusika yangempela yefayela le- ukusika i-laser yensimbi umshini, ukushuba kwepuleti elisikiwe kukhawulelwe, okusondelene kakhulu nokuhluleka kwensimbi yangaphambili yokusika ukuthi ingashiswa ngokuqinile. Inqubo yokusha kufanele iqhubeke futhi izinga lokushisa ngaphezulu kwesikhala kufanele lifinyelele lapho kufakwa khona ukuthungela. Amandla akhishwa yi-ferrooxidation reaction kuphela awaqinisekisi ukuthi inqubo yomlilo iyaqhubeka.

Ngakolunye uhlangothi, ngoba isinqanda sipholisa ngokuqhubekayo ukugeleza komoya-mpilo ovela embusweni, izinga lokushisa langaphambili lisikwa: ngakolunye uhlangothi, ungqimba lwe-oxide olwenziwe ngomlilo lumboza ubuso bento yokusebenza, luvimbela ukusabalaliswa komoya-mpilo, futhi kunciphisa ukuminyana komoya-mpilo.

Ezingeni elithile, inqubo yokuvutha izophuma. Lapho ukusika kwe-laser ngogongolo oluvamile oluguquguqukayo, indawo ye-laser beam esebenza phezulu incane. Ngenxa yobuningi bamandla e-laser, izinga lokushisa elingaphezulu kwendawo yokusebenza lifinyelela endaweni yokuthungela hhayi kuphela esifundeni semisebe ye-laser, kodwa nangenxa yokushisa kokushisa. Indawo ifinyelele izinga lokushisa lomlilo.

Ububanzi bokugeleza komoyampilo ebusweni bomsebenzi bukhulu kunobubanzi be-laser beam. Lokhu kukhombisa ukuthi akukhona nje kuphela ukusabela okuvuthayo okunamandla endaweni ye-laser irradiation, kodwa futhi ukusha kwenzeka kanyekanye endaweni ekhanyiswe yi-laser beam.

Lapho i-slab inqunywa, ijubane lokusika lihamba kancane, futhi ubuso be-workpiece bushiswa ngesivinini esisheshayo kunekhanda lokusika. Ngemuva kokushisa isikhathi esithile, inqubo yokuvutha iyacinywa ngenxa yokuncipha kokuhlushwa komoya-mpilo. Kuphela lapho ikhanda lokusika lihamba kule ndawo, ukusabela komlilo kuqala futhi.

Inqubo yomlilo ngaphambili kokusika yenziwa ngezikhathi ezithile, okubangela ukushintshashintsha kwezinga lokushisa ngaphambili okusikiwe kanye nezinga eliphansi lokusika.

2. Kunzima ukugcina ubumsulwa bomoya-mpilo kanye nengcindezi esiqondisweni sobukhulu.

Lapho umshini wensimbi wokusika i-laser usikwa waba amapuleti awugqinsi, ukwehla kokuhlanzeka komoya-mpilo nakho kuyinto ebalulekile ethinta ikhwalithi yokusikwa. Ubumsulwa bokugeleza komoya-mpilo bunethonya elinamandla kunqubo yokusika. Lapho ukuhlanzeka kokusakazwa komoya-mpilo kwehla ngo-0.9%, izinga lokusha kwe-ferrite lizokwehla ngo-10%; lapho ukuhlanzeka kwehla ngo-5%, izinga lokusha lizokwehla ngo-37%.

Ukwehla kwesilinganiso esivuthayo kuzonciphisa kakhulu ukufaka amandla esinqeni phakathi nenqubo yomlilo, kunciphise isivinini sokusika, futhi kwandise okuqukethwe yensimbi kungqimba lwamanzi lendawo yokusika, ngaleyo ndlela kwandise i-viscosity ye-slag, okuholele ekutheni ubunzima bokukhipha i-slag. I-slag enamandla izovela engxenyeni engezansi, okwenza ikhwalithi yesikhumba ingamukeleki. Ukuze ugcine ukusika kuzinzile, kuyadingeka ukuthi ubumsulwa nengcindezi yokugeleza komoya-mpilo okusikwe kusiqondiso sokujiya kugcinwa njalo. Enkambisweni ejwayelekile yokusika i-laser, kuvame ukusetshenziswa umbhobho ovamile oyindilinga, ongahlangabezana nezidingo zokusetshenziswa ekusikeni ipuleti elincanyana.

Kodwa-ke, lapho usika amapuleti aminyene, njengoba ingcindezi yokuhlinzeka inyuka, amagagasi ashaqekayo akhiwa kalula emkhakheni wokugeleza kombhobho. I-wave wave inezingozi eziningi enqubeni yokusika, inciphisa ubumsulwa bokugeleza komoya-mpilo futhi ithinta ikhwalithi yokusikwa.

Ngokuvamile kunezindlela ezintathu zokuxazulula le nkinga:

- (1) ukwengeza ilangabi lokushisa ngaphambili komsele wokusika we-oksijini;

- (2) ukufaka ukugeleza komoya-mpilo osizayo ezungeze ukusika kwe-oksijeni okusika;

- (3) Dizayina ngokufanele udonga lwangaphakathi lombhobho ukuze kuthuthukiswe izici zensimu yokuhamba komoya.

Xhumanisa nale ndatshana: Ubunzima nezixazululo zokusika kwe-laser kwamapuleti ensimbi awugqinsi

Isitatimende Esiphrintiwe: Uma ingekho imiyalo ekhethekile, zonke izindatshana ezikulesi sayithi zingokoqobo. Sicela ukhombise umthombo wokuphrinta kabusha: https: //www.cncmachiningptj.com/ ezinthanks!

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china izinsiza.ISO 9001: 2015 & AS-9100 eqinisekisiwe. 3, 4 no-5-eksisi ngokunemba okusheshayo Ukufakwa kwe-CNC izinsizakalo kufaka phakathi ukugaya, ukuphendukela ekucacisweni kwamakhasimende, Izinsimbi ezisebenza ngensimbi nezipulasitiki ezine- +/- 0.005 mm ukubekezelelana.kufa,ishidi lensimbi futhi uyanyathelaUkunikeza ama-prototypes, ama-run aphelele wokukhiqiza, ukwesekwa kwezobuchwepheshe kanye nokuhlolwa okugcwele yezimoto, i-aerospace, isikhunta nokulungiswa, ukukhanya okuholelekile,zezokwelapha, ibhayisikili, nomthengi electronics izimboni. Ukulethwa ngesikhathi, sitshele kancane ngesabelomali sephrojekthi yakho nesikhathi esilindelekile sokulethwa. Sizokwenza amasu nawe ukuze sinikeze ngezinsizakalo ezingabizi kakhulu ukukusiza ukuthi ufinyelele lapho ubheke khona, Siyakwamukela Xhumana nathi ( sales@pintejin.com ) ngqo iphrojekthi yakho entsha.

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi