Ama-nanocrystals azinzile kakhulu atholakala ezinsimbi

Ama-Nanometals anozinzo olumpofu ngenxa yokwethulwa kwenani elikhulu lemingcele yokusanhlamvu. Ngokuvamile, izinga lokushisa lokukhula kwezinhlayiya zekristalu lama-nanocrystals liphansi kakhulu kunezinga lokushisa lekristalu lamakristalu amaholo, kanti ezinye izinsimbi ezihlanzekile ze-nanocrystal zikhula ngisho nasezingeni lokushisa elilingana negumbi. Ukungaqini kahle kuye kwaba ibhodlela eliyinhloko elivimbela ukulungiswa nokusetshenziswa kwe-nano-metals. Indlela yendabuko yokuzinzisa ama-nanocrystals ikakhulukazi ngokusebenzisa i-alloying ukunciphisa amandla esixhumi esibonakalayo noma ukwakha umthelela wokudonsa ekufudukeni kwemingcele yokusanhlamvu.

Eminyakeni yamuva, i-Nanometal Scientist Studio ye-Shenyang National Research Center for Materials Science, Institute of Metal Research, i-Chinese Academy of Sciences yenze ucwaningo oluhlelekile mayelana nokuzinza kwama-nanometals. Ngo-2018, abacwaningi be-studio bathola umphumela ongavamile wosayizi wokusanhlamvu ekuzinzeni okushisayo kwama-nanocrystals ethusi elihlanzekile le-nanocrystalline kanye ne-aluminium ehlanzekile elungiselelwe ukuguqulwa kwepulasitiki, okungukuthi, okuncane kunosayizi obalulekile, njengoba usayizi wokusanhlamvu uncipha, ukonakala kwezinto. ukusuka ekubuseni okugcwele kokugudluzwa kuya ekubuseni kokususwa okungaphelele, indlela yokuphumula yomngcele wokusanhlamvu iyasebenza, futhi ukuzinza kwama-nanocrystals akunciphi kodwa kuyakhuphuka (Isayensi, 360, 2018). Kamuva, bathola ukuthi nakuba indlela yangaphakathi yokufuduka komngcele wokusanhlamvu ngaphansi kokushisisa ihlukile, ukuzinza kwemishini yama-nanocrystals ngaphansi kwengcindezi nakho kunalo mphumela wosayizi wokusanhlamvu ongajwayelekile (Phys Rev Lett, 122, 2019). Lolu cwaningo lukhethwe njengomsebenzi ogqamile weSayensi onesihloko esithi "A size limit for softening" (Science, 364, 2019).

Kuyaqondakala ukuthi kwamanye ama-nano-metals, njengethusi elihlanzekile, izinhlamvu ze-nano-crystalline zikhula ngisho nasezingeni lokushisa elivamile. Lokhu kungazinzi okungokwemvelo, ngakolunye uhlangothi, kuletha ubunzima ekulungiseleleni izinto ze-nano-metal, ngakolunye uhlangothi, futhi kukhawulela ukusetshenziswa okungokoqobo kwezinto ezisetshenziswayo ze-nano-metal.

Ucwaningo luphinde lwathola ukuthi ukuzinza okungavamile kwama-nanocrystals akwenzeki kuphela ezinsimbi ezinamandla okunqwabelana okuphansi nokuphakathi njengethusi elimsulwa, kodwa futhi kwenzeka ku-nickel emsulwa enamandla amakhulu amaphutha. Ukutholakala kwama-nanocrystals okuzinza kwe-ultra-high akubalulekile nje kuphela ukuthi siqonde indlela yokuguqula ama-nanocrystals kanye nokuziphatha kwemingcele yokusanhlamvu kumasayizi we-nanometer, kodwa futhi kubonisa ukuthi kungenzeka ukuthuthukisa ama-nanocrystals asetshenziswa emazingeni okushisa aphezulu.

Kodwa-ke, usayizi wokusanhlamvu wezinsimbi ezihlanzekile olungiselelwe izindlela zokuguqulwa ezinzima zepulasitiki ezivame ukusetshenziswa (ezifana nokukhishwa kweshaneli okulinganayo, ukugoqa isitaki, njll.) ngokuvamile usesikalini se-sub-micron, futhi kunzima ukwenza kusebenze indlela yokuphumuza umngcele wokusanhlamvu. ngesikhathi sokucubungula. Isibonelo, usayizi wokusanhlamvu wethusi ohlanzekile olungiselelwe ukuguqulwa okunzima kwepulasitiki ikakhulukazi ku-100-200 nm, ngokuzinza okungalungile, futhi izinga lokushisa lokukhula okusanhlamvu liphansi kakhulu kunamakristalu amaholo. Muva nje, ucwaningo olwenziwa yisitudiyo uLi Xiuyan nabanye bathole ukuthi ukushisa okusheshayo kungethula amawele anamathela ngethusi le-nanocrystalline, ngaleyo ndlela kufinyelele "ukuphumula okushisayo" kwemingcele yezinhlamvu ze-nanocrystalline futhi kuthuthukise ukuzinza okushisayo kwe-nanocrystalline. Obunye bobunzima bokwethula amawele a-annealing nge-nanocrystalline copper yilokhu: ama-nanocrystals angazinzile, okuzinza kwawo okusanhlamvu okusanhlamvu kungu-393 K kuphela, okungaphansi kakhulu kwezinga lokushisa lamawele annealing (-523 K). Ngaphambi kokuba amawele akhiqizwe ngesikhathi sokushisa, izinhlamvu zekristalu zikhule kuqala. Ngokusekelwe kumphumela we-Kissinger, abacwaningi bahlongoze ukuthi ukwandisa izinga lokushisa kungakhuphula izinga lokushisa lokukhula okusanhlamvu ngaphandle kokuthinta izinga lokushisa lokukhula kwamawele. Ngakho-ke, ukwamukela ukuphakama okusheshayo kwezinga lokushisa akuvimbi kuphela ukukhula okusanhlamvu, kodwa futhi kukhiqiza amawele okukhula. I-Cu ehlanzekile enosayizi wokusanhlamvu ongaba ngu-80 nm yashisisa ngokushesha ku-523 K ngesilinganiso esingu-160 K/min futhi igcinwe ku-523 K imizuzu engu-15 bese ipholiswa. Ubukhulu bokusanhlamvu bezinto azizange zishintshe kakhulu, kodwa inani lamawele landa kakhulu. Njengamawele e-deformation, lawa mawele okukhula angakwazi futhi ukukhulula imingcele yokusanhlamvu futhi athuthukise ukuzinza okushisayo kwama-nanocrystals. Ngemuva kokwelashwa okushisa, izinga lokushisa elibonakalayo lokukhula lama-nanocrystals lenyuka lisuka ngaphansi kwama-393 K laya ngaphezu kuka-773 K.

Indlela yokuphumula eshisayo yokushisa ngokushesha ukuze kuthuthukiswe ukuzinza kwama-nanocrystals ingasetshenziswa ukuthuthukisa ukuzinza kwe-submicron nama-nanocrystals atholwe ngokuwohloka okuqinile kwepulasitiki okujwayelekile, okubaluleke kakhulu ekuthuthukisweni kwama-nanomaterials azinzile kanye nokukhuthaza ukusetshenziswa kwe-nanocrystals. ama-nanometal.

Lo msebenzi usekelwa Uhlelo Olubalulekile Lwe-R&D Lomnyango Wesayensi Nobuchwepheshe, Isisekelo Sikazwelonke Sesayensi Yemvelo yaseChina, kanye ne-Chinese Academy of Sciences.

Ama-Nanometals anozinzo olumpofu ngenxa yokwethulwa kwenani elikhulu lemingcele yokusanhlamvu. Ngokuvamile, izinga lokushisa lokukhula kwezinhlayiya zekristalu lama-nanocrystals liphansi kakhulu kunezinga lokushisa lekristalu lamakristalu amaholo, kanti ezinye izinsimbi ezihlanzekile ze-nanocrystal zikhula ngisho nasezingeni lokushisa elilingana negumbi. Ukungaqini kahle kuye kwaba ibhodlela eliyinhloko elivimbela ukulungiswa nokusetshenziswa kwe-nano-metals. Indlela yendabuko yokuzinzisa ama-nanocrystals ikakhulukazi ngokusebenzisa i-alloying ukunciphisa amandla esixhumi esibonakalayo noma ukwakha umthelela wokudonsa ekufudukeni kwemingcele yokusanhlamvu.

Eminyakeni yamuva, i-Nanometal Scientist Studio ye-Shenyang National Research Center for Materials Science, Institute of Metal Research, i-Chinese Academy of Sciences yenze ucwaningo oluhlelekile mayelana nokuzinza kwama-nanometals. Ngo-2018, abacwaningi be-studio bathola umphumela ongavamile wosayizi wokusanhlamvu ekuzinzeni okushisayo kwama-nanocrystals ethusi elihlanzekile le-nanocrystalline kanye ne-aluminium ehlanzekile elungiselelwe ukuguqulwa kwepulasitiki, okungukuthi, okuncane kunosayizi obalulekile, njengoba usayizi wokusanhlamvu uncipha, ukonakala kwezinto. ukusuka ekubuseni okugcwele kokugudluzwa kuya ekubuseni kokususwa okungaphelele, indlela yokuphumula yomngcele wokusanhlamvu iyasebenza, futhi ukuzinza kwama-nanocrystals akunciphi kodwa kuyakhuphuka (Isayensi, 360, 2018). Kamuva, bathola ukuthi nakuba indlela yangaphakathi yokufuduka komngcele wokusanhlamvu ngaphansi kokushisisa ihlukile, ukuzinza kwemishini yama-nanocrystals ngaphansi kwengcindezi nakho kunalo mphumela wosayizi wokusanhlamvu ongajwayelekile (Phys Rev Lett, 122, 2019). Lolu cwaningo lukhethwe njengomsebenzi ogqamile weSayensi onesihloko esithi "A size limit for softening" (Science, 364, 2019).

Kuyaqondakala ukuthi kwamanye ama-nano-metals, njengethusi elihlanzekile, izinhlamvu ze-nano-crystalline zikhula ngisho nasezingeni lokushisa elivamile. Lokhu kungazinzi okungokwemvelo, ngakolunye uhlangothi, kuletha ubunzima ekulungiseleleni izinto ze-nano-metal, ngakolunye uhlangothi, futhi kukhawulela ukusetshenziswa okungokoqobo kwezinto ezisetshenziswayo ze-nano-metal.

Ucwaningo luphinde lwathola ukuthi ukuzinza okungavamile kwama-nanocrystals akwenzeki kuphela ezinsimbi ezinamandla okunqwabelana okuphansi nokuphakathi njengethusi elimsulwa, kodwa futhi kwenzeka ku-nickel emsulwa enamandla amakhulu amaphutha. Ukutholakala kwama-nanocrystals okuzinza kwe-ultra-high akubalulekile nje kuphela ukuthi siqonde indlela yokuguqula ama-nanocrystals kanye nokuziphatha kwemingcele yokusanhlamvu kumasayizi we-nanometer, kodwa futhi kubonisa ukuthi kungenzeka ukuthuthukisa ama-nanocrystals asetshenziswa emazingeni okushisa aphezulu.

Kodwa-ke, usayizi wokusanhlamvu wezinsimbi ezihlanzekile olungiselelwe izindlela zokuguqulwa ezinzima zepulasitiki ezivame ukusetshenziswa (ezifana nokukhishwa kweshaneli okulinganayo, ukugoqa isitaki, njll.) ngokuvamile usesikalini se-sub-micron, futhi kunzima ukwenza kusebenze indlela yokuphumuza umngcele wokusanhlamvu. ngesikhathi sokucubungula. Isibonelo, usayizi wokusanhlamvu wethusi ohlanzekile olungiselelwe ukuguqulwa okunzima kwepulasitiki ikakhulukazi ku-100-200 nm, ngokuzinza okungalungile, futhi izinga lokushisa lokukhula okusanhlamvu liphansi kakhulu kunamakristalu amaholo. Muva nje, ucwaningo olwenziwa yisitudiyo uLi Xiuyan nabanye bathole ukuthi ukushisa okusheshayo kungethula amawele anamathela ngethusi le-nanocrystalline, ngaleyo ndlela kufinyelele "ukuphumula okushisayo" kwemingcele yezinhlamvu ze-nanocrystalline futhi kuthuthukise ukuzinza okushisayo kwe-nanocrystalline. Obunye bobunzima bokwethula amawele a-annealing nge-nanocrystalline copper yilokhu: ama-nanocrystals angazinzile, okuzinza kwawo okusanhlamvu okusanhlamvu kungu-393 K kuphela, okungaphansi kakhulu kwezinga lokushisa lamawele annealing (-523 K). Ngaphambi kokuba amawele akhiqizwe ngesikhathi sokushisa, izinhlamvu zekristalu zikhule kuqala. Ngokusekelwe kumphumela we-Kissinger, abacwaningi bahlongoze ukuthi ukwandisa izinga lokushisa kungakhuphula izinga lokushisa lokukhula okusanhlamvu ngaphandle kokuthinta izinga lokushisa lokukhula kwamawele. Ngakho-ke, ukwamukela ukuphakama okusheshayo kwezinga lokushisa akuvimbi kuphela ukukhula okusanhlamvu, kodwa futhi kukhiqiza amawele okukhula. I-Cu ehlanzekile enosayizi wokusanhlamvu ongaba ngu-80 nm yashisisa ngokushesha ku-523 K ngesilinganiso esingu-160 K/min futhi igcinwe ku-523 K imizuzu engu-15 bese ipholiswa. Ubukhulu bokusanhlamvu bezinto azizange zishintshe kakhulu, kodwa inani lamawele landa kakhulu. Njengamawele e-deformation, lawa mawele okukhula angakwazi futhi ukukhulula imingcele yokusanhlamvu futhi athuthukise ukuzinza okushisayo kwama-nanocrystals. Ngemuva kokwelashwa okushisa, izinga lokushisa elibonakalayo lokukhula lama-nanocrystals lenyuka lisuka ngaphansi kwama-393 K laya ngaphezu kuka-773 K.

Indlela yokuphumula eshisayo yokushisa ngokushesha ukuze kuthuthukiswe ukuzinza kwama-nanocrystals ingasetshenziswa ukuthuthukisa ukuzinza kwe-submicron nama-nanocrystals atholwe ngokuwohloka okuqinile kwepulasitiki okujwayelekile, okubaluleke kakhulu ekuthuthukisweni kwama-nanomaterials azinzile kanye nokukhuthaza ukusetshenziswa kwe-nanocrystals. ama-nanometal.

Lo msebenzi usekelwa Uhlelo Olubalulekile Lwe-R&D Lomnyango Wesayensi Nobuchwepheshe, Isisekelo Sikazwelonke Sesayensi Yemvelo yaseChina, kanye ne-Chinese Academy of Sciences.

Xhumanisa nale ndatshana:Ama-nanocrystals azinzile kakhulu atholakala ezinsimbi

Phinda Uphrinte Isitatimende: Uma ingekho imiyalelo ekhethekile, zonke izindatshana ezikule sayithi zingezangempela. Sicela ukhombise umthombo wokuphrinta kabusha:https://www.cncmachiningptj.com

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china amasevisi.ISO 9001:2015 &AS-9100 eqinisekisiwe.

I-PTJ® inikeza uhla oluphelele lwe-Custom Precision i-cnc machining china amasevisi.ISO 9001:2015 &AS-9100 eqinisekisiwe.

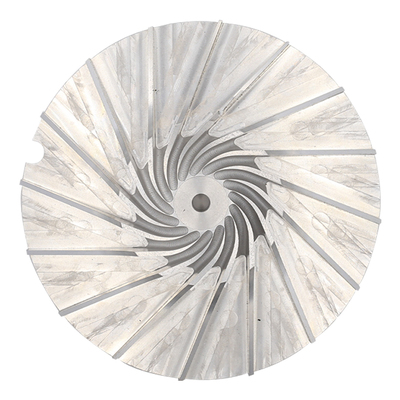

Isitolo somshini onguchwepheshe bezinsizakalo zokwenziwa kwezimboni zokwakha nezokuthutha. Amakhono afaka i-plasma kanye ne-oxy-fuel cutting, Imishini ehlanganisiwe, MIG kanye I-Custom Aluminium CNC Precision Milling Welding Jig Fixture, ukwakhiwa komqulu, ukuhlanganisa, Lathe machining steel stainless cnc umshini umphini, ukugunda, futhi Izinsizakalo ze-CNC Swiss Machining. Izinto eziphathwayo zifaka i-carbon kanye Passivation Stainless Steel Machining Cover Izingxenye Zeplate.

Sitshele okuncane mayelana nesabelomali sephrojekthi yakho kanye nesikhathi sokulethwa okulindelekile. Sizokwenza amasu nawe ukuze sikunikeze izinsiza ezingabizi kakhulu ukukusiza ufinyelele umgomo wakho, wamukelekile ukuthi uxhumane nathi ngqo ( sales@pintejin.com ).

- 5 I-Axis Machining

- I-Cnc Milling

- Ukuguqula i-Cnc

- Machining Izimboni

- Inqubo YeMishini

- Ukwelashwa Kwendawo Engaphezulu

- Izimboni Zensimbi

- Imishini yePlastiki

- Powder Metallurgy Isikhunta

- I-Die Casting

- Izingxenye zegalari

- Izingxenye ze-Auto Metal

- Izingxenye Zomshini

- I-LED Heatsink

- Izakhi Zokwakha

- Izingxenye Zeselula

- Izingxenye Zezokwelapha

- Izingxenye ze-elekthronikhi

- Machining eyenzelwe

- Izingxenye zebhayisikili

- I-Aluminium Machining

- I-Titanium Machining

- Engagqwali Machining

- Machining yethusi

- Brass Machining

- Super Ingxubevange Machining

- IMeching Peek

- Imishini ye-UHMW

- Hlanganisa iMachining

- Imishini ye-PA6

- Imishini yePPS

- I-Teflon Machining

- I-Inconel Machining

- Ithuluzi Steel Machining

- Izinto eziningi